07/ computer-controlled machining

This week is to make something BIG!

1. group assignment

2. design

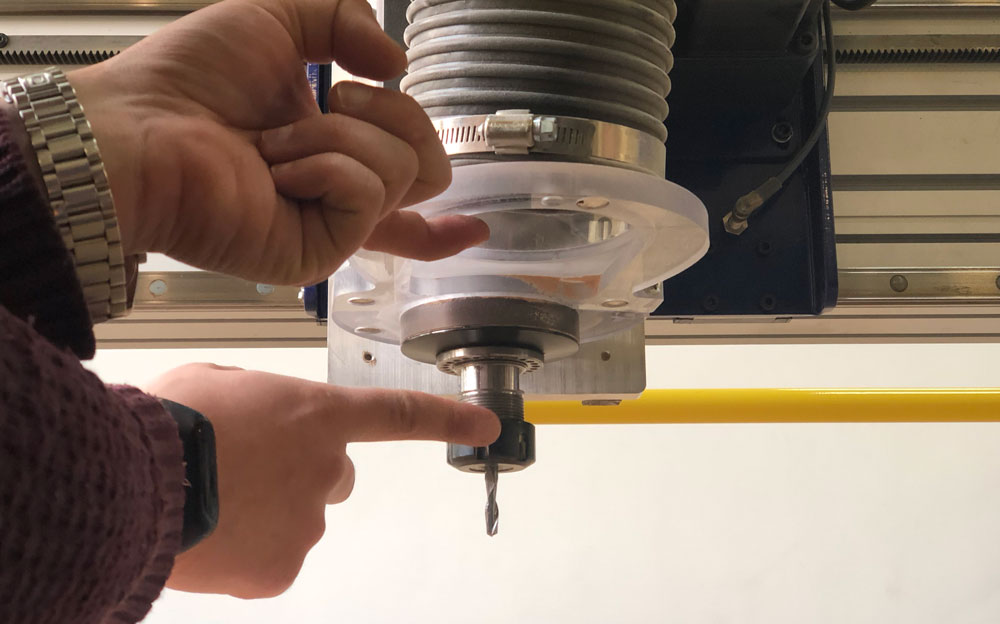

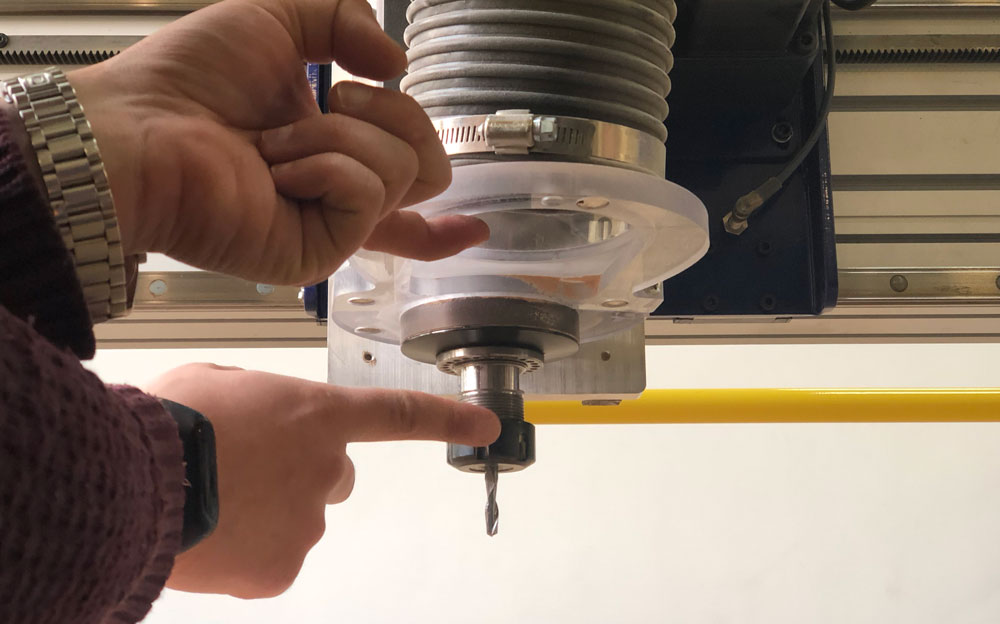

3. milling

4. assembling

← previous

→ next

⋯ assignment list

🏁/ final project

Group assignment

For group assignment we need to test runout, alignment, speeds, feeds, and toolpaths for our machine. Nick has documentation on his page:

group assignment documentation link

This is the shopbot we have at shanghai Tech University :D It is a room-size CNC that can cut materials such as wood, plastic, foam, aluminum and many composites. Saverio gave us a demo on how to use the machine.

The steps of using CNC machine is:

- 1. clean the surface

- 2. place the material sheet, position it to line up with the right side of sacrificial layer, and fix the sheet to the base with nails or clamps

- 3. turn machine on with the red button

- 4. disengage spindle(important!) and change endmill. Use downcut endmill for the first 3mm cut because it leaves clean and nice surface edges, upcut for deepcut because it takes material out effectively and drill endmill for drilling.

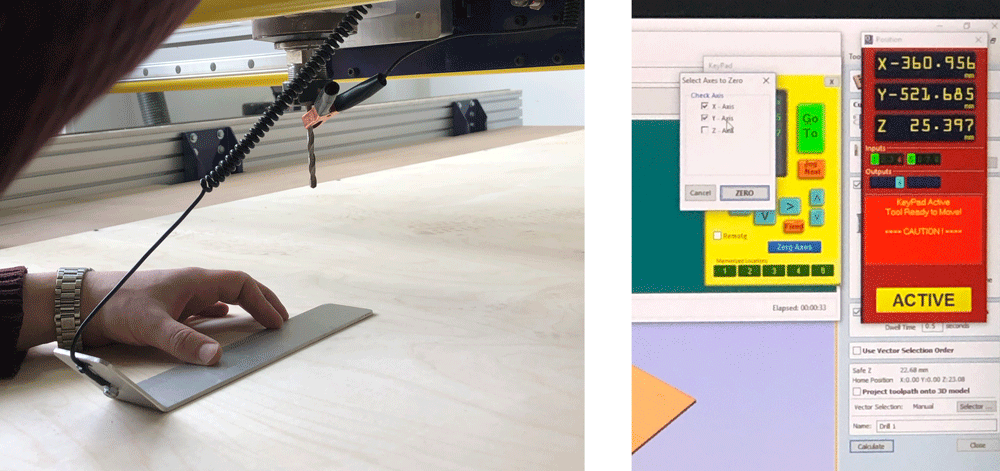

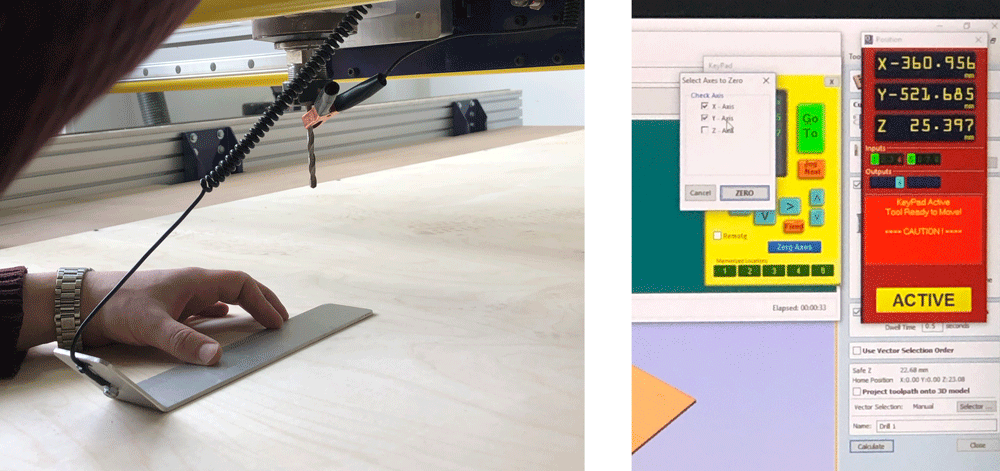

- 5. open shopbot software, move spindle head to locate XY position

- 6. locate Z axis using the aluminum board and clasp attached to the machine's spindle head

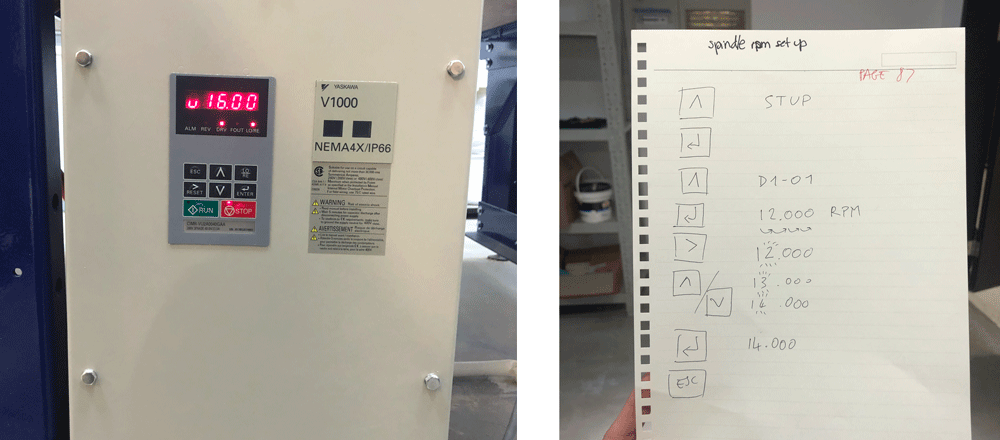

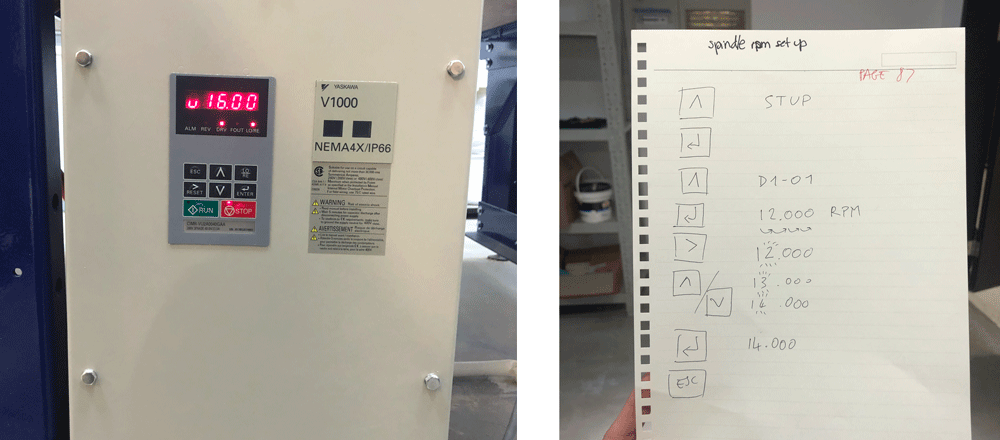

- 7. set up spindle RPM that matches your file's setting, and turn spindle on by hitting LO/RE and then RUN

- 8. use Vcarve to prepare tool path

- 9. add tabs in Vcarve to make sure pieces do not jump out while cutting

- 10. export tool paths from Vcarve and import into shopbot software

- 11. turn on vacuum pipe to take away cut out materials

- 12. start the job, hold the emergency stop botton in hand

- 13. after the job is done, turn spindle off

- 14. use a cheasel to cut out the tabs and remove pieces

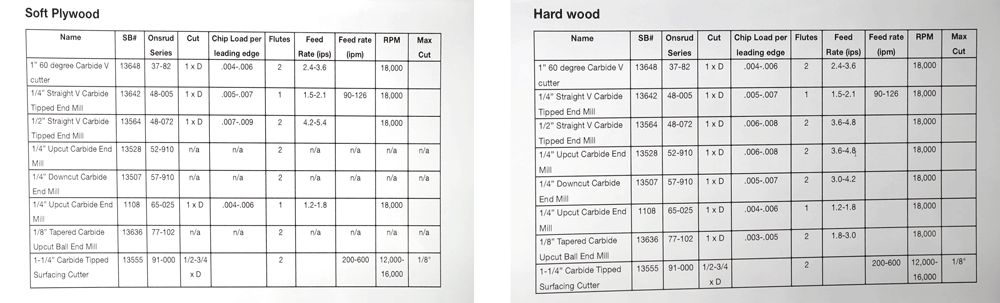

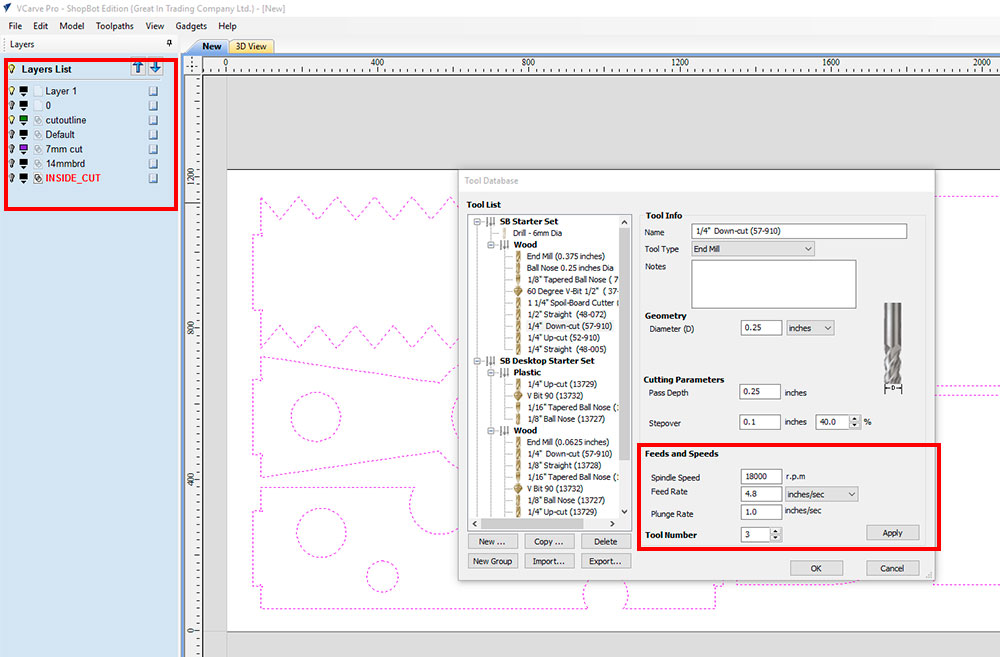

These are the tests we made for 14mm wood stock :D We tried different RMP and feed rates with either conventional or climb. It turned out the piece cut at 18000 RMP/4.8 feed rate with conventional cut was the best.

Here are some setting data for common materials.

Design

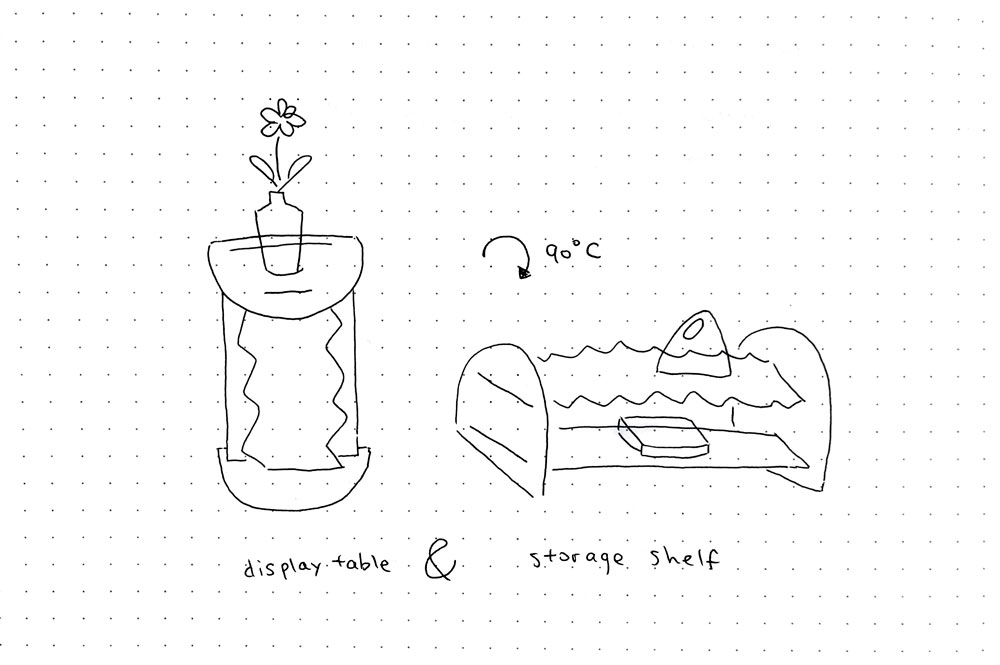

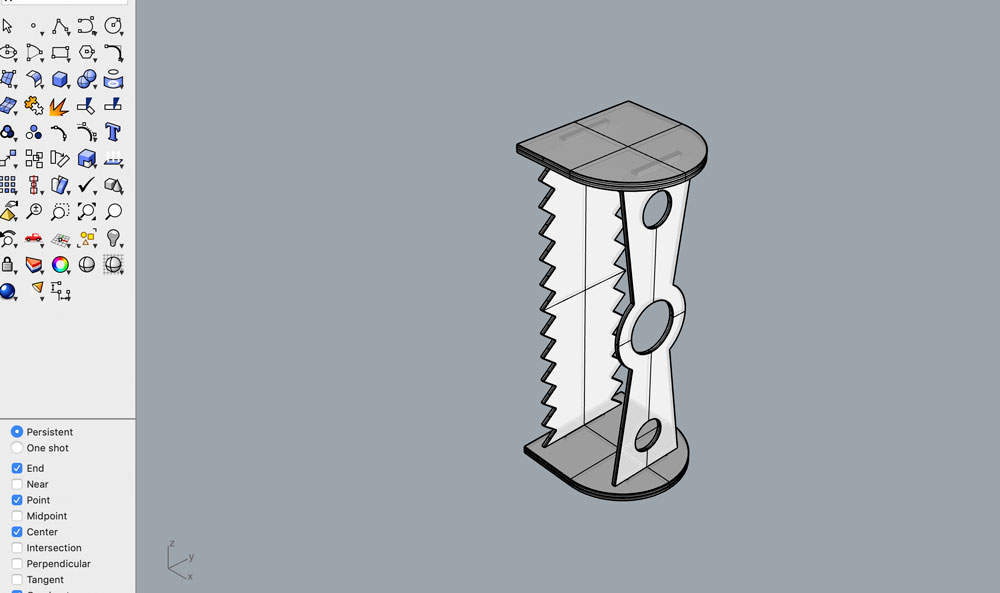

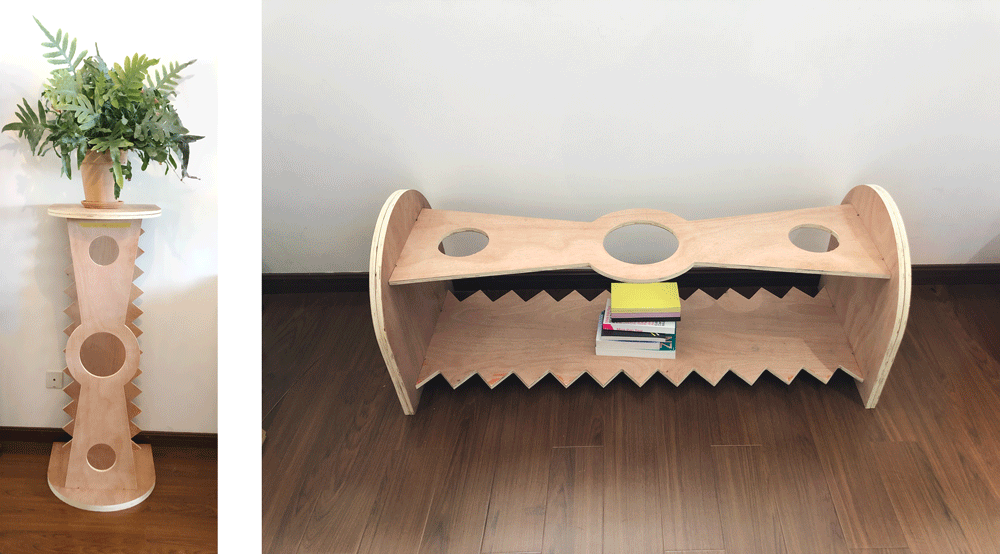

My idea is to make a two-way shelf that can be used as a display table on one side and a storage shelf when laying down.

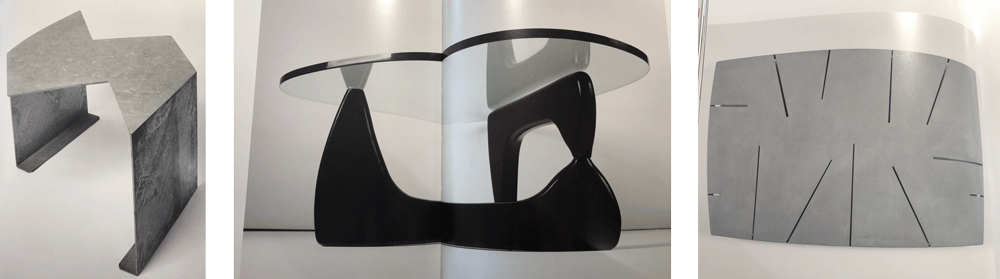

The design inspiration comes from the simple and organic forms of Isamu Noguchi's sculptures. I decided to stick with basic geometric shapes with a little bit decoration.

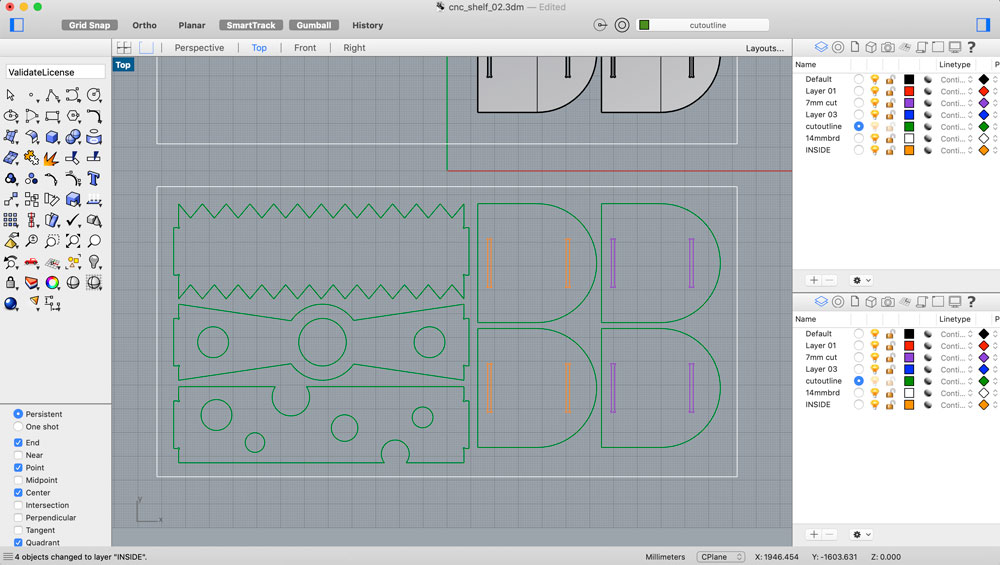

I modeled the shelf in Rhino, set the outline for cutting at different layers, and exported the .dxf file.

It is important to seperate the inside/outside cut paths onto different layers, which will be helpful when working in Vcarve next step. Outside cut is good for outlines becaue the endmill goes around the outer side of the shape. The cut outline matches your desgin trace. Inside cut is for slots so they will not be bigger than what they should be.

For design I need only two long pieces for the shelf, but I cut three to maximize the use of my piece of wood. Now I have more assembly options for my shelf :D

The next step is to create tool paths for my design in Vcarve.

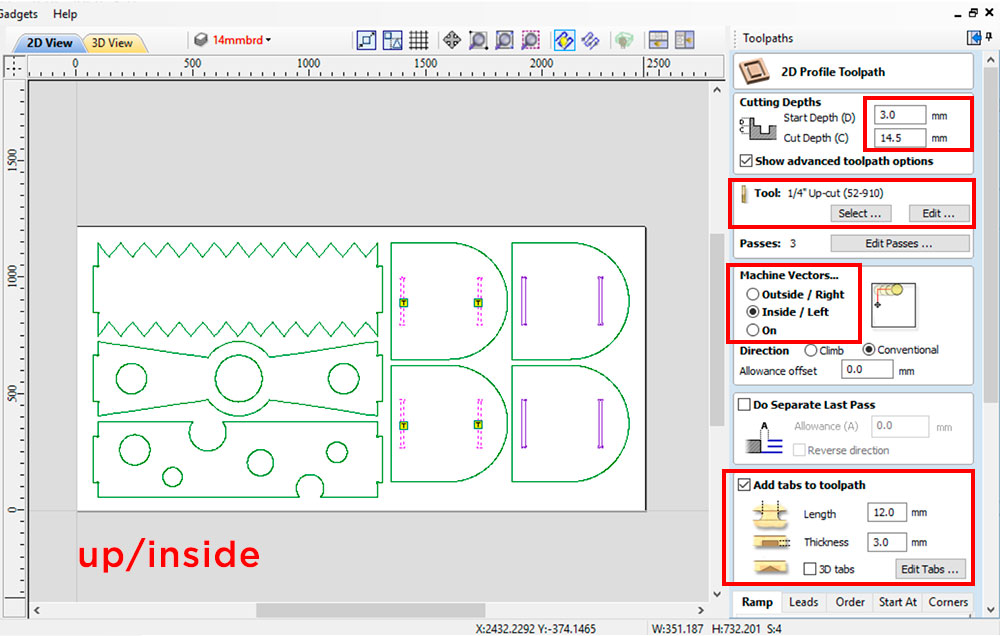

Open the .dxf file in Vcarve, double-check canvas size and XY original point. Different parts of the design needs to generate tool paths seperately with their own settings. It is helpful to seperate and turn on/off layers for each path to avoid selecting wrong paths. Based on the tests we made for 14mm plywood, I changed the tools setting.

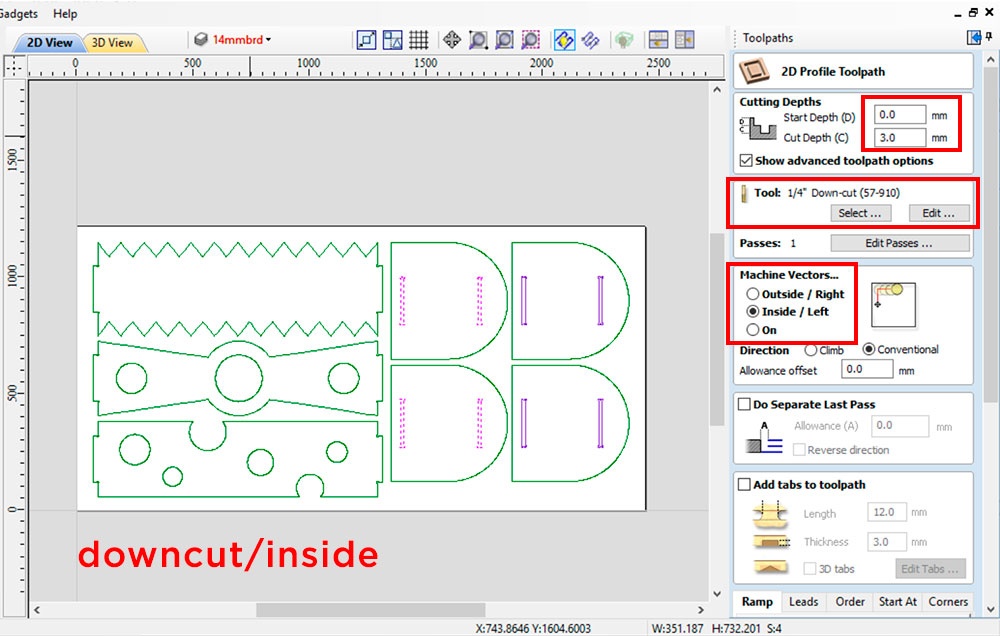

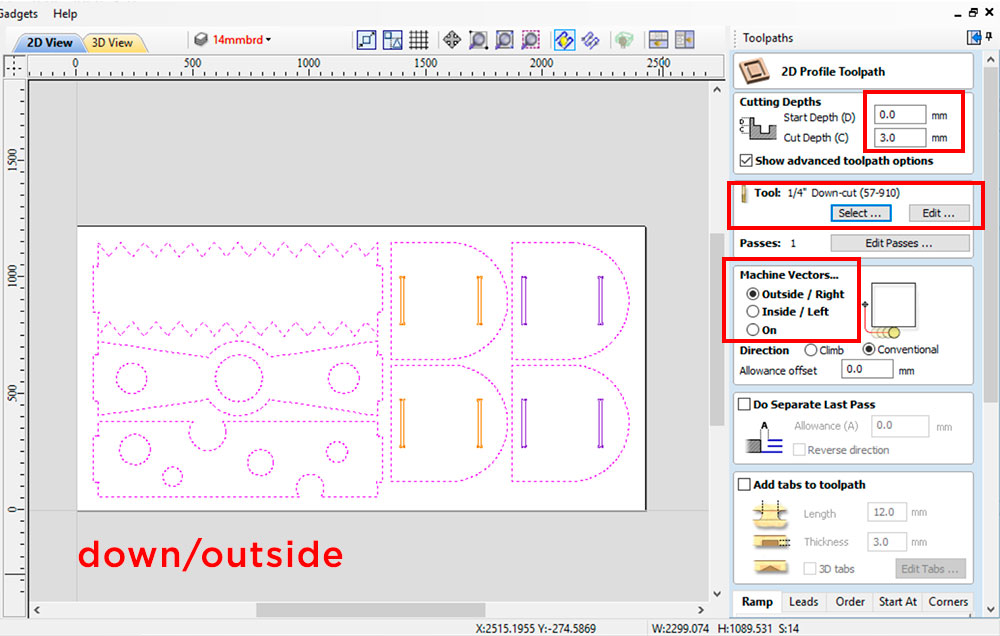

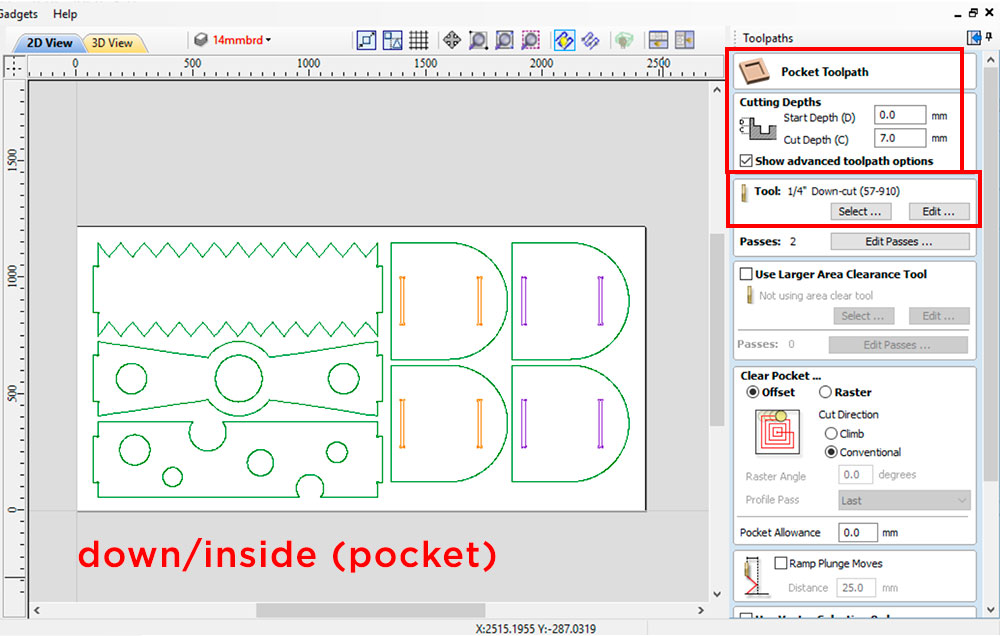

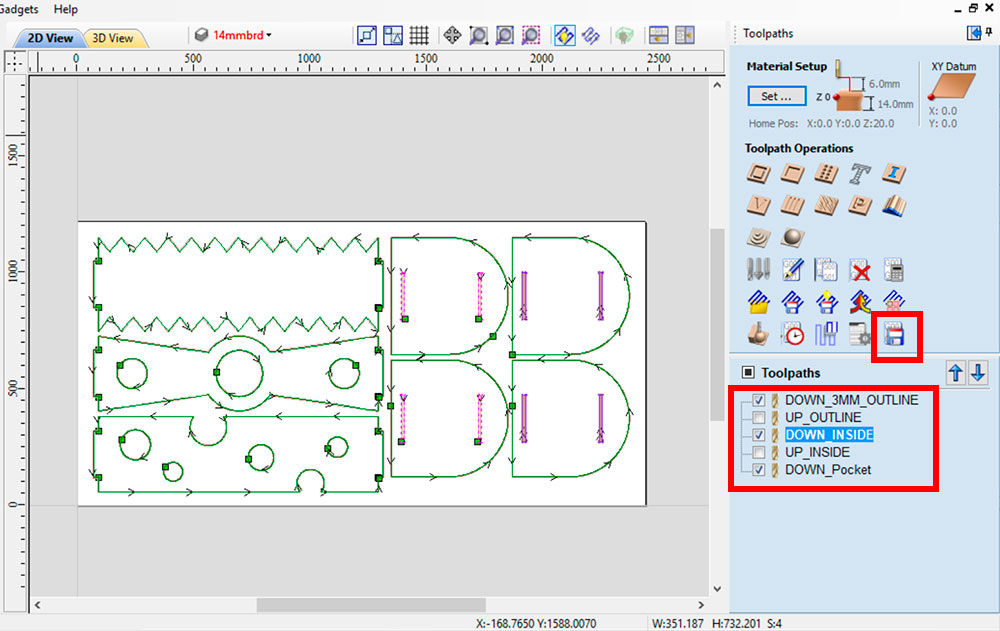

Then I set up individual tool path for each job. For downcut endmills, I have a 3mm depth first layer outline cut job from outside, 3mm depth inside cut for slots and 7mm depth pocket cut.

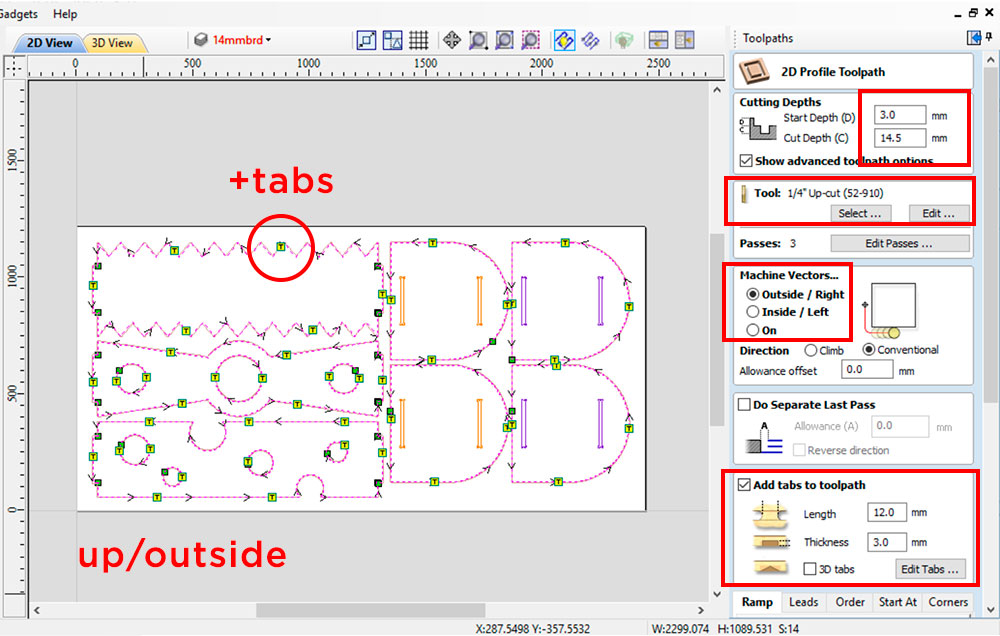

For upcut endmill, I have outside cut for outline and inside cut for slots. Upcut jobs will cut all the way down into the wood sheet and exceed into scacrificial layer a little bit to make sure it cuts through. It is important to add tabs for upcut jobs.

After I have all tool paths ready, I group them by tools (up and downcut endmill), save combined tool paths into one file and export the files.

↓ download .dxf file: cnc_shelf_V4.dxf

milling

We use shopbot3 software to control the machine.

This is me drilling nails to stable the sheet and the two types of endmills (1/4' upcut and downcut) I use for the job.

This video is me taking 0 position for Z axis.

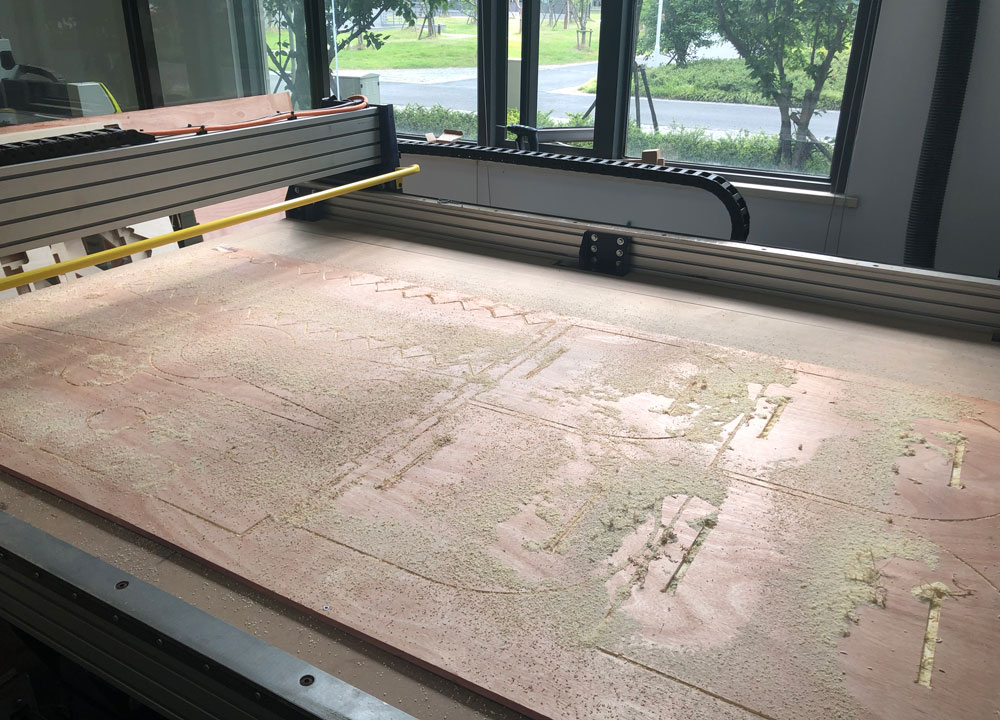

After the preparation is done, I imported the tool path files created in Vcarve into shopbot3 and start cutting. First I used downcut endmill. This is the look of my sheet when the combination of downcut cut jobs are finshied.

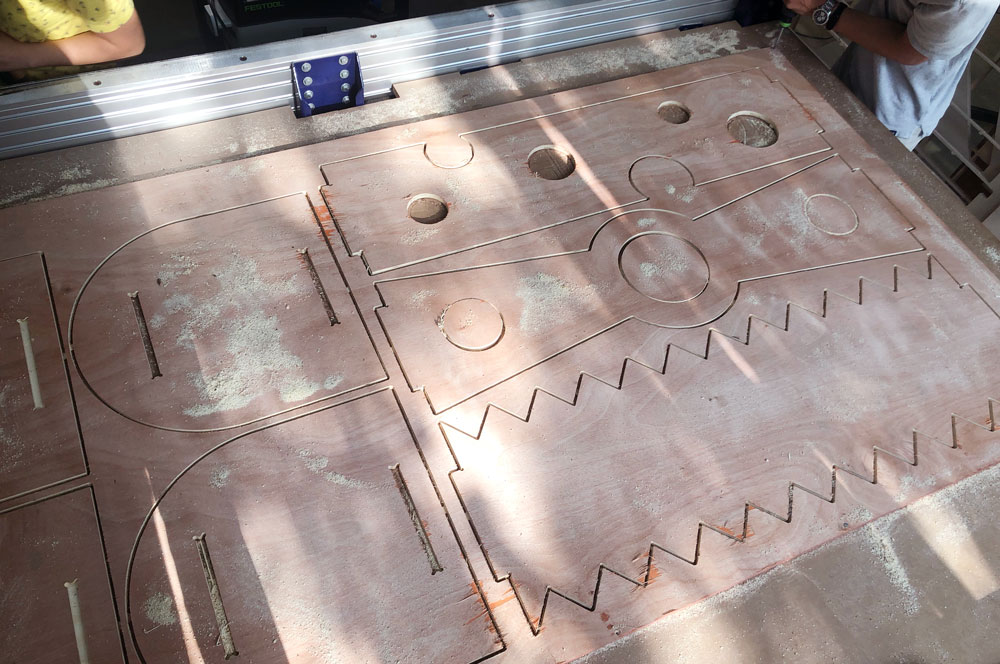

Then I switched to upcut endmill and ran the upcut jobs. There might be some problem with Z axis for the cut was not deep enough. The endmill was cutting from surface to 11.5mm instead of starting from 3mm to 14.5mm.

I hit the emergency red button in hand to stop the job, which I regreted very very much :'( because it forced quit the program and I lost all my 0 positions for XYZ axis :'( It's better to stop by hitting the stop button in the computer program next time.

The left image below shows the wrong depth of upcut. In the right image the end of endmill was broken because I did not screw the endmill in tight enough so the endmill came off :'(

Then I went through many tests to adjust XY 0 point positions for the upcut trace to match the previous downcut trace. Finally I got the right registration and machine finished job without any futher problems.

The cut is done :D

assembling

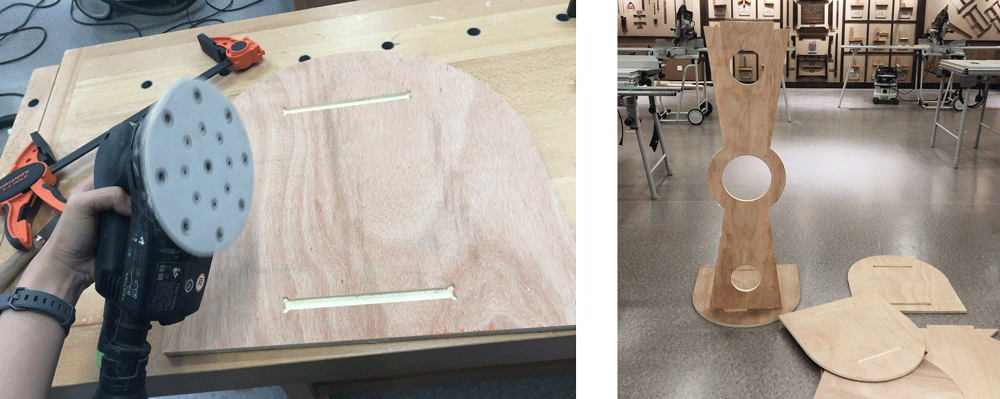

After cutting with the machine, I took the pieces to the woodshop nextdoor and sanded my pieces :D I tested the slots as well. The pieces fit to each other well.

(Updated 12.06.2019)