Computer-controlled machining

Assignments

#1 - Make something big

Ok.. big... how big ? I checked previous years projects and it looks like it ends up often with some king of furniture, like a chair or a table.

I would like to experiment something different and I have no clue whether it is possible to make it using the big CNC. The idea is to build a marble machine.. wall. Yes, I wrote "wall" ! It should look great when you visit a Fab Lab for the first time to see a set of homemade machines running. I know marble machines are totaly useless but it is funny !

Since I have only one week to make it happen, I will focus on building one section of the wall, let's say a 2' by 2' box, with 2 wood gears and a motor. It should be similar to the wood gear that you can see in this video

References

Lecture

This week is about using a large scale CNC:

- What is a marble machine and how to make one ?

- What design tools should I use ?

- How to design wood gears ?

- How to get started with FreeCad ?

- How to create a set of gears using FreeCad ?

- How to make it ready for the CNC once my design is ready ?

- How to prepare the CNC

- How to integrate the gears in the enclosure a> ?

Learnings

Marble machines

(from Wikipedia) A rolling ball sculpture (sometimes referred to as a marble run, ball run, gravitram, kugelbahn, or rolling ball machine) is a form of kinetic art – an art form of that contains moving pieces – that specifically involves one or more rolling balls. Rolling ball sculpture art typically includes rails or tracks made of metal, wood, plastic, or other material, and one or more balls or marbles that travel down the tracks. Ball types include, but are not limited to, steel, acrylic, wood and glass. Rolling ball sculptures are often described as being both busy and soothing at the same time. They are an artistic form of mechanical motion.

Wood gears

(from Wikipedia) Gears are commonly made from metal, plastic, and wood. Although gear cutting is a substantial industry, many metal and plastic gears are made without cutting, by processes such as die casting or injection molding. Gear cutting is any machining process for creating a gear. The most common gear-cutting processes include hobbing, broaching, milling, and grinding. Such cutting operations may occur either after or instead of forming processes such as forging, extruding, investment casting, or sand casting.

For this class, we will use the big CNC to mill our wood gears

There are many models but I found out that involute gears are the best for such a project

For calculations and a little bit more of theory, you may visit this site. Note: in FreeCAD, there are two properties to set to generate a involute gear: the number of teeth and the "module" (the unit of size that indicates how big or small a gear is. It is the ratio of the reference diameter of the gear divided by the number of teeth)

Design tools for 2D, 2.5D and 3D ...

During week3 I designed a wood gear using FreeCad and I will start from there. The output was a wheel with slots for marbles. This model is kind of a 2.5D model. It could be manufactured on a laser cutter as well but the thikness would be limited, depending on the model.

A quick refresh on FreeCad first. I found out some great videos here:

- Let's start with the foundations

- Then learn about tools and controllers

- And now we are ready to create a CAM job and to discover the vizualization tools

- Now let's talk about the operations

That part has been designed in the Part workbench. We now have to switch to the Path workbench. The main concepts in this workbench are the followings:

- Job: this contains all the information required to generate the necessary G-Code to process the Job on a CNC mill, a set of tools and it follows certain commands controlling speed and movements (usually G-Code).

- Tools are selected as required by the Job Operations. Each tool has settings: horizontal and vertical speed (in feed mode and rapid movement modes) and spindle speed, material (like high speed steel), diameter, length, cutting edge, ..

- Operations: milling paths are created and sequenced in a workflow using path objects: contour, pocket and drilling

- Contour: a simple external contour cut of complex 3D Part-based objects. In our example, this is the gears but I didn't realize at the time I wrote this that the slots for the marble could be manufactured using the "contour" pattern as well.

- Pockets: a pocketing operation from selected bottom faces or walls of one ore more pockets of the jobs base object. In our example, slots for marble are all pockets

- Drill: this is similar to pockets but this goes through the material. Currently, I don't know whether I should use pockets or drilling holes for the marble slots

- Facing a surface: initialy, I tought it was just about getting a plane surface but... stay tuned ... r

- Stock material: well, this is ... the material you are cutting/drilling into

The last step is the post-processing, i.e. to generate G-Code for the target mill. This outputs the G-Codes to a file that can be uploaded to the target CNC machine controller

Once everything is configured, we have to verify the created paths. G-code can be inspected and even simulated. You can do this using FreeCad or just use the generated G-code and render it using this online tool for example

Note: as many other SW, FreeCad can "render" the job for a specific machine type. The CNC at echoFab accpts "GRBL" code and the SRM-20 I have at home relies on "RML". In the file menu, there is an "export" features and I thought I had to use it to create the file for the CNC. This is NOT the case, the file I got contains machine specific code but (for a reason I cannot figure out) it does not contain all the code. The control of the spindle speed for example is missing. The rigth was to create the output is 1) to specify the rendering type in the Job "Output - post processor" property and 2) to click on the "post process icon" ![]()

Preparing the large scale CNC

Here is the SMX2436.. and a demo video

This is a half size bench (2' by 3') but it still does the job for my small project. But there is another issue: I planned to use 3/4" plywood and there is only 1" plywood in stock. The trouble starts.. here..

Using the CNC

First attempt (in the air as suggested): hard to figure out what part of the design the machine runs. I would suggest to use a pencil or maybe a spray and to run the job over a sheet of paper. It would not help regarding the Z axis but it would for the two other axes. We still see there is someting wrong with spindle. It goes way to slow. Back to FreeCad to fix it.

Next attempt, with a real tool (1/4 inch flat mill) and a real board. Two things are not ok: the slot diameter (way to big) and the way it is produced.It looks like a flower, not a circle.

Here are the root causes and the fixes

- Diameter is not ok. Definitely a 6th grade student mistake. Diameter and radius are different thing... I put the constrainst on the radius but assuming it was on the diameter.

- The "flower" pattern. First, the wrong tool has been selected. The one on the CNC is 1/4 inch end mill and the one in my design is (in some but not all places) a 4mm end mill

- There is something wrong with the way the slot is created. There are several patterns in FreeCad and I took the "pocket" one, assuming those slots should be seen as pockets. Here are the other available patterns:

- Contour: the obvious choice for the wood gear teeth

- Profile based on face

- Profile based on edge

- Pocket based on face: I took this one for the slots but with a limited success. I switched to "contour" for my second attempt. The drawback is the fact that a small piece of wood (slot diameter minus 2 times the bit diameter) remains in the slot once the cut is done. This could be dangerous since it is a moving part and I do not like that method at all

- Drill

- Helix

- 3D pocket based on a face

- Engraving

- Facing from a model or face: this is the right one ! ... I discovered it is usefull when you want to drill holes that are bigger than the tool diameter. On the picture, the hole on the left is created using a "contour" and the one on the right is created using "facing". The second one takes a little bit more time but there is no remaining center hole that could hurt anybody if it goes out

In the following picture, the slot on the bottom is based ton the "contour" pattern. The tool follows a circular path around the edge. The one in the middle is "pocket" based, with a zig-zag approach and the third one is based on "pocket" as well but with the "line" approach. The one based on "contour" will definitely not create the "flower pattern", will take less time BUT there is a small piece of wood that remains free and potentialy dangerous in the middle. A workaround could be to keep a very small slice of material in the bottom and to remove it after manually.

Third attempt: now the issue is the fact that the wood burns ! I think it goes too slow but with a too deep path (currently equal to bit diameter as suggested). I should go faster but cut the depth by two to keep the tool (and myself) safe.

Enough experiment, let's have a look to the theory

Flute types (from ShopBot quick start guide): the one we are using is a 1/4" spiral compression (similar to the one on the right)

Depth of cut : how deep in the Z axis we move per pass. bits are typically allowed a cut depth per pass equal to the cutting edge diameter unless otherwise specified. For a deeper cut, it will be necessary to reduce the chip load. For twice the depth of cut, reduce the chip load per tooth by 25% and for triple the depth of cut, reduce the chip load by 50%.

Spindle Speed (Revolution Per Minute): a spinning bit generates friction and heat as it moves through the material, and part of this heat is pulled away by the flying chips. A larger chip load pulls awaymore heat, but also puts more stress on the cutter. Each material has its own ideal chip load range that balances heat dissipation with cutter stress.

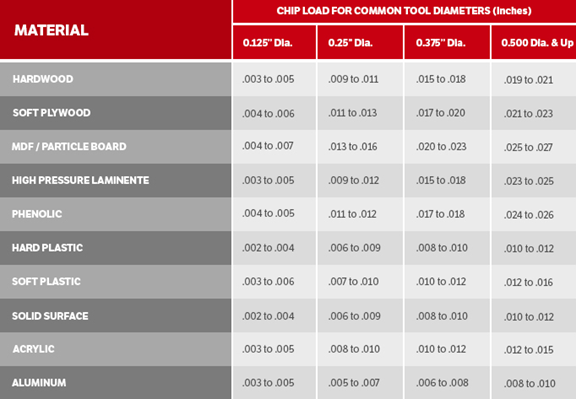

Chip Load: the actual thickness of the chip cut by each revolution of the cutter. It is the measurement that all feed/speed calculations are based on. Chip load = feed rate (RPM * number of flutes on the tool).When chip load is too small, bits will get too hot and dull quicker. When chip load is too high, the tool will deflect creating a bad surface finish and, in extreme cases, chip or break the bit. Depending on the size of your bit, the chipload for plywood is between 0.005 inches 0.01 inches per tooth. For small bits below 1/8 inch start with 0.005 and increase from it there. For bits 1/4 inch and larger you will probably not break anything starting out at 0.01.

Feed Rate (inches per second or inches per minute): this is how fast we move the tool into the material (i.e how fast we feed the material into the tool).

The cutter gets hot because it can’t eject chips fast enough – so the material being cut starts to burn and the bit overheats. It’s bad for the cutter and potentially a dangerous situation. It’s bad for the cutter and potentially a dangerous situation.Here we are and here is why it burns ! Wrong mix of spindle speed and feed speed

Let's bring all this together:

- SMX-2436 has a maximum speed of 4 meters (or 157 inches) per minute (linear velocity). Since linear velocity (in meter per second) = radius (in meter) * angular velocity (in RPM), therefore the angular velocity is 4 * 60 / 0.00635 = 38000 RPM (in theory...) but most CNC are in the 7,000 rpm to 18,000 rpm range. Am I wrong here ???

- We are using a 1/4 inch flute with TWO cutting edges

- CNC runs at 24000 RPM (as I have been told by my instructor)

- Chip load target is between 0.011 inches 0.013 inches per tooth (we are using plywwod)

- Feed Rate (FR, in inches per minute, at 1 * cutter diameter depth of cut) = RPM * tool diameter * # of cutting edges * chip load. FR = 24000 * 0.25 * 2 * 0.012 = 144 inch/min = approx 61 mm per second

Now I have a better undestanding, let's try again.... No fumes... no cries... and here is it !

Integrating the wood gears into to marble machine module ...

The module is a 2' by 2' by 4" box with a plexy on the front side. For information, here are the steps to build it. This is not part of Fab Academy but more a woodworking project. Pine wood material is cut on the bandsaw and a groove is created to support the plexy. Parts are assembled using biscuits and glue. The motor is a refurbished wiper motor

And the final result is ...

Note: I have a few things to improve. Currently, I cannot figure out how to feed the DC motor (i.e which wires out of .. 5 wires) and I need to create paths to bring the marbles at the right location on the bottom so they could enter into a slot in the wheel ...

Achievements

Design

I feel more confortable with FreeCad Part Design workbench

CAM

First try with FreeCad Path workbench. I like it (BUT the misleading "export" feature)

CNC

First try with a big (well, not THAT big... ) CNC

Capstone

My capstone project is not a big object in size and there is therefore no link between this week and my project