Week 17: Wildcard

AssignmentAssignment

For this assignment we have to design and produce something with a digital fabrication process we haven't used in other assignments.

I did make a box with composite and made a digital clock in wood.

Part 1: Composite

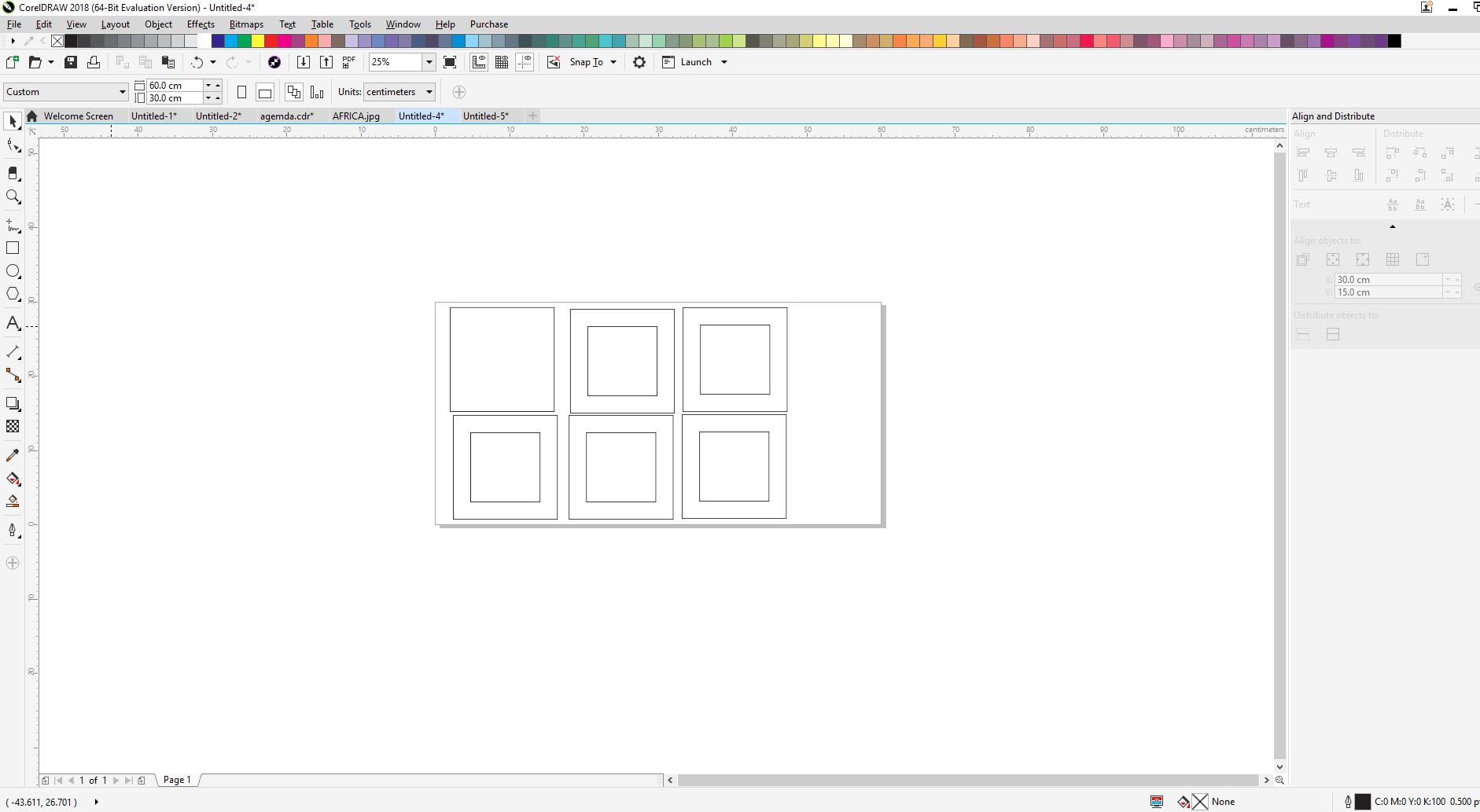

I started to design the shape I wanted to used when making a box.

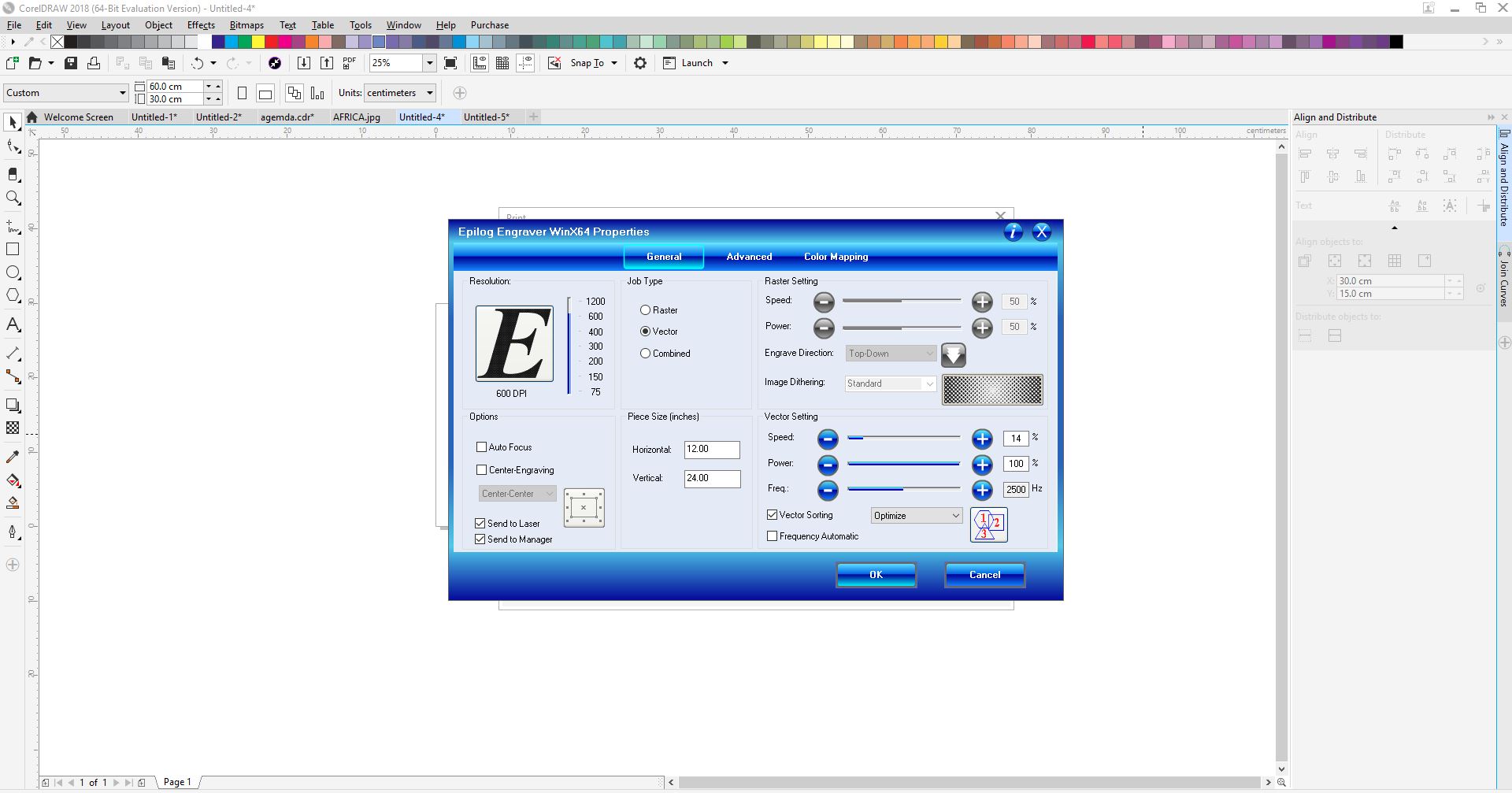

I used CorelDRAW software to design, after I cutted the pieces with lasercutter.

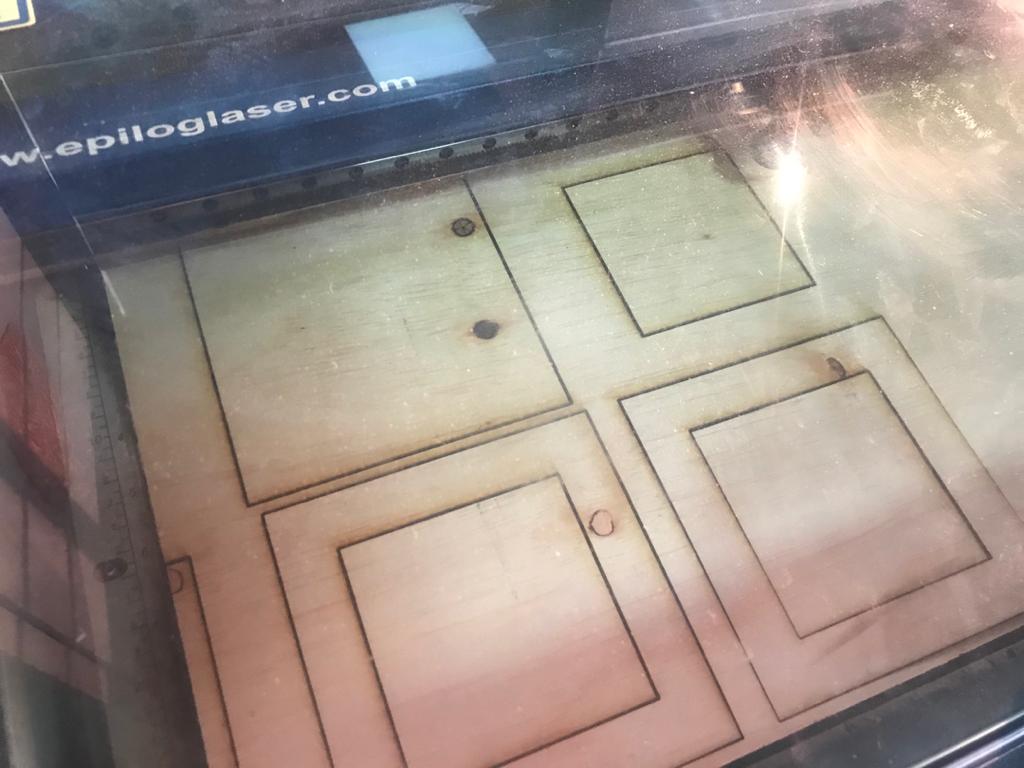

Here the lasercutter was cutting pieces in a wood.

These are pieces were cutted on the lasercutter.

From here the next step was to prepare the epoxy to use.

Before working with epoxy we must read safety and precausions to take, and you can find it here.

I started by measuring the weight I wanted to use, the epoxy I used is mixed with a ratio of 2 to 1 where you measure double weight of epoxy to 1 of the harderner.

Then I mixed the epoxy with harderner.

I cutted a piece of a cloth I wanted to use.

I applied the epoxy solution on the cloth.

I layed the pieces of wood I previously cutted on the cloth.

I stacked those pieces on top of each other to make a box shape.

I applied the epoxy solution on each part of the wood.

After I closed it with the other part of the cloth.

This is how the final result looks like.

Part 2: wooden clock

For this week I made a clock through a timber.

I bought a plastic clock and disassembled it to remove the mechanical and pointers that I will be using.

I measured the size of the mechanical box.

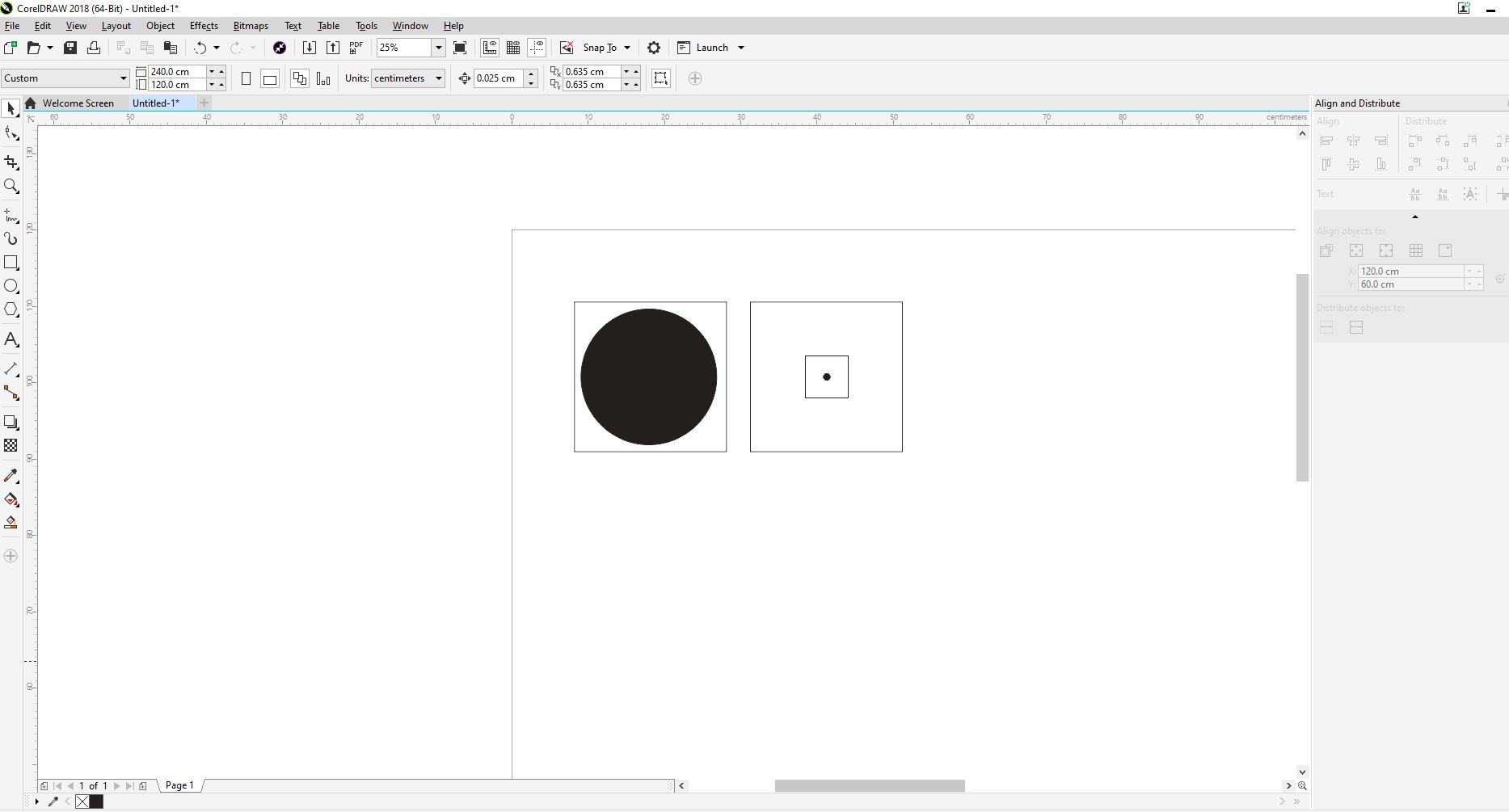

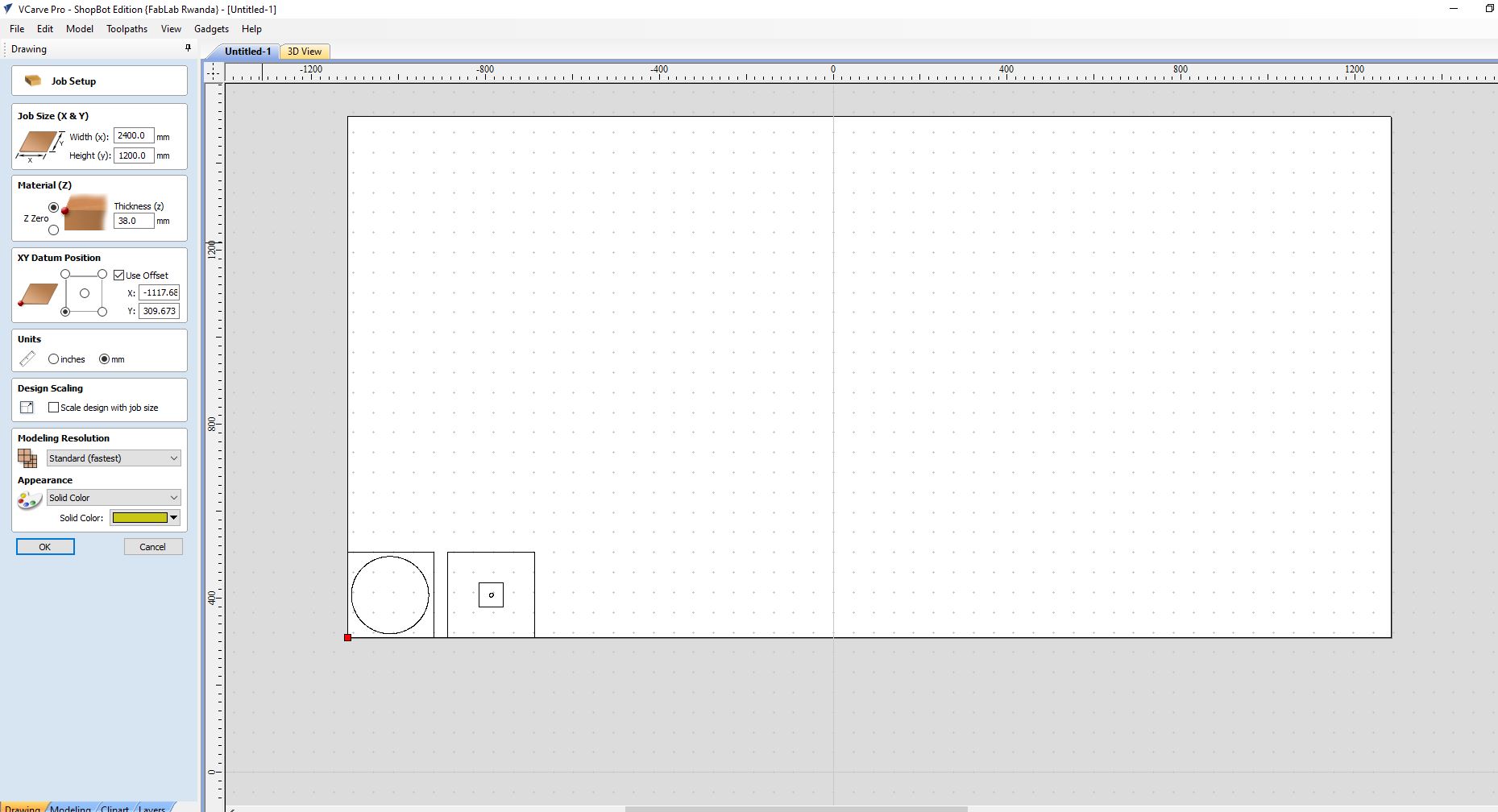

I used CoreDraw to design the parts I would be cutting in timber.

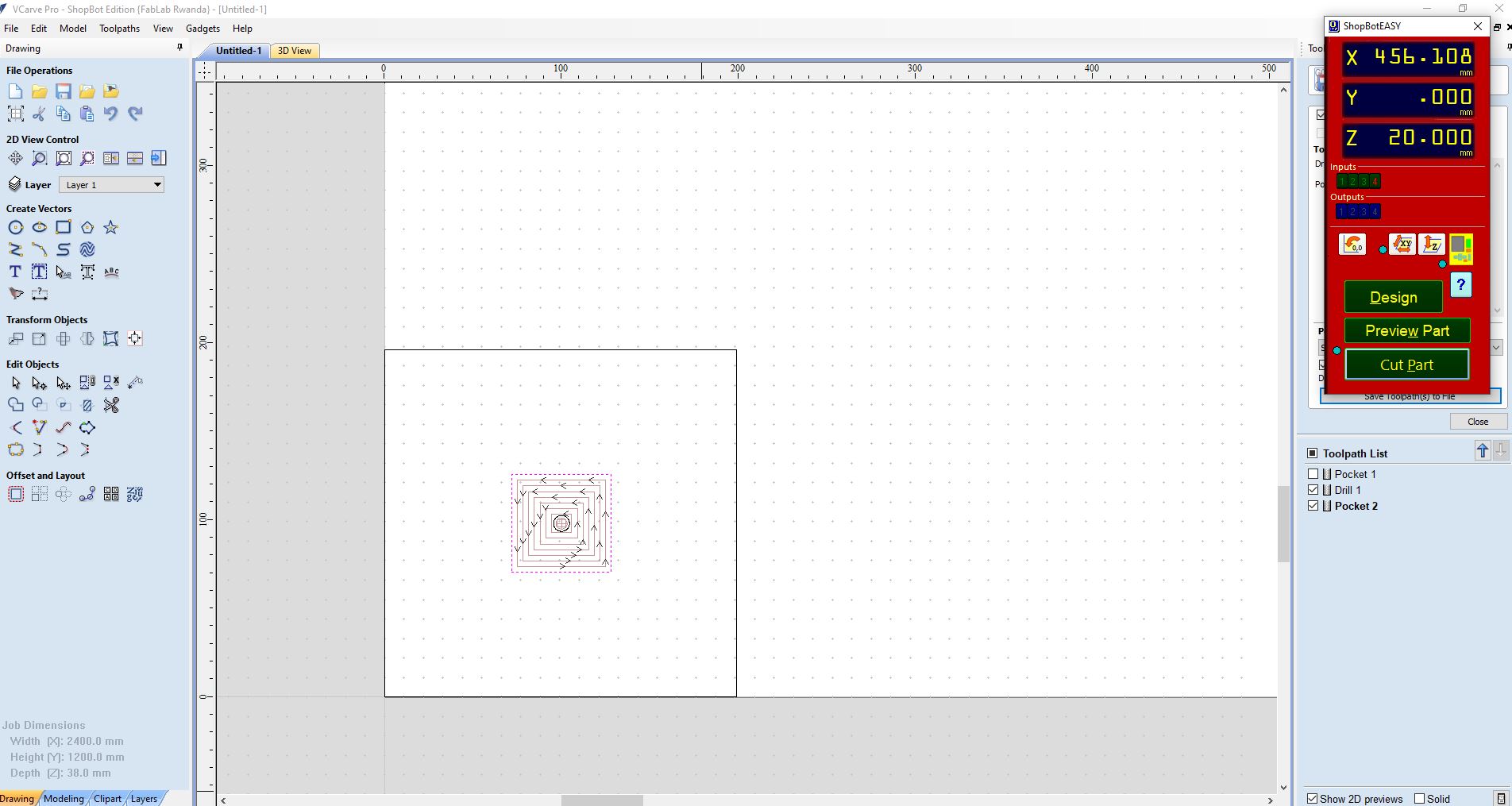

Experted in dxf file to be used in Vcarve for working with shopbot.

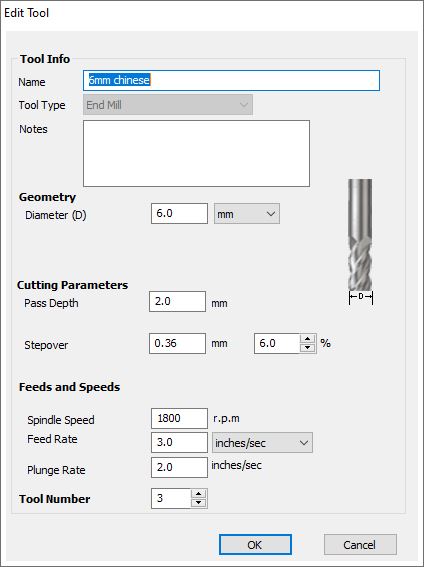

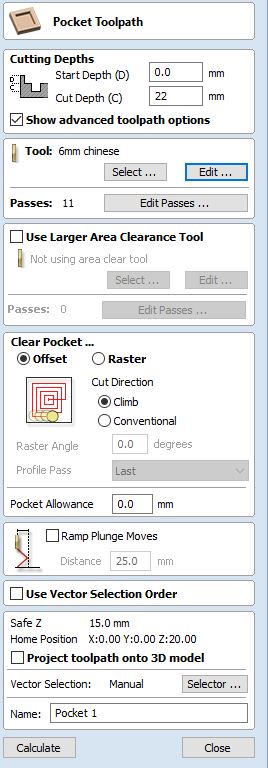

For generating toolpath this are the settings I used.

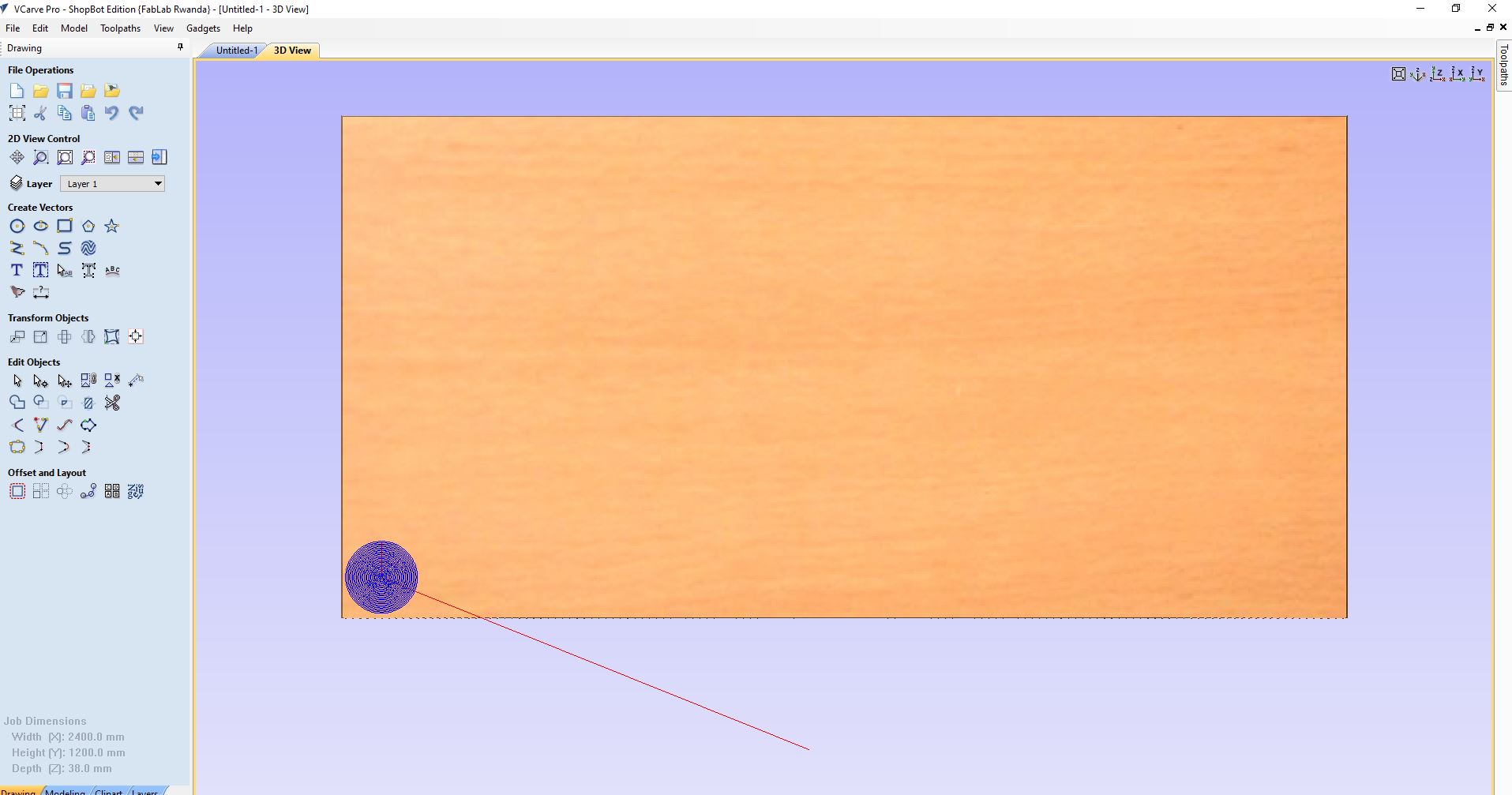

Generated toolpath for pockets.

This is a small video of the shopbot milling the timber.

After I sanded the parts for making a smooth finish.

This is the look of the timber after sanding.

I installed the clock needles.

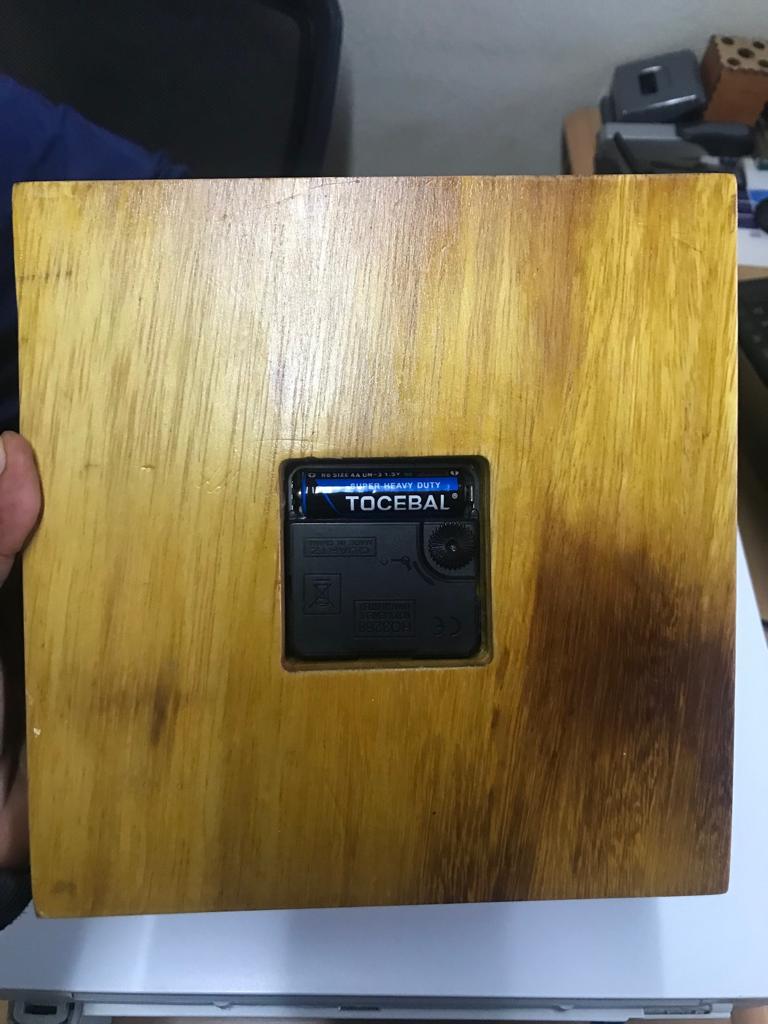

and installed the mechanical box.

This is the final look of the clock after installing everthing.

This is a short vid of the clock working.

File used can be found here.