Makerbot 2x

For this assignment, I printed some of the pieces for my final project. The pieces will be integrated with some ball bearings.

Fig1. 3D printer-Makerbot 2x.

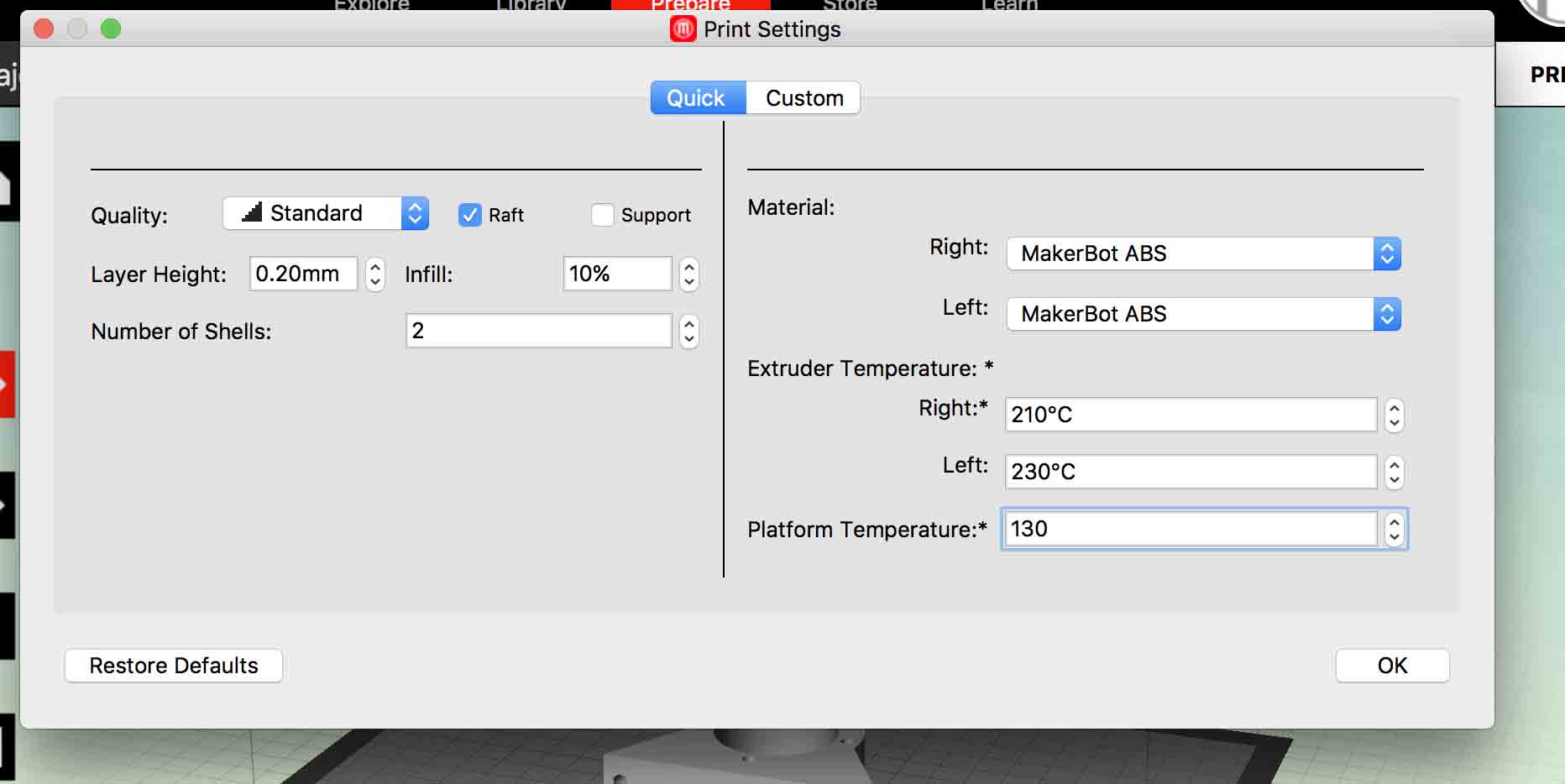

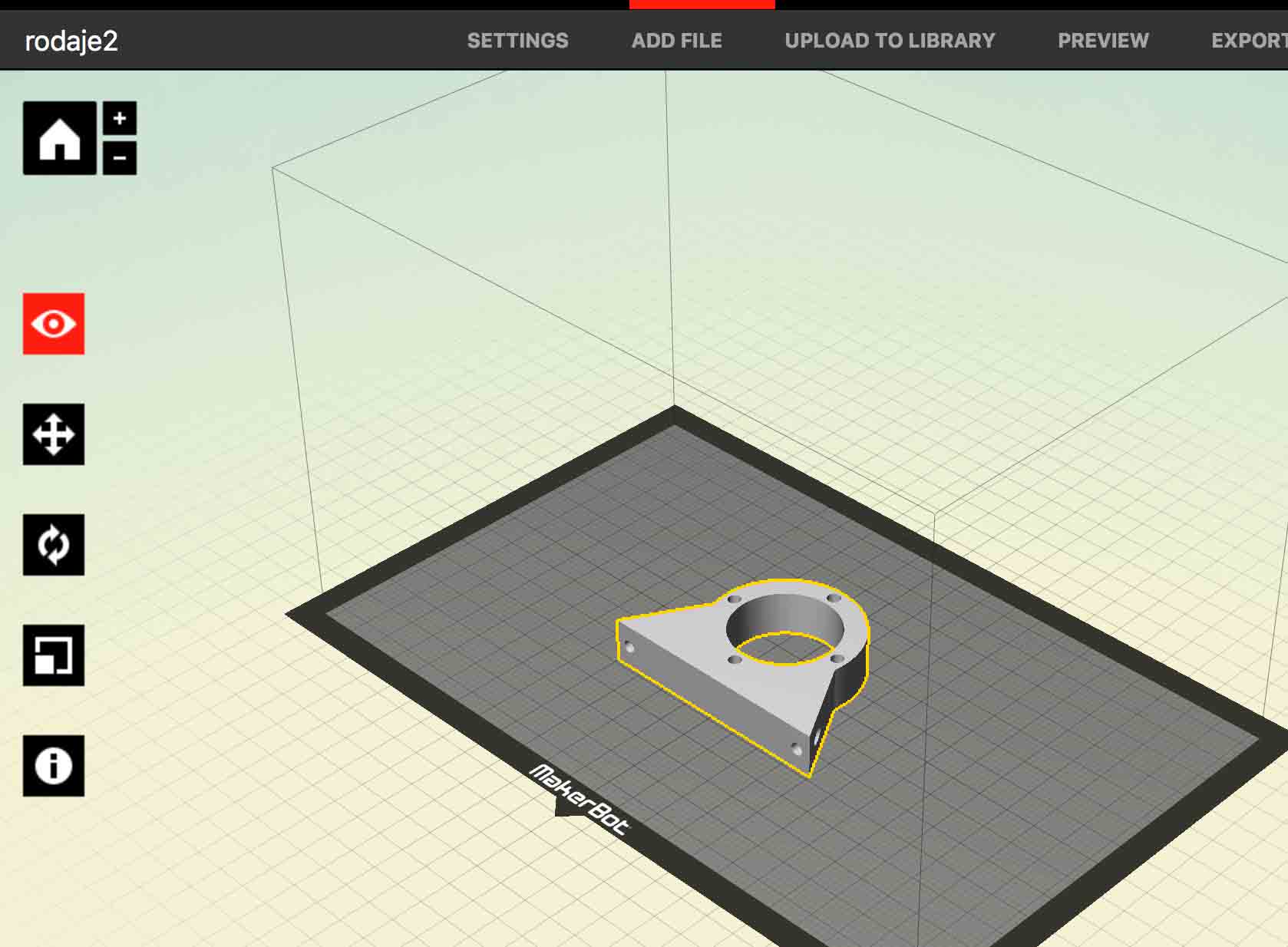

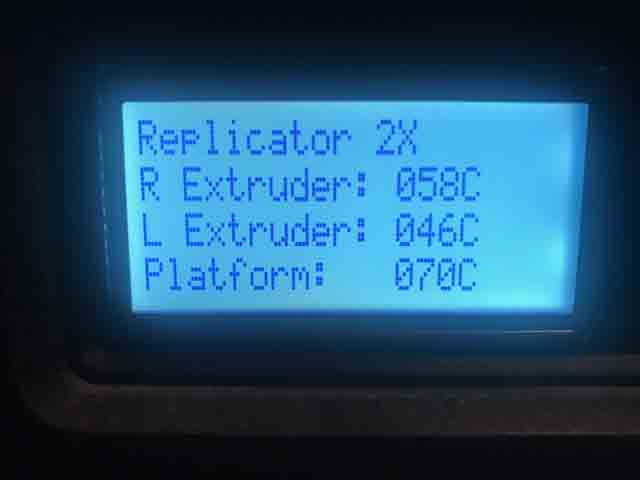

The seconds example shows the rowlock printed on ABS material. The printer in this case used Makerbot 2x. The parameters were explained in the follow pictures. The markerbot 2x contains a hot plate with 130 ⁰C which is needed in order for the material to stick well on the plate and enable ABS printing.

Fig 2. Parameters on makerbot 2x.

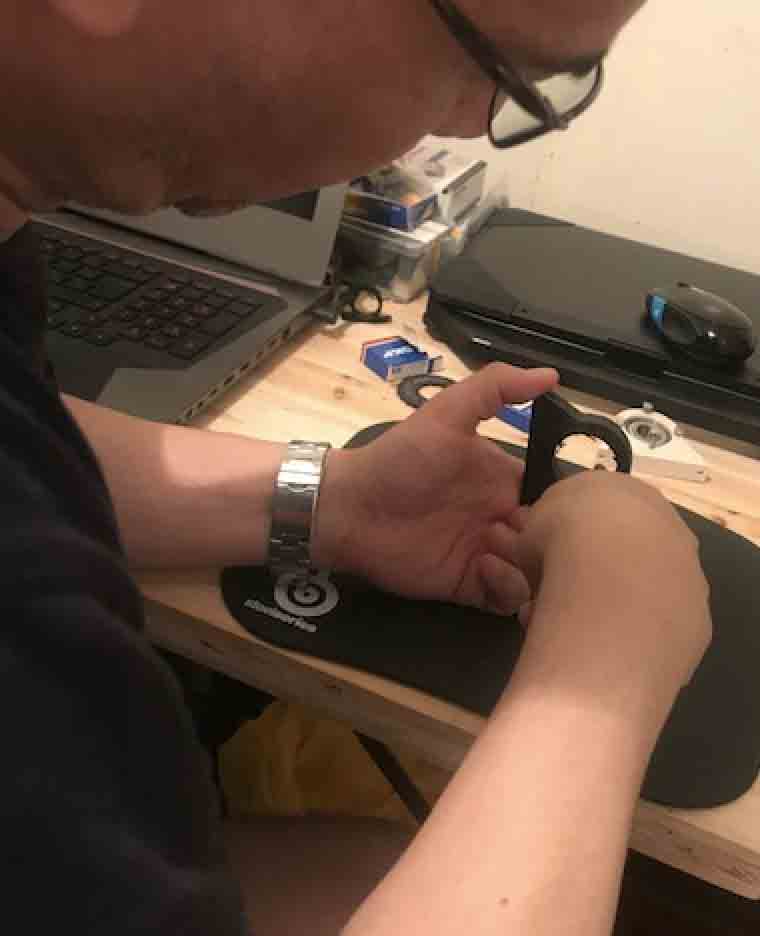

The heat of the extruder was 230 ⁰ C and the platform temperature in this case was 130 ⁰ C . The travel speed was 100 mm/s and in the Z axis travel speed was 23 mm/s . Standard mode was use. Fig 3.The layer Height was 0.20 mm and two shells number on makerbot 2x. Fig 4. The rowlock as seen on the Makerbot software before to printing on makerbot 2x. Fig 5. Before removing the rowlock on makerbot 2x the platform needed to be cooled to avoid injuries. Fig 6. The total printing time on the makerbot 2x. This printer was a little bit slower than the Makerbot 2. Fig 7. Remove rowlock with some tools on makerbot 2x. Fig8. Removed the support of the piece. Fig 9 Some remaining of the abs were inside the hole, I needed to remove them in order for the bearing to fit in it. Fig 10. In contrast with the one printed on PLA, the remainings of the ABS had to be removed with a knife. Fig 11.The ball bearing is tighter than with the PLA rowlock. Fig 12. But in the end, the bearing fit perfectly on it. Fig 13.All pieces fitting perfectly.

GO TO :3D SCANNING AND PRINTING.

Drum

Gear.

Rowlock