Project Development

Assignment

Complete your final project, tracking your progress:

what tasks have been completed, and what tasks remain?

- Design the 2D and 3D trolley frame. - DONE

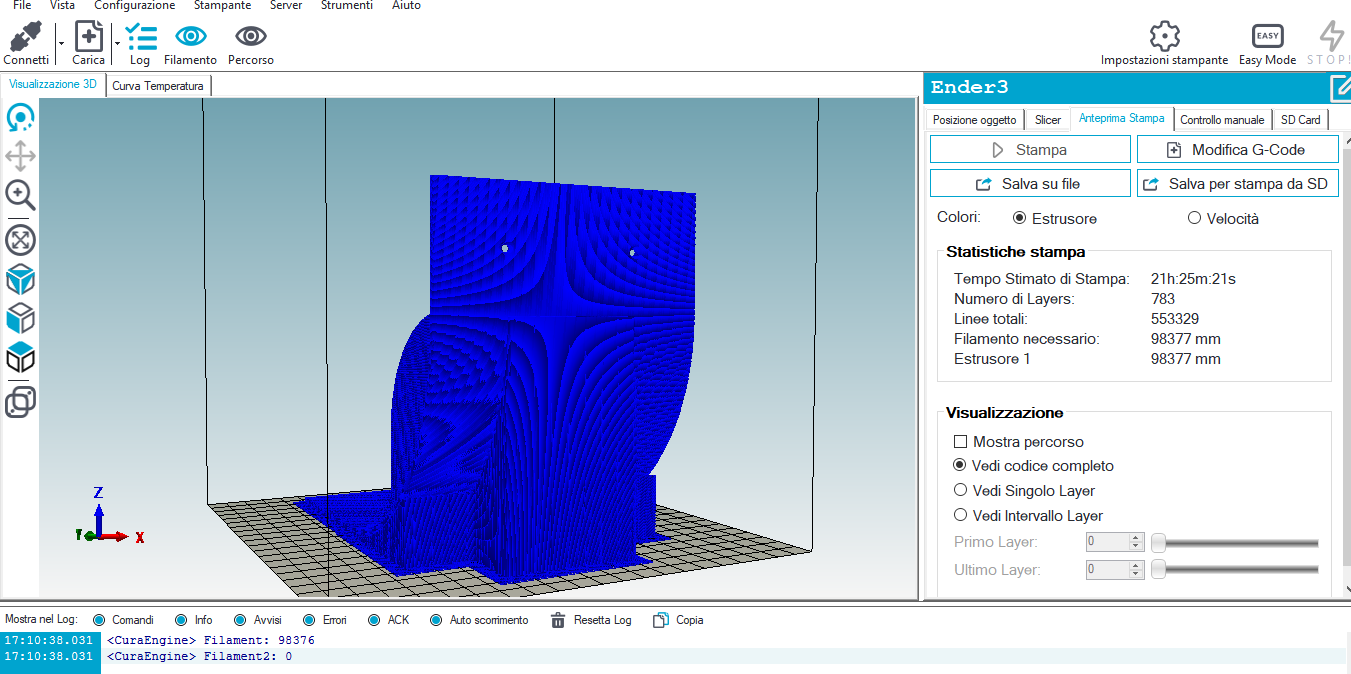

- Print in 3D all the components of the frame - DONE

- Laser cut the frame - DONE

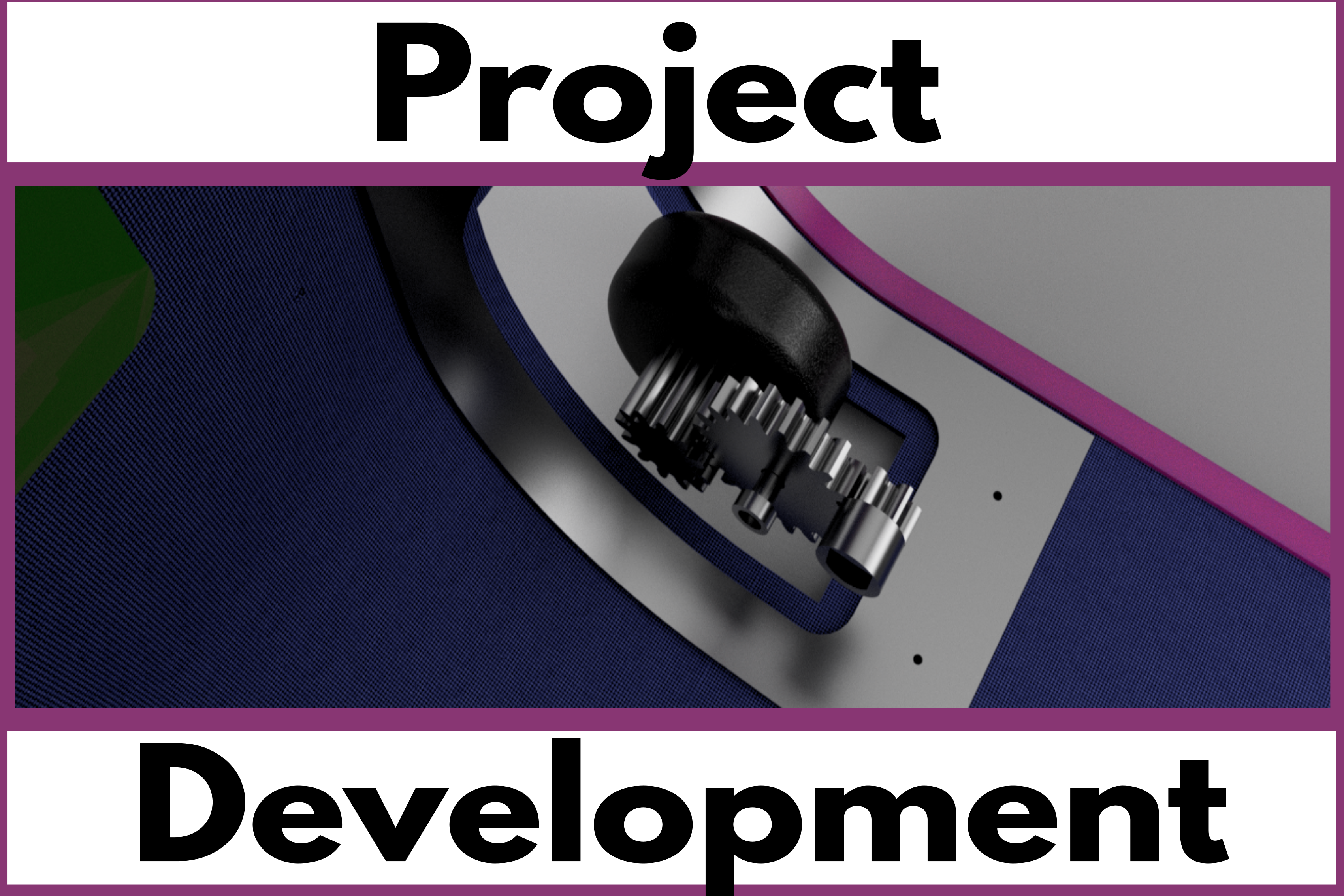

- Design and print the gears that transmit power to the dynamo - DONE

- Find the right dynamo or build it - DONE

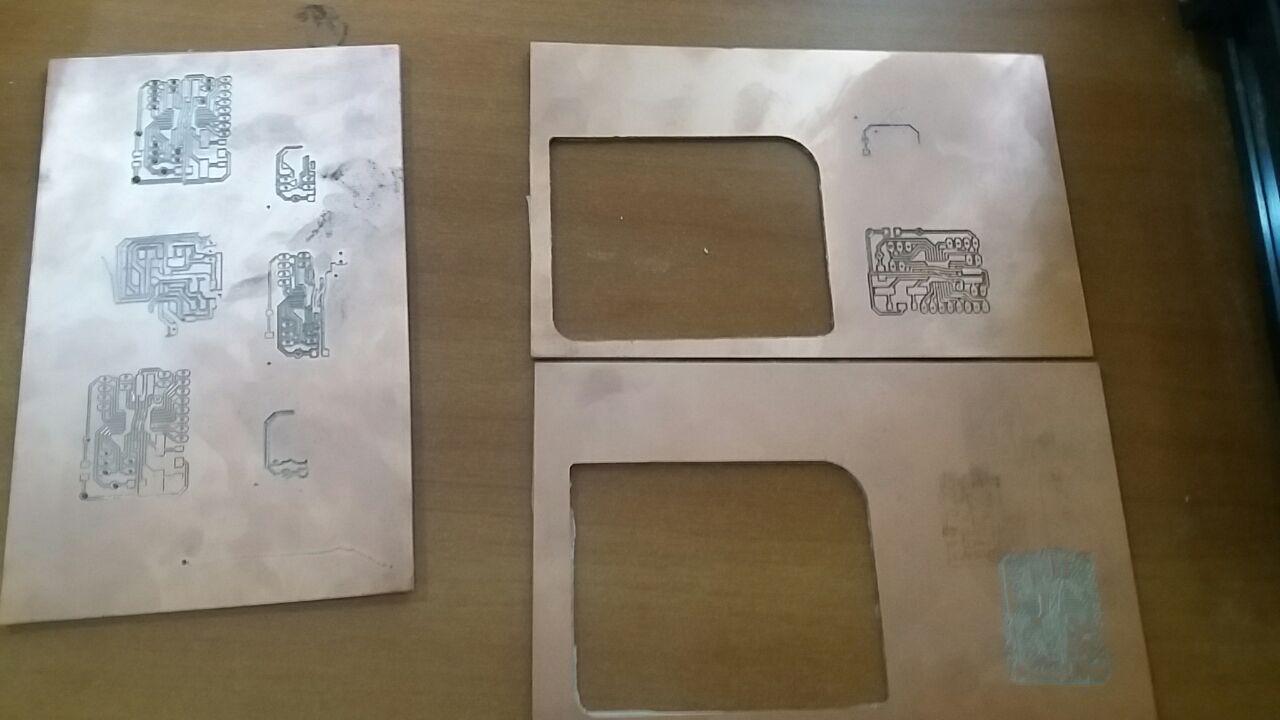

- Design and fab the board that measures the charge level of the battery - DONE

- Putting all together - DONE

what has worked? what hasn't?

At first I used a dynamo already built, those of hand that generate 5 V. Unfortunately because of the gear motor there was a high resistance to the rotation of the wheel of the trolley, this would have blocked the wheel creating problems to the movement for which the trolley born

At the end I decided to build my own dynamo, reusing a 5V motor to which I applied the gears and a stepup module 0.9V - 5V

what questions need to be resolved?

- Will the trolley have a smooth movement during normal use?

Fortunately, after installing the dynamo I built, the movement of the trolley and gears is very fluid, without any tearing or interruption of motion

- How much electricity can I generate?

I searched for an economic solution, without exceeding the budget allocated for the final project, which is why I chose to build a dynamo with very simple components. I could have also used a 12 volt motor instead of a 5V one (as in reverse operation it does not produce the same tenaione for which it was built) but I would have had more space and weight problems. I'm sure on the market you can find very small electric motors that can generate a much higher voltage than the one generated by me. Moreover, I am satisfied with my results

- Why didn't I build the fabric part?

For the reason I explained, my main interest was to create a functional prototype, respecting the budget assigned to me. The prototype I made allowed me to meet all the goals I set. Creating the fabric part would have involved a further use of economic resources and time. I think it's one of the things to definitely implement

- What can be improved ?

The choice of a good electric motor to generate current.

The led display separate from the main board.

Create the small and middle version of the trolley

what will happen when?

The pieces on which I had no doubt more problems in printing them are the wheel covers.

Unfortunately for the very complex shape of the pieces they moved from the printing plane. Using the plaPro 3D fuel and wax glue, I solved the problem. Similar situation for the parts of the handle cover.

I am satisfied with the result, and I painted all the pieces of black color, to make everything uniform

A photo for those who believe it is easy

what have you learned?

It was really very important for me to make the Fabtrolley, it was the realization of a dream. It's really hard to explain how important this project is to me. All my adventure within the Maker world and the FabLabs began with the Fabtrolley. I had the chance to learn the techniques to be able to do anything. I hope to offer this possibility to other young people like me through KromLabòro Caserta FabLab

I had a lot of fun and received great feedback for the project I did during the "Computer controlled machining" week with the aim of doing "Something Big". My Balance Bike has been a great success, I am really very satisfied

First of all I would like to thank my instructor Sebastiano Mestre, for believing in me, for the trust placed in me and his enormous technical and moral support.

I would like to thank prof. Neil Gershenfeld for the lessons and for the great inspiration he was able to give me.

And finally I would like to thank all those who supported me with a small gesture during this adventure: (or that inspired me to do my job better):

- Massimo Menichinelli

- Fiore Basile

- Enrico Bassi

- Amleto Picerno Ceraso

- Antonio Mele

- Andrea Turco

- Alessandra di Vico

- Marco della Sala

- Sposito de Lucia Francesca (my mother)

* Dedicated to my father Antonio *

Home