Week 7

Feb 27. Electronics Design

Group Assignment

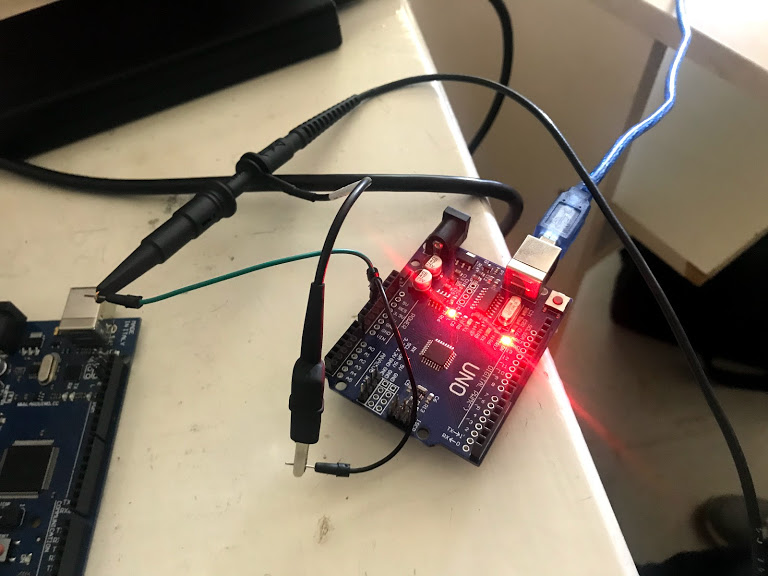

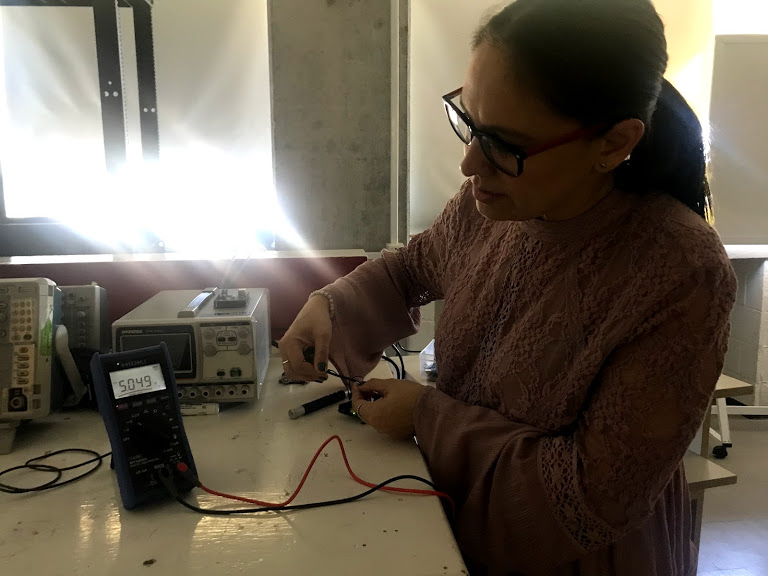

Use the test equipment in your lab to observe the operation of a microcontroller circuit board.

Instructions

- Connect the oscillometer tips to the oscillometer

- Start the oscillometer

- Connect the tips to a PCB to test

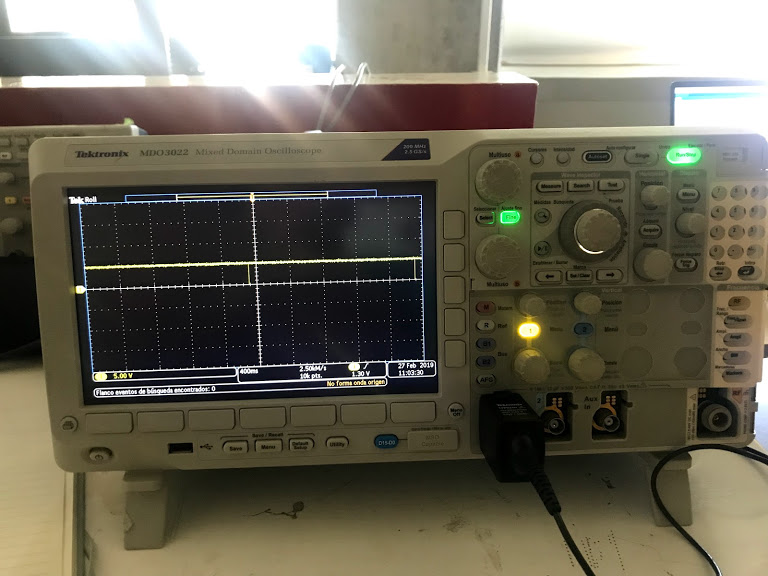

- Send a binary pulse and observe

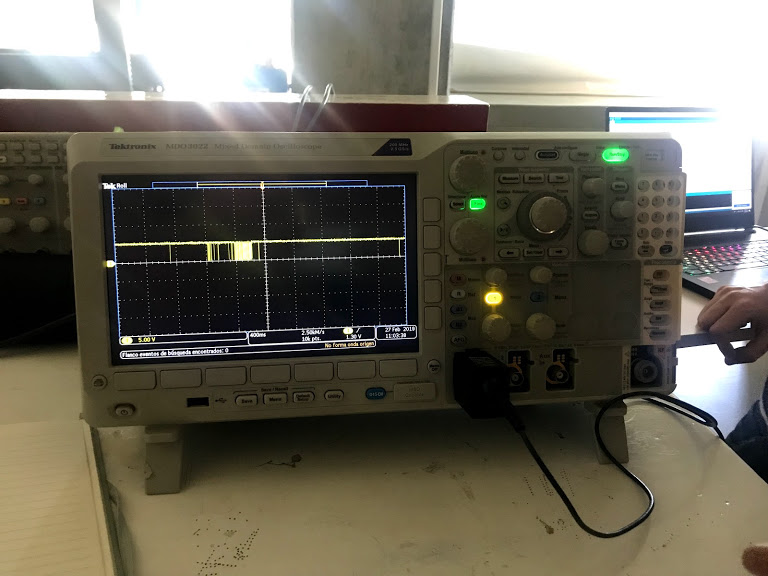

- Send a 123 abc pulse and observe

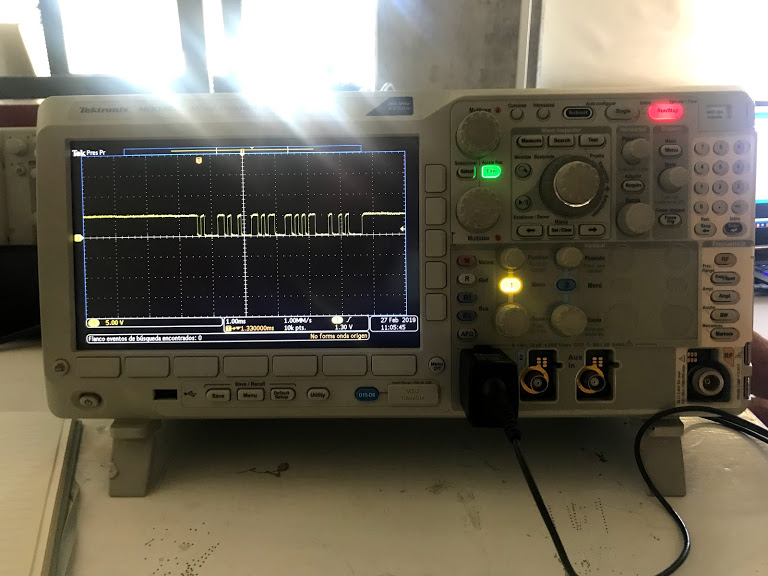

- Elongate in time the 123 abc wave pulse and observe

- Use an ammeter to test the amperage of the PCB's input current

Individual Assignment

Redraw the echo hello-world board, add (at least) a button and LED (with current-limiting resistor) check the design rules, make it, and test it. Extra credit: simulate its operation

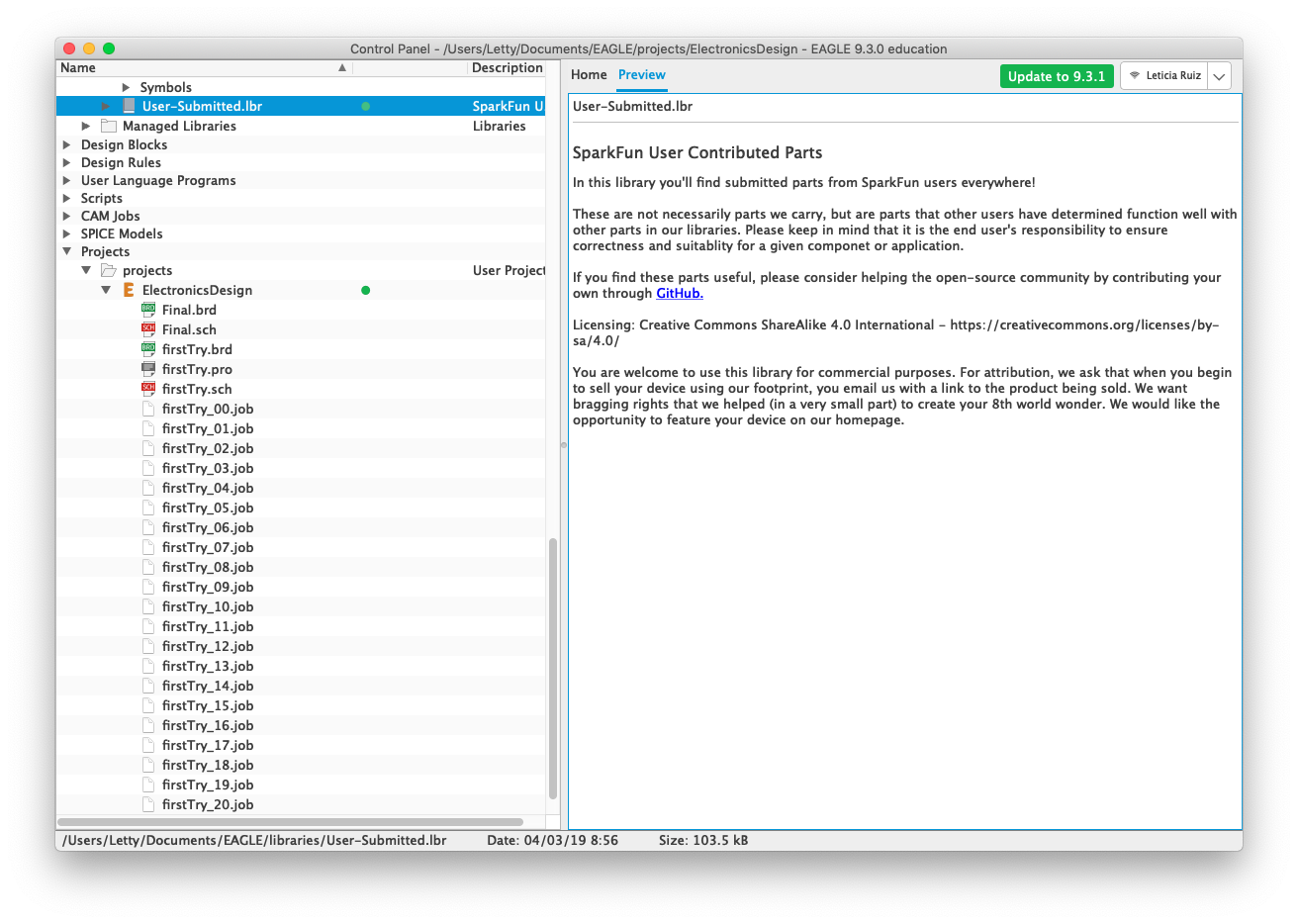

Eagle Control Panel

Add Sparkfun libraries (or any other you need) to guarantee that you have all the ocmponents in stock at your FabLab.

Instructions

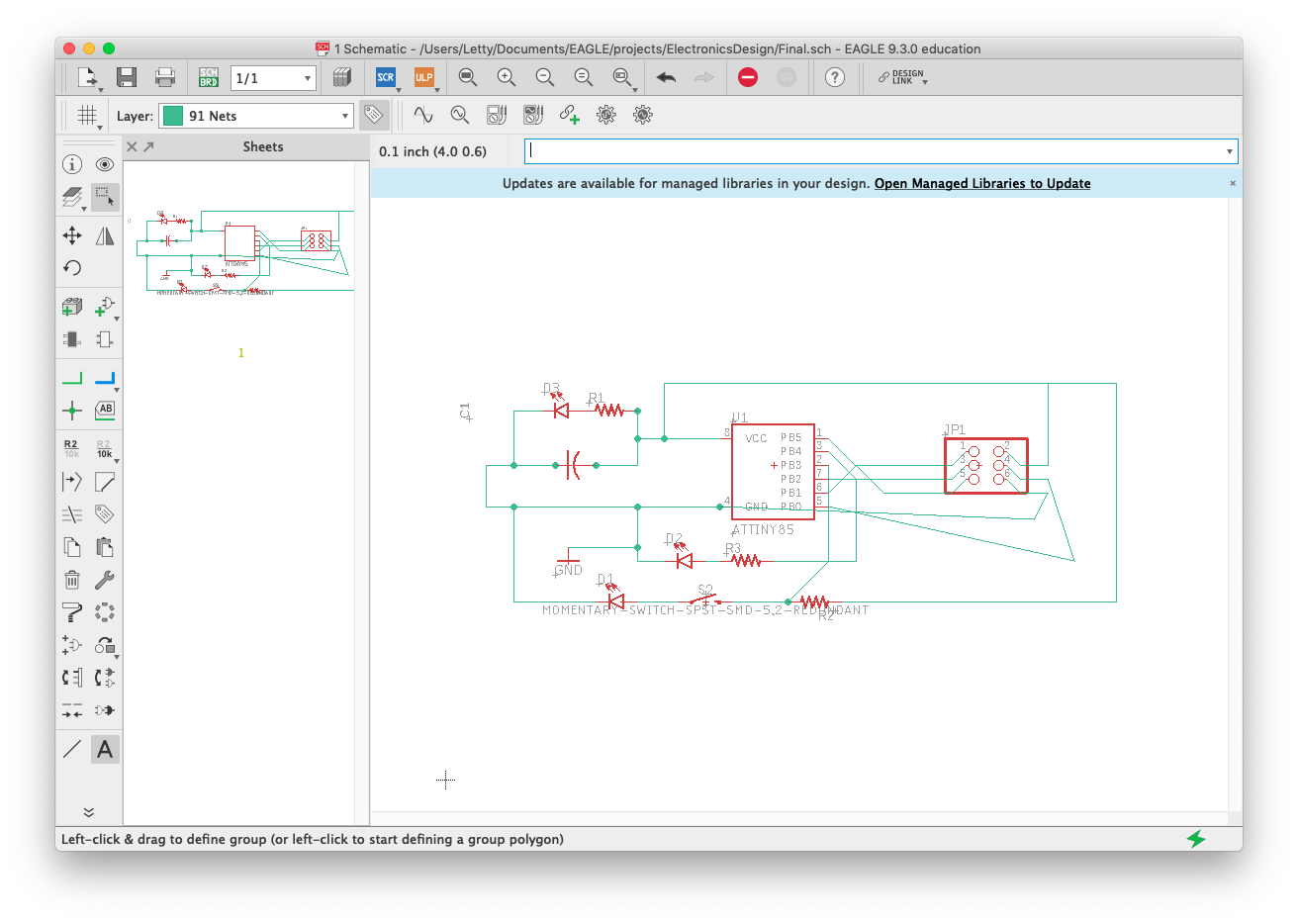

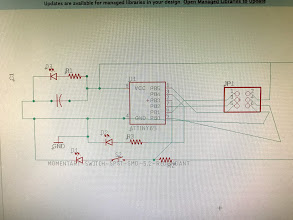

- Define components to be used: three LEDs, three resitors, one capacitor, one tiny45 microcontroller, 6 pin piece, one push button.

- Define your schematics on paper

- Open AutoDesk Eagle

- Look for the tiny45 microcontroller and include it in your schematics

- Add the 6 pin piece, connect to the pins you'll need

- Add the resistors and connect to VCC

- Add the LEDs after the resistors, one of them will go on when connected, another one will be programmed and the third one will be lighted by the button

- Add the capacitor rigth after VCC and on parallel with resistors

- Add the button before a LED

- Connect all components

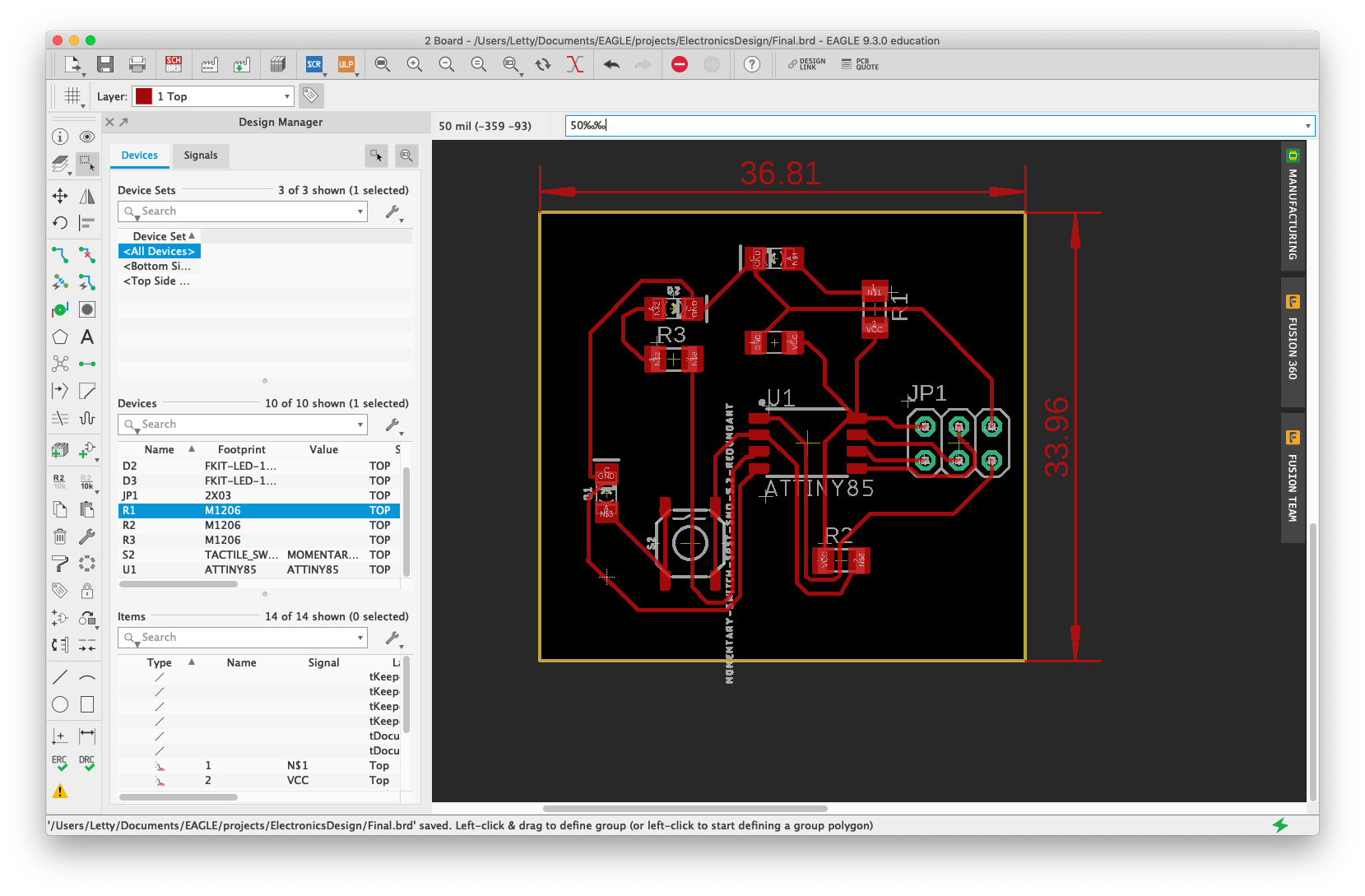

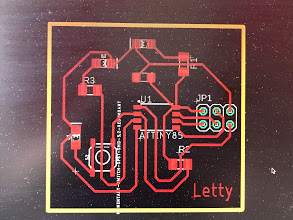

- Go to the Board on Eagle

- Move your components into the PCB canvas (within the yellow lines)

- MOve the ocmponents as close to each other as you feel comfortable, remember you'll need to solder afterwards

- If you feel lucky try the automatic connection generator

- If you don't, move the ocmponents around (rotate, change positions, etc) to eliminate any lines crossing

- After you see very few lines crossing, or none at all, run the automatic connection generator

- Once you have zero error in the alert section you are finished (it can take several trials)

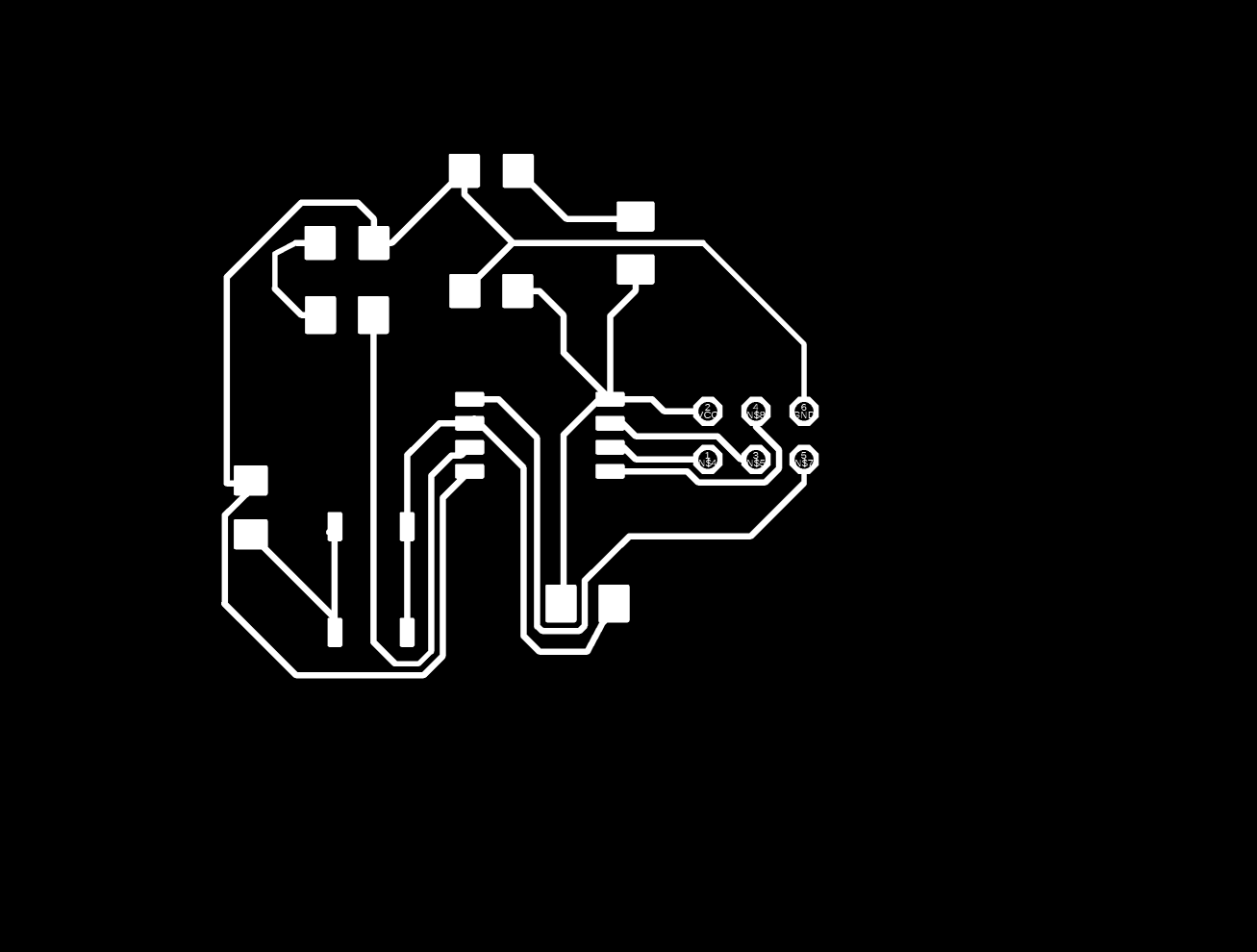

- Eliminate all the layers from the view except the top/engraving one (red) and export to image to make inner PNG

- Eliminate all the layers from the view except the dimensions one (yellow) and export to image to make the outer PNG

- Run the inner PNG by fab modules to create inner rml file

- Run outer PNG by fab modules to create outer rml file

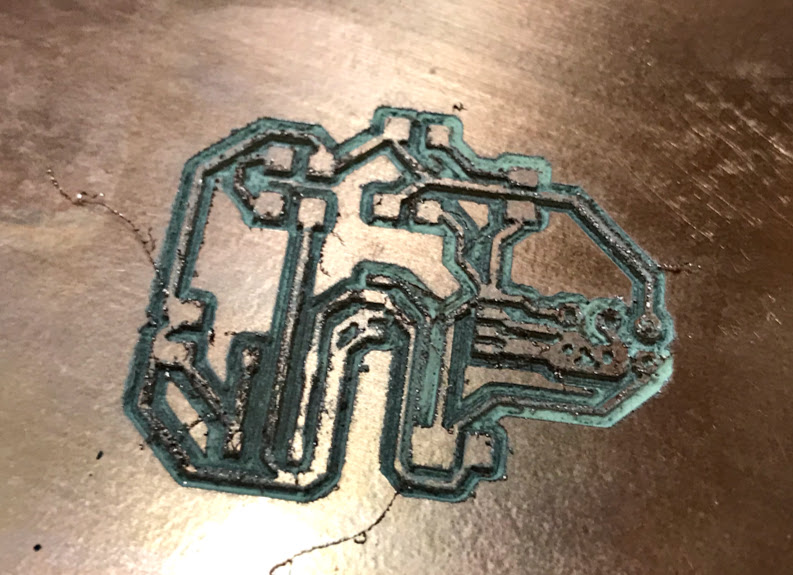

- Run the inner rml file through the RolanMill to engrave

- Our equipment is having a bit of trouble cutting still

- We finally were able to cut using a mini mill, same process than for the Roland mill just adjusted parameteres

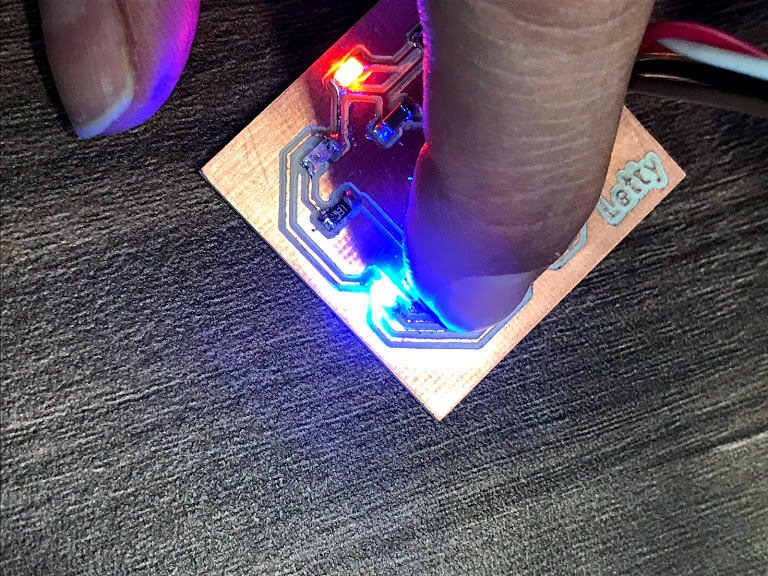

- After engraving and cutting the next process is solding the components following your schematics to the PCB

- Program the PCB to recognize the button and the different LEDs

- Test the PCB connected to your USBTiny previously programmed