My final project

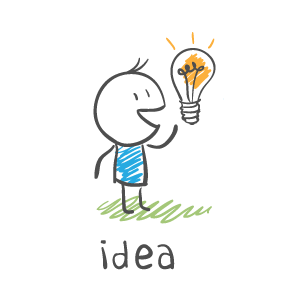

{Smart Heat Retention Box}

Description of the problem

The progress in Indian Rural development is very slow. They don't get the facilities that are available in urban areas. I think the development in rural area is also as important as the development in Urban areas. In urban areas making meal is a very easy task as there is availability of many facilities but what about the villages? Also, the prices of conventional fuels are increasing which makes them cut trees to burn them and use it as fuel. It results into deforestation which is directly related to the environment and wild life.As majority of the population are farmers this adds to the problem of Global warming. It is understood that presently only 8% of the energy used on earth comes from renewable resources which is why People have to use the LPG or woods to repeatedly heat up or cook food, due to which excess energy is wasted, therefore, I would work on to make a useful product for farmers to use for heating up their food like a Smart Heat Retention Box.

Existing Solution

We have seen the market that the market has got lots of products to keep warm, but it is very costly for the people of the village. Looking at the problem of those people, I have thought of doing this project so that the villager can use to warms their food and also they can make these boxes themselves locally which i think is pretty cool.

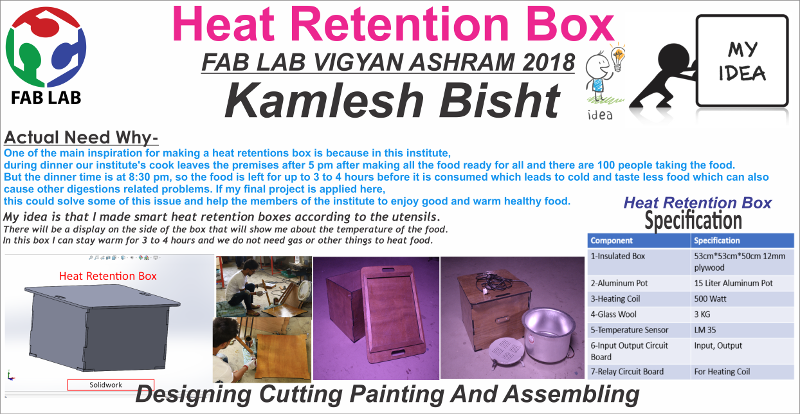

Actual Need Why-

One of the main inspiration for making a heat retentions box is because in this institute, during dinner our insitute's cook leaves the premises after 5 pm after making all the food ready for all and there are 100 people taking the food. But the dinner time is at 8:30 pm , so the food is left for up to 3 to 4 hours before it is consumed which leads to cold and taste less food which can also cause other digestions related problems. If my final project is applied here, this could solve some of this issues and help the members of the institute to enjoy good and warm healthy food.

|

|

|

|

|

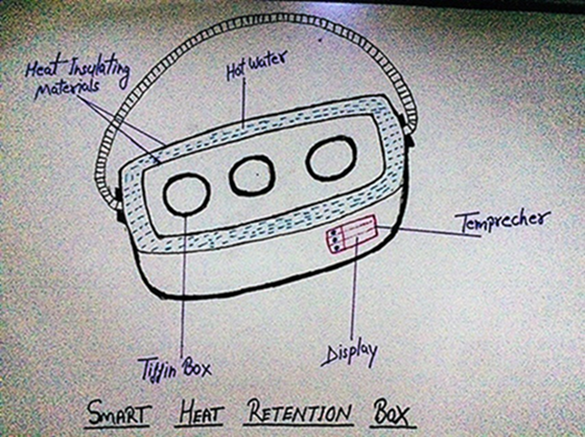

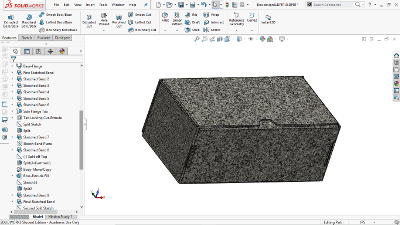

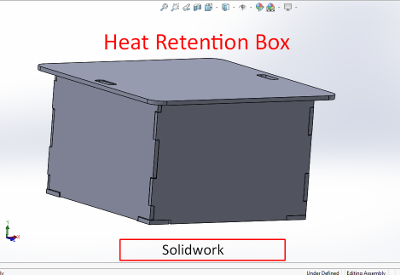

My heat retention box design in the solidwork

The below images shows the working of the final project board.

Input Board With temperature Sensor |

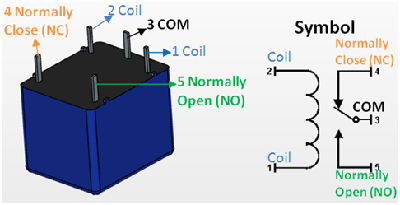

Relay Board |

With temperature Sensor |

output Board |

Final Box Cutting process of 12mm MDF Sheet

|

|

|

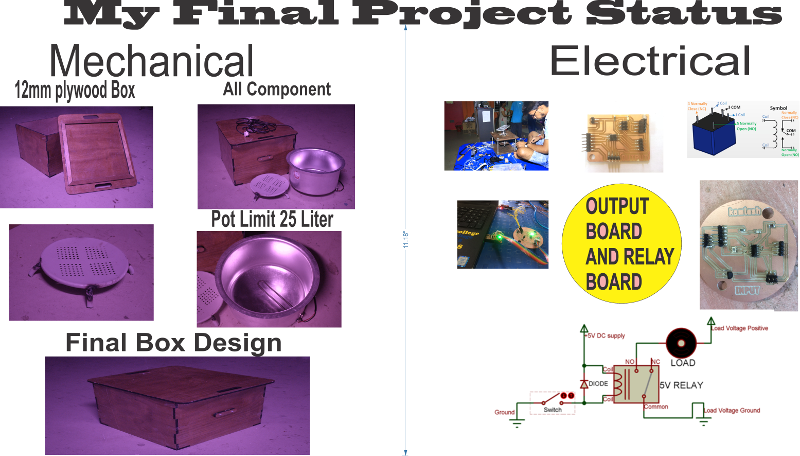

Here is my project slide :

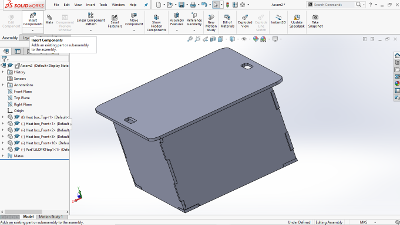

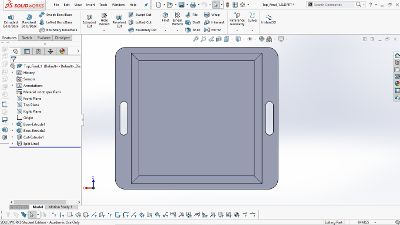

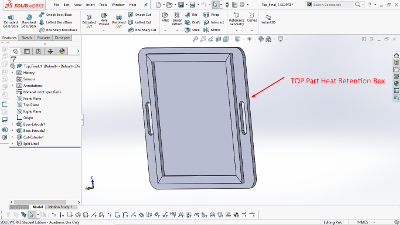

My box design In solidwork

|

|

Box top part design:-

|

|

My Heat Retention Box part designing, programming, process and assembly :-

Laser cut 12 mm plywood |

Nest step assemble box parts |

screw |

Fitting screw |

welding |

Bottom part Heating coil and stand |

Measuring the handle parts |

Box Handle |

Fitting Box Handle with Screw |

Glasswool |

Next step after glasswool fix the aluminum sheet |

Properly fix the hol parts |

Final product Heat Retention Box

Assembly

Fest I assemble the box and next step inside the box 2cm insulation in glasswool and put a pot 25 liters this pot bottom side fix a heating coil 250 watt .and heating coil up side one part. the part support in food pot.and properly fix the all component and temperature sensor fix pot inside area and the temperature is fix 45 to 50 degree 50 to up and 45 to down auto cut. all electronic parts for make one box and the box inside my final board,relay board and temperature display Oled,mane switch,indicator and all wearing systems

Electronic connection

I used fest step 230 volt ac input in the indicator and then connect relay board relay board input power 5 volt threw my final board because my final project board input and output 5 volt dC,project board input power I used 5 volt adapter. Relay board output 230 volt for heating coil.and temperature sensor and o LED input power and signal going threw my projector board .

Here is my project slide:-