Week 3: Computer-Controlled Cutting

Group Assignment

Our group assignment was documented on this page.

Assignment

Group assignment: make laser cutter test part(s), varying cutting settings and slot dimensions.

Individual assignment: design, make, and document a parametric press-fit construction kit, accounting for the laser cutter kerf, which can be assembled in multiple ways. Cut something on the vinylcutter.

For this week we have to make both individual and group assignments in the laser cutter and vinyl cutter.

Vinyl cutter

For the viynl cutting assignment I decided to edit a picture from internet to see the out come from CutStudio

I downloaded a head of a lion.

I generated image outline through CutStudio software

This is the outline generated.

Sent cutting command to the vinylcutter.

Laser cutter

Laser cutters are used to cut and engrave a wide variety of materials such as cardboard, MDF, plywook, acrylic, fabric, etc., the power and speed vary among material kind and thikness.

This time we try 3mm MDF sheet to make the group and individual assignments.

In this assignment we had to make a parametric design and cut it on the laser cutter. For me, I designed a circular shape with 4 slots. I set the size of the slot to equal to the thickness of the material I was going to use.

I designed it in Solidworks.

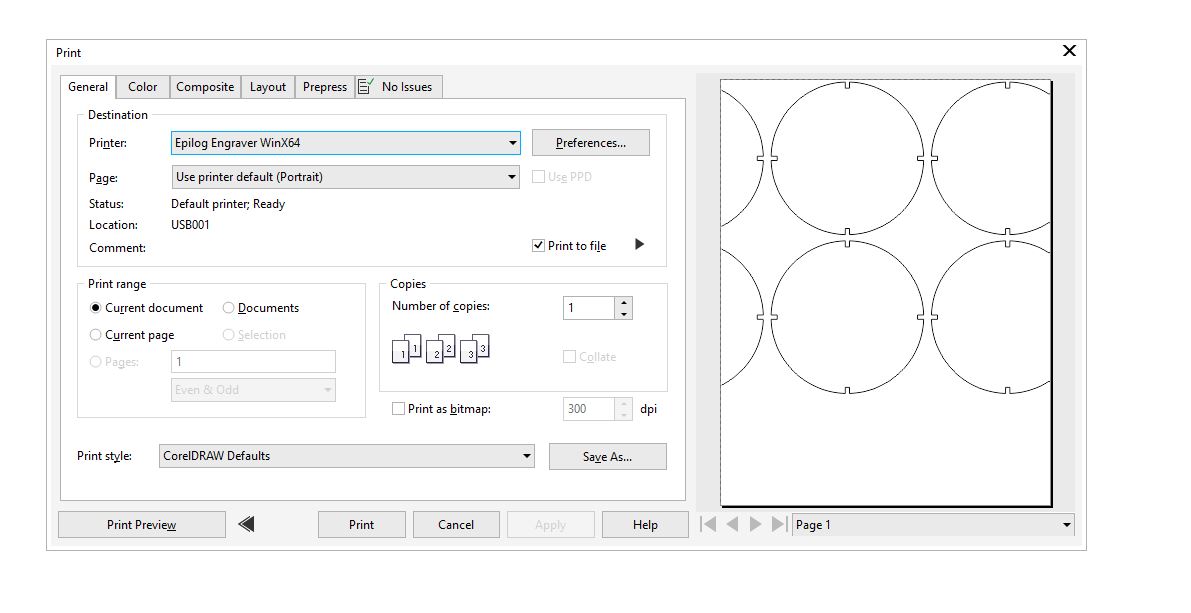

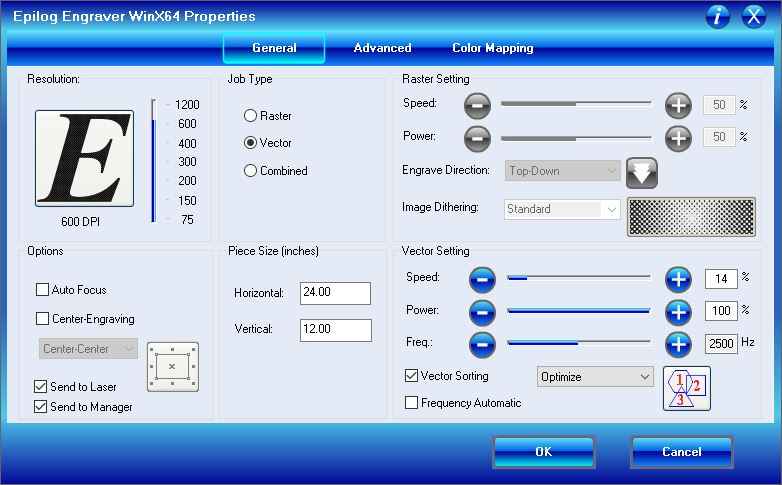

After designing I set printing parameters the laser will follow.

For parameters I used vector and set the speed to 14 percent and maximized the power, only that was enough for cutting.

I sent the file to cut those circles in lasercutter.

Here after cutting them in the lasercutter.

This is the assembly of the parts I cutted in lasercutter.

Conclusion

When I was reading about parametric design, I saw many benefice it brings but I wasn't able to experience most of it because of my small design. However parametric design is something I would like to experience more in my design more.

The original files used for this assignment can be downloaded here.