This week we worked on tasks refered to Machine design in order to 'work and communicate effectively in a team and independently; design, plan and build a system; analyse and solve technical problems; recognise opportunities for improvements in the design'. This was the assignment:

Group Assignment

First thing was to review the tasks to be afforded in a new meeting after the class:

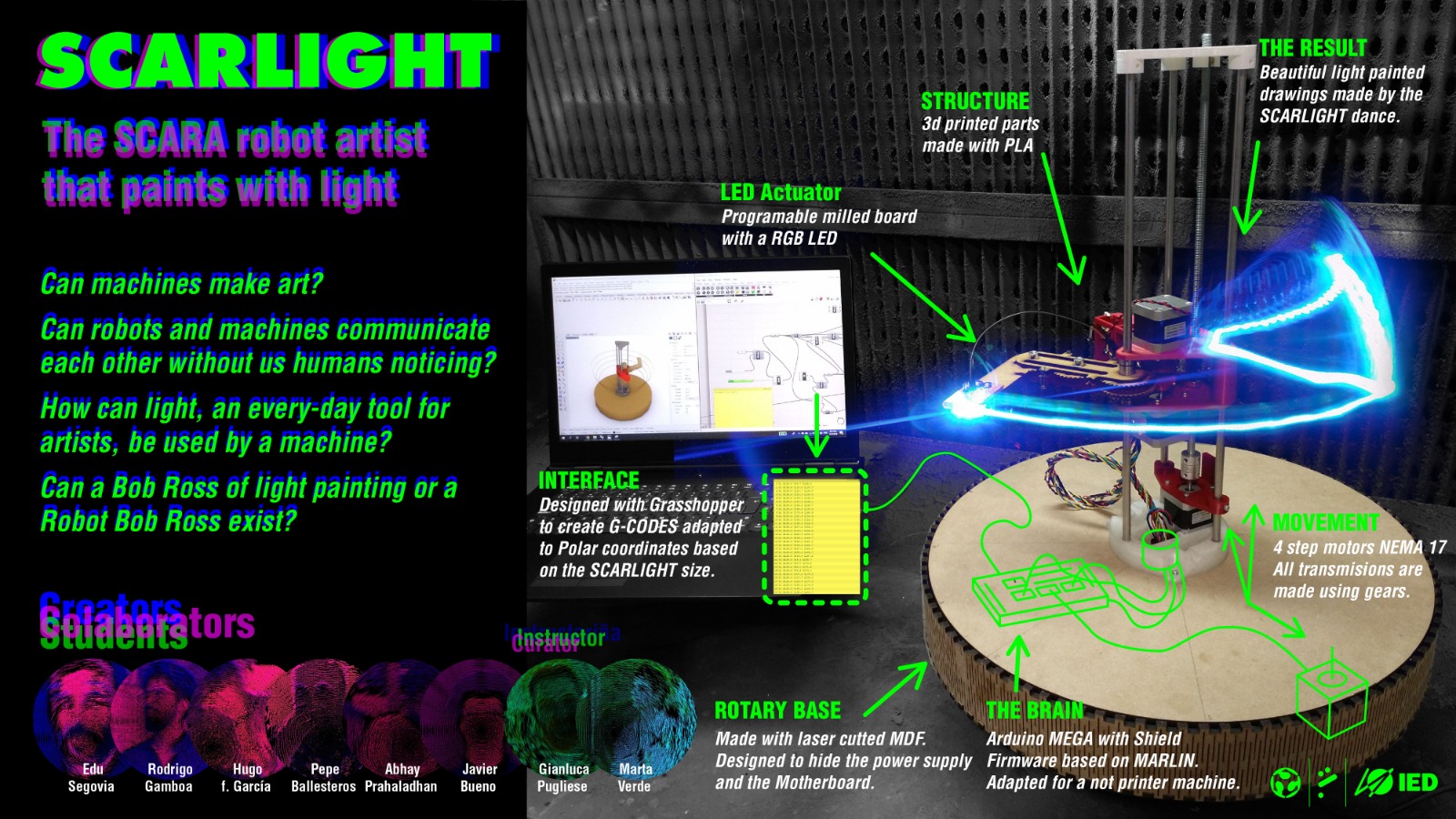

Electrical components must be integred to the system, like power supply, wires and controller board (Arduino + Ramps).

For that, some parts should be replaced/modified:

Arm

Base

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Tower

Also, it was very important to put together all personal capabilities to agree in the way to work.

Simmulations

After reaching an agreement about the first idea of the machine, this is a simulation of its use in grasshopper. the behavior is simplified, and it should be understood that a led would light on each sphere that grasshopper draws

starting to write code this is a simulation using arduino one where it is only intended to establish an order of execution. the green LEDs would light simulating the lit ones to draw, and the red one whenever there was a movement in z

this simulation is similar, only that in this case a servo is assigned to simulate the behavior of the forearm

Also, it has this other parts/components:

To accomplish this goal, the Trello platform was used to organize the work by defining:

This is the Trello in use, showing tasks, workflow and people in categories:

This is the bom made:

By this way, tasks were assigned to allow working on design before meeting again for the production process.

These are the designs made based on the original one, using Rhino and Grasshopper, Fusion360 and Illustrator.

The processes followed to make the machine were 3D printing and lasercut:

One of the problems founded was that the idea of using a slip ring for connections on a rotatory axis, was out of the bom plan; Adafruit is the only provider with high shipping cost and so much time to deliver the component.

Another problem was that maybe the light would not be seen when the arm passes behing the tower, or if the LED holder hides the LED on some positions. One idea to solve this was to put the LED, extended with wires, at the end of the arm, while the controller board could be placed into the actuator piece near the tower. Another solution for that is to use all the faces of the actuator to hold different LEDs

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)