Week 17

May 15. Machine Design

Group Assignment

Actuate and automate your machine. Document the group project and your individual contribution

Group Page

Individual Assignment

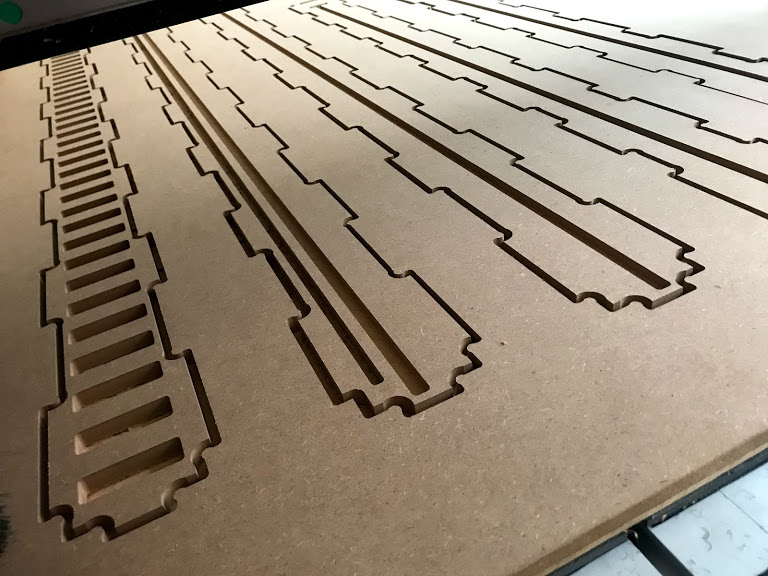

Aside from participating in the integration and testing processes with my team mates, my main assignment was to create the frame for our final piece. The first problem was that we decided on a very large scale, it ended up being 2 x 1 square meters. We decided on 15 inch MDF and it was really heavy to move, if you plan on building a new one, scale it down.

Instructions

- Define which software you are going to use, I chose AUtoCAD since at this point it's the software that I feel most comfortable with.

- Create the back part and define the dented pieces, everything should be parametric in case you need to change the material, we actually changed the material twice due to different circumnstances.

- Duplicate your back piece and create a window for the fornt opening, similar to frame.

- For the midddle section, you'll need a smaller rectangle, bigger than the window but that press fits into the sides.

- Create the sides and marke the dented pieces for press fitting.

- the middle piece and the base are very similar, the difference realies on which side would be press fitted with the middle section.

- For the top row beacuse it's a vent you0ll need to certe dents all over to guarantwee the piece won't overheat in use.

- The motors were loceted in the top corners to allow for the center piece to move within the window.

- After all your pieces are defined, check if they fit together the way you intendede, this is trickty because sometimes you need to adjust, adn adjust, and adjsut again until everything fits perfectly, at least on your CAD software.

- Prepare your Router files and cut

- Assemble all of your pieces into the final frame and test the structure before adding weight.

- For further detail please go to our Fab Lab Puebla - Group Page