Week 14 assignments:

Mechanical design

From Fab Academy 2018 assignments

1. Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually.(GROUP PROJECT).

Have:

Explained your individual contribution to this project on your own website

1.Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually.(GROUP PROJECT).

For this assignment we have decided with the team to design and manufacture a 3-axis computer numerical control machine similar operation and structure that our Roland MX-40 CNC milling machine, which has the flexibility to exchange its head for use in different applications.

As a starting point it is important to use design criteria in the selection of the type of recorder to be made.

If we go deeper into the subject we will find that there are a number of configurations of the displacement axes

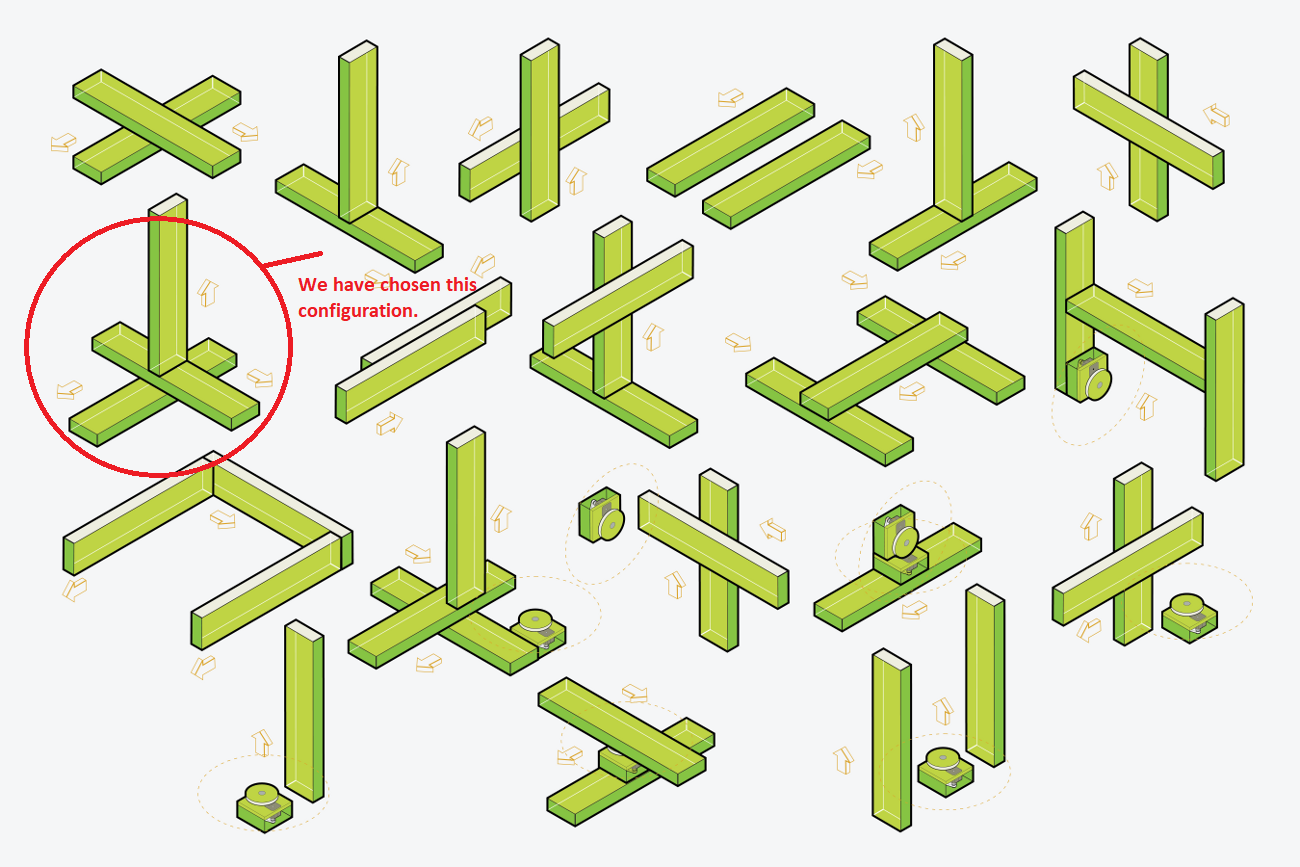

Firstly, it is important to identify the most suitable system to build according to the activity that our machine will perform, in this case the engraving of electronic boards. CNC machines have many configurations of their step motors, their positions vary, the following graphic best illustrates some of the possible configurations.

Once the system to be made is chosen, the design of the structure must be planned in CAD software, the collection of materials to be used, the cutting of parts and assembly of the electronic boards, as well as the testing of the stepper motors, the development of the electronic system and the compatibility with the software of engraving or printing.

Para esta actividad hemos dividido el trabajo entre el equipo de la siguiente manera:

- Jose Acosta: Mechanical Design

- David Arias: Design of the coupling system for drills

- Eduardo Cartagena: Electronic design

Mechanical Design

My partner Jose Acosta , made the design of the structure of the machinea

Design of the coupling system for drills

My partner David Arias , Design a coupling for the adaptation of the head

Design 1

Design 2

Electronic Design

For the operation and operation of the machine I have designed a shield that can be adapted to the board manufactured in the week of interfaces interfaces and aplications.

The circuit will allow controlling 3 motors for the movements in the X, Y, Z axes. What is sought is to provide a new circuit model that allows to control CNC machines as an alternative that can be developed by digital manufacturing and be an alternative to the boards trades

For the design use the eagle software.

The assembly and operation is explained in the week of Machine Design

DOWNLOADS

- File 1: Eagle File: Motors Shield