Week 6

Feb 20. 3D Scanning and Printing

Group Assignment

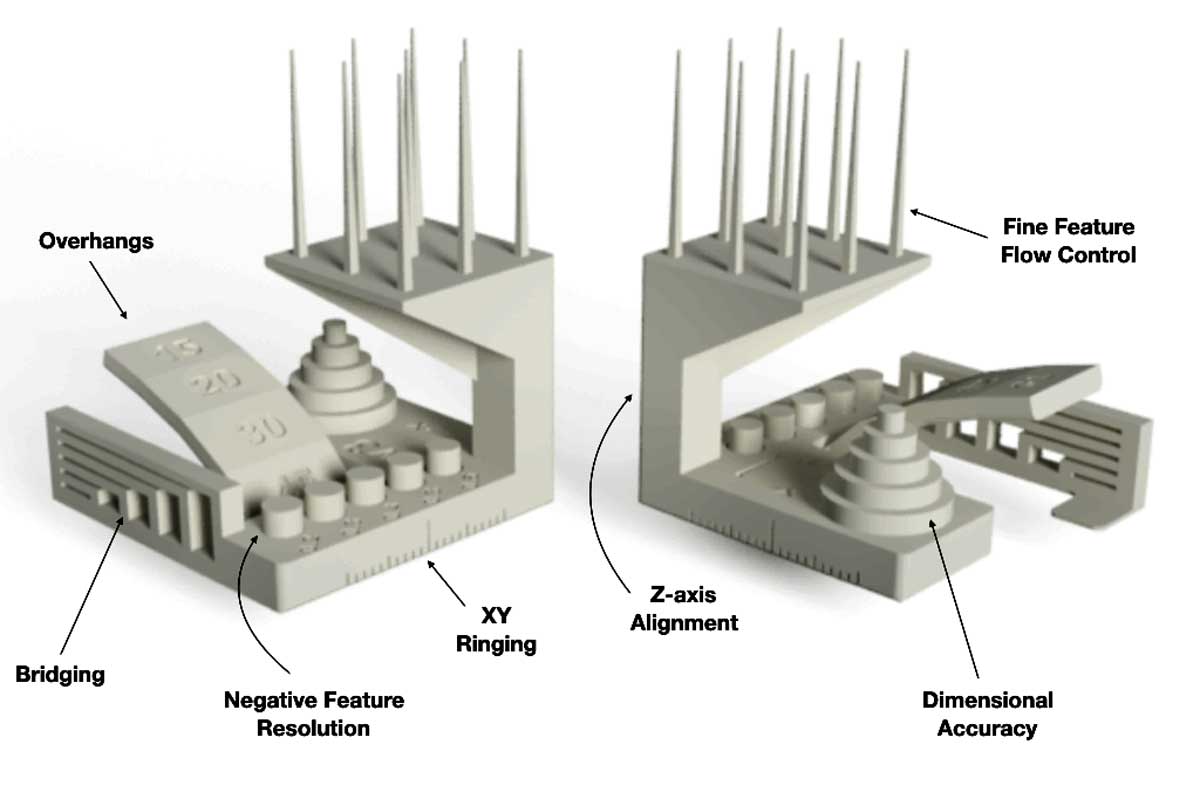

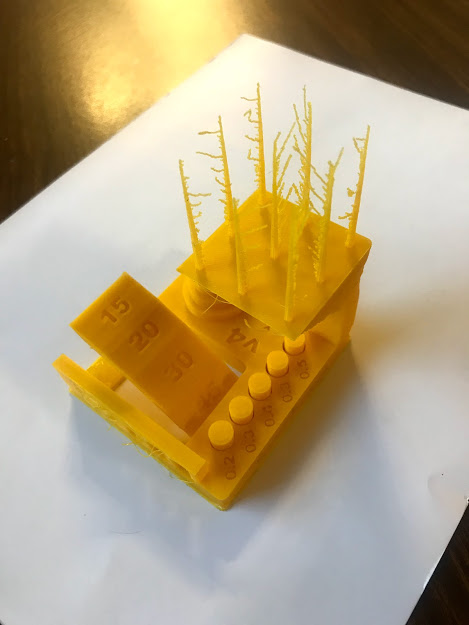

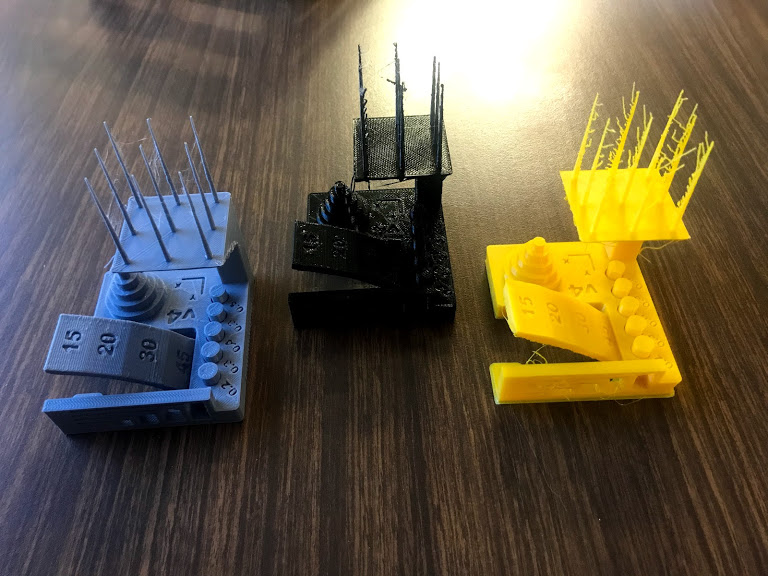

Test design rules for the 3D printer to be used. We tested three an ultimaker, a rostock and a syndoh to define which one to used in each assignment.

Instructions

- Look for a test model and download from Internet

- Guarantee is a small enough piece that it will print within a small am ouont of time (took 4 hours each)

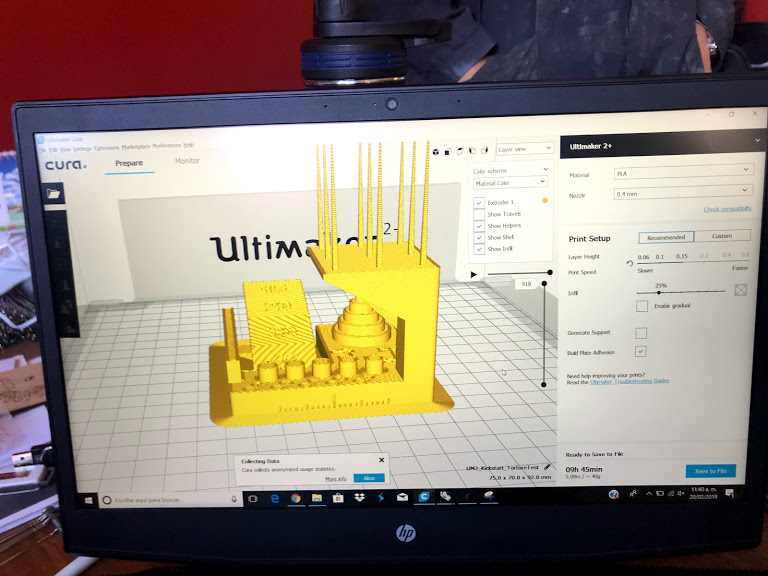

- Open in the program for 3D printing

- The parameters used for all printers were. layer height 0.15 and Fill 25%

- Open in 3D printer

- Press start

- Wait until ready

- Eliminate any excess material from the piece

- Repeat with Rostock and Syndoh

- Compare pieces

- I decided to print all of my pieces in the ultimaker despite Syndoh being the best quality overall becauase I did not need to print any angles or vertical lines.

Individual Assignment

3D scan an object with different techniques and optionally print it. I used three different techniques, laser arm scan (Romer), white lighting scanning (Shining 3D) and photometrics (Qlone for iPhone).

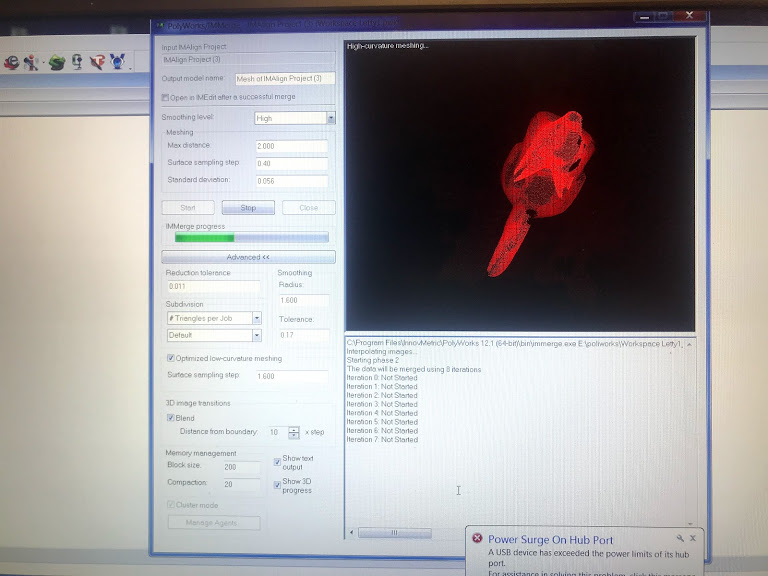

Instructions Romer

- Start arm and connect to the computer

- Start software and open scanning mode

- Start moving the laser scan all around the piece

- Continuosly check that the piece is being formed in the computer software

- Continue scanning until th efigure is recognizable

- Save the final result as a txt with coordenates

- Open txt fil in GeoMagic

- Close mesh as good as possible

- Define if you are going to priint the file, if yes export to .stl (I did not print this one)

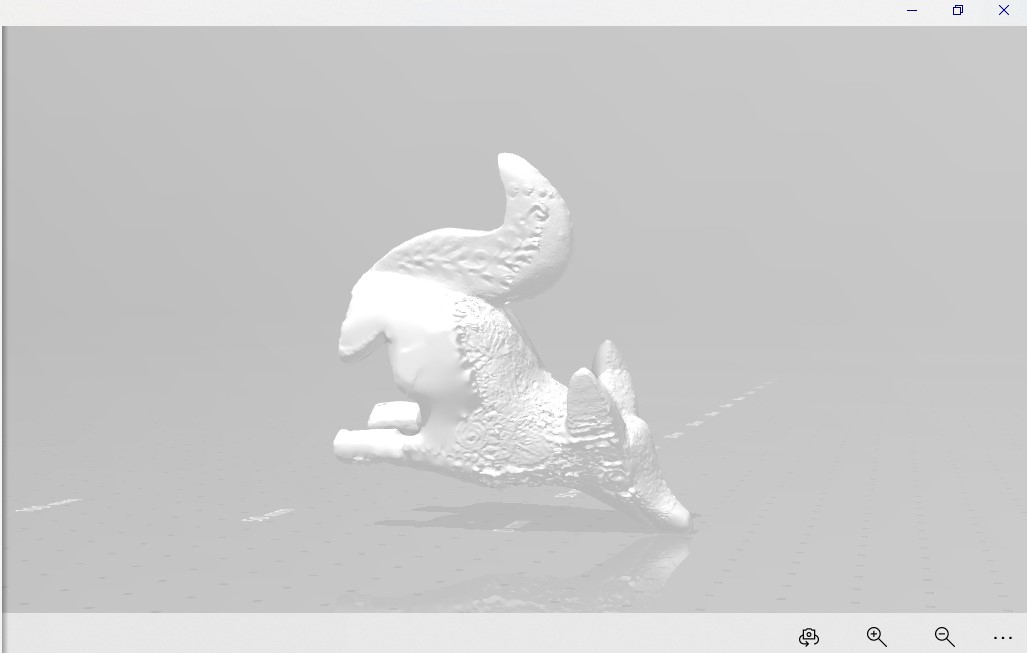

Instructions Qlone

- Install Qlone onyour phone or tablet

- Print mat to define scanning region

- Put your piece in the center of mat

- Start app

- Follow your phone trying to get rid of the dome that the app creates over your piece

- Once the dome is transparent your piece is finished

- The end result is gorgeous, exactly like the original

- Export to as many formats as you want (and/or want to pay for)

- You can even play with your model with Augmented Reality

- I decided not print this model although it was the best by far, because creating an stl file came with a price

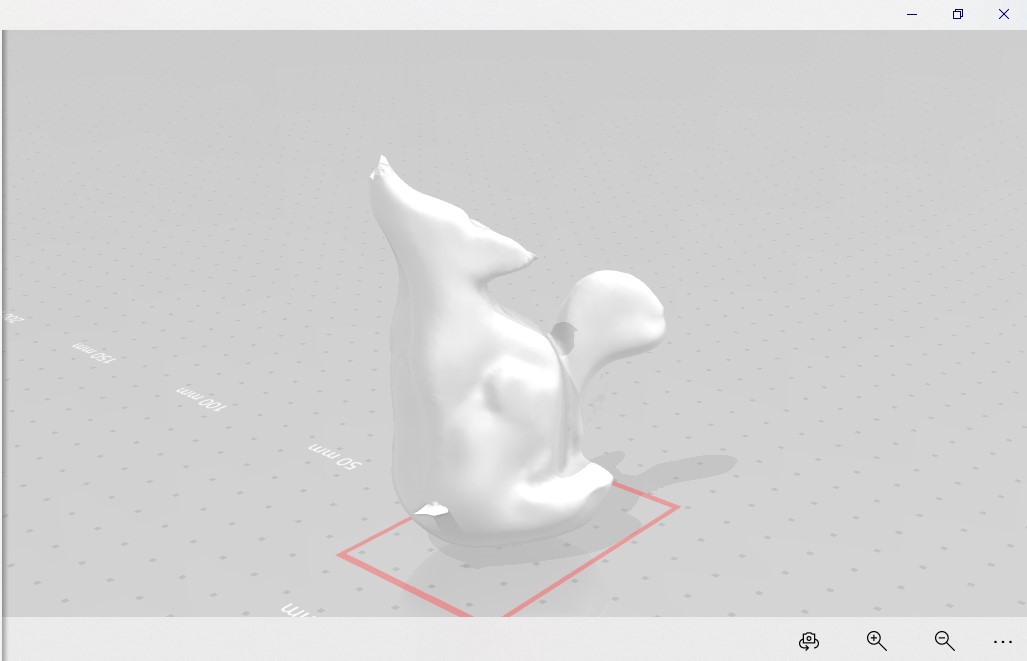

Instructions Lighting Scanner

- Install the scanner and connect to your computer

- Open the scanning software

- Callibrate, if the scanner is not callibrated it won't work (believe me we tried)

- Set your piece in the middle of the rotating plate

- Set the scanner to identify your piece, this means selecting the kind of color it will receive (light or dark pieces need differente parameters)

- Select the number of loops it will make, 25 loops in this case

- Press play and start scanning

- Don't move your piece while scanning, be patient

- After the scanning is finished put your piece on the side and start scanning again

- Don't move your piece

- After both scans are finished merge both mesh

- Save your project

- Open in Mesh mixer to clean up a bit

- Export to stl to be printed

- This was the easiest way to scan

Instructions Printing

- Open in the program for 3D printing

- The parameters used for all printers were. layer height 0.15 and Fill 25%

- Open in 3D printer

- Press start

- Wait until ready

- Eliminate any excess material from the piece

- Compare to original piece

Individual Assignment

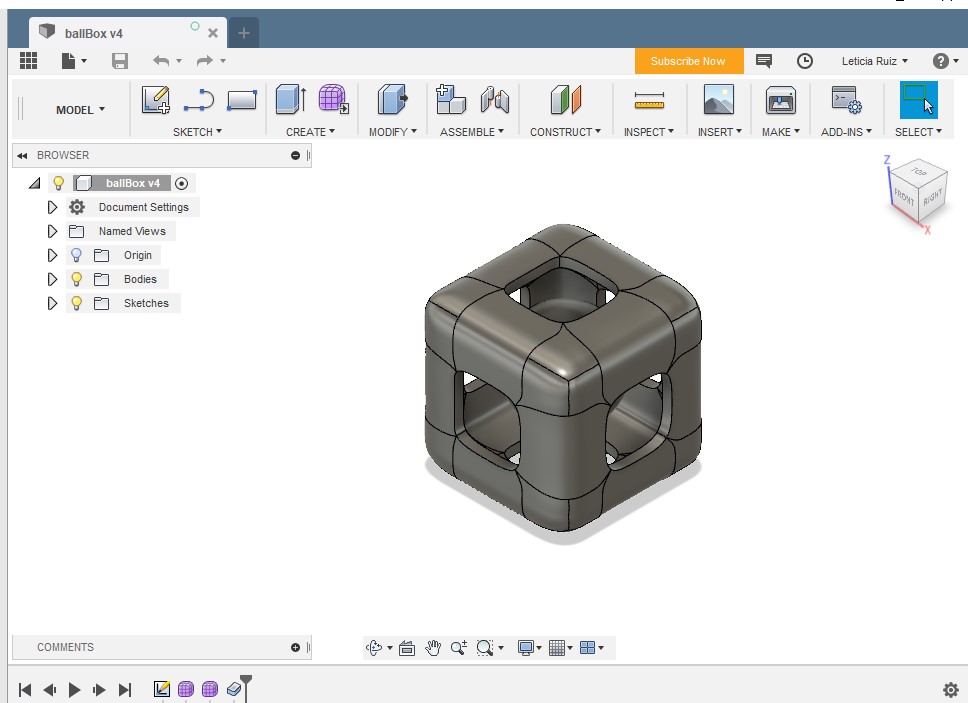

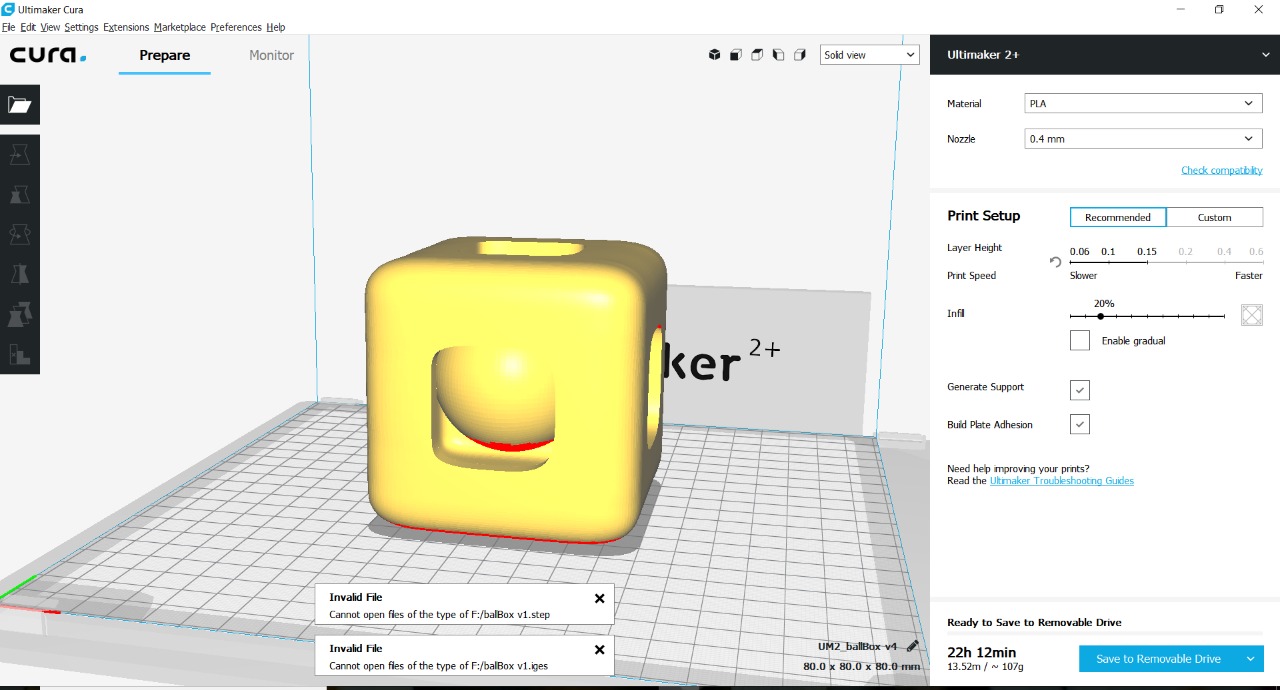

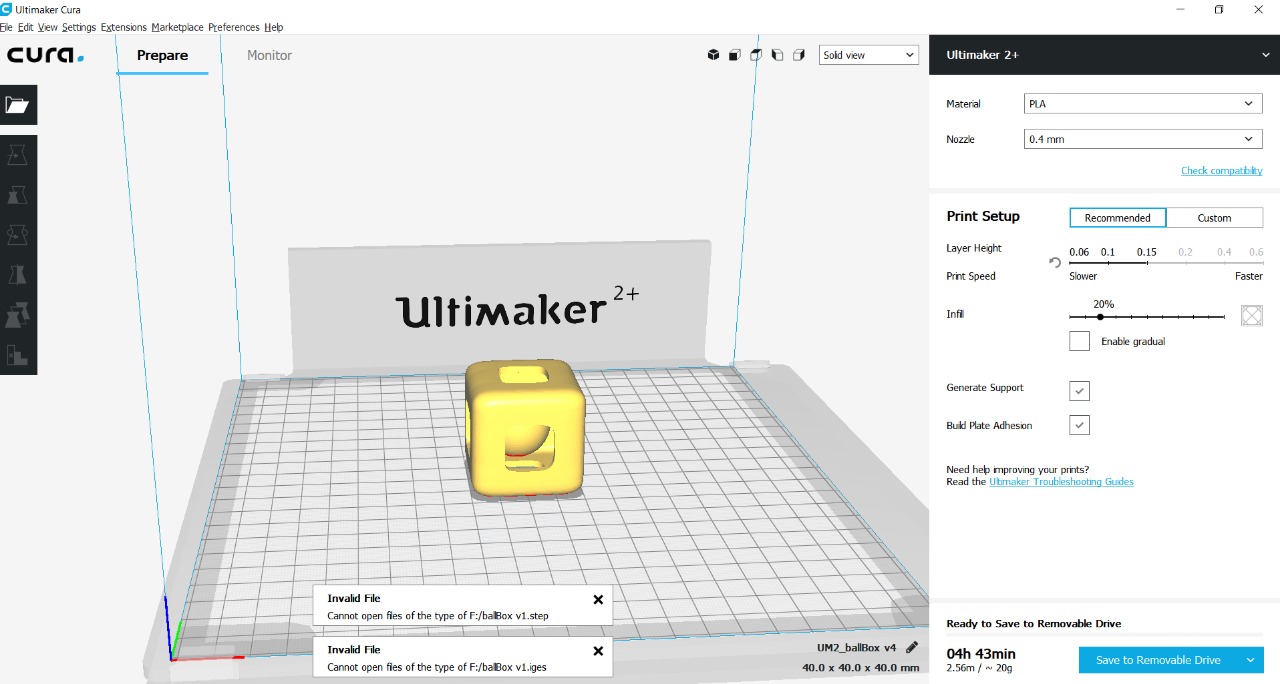

Design and 3D print an object (small, few sqaure centimeters, limited by printer time), that could not be made substractively.

Instructions

- Open Fusion 360

- Go to the sculpting tools

- Create a square and start subdividng each face

- Eliminate excess faces to create a whole in each side

- Create a sphere and insert within the square

- Extrude the square to 5 mm so it will have depth and can be printed (my first attemp was not extruded and couldn't be printed)

- Export to stl for 3D printing

- Open in 3d printer software, set parameteres, fill 25%, minimum support

- Print and wait for final result

- Eliminate support and excess material from piece

- Play with it, it rattles!