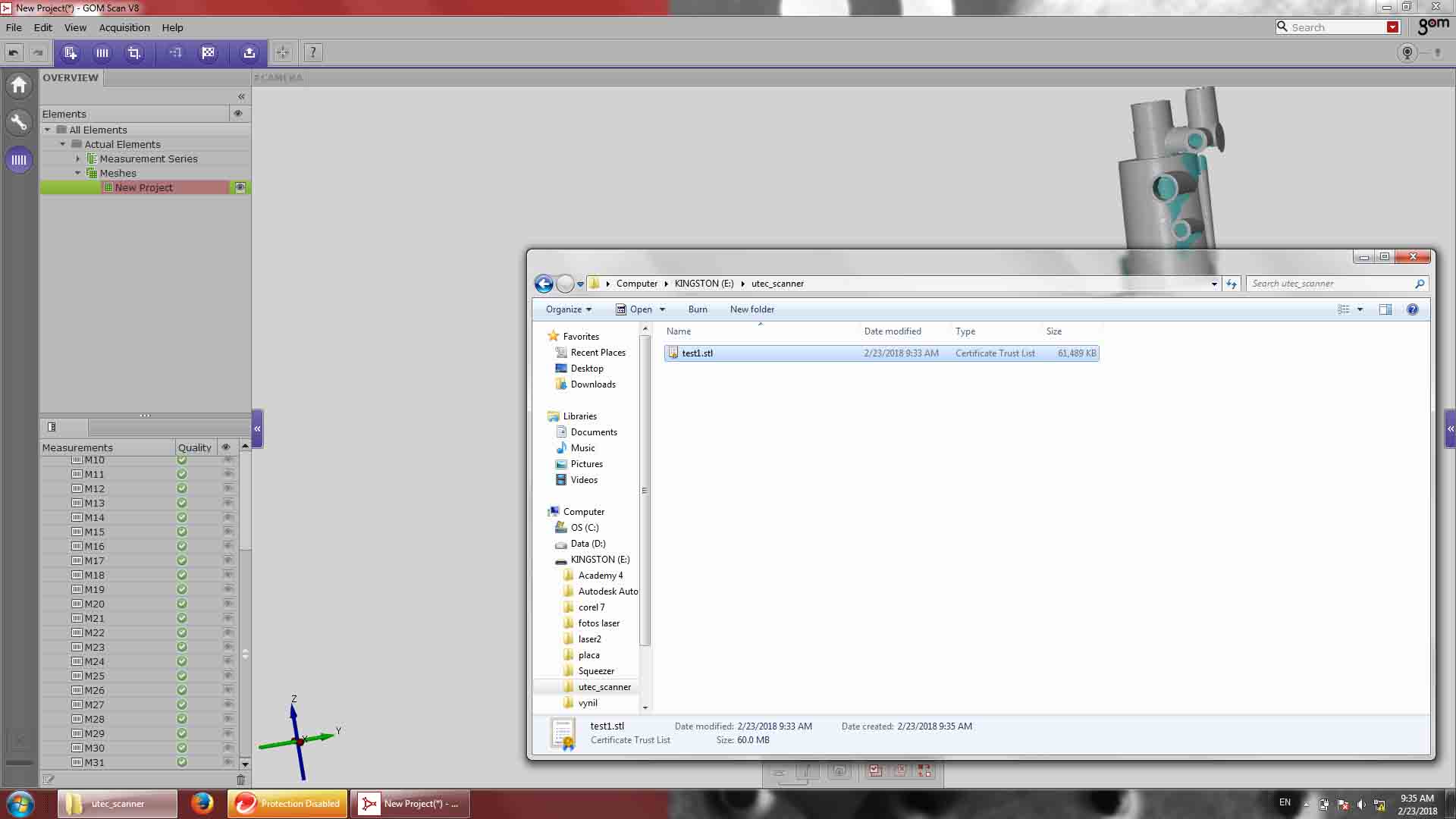

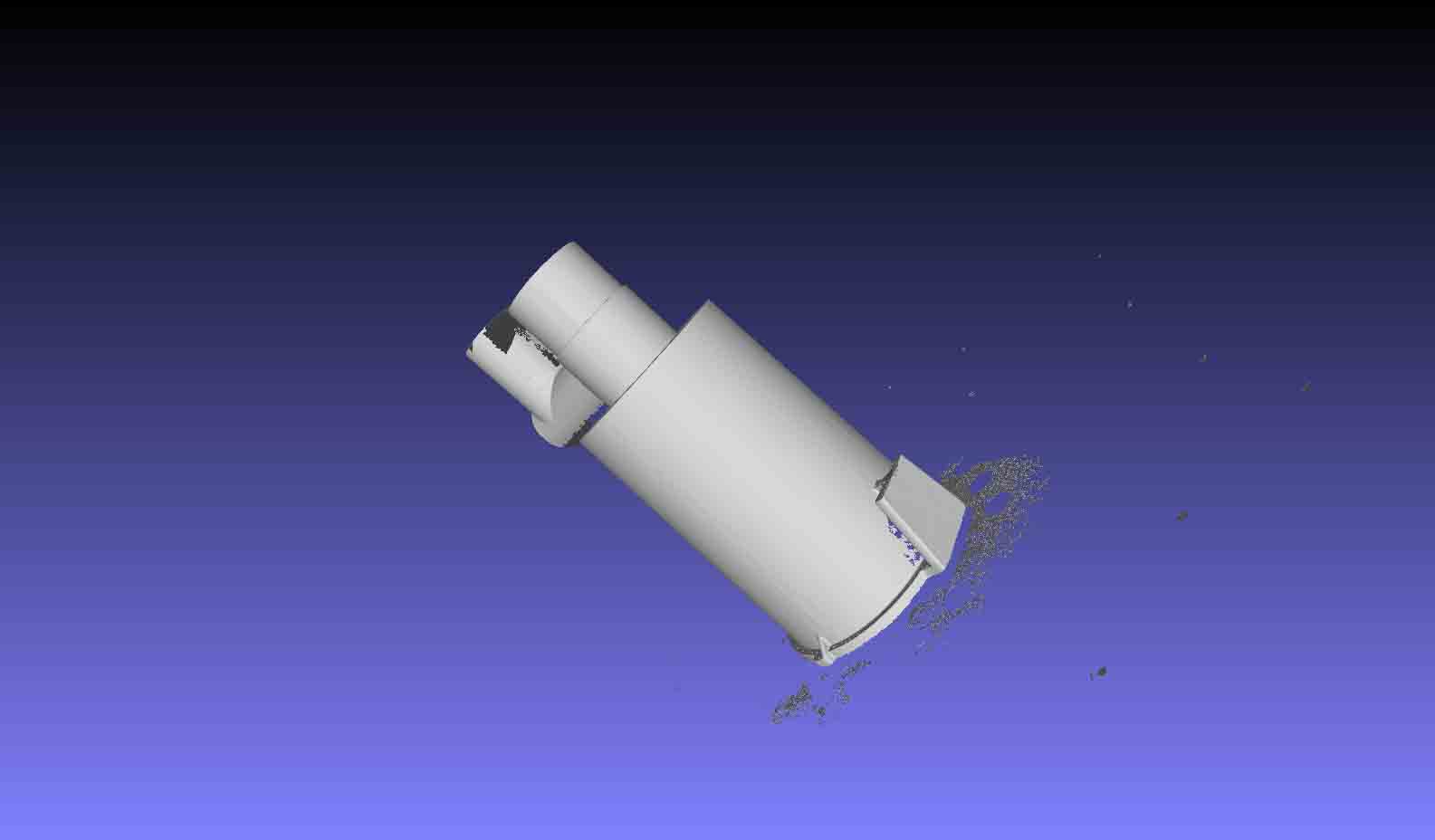

ATOS Core.

The best technology and fastest way for reverse engineering, this technique provides new alternatives to copy and improve existing models. In the market there currently are different and complex brands of 3D scanners. Its prices varies between 100 and hundred of thousands of dollars. We should choose the one with the greatest resolution. The first scanner used was ATOS Core. ATOS Core is the specialist for the three-dimensional measurement of small components up to 500 millimeters in size.

Fig 1 .Scanner: Atos core.

Fig 2. Fig 2 GOM Inspect.

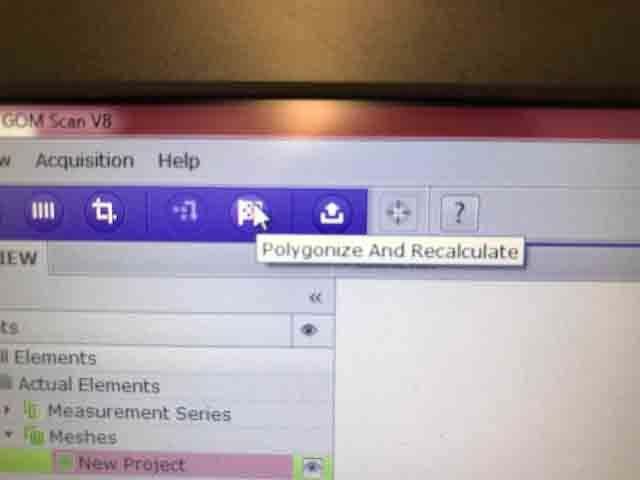

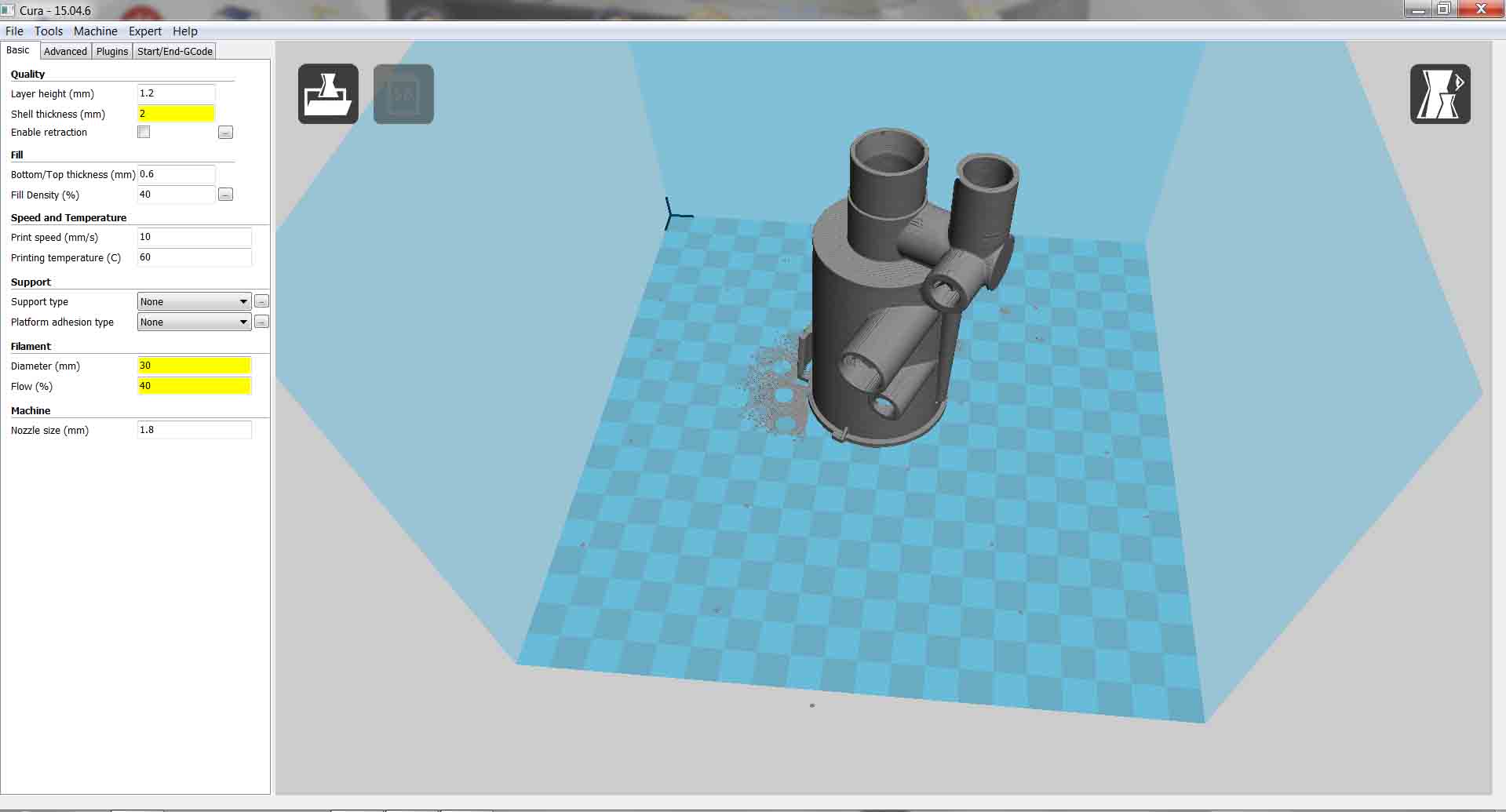

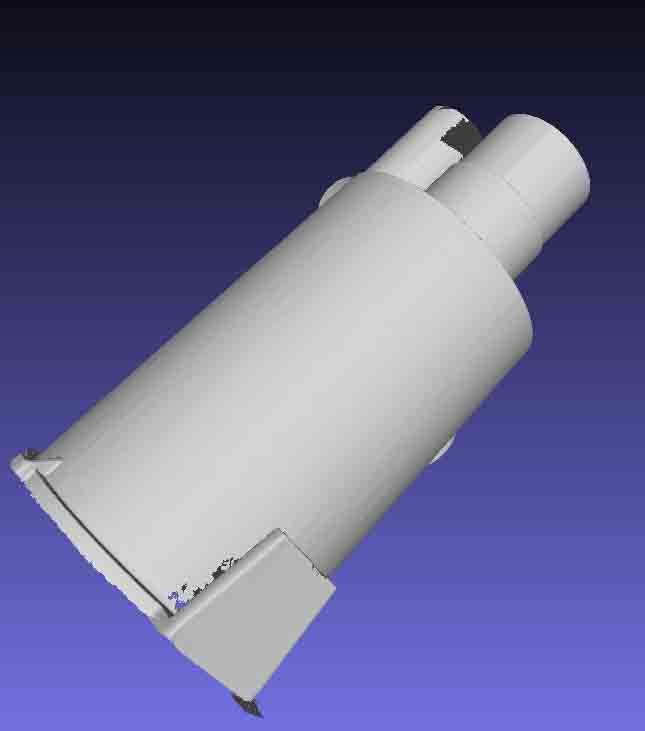

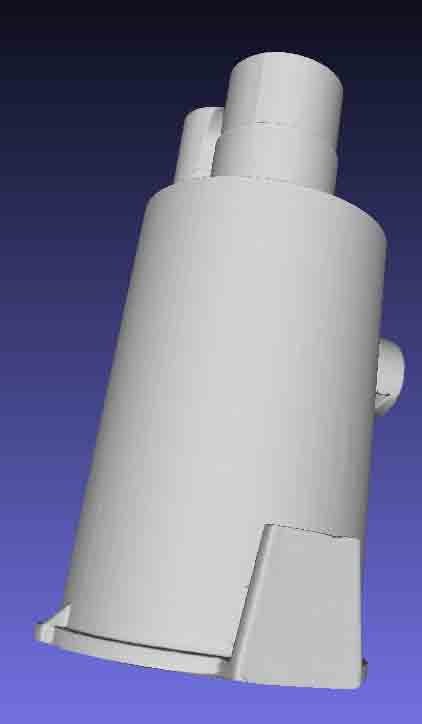

GOM Inspect Professional and GOM Inspect are the software packages for the analysis of 3D measuring, data acquisition for quality control, product development and production. The GOM software is used to evaluate 3D measuring data derived from GOM systems Fig 3. GOM Inspect in action. Fig 4.We needed to manually move the plate to have all sides of the pieces scanned. Fig 5. After taking different pictures, the software completes missing details. Fig 6 .After different pictures the software polygonize and recalculate the process image. Fig 7 .Exported to Cura Software in order to see how it was viewed on STL format and in a printing environment. Fig 8 .Export to MeshLab for post treatments. Erase the noise on the model. Fig 9 .On MeshLab post treatments was made to fill the holes. Fig 10 . Finally, the piece was finished and ready to be printed.

GO TO :3D SCANNING AND PRINTING.

Drum

Gear.

Rowlock