6. 3D Scanning and printing¶

This week I worked on 3D printing and Scanning.I found the stuffs really cool and interesting. So for the assignment I went through below steps.

Group Assignment¶

- Test the design rules for 3D printer(s)

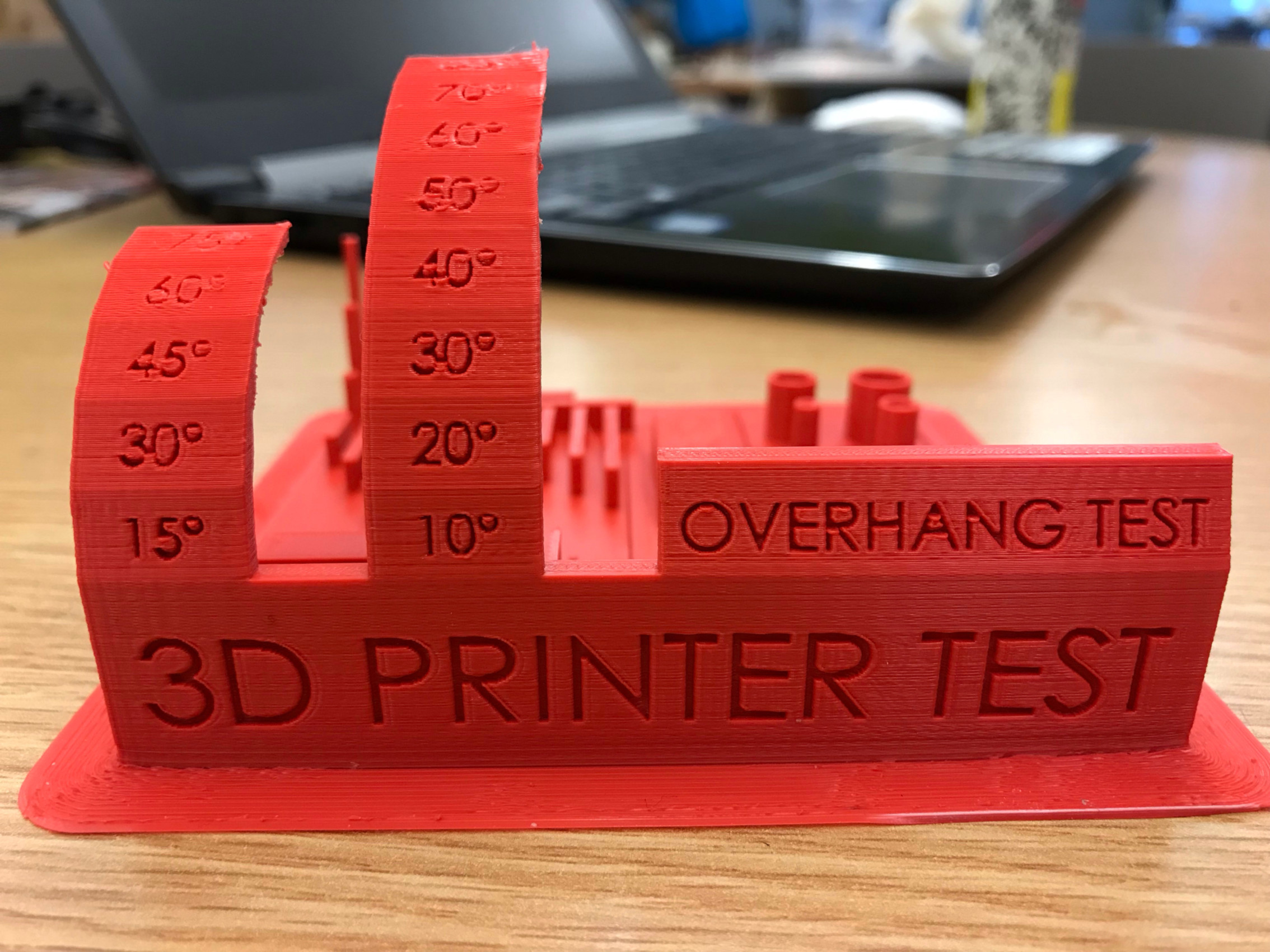

For the group assignment i have choose this ‘3D object’

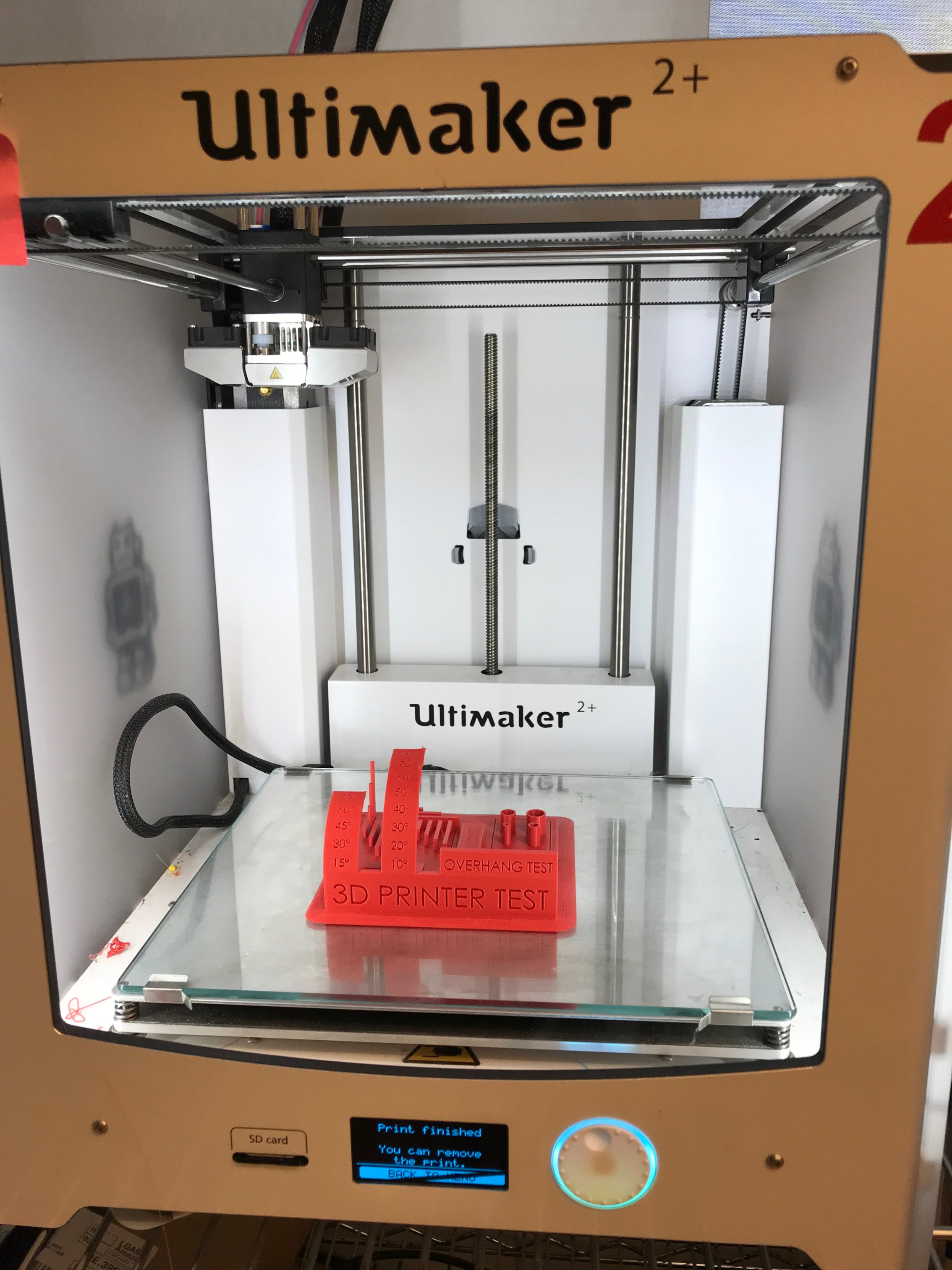

To Test the design rules I have used a Ultimaker 2+

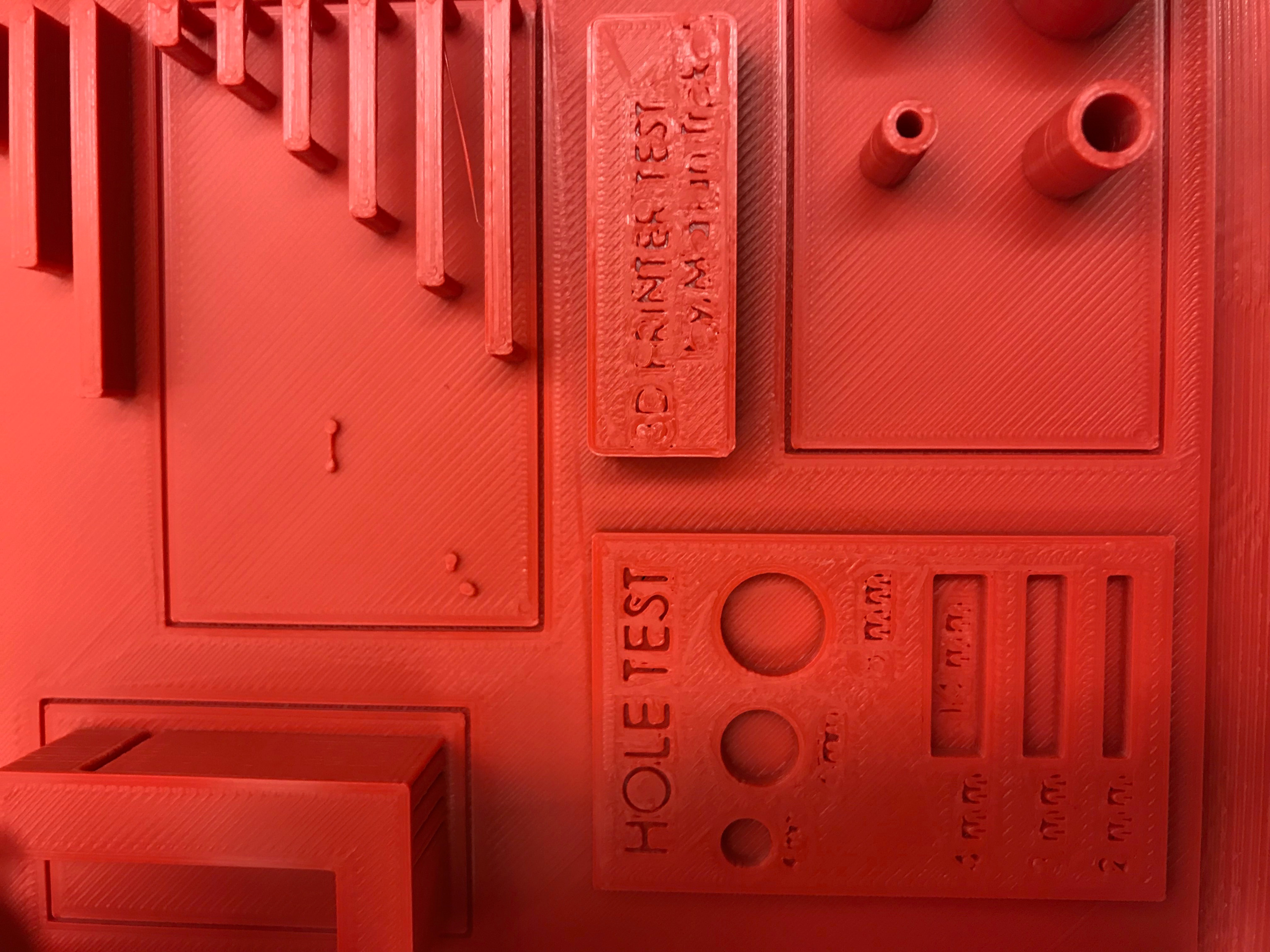

For the test i have tried this belong design

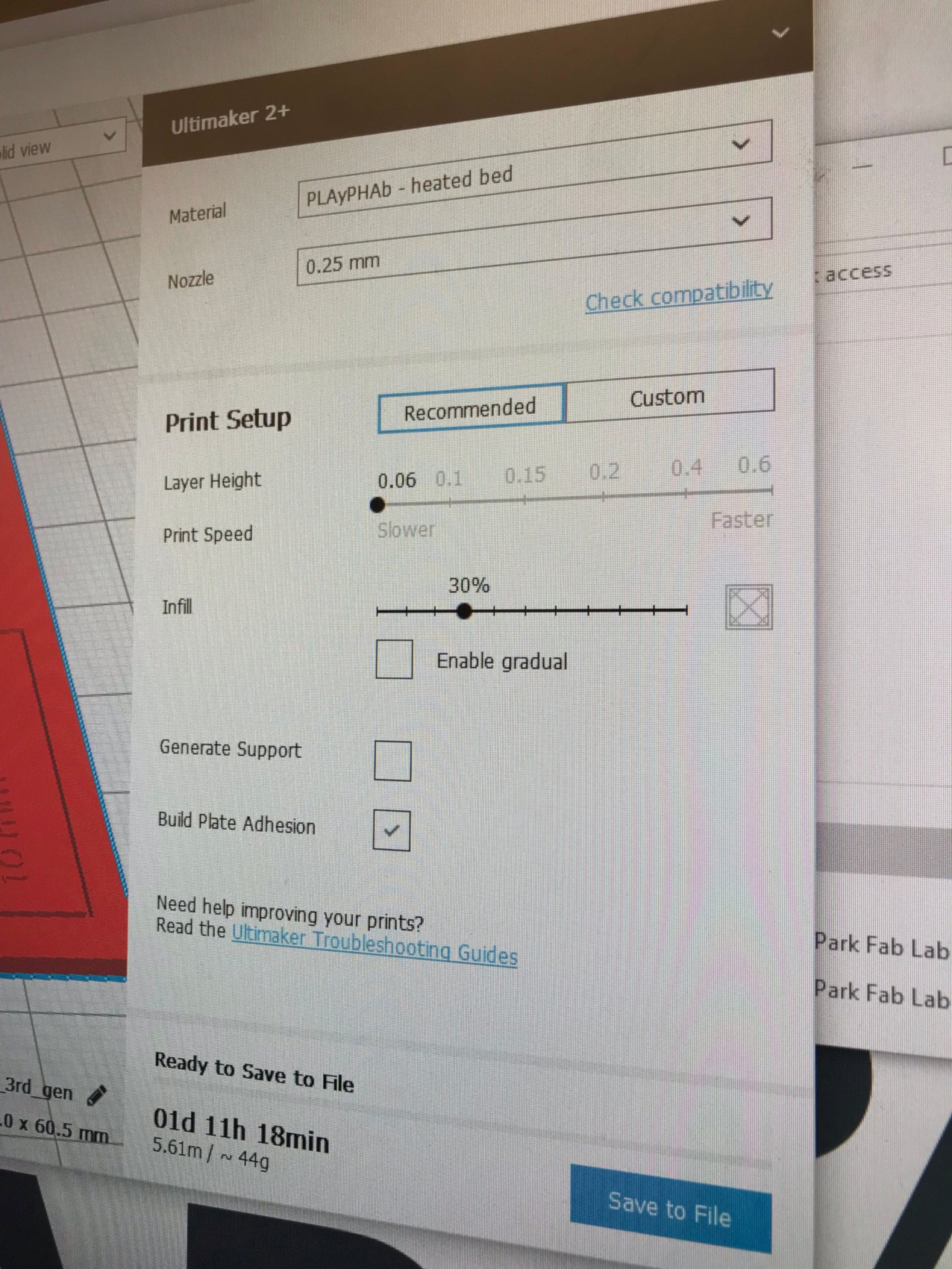

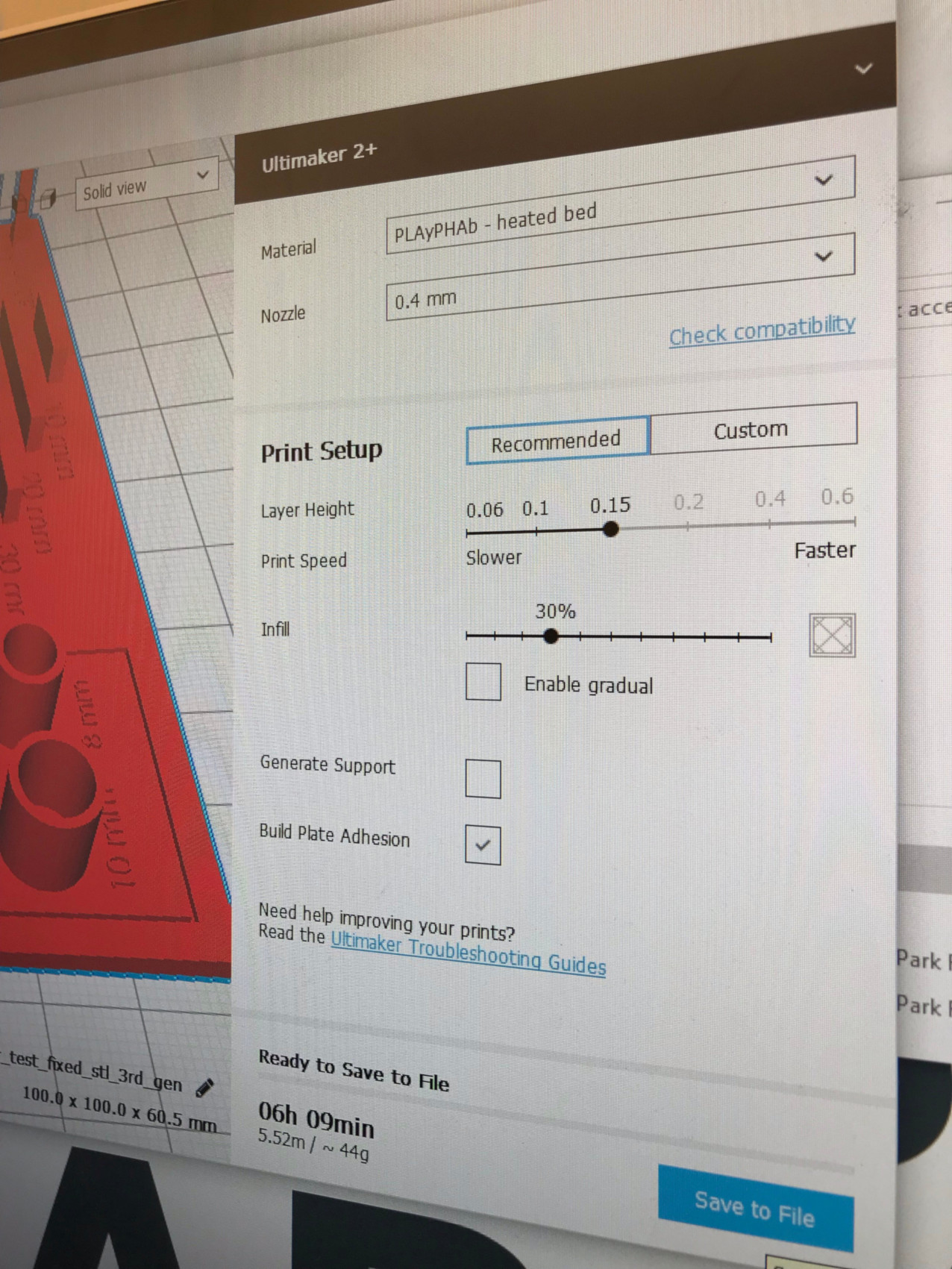

To design this object i have used ‘Cura’ and also to print the object i needed to setup the ultimaker 2+ machine environment One can see evry clearly in this below image that when i set layer height 0.06 slower and infill 30% it was supposed to take 1day 11 Hour and 18 minutes

again when i set layer height 0.15 and infill 30% it was supposed to take 6 Hour and 09 minutes which is a big difference.

So we can say printing time depends on machine print set up

Result¶

The Ultimaker 2+ couldnot make the actual object .One can see the pick side of my object is not so smooth and some of the text were missing .

individual assignment:¶

- design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

3D Scanning¶

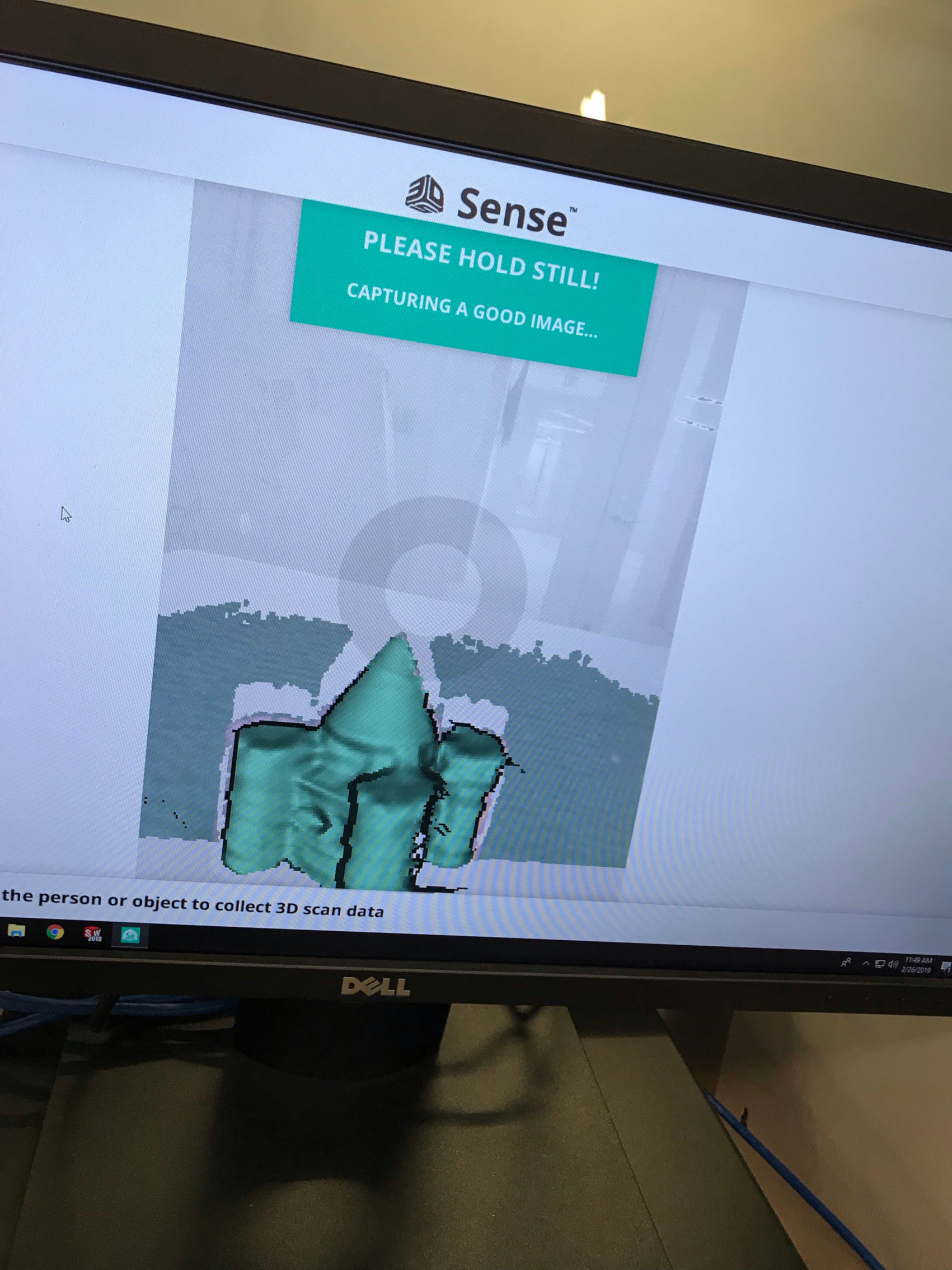

3D Scanner was an interesting thing to do . I didn’t know that Sense 3D Scanner is the machine with which i was going to do my 3D scanning.

For the 3D scanning i had to be very patient . I choose this object and put it on a round table so that i can move it 360 degree easily but every time i was moving fast the software was giving me warning.So i needed to spend at least 7/8 min to scan it.

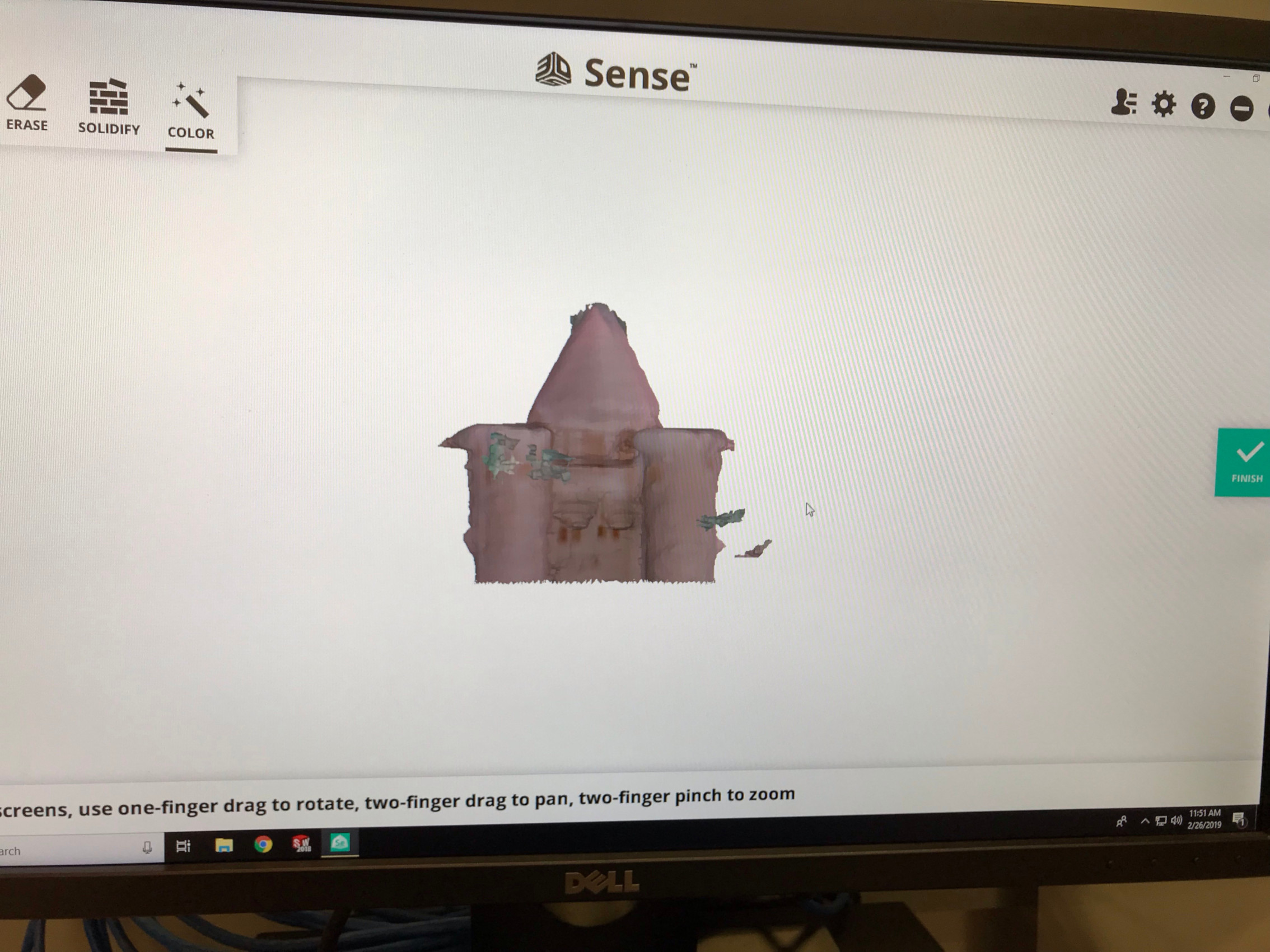

Finally i got the image of the 3D Scanning

Thanks For This week. Lot to Come Yet !!