The work flow on

Multicam 3000 Series.

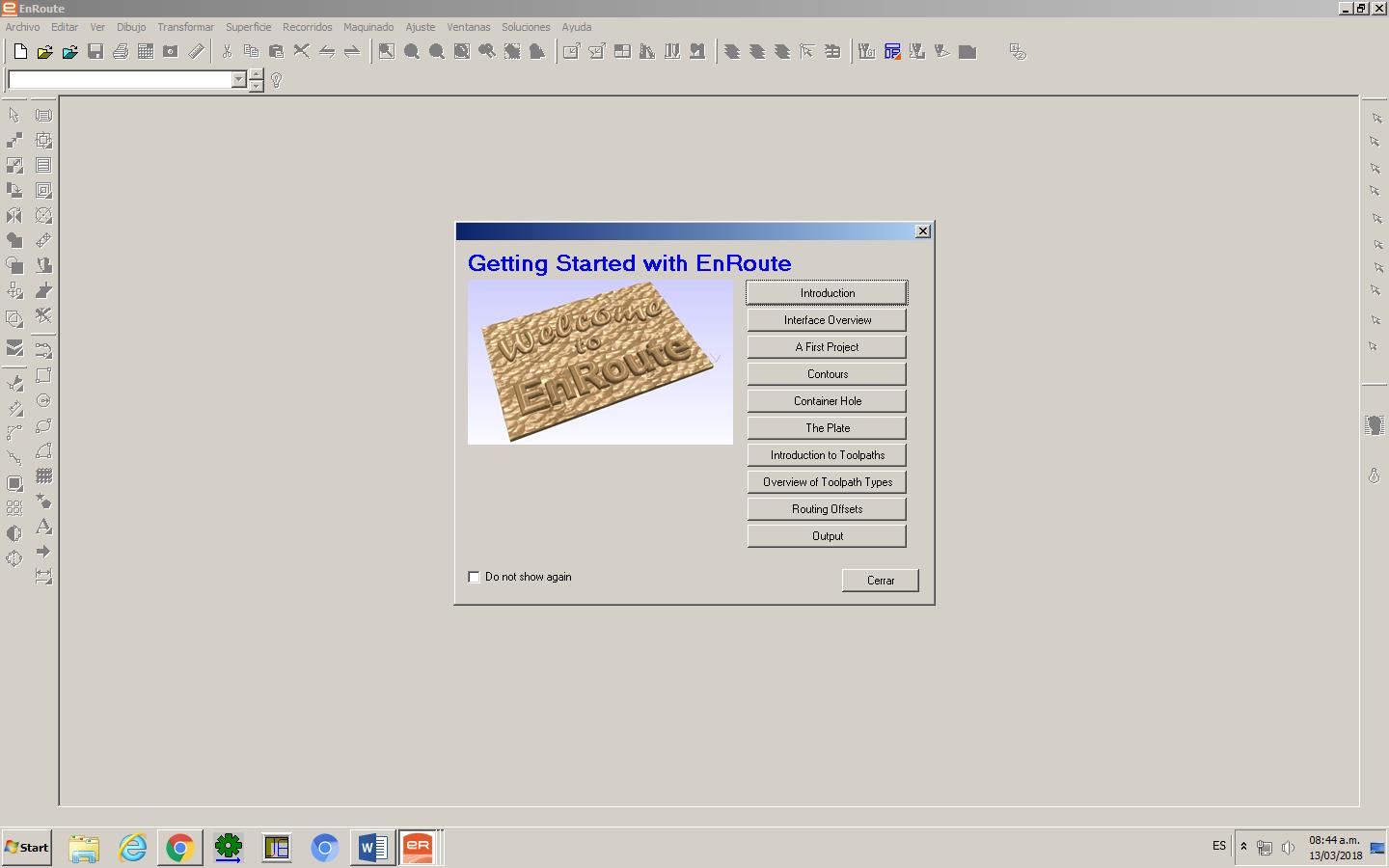

Since I have all the machinery needed at work I used the Multicam 3000 series as the cnc machine for this assignment. The CAM software for the Multicam was EnRoute.

Fig1. Export from Eagle to FlatCam file .

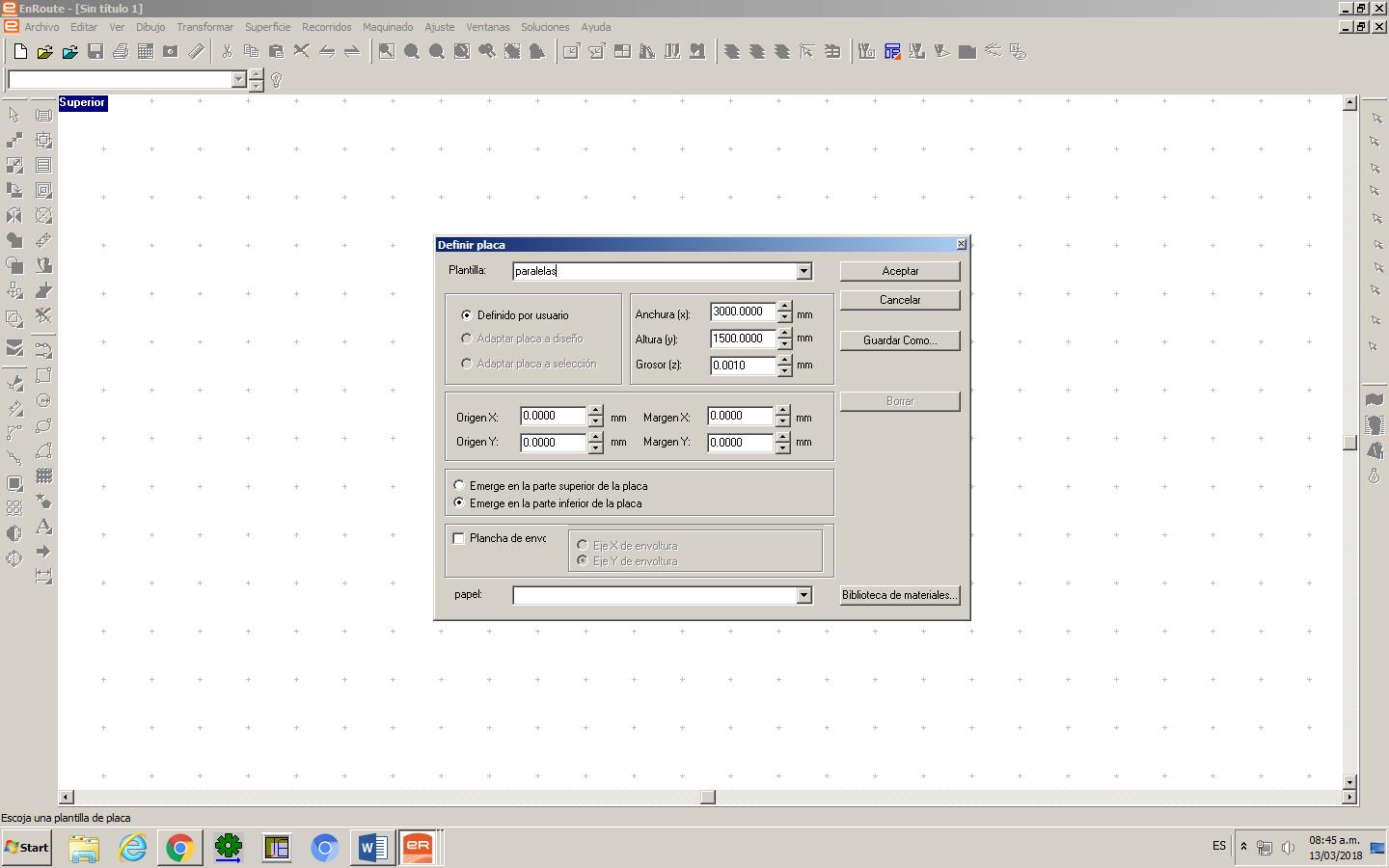

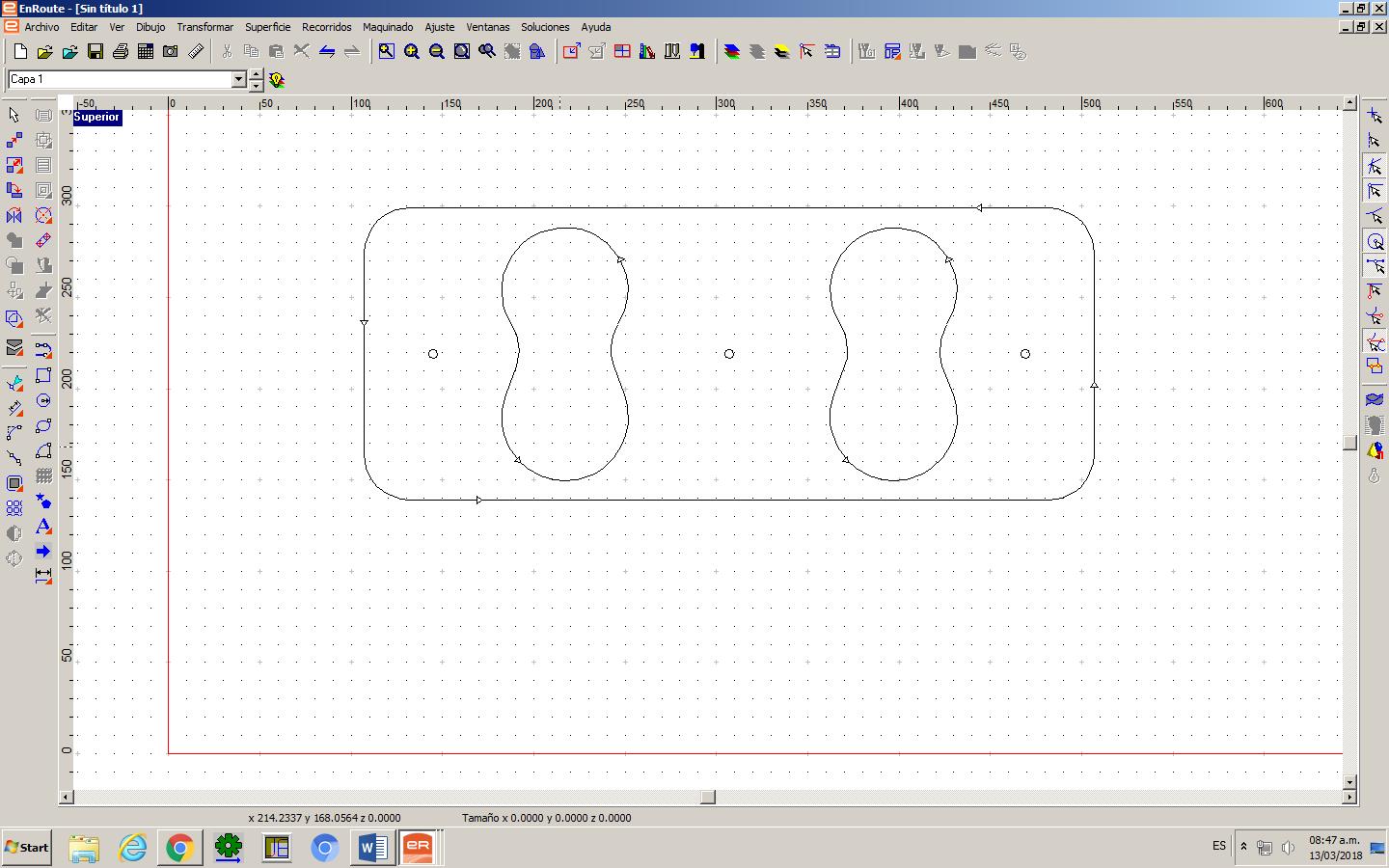

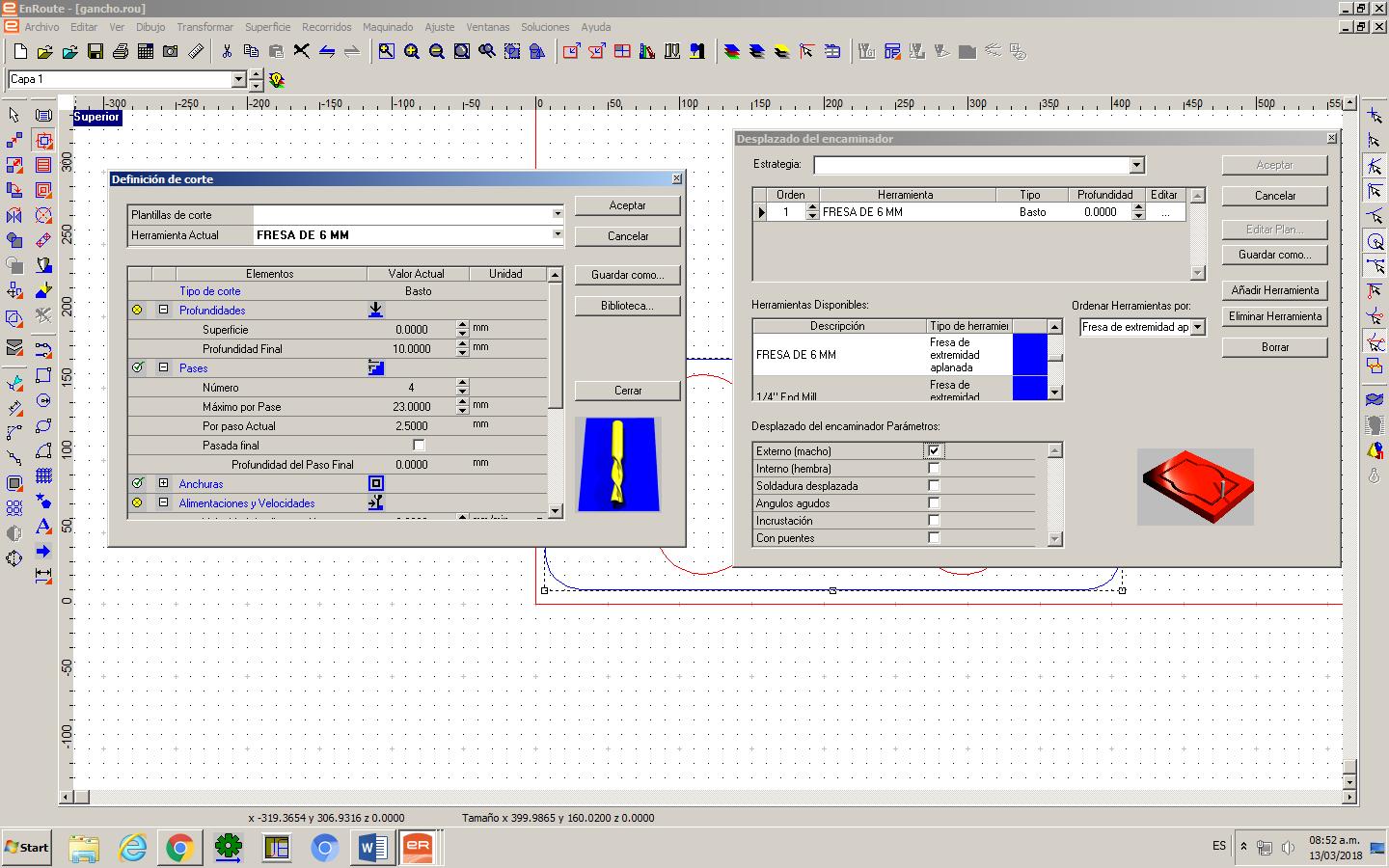

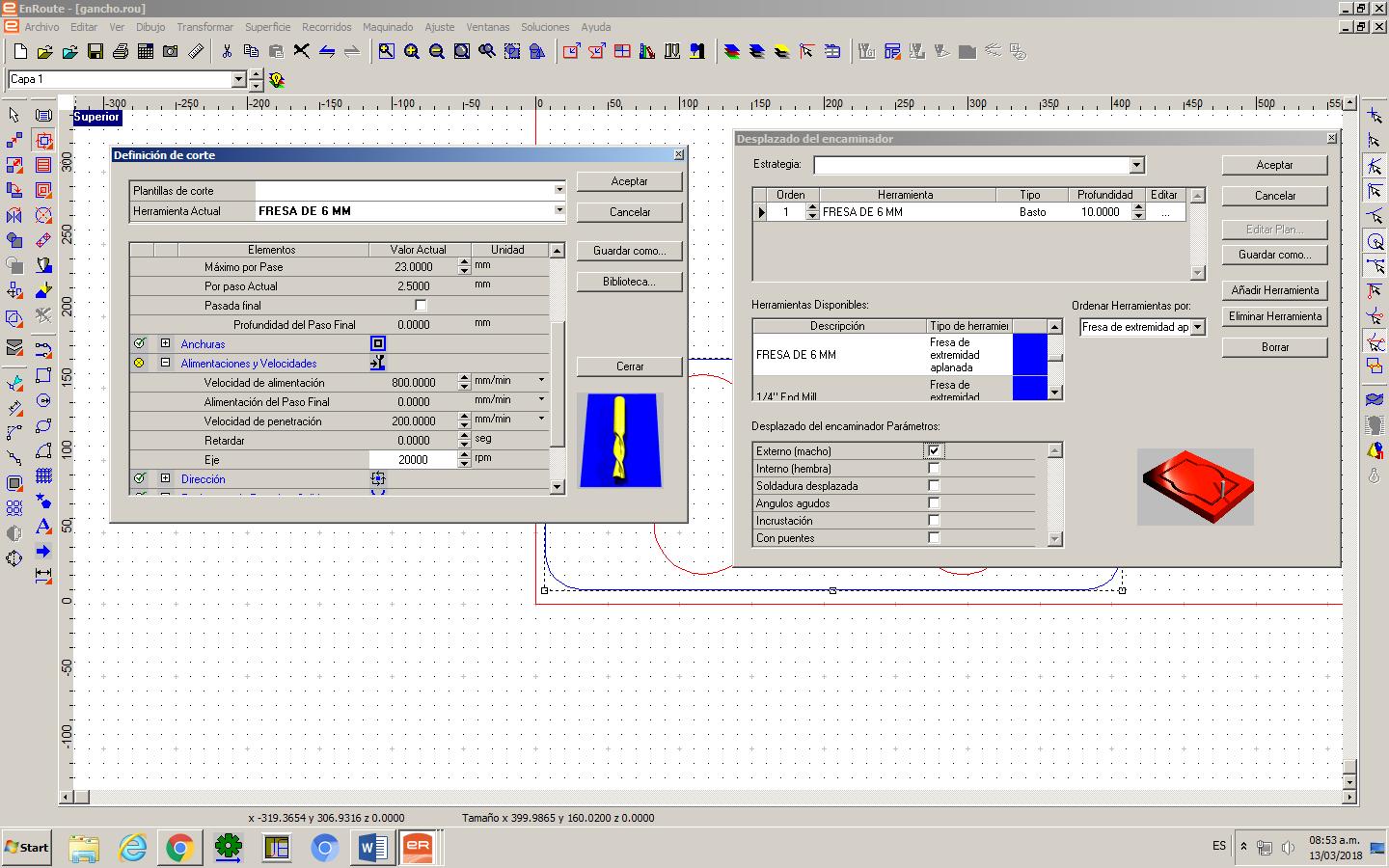

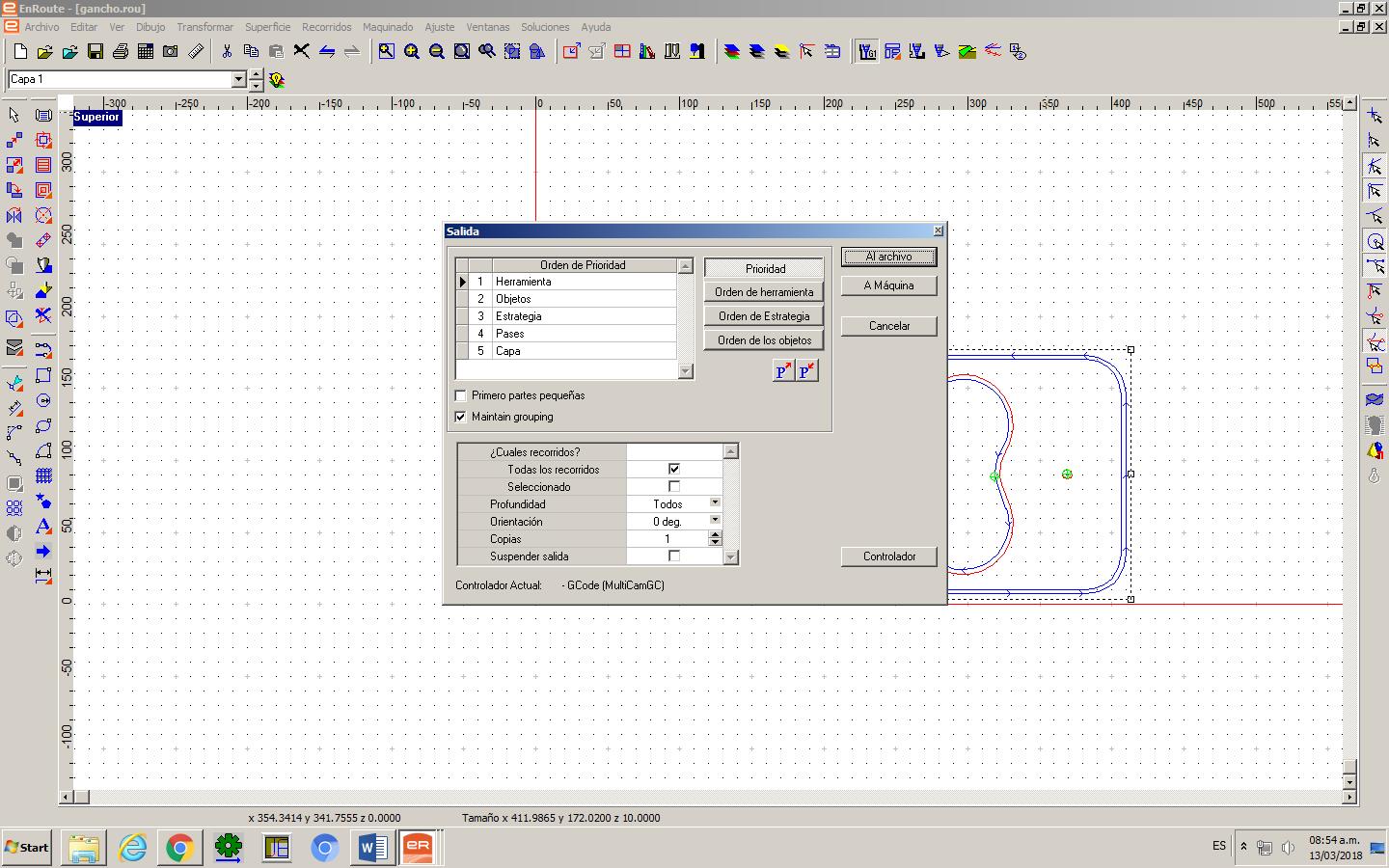

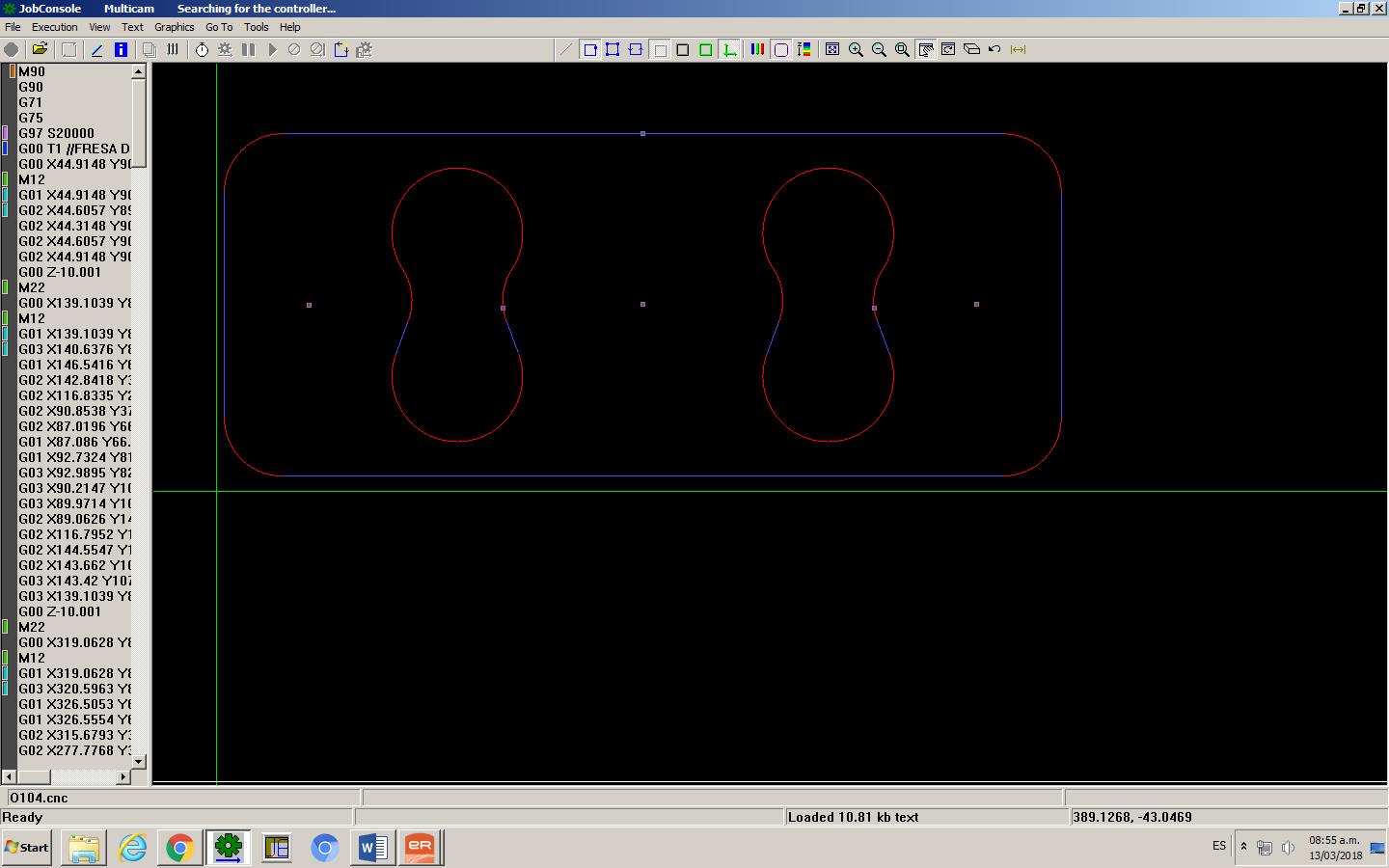

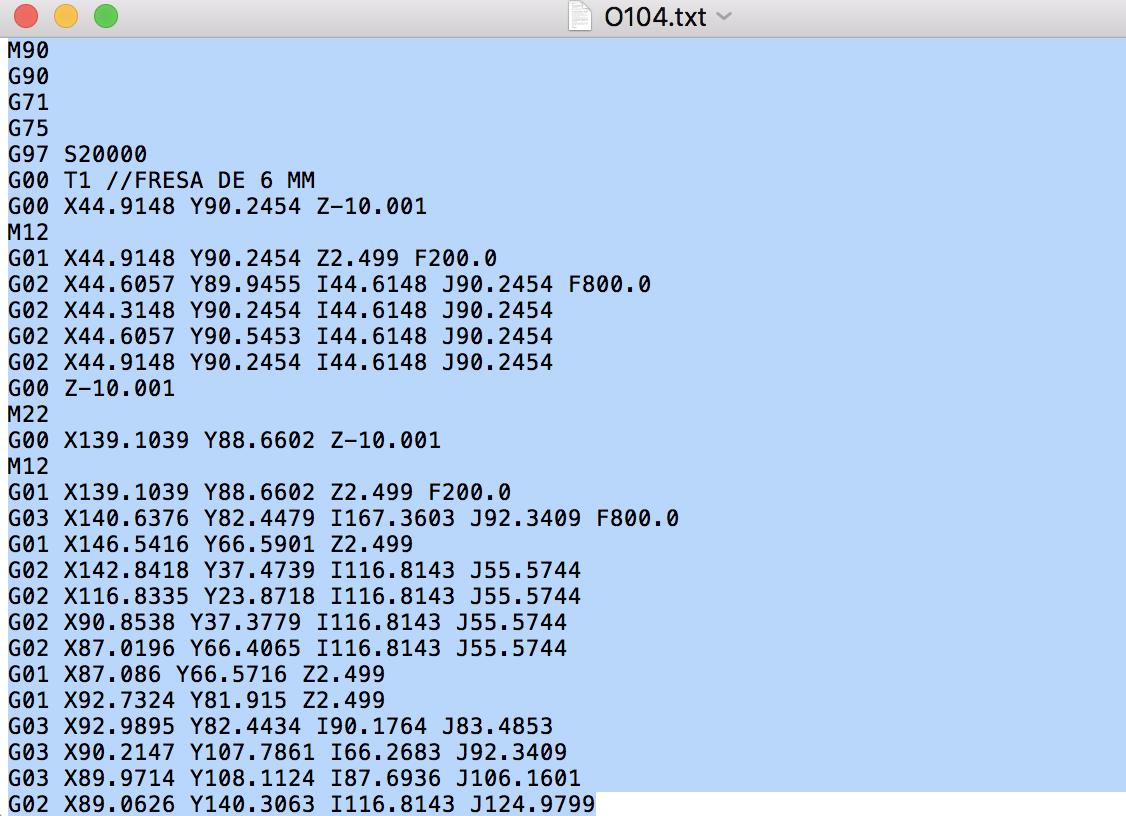

Fig 2. The ininial step needed is to set up the correct table. Fig 3. I exported all files to Enroute program on PDF, DXF and DWG extensions. Then I joined the diferent segments on the software. Fig 4.Then, selected the tool diameter, in my case was 6mm. the cut dept was 10mm since the material had 9mm width and I had to ensure the cutting because sometimes the MDF curves and lifts the material from the plate. Then, I set it up for 4 passes (each one of 2.5mm) and 20000 RPM then generate and pickup the area on blank, the software will paint the selected area. . Fig 5. the cutting speed was 800 mm/min, and the depth speed was 200 mm/min Fig 6. Then select the operation, in my case external mill. Fig7. The Jon Console is a program to generate the G code. Fig8. It geneates the G code. exported to the machine. Fig9. In the machine code. Fig10. Then received the G code. this machine needs to warm up for about 15 minutes before any job. Fig11. Then I proceeded to set the zero points on two diferent point on the table.