Wegstr CNC

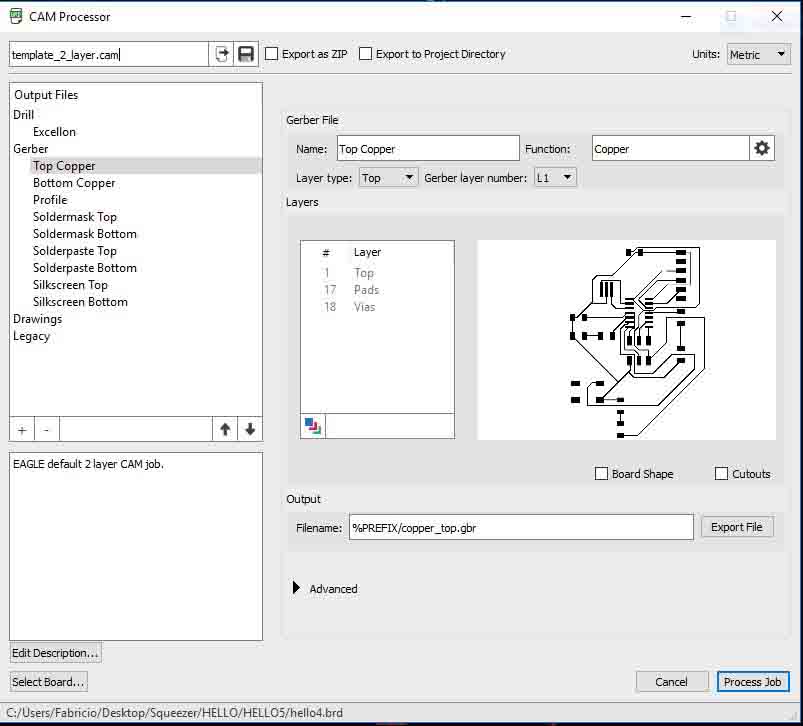

For this assignment, In the first machine was Wegstr CNC. I also used flatCam to generate the Gcode, for this purpose, I used the EAGLE CAM processor and export the file generated as copper_top.gbr

Fig1. Export from Eagle to FlatCam file .

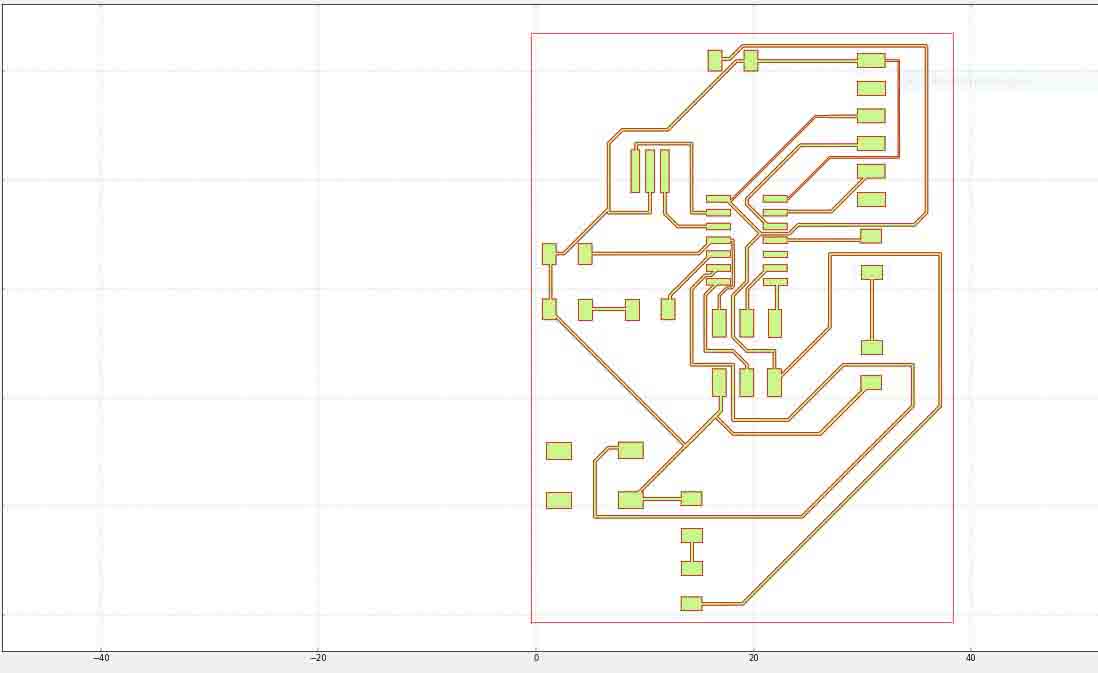

Fig 2. The file cooper_top.gbr

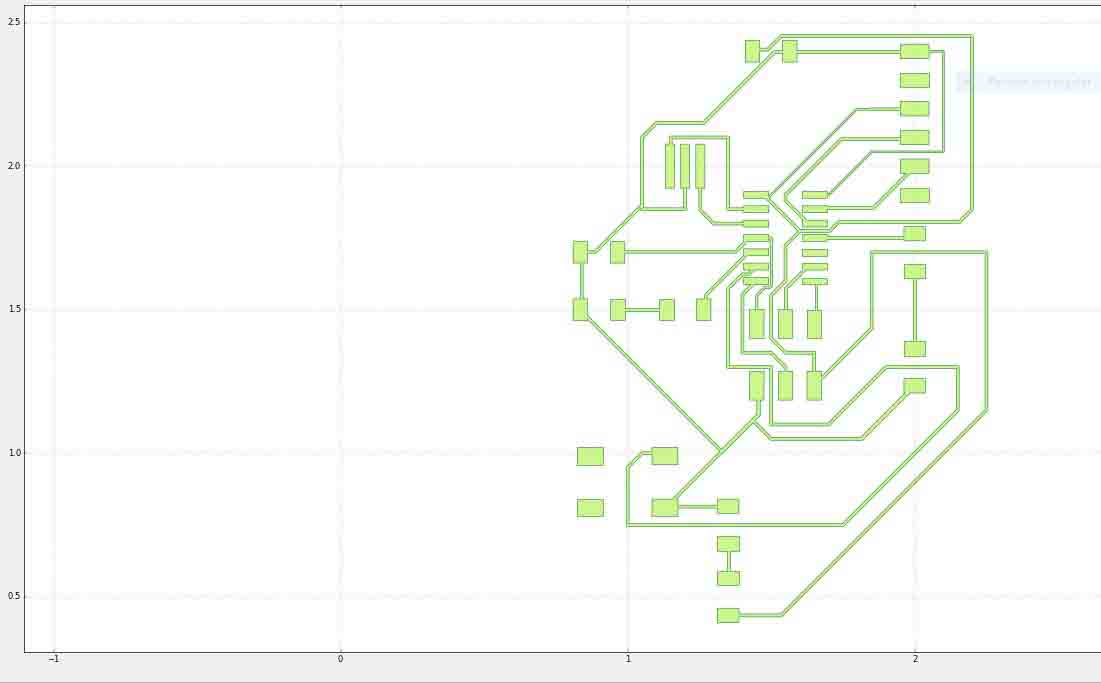

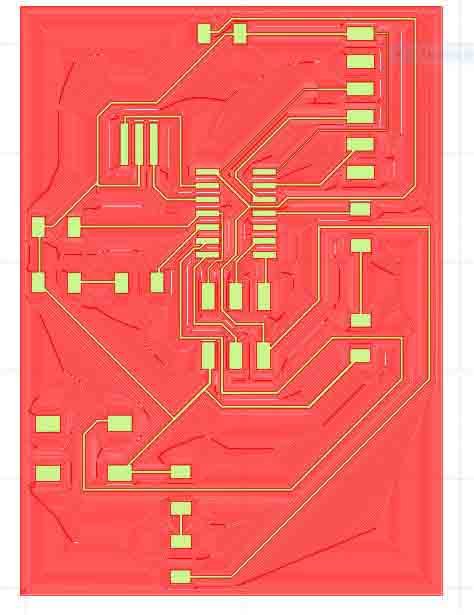

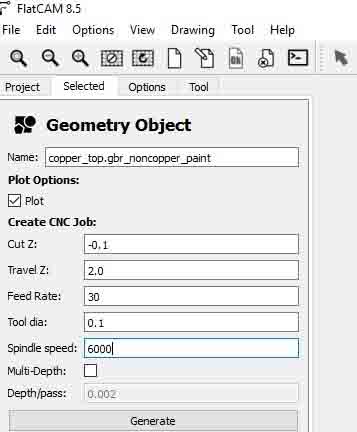

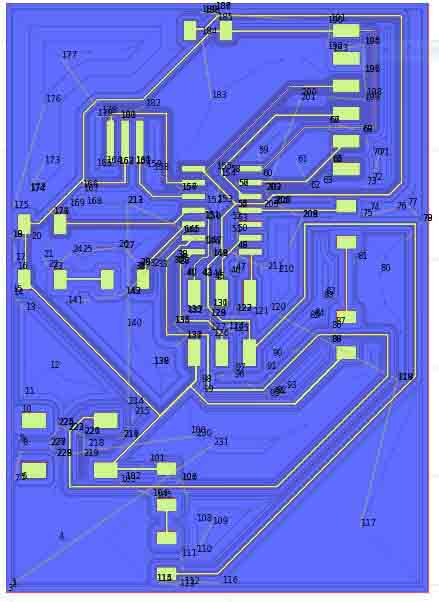

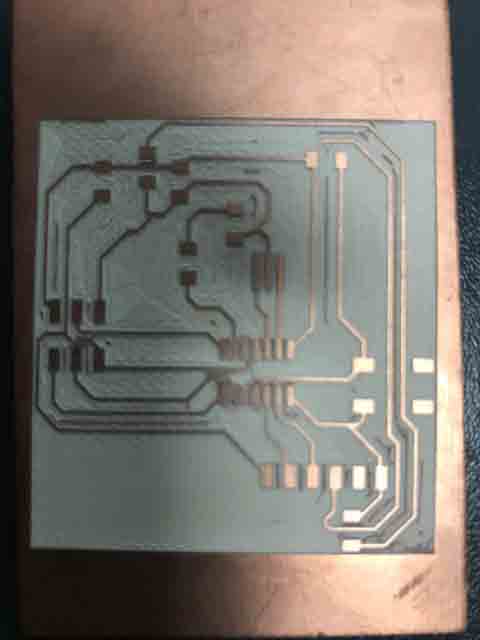

On Flat Cam open a cooper_top.gbr and Set the zero point or origin with a 0.5 offset fromn the traces. Fig 3. Non-coppper regionboundary Margin 1.0 Fig 4. On project open the new copper_top.grb_noncopper, geometry object, select the following options: Paint area Tool dia:0,1 Overlap 0.05 margin 0.0 then generate and pickup the area on blank, the software will paint the selected area. . Fig 5. Now go to: Copper_top.gbr_noncopper_paint Fig 6. And the generating_CNC Job. And copper_top.gbr_noncopper_paint_cnc will be the file containing the Gcode. And then, export G-code save it and change the format with .txt extension. Then create the border on copper_top_gbr And select board cutout and select: Tool select diameter 1.0, margin 1.0 and gap size 0.5 and gaps select 4 and generate the geometry Fig7. AIt milled the PCB greatly, but the elapsed time was too much, about 6 hour to finish.

GO TO:

ELECTRONIC DESIGNGcode

borde