How to fix bins

I have searched a way to fix parts of the modular e-bin. I think of doing prototype bins wall in MDF ( Medium Density Fiberboard).

I have searched a way to fix parts of the modular e-bin. I think of doing prototype bins wall in MDF ( Medium Density Fiberboard).

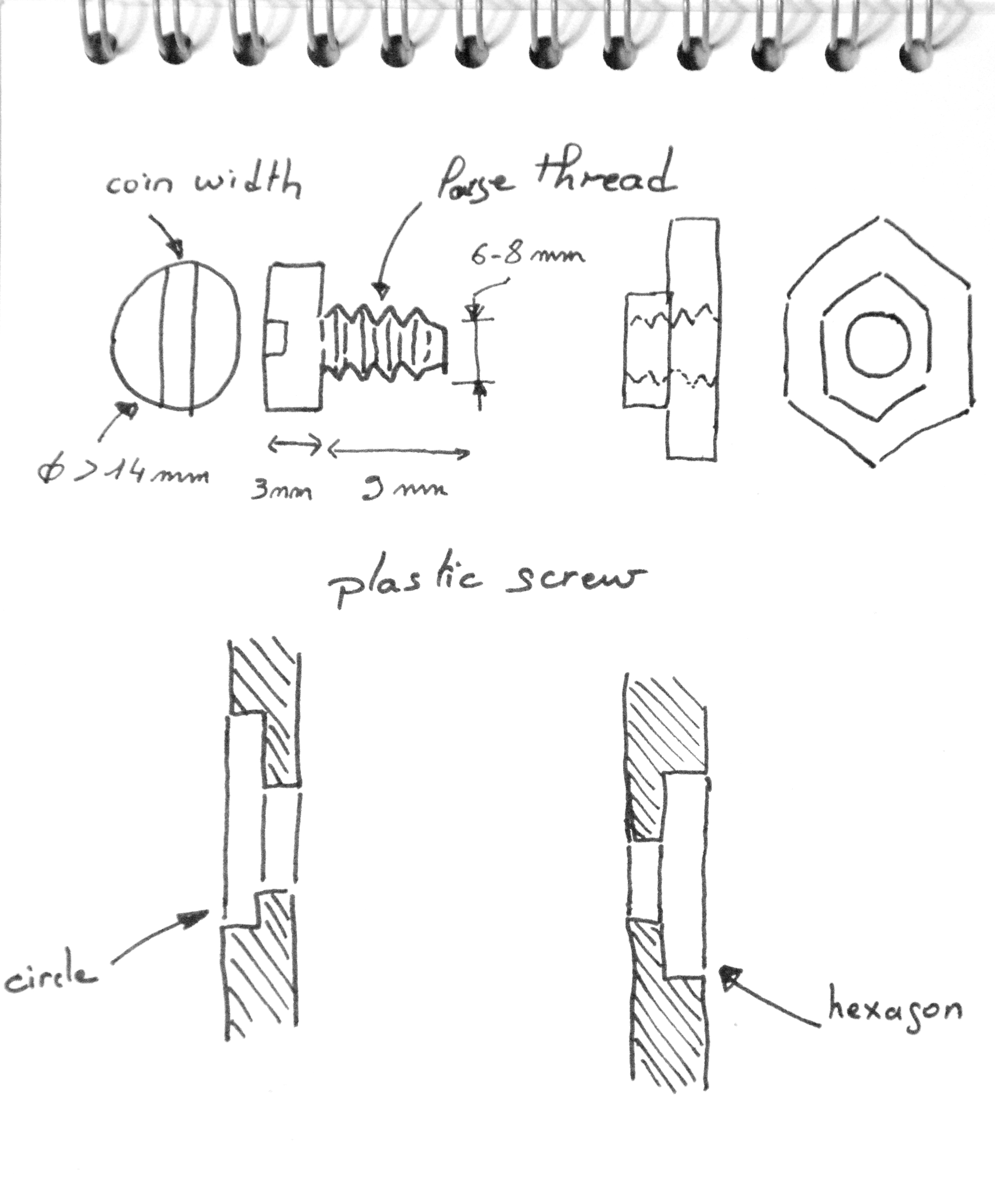

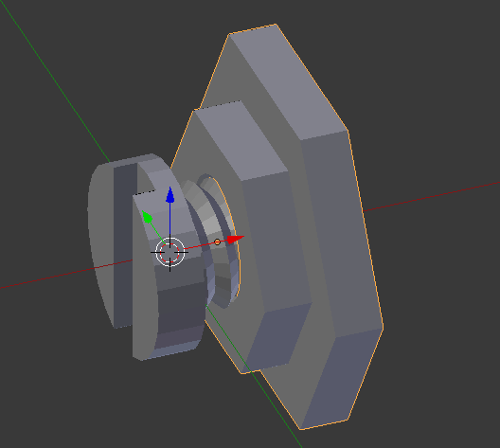

Maybe plastic screws can be a solution to make a good plug system. So, I designed screws to make tests.

I did it in blender. I have to print screw and nut in 3D now to verify it works well.

I did it in blender. I have to print screw and nut in 3D now to verify it works well. No need to use a screwdriver. I changed my screw design to be able to use a 2€ coin to screw. This coin diameter is 2.5cm and thickness is 2.3mm.

No need to use a screwdriver. I changed my screw design to be able to use a 2€ coin to screw. This coin diameter is 2.5cm and thickness is 2.3mm. In my first screw prototype, I need different hole for bolt and nut. I have searched a way to have the same hole.

In my first screw prototype, I need different hole for bolt and nut. I have searched a way to have the same hole. I printed my bolt and nut. I made a 16mm bolt thread diameter and 16.6mm nut thead diameter to have a 0.3mm float between bolt and nut.

I printed my bolt and nut. I made a 16mm bolt thread diameter and 16.6mm nut thead diameter to have a 0.3mm float between bolt and nut.