|

|

|

|

Week7. Electronics Design

assignment

group assignment:

use the test equipment in your lab to observe the operation

of a microcontroller circuit board

individual assignment:

redraw the echo hello-world board,

add (at least) a button and LED (with current-limiting resistor)

check the design rules, make it, and test it

extra credit: simulate its operation

extra credit: render it

1. ReDesign Hello-world board

Software : KiCad

* note : Stable version is recommanded, but, I'm using nightly development builds version.

Reference design

Download materials

- Hello-world board schematic

- KiCad Library(scroll down to circuits section)

Schematic design

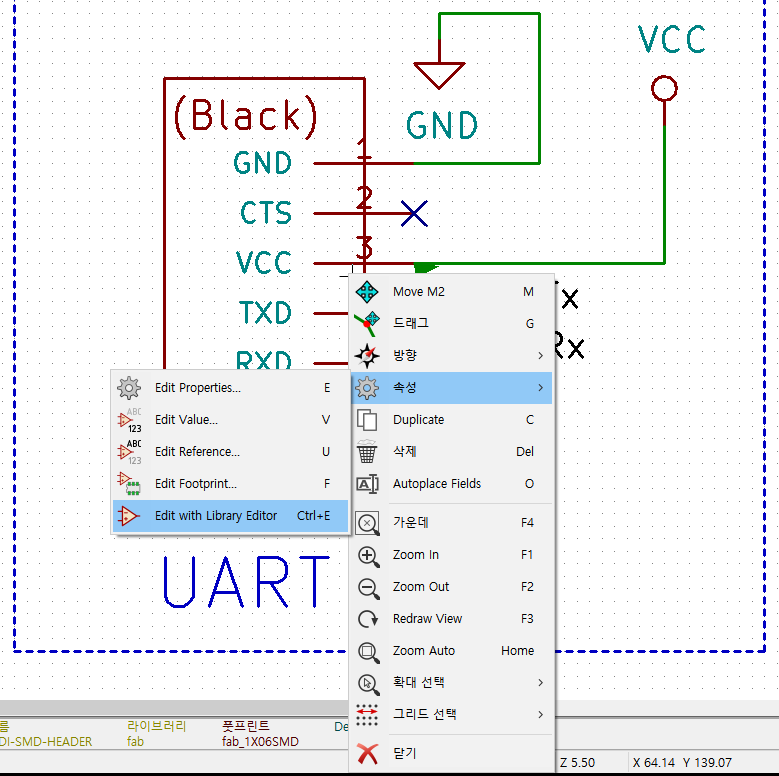

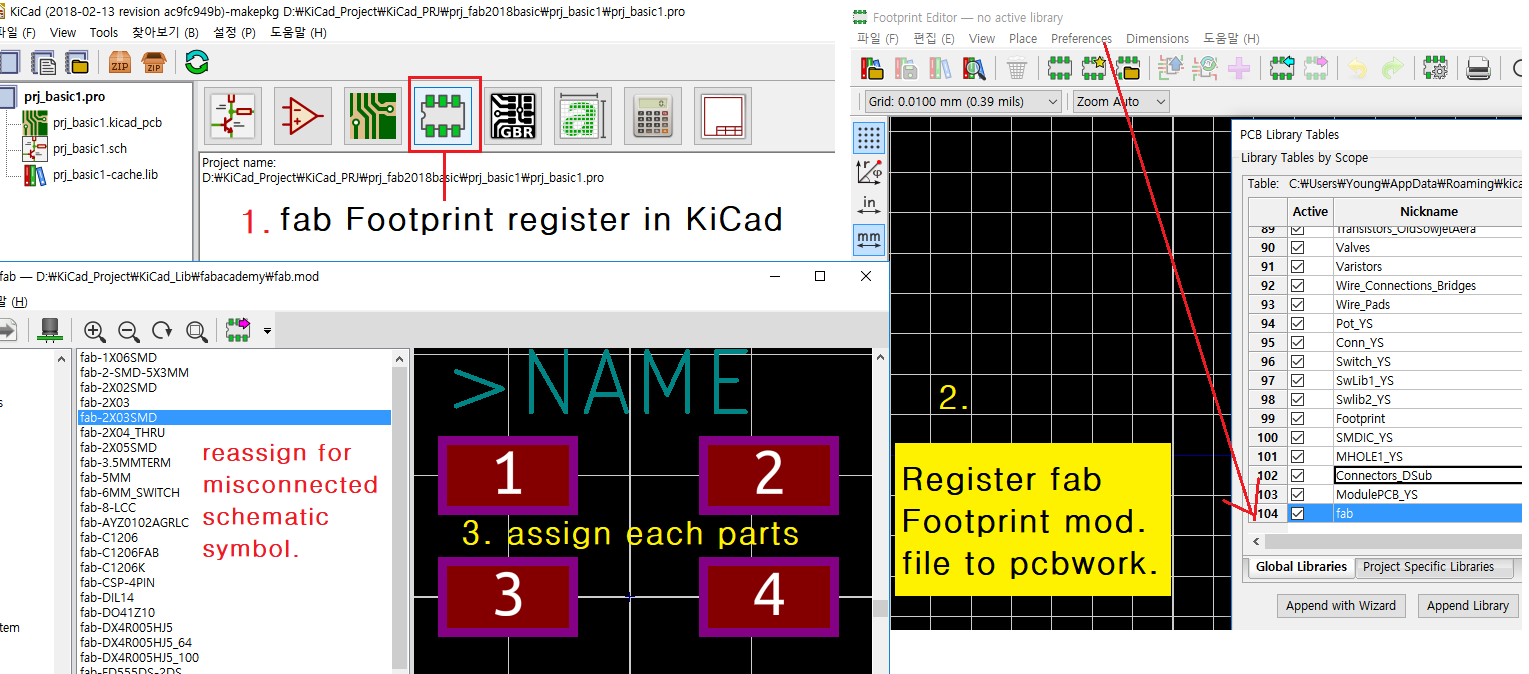

At first library files store to project folders, then register to software modules(Schematic Layout editor/PCB layout editor).

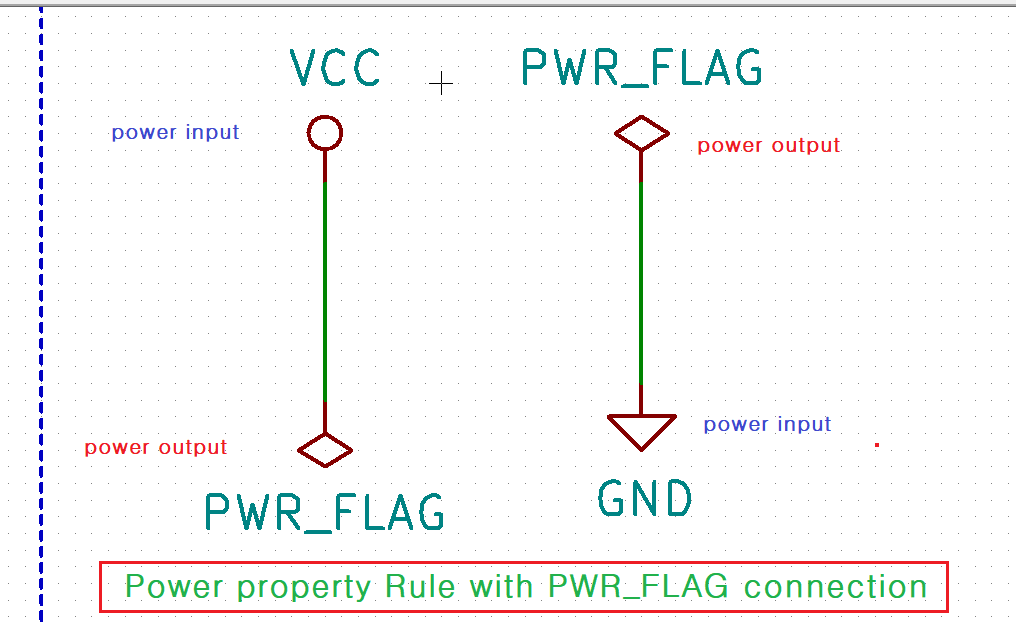

In KiCad schematic editing, need to be connect Power symbol to PWR_FLAG.

That module check about this for ERC run.

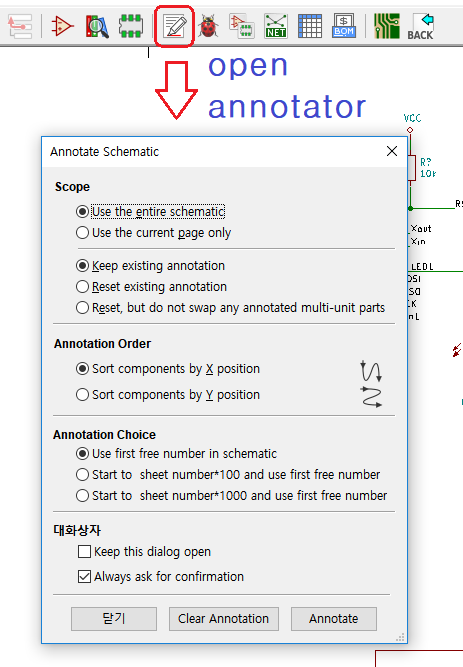

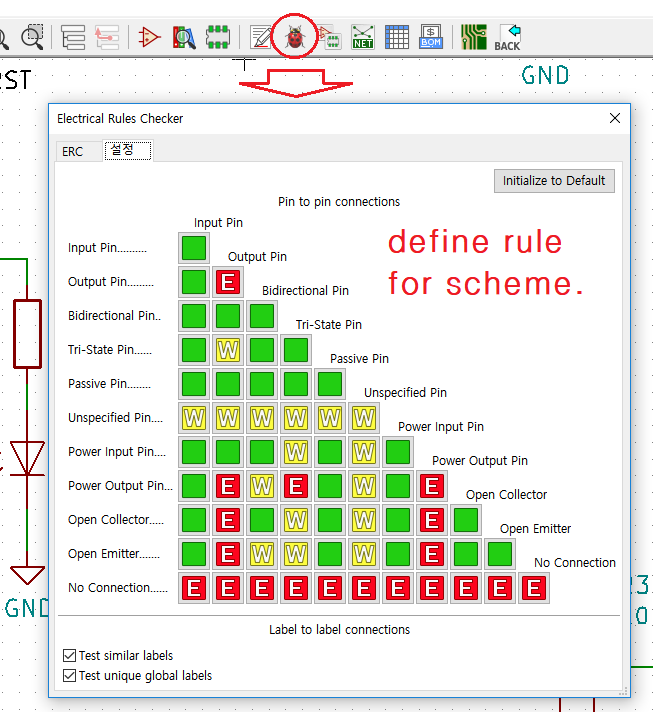

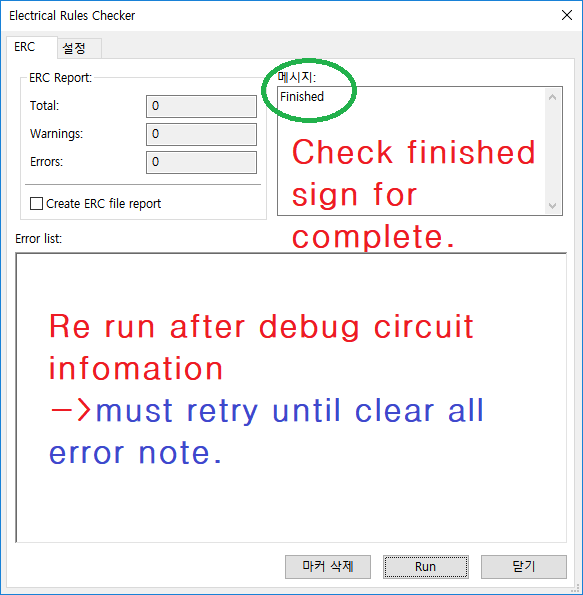

annotate each symbols to get id numbering, before netlist generation, check for electrical Rule check.

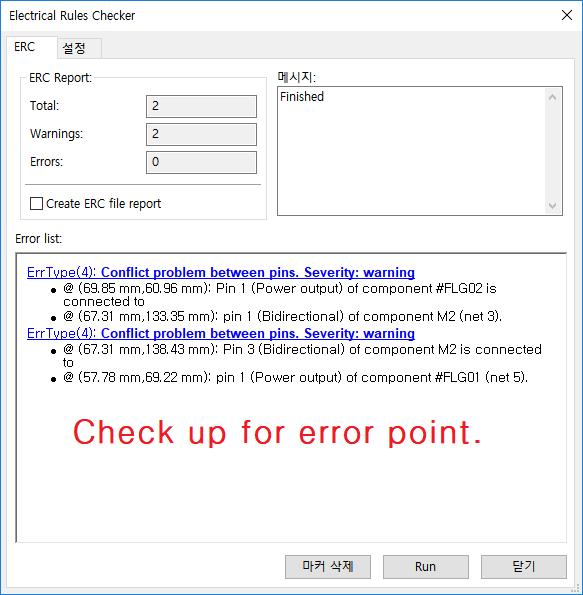

here are some errors, Follow to indication, find error dagger, that means mismatching electrical type.

i.e. Power Symbol must have Power input property and PWR_FLAG need to have Power output property.

in my drawing, PWR_FLAGs property was Bidirectional type set, so edit symbol property correctly.

here is my complete drawing.

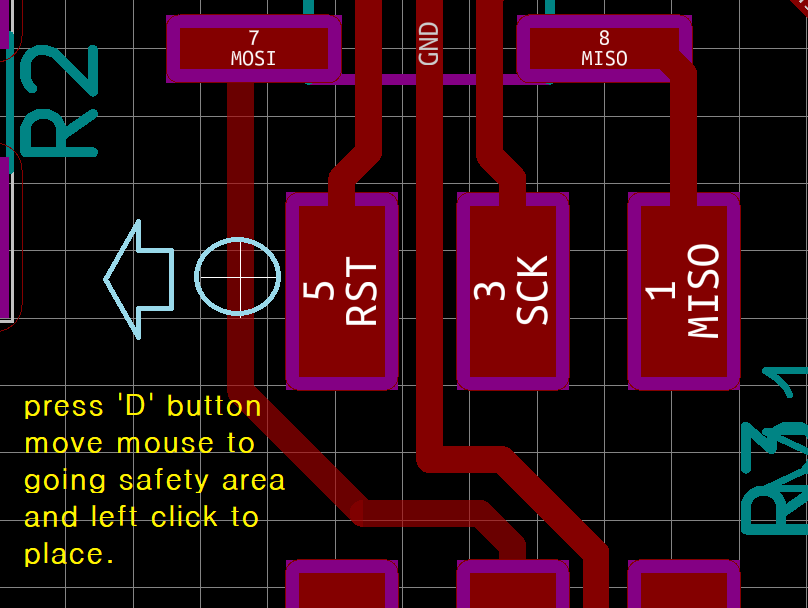

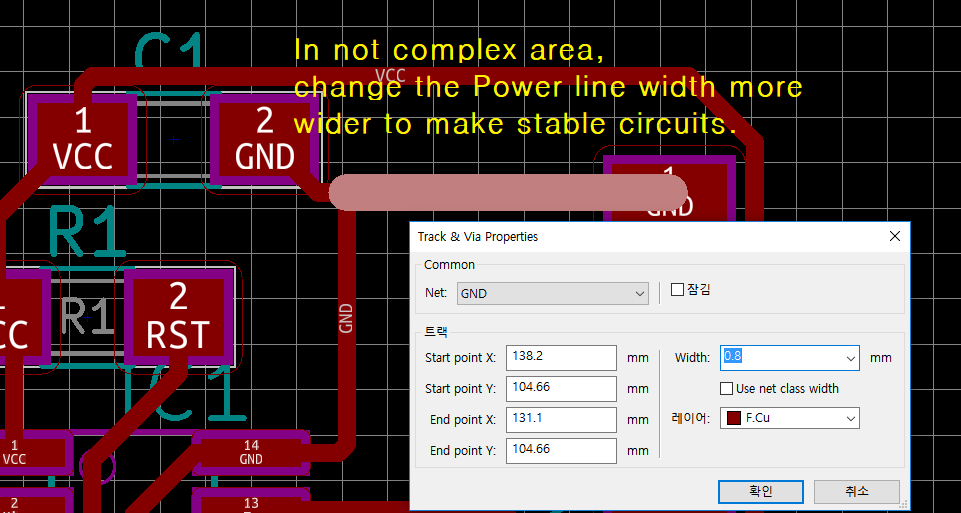

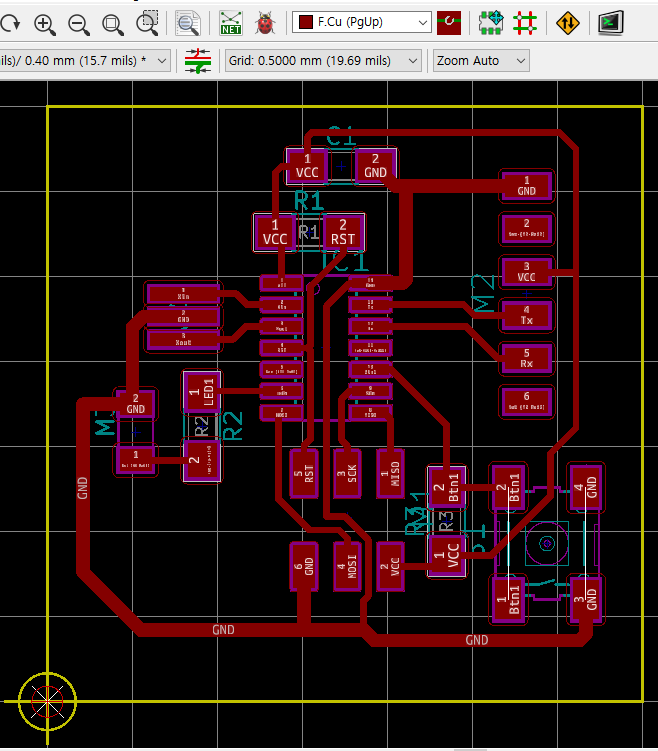

PCB artwork design

In Footprint editor, add 'fab.mod' file to use current work process.

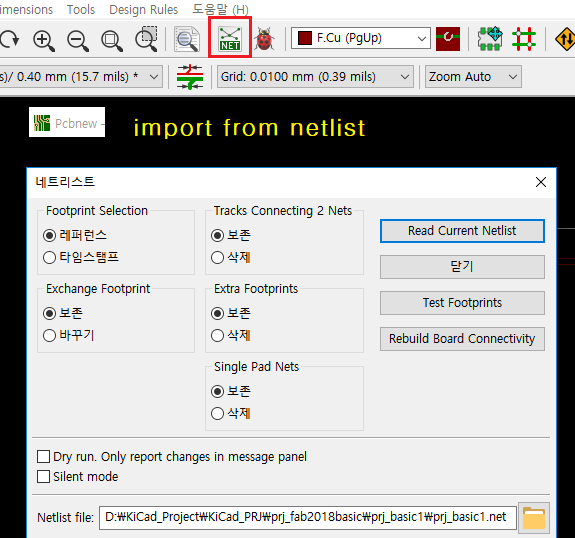

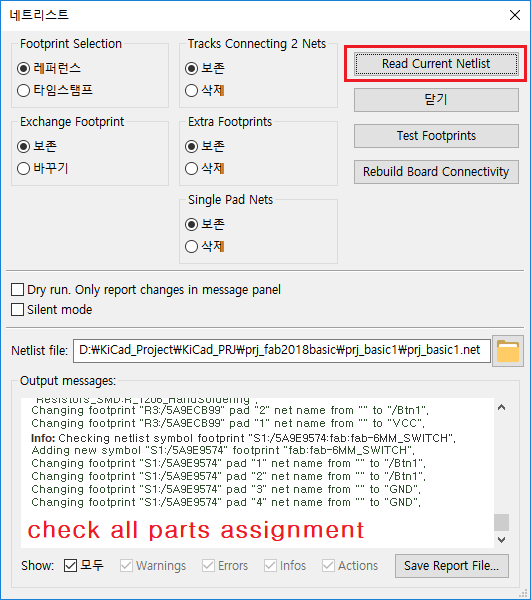

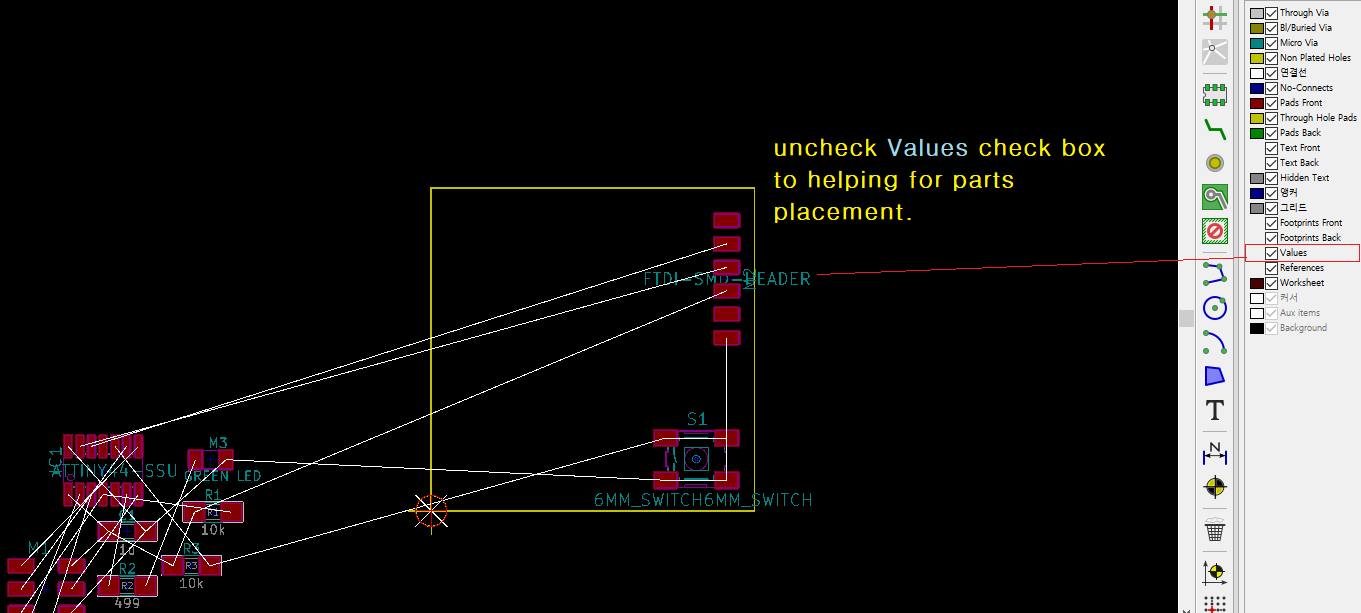

Load netlist file from schematic to place with linked footprints of previous added.

Check about all parts placed correctly, then draw a simple out-line for PCB outcut mill.

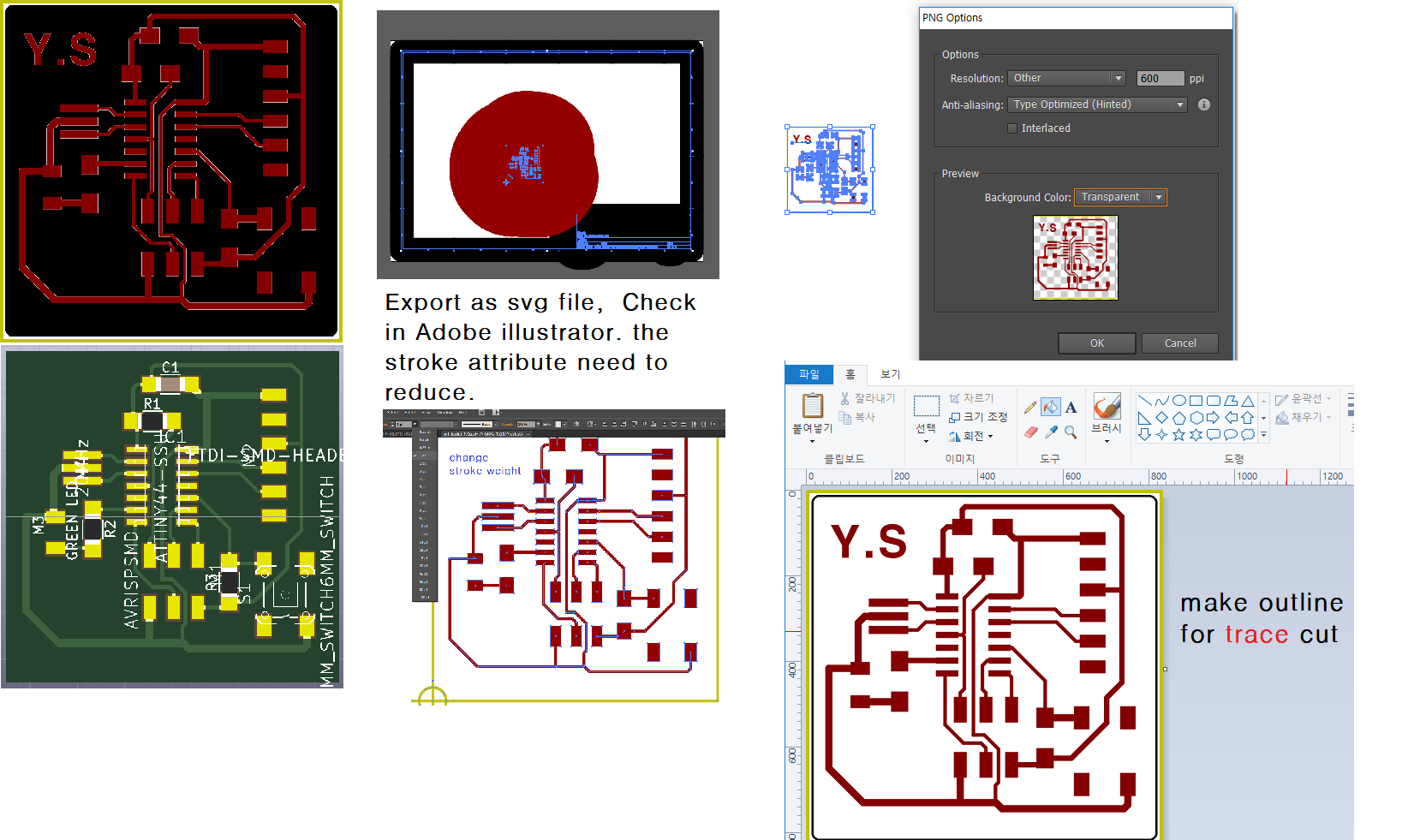

Artwork and make .png file to use in fabmodules.

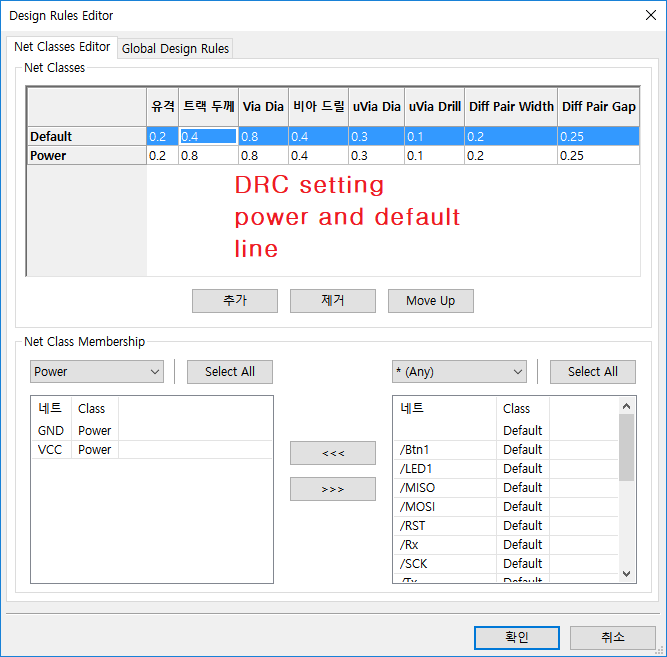

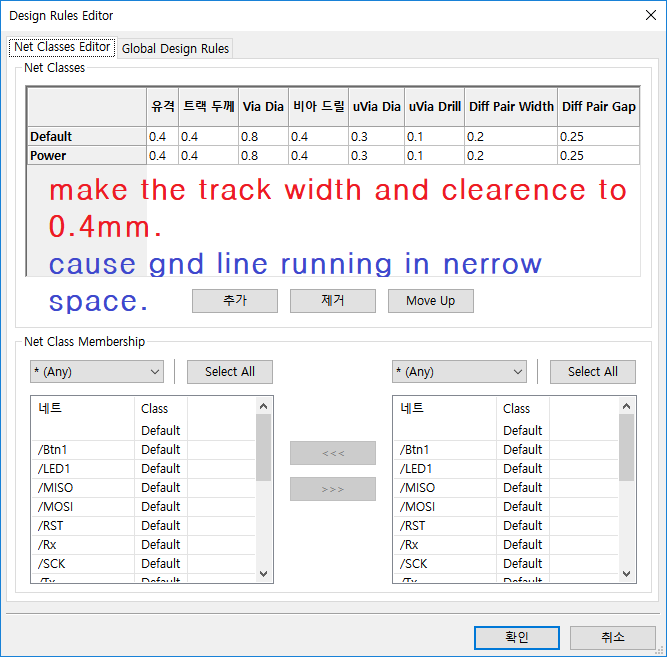

given DRC clearance default set is 0.2mm, it makes some lines conflict near pads.

I made a rule clearence to be 0.8mm but, in this design need to more narrow way to join,

I will try change to 0.4mm and fine control line spacing.

Here I choose .png file to make mill data. First export .svg file can be read in Adobe illustrator.

It is appear line thickness too big. Reduce weight so clear find circuit. But, all thickness has the same thickness.

So, make png format output and remapping width in windows paint program.

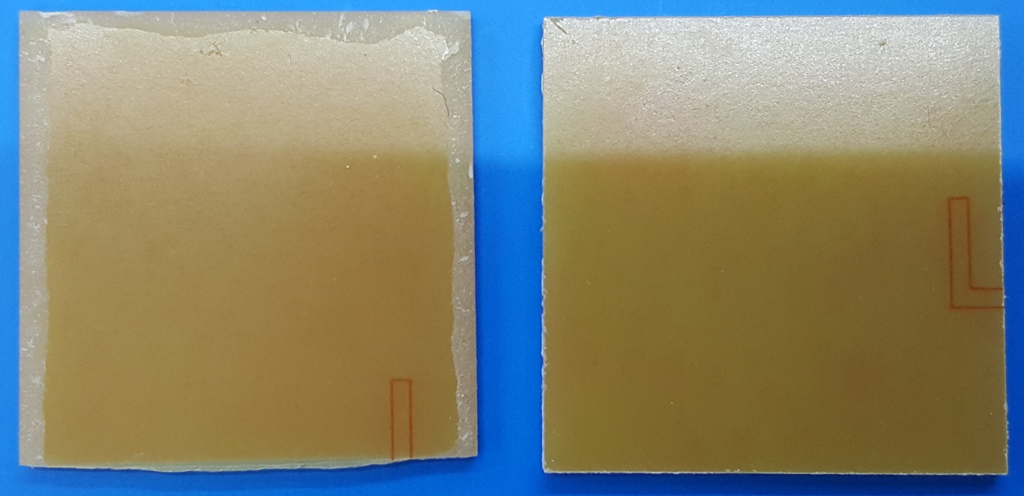

Now, divide trace pattern and outline pattern.

download files:

- trace image file:prj_basic1-F.CuToptracereverseR.png

- outline image file:basic1_outline.png

2. Making Board

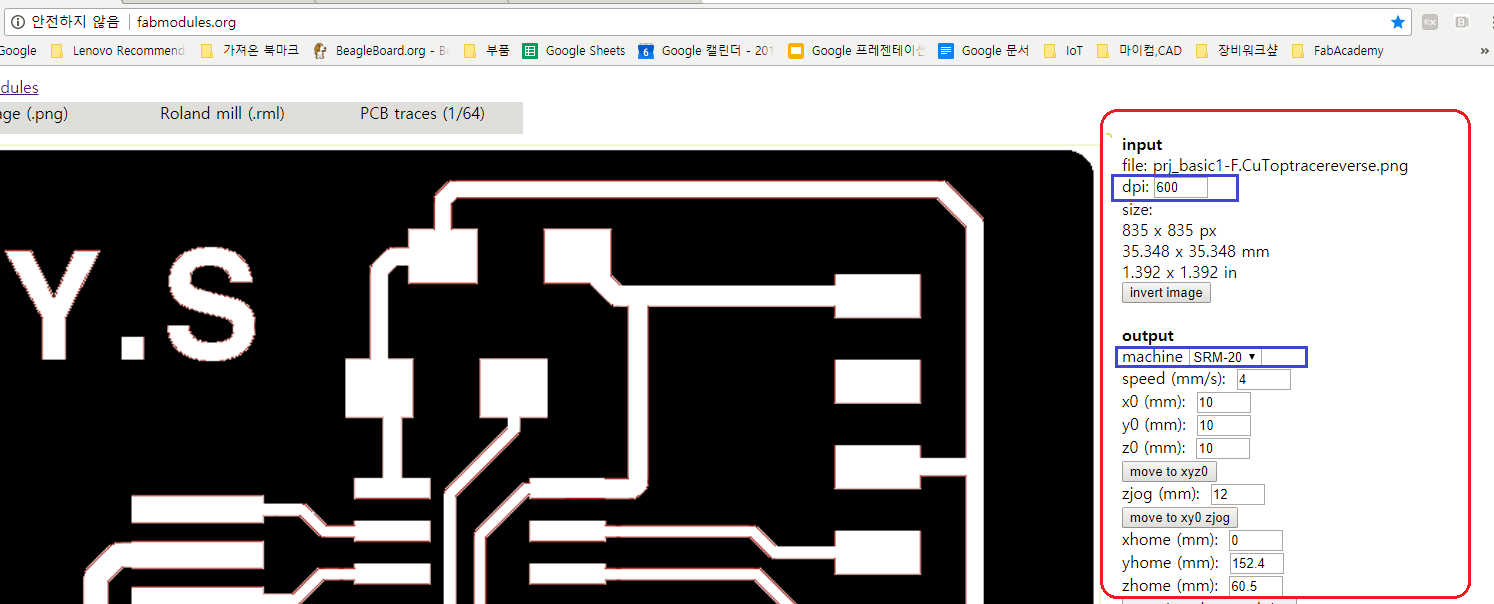

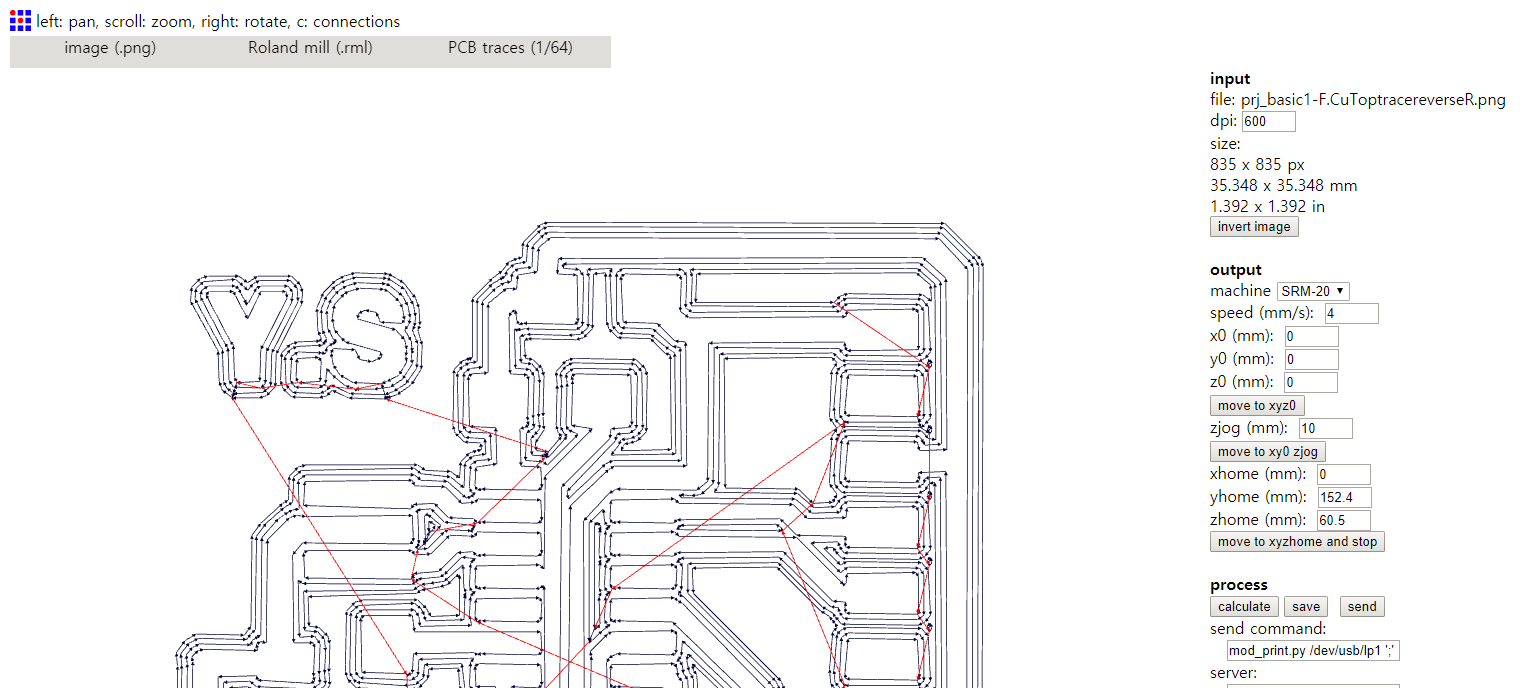

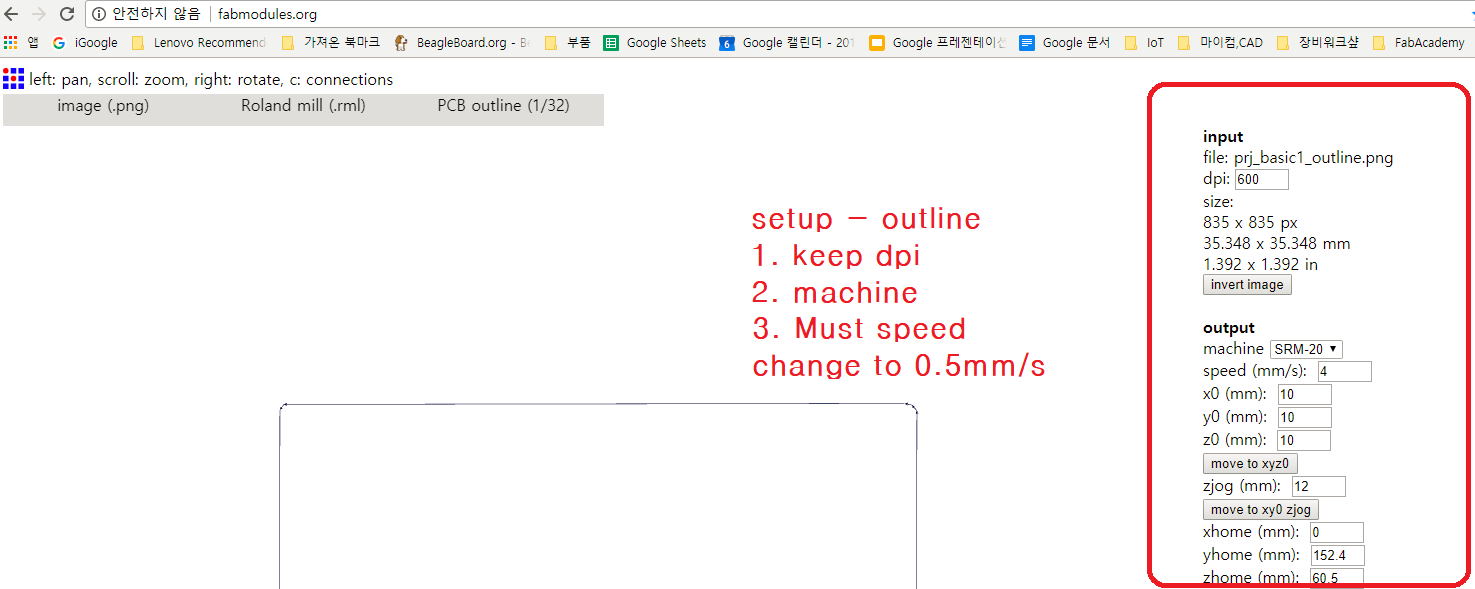

Making milling work file

Before setting up parameters, check about dpi(dots per inch) relation. Wrong dpi value makes different board size.

Then machine status check before mill.

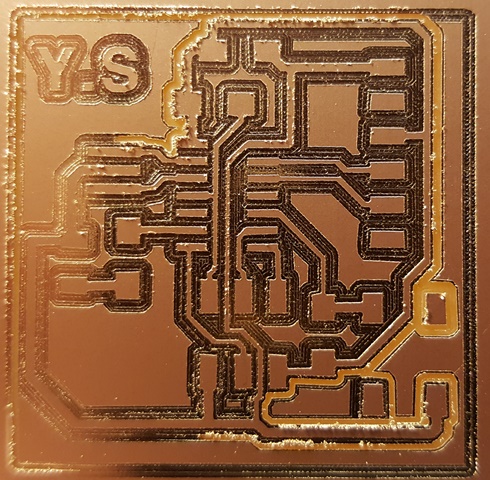

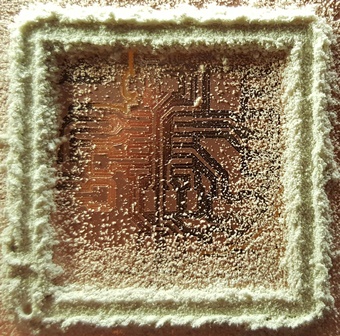

1st Milling

Error check and fix

I found some errors on depth cut(Z axis), first for trace cut, most area didn't cutting

also outline cut seems to be left up.(compare to 2nd cut on the right.)

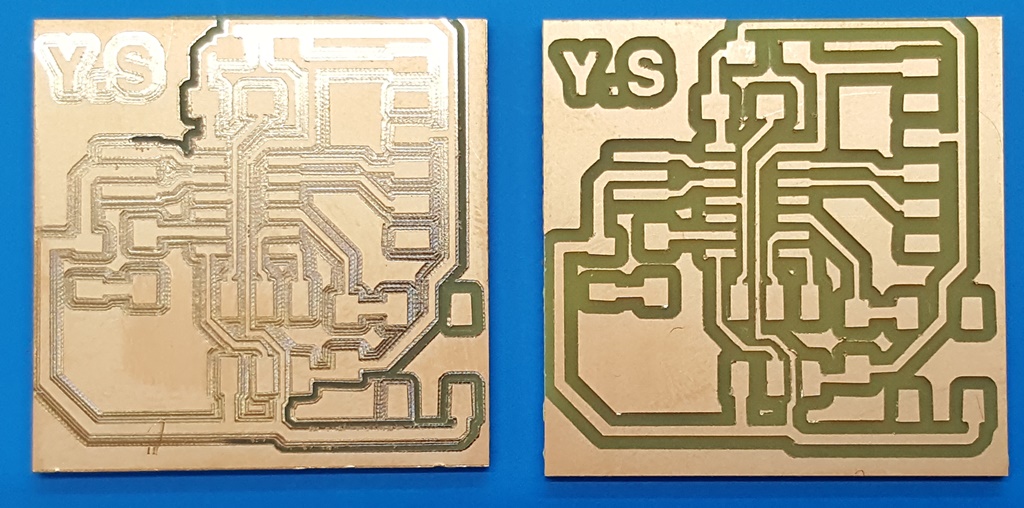

2nd Run

For the 2nd cut, I check several times on fabmodules and make sure z-origin point on SRM-20.

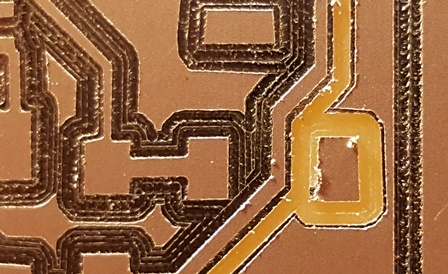

Other error fix

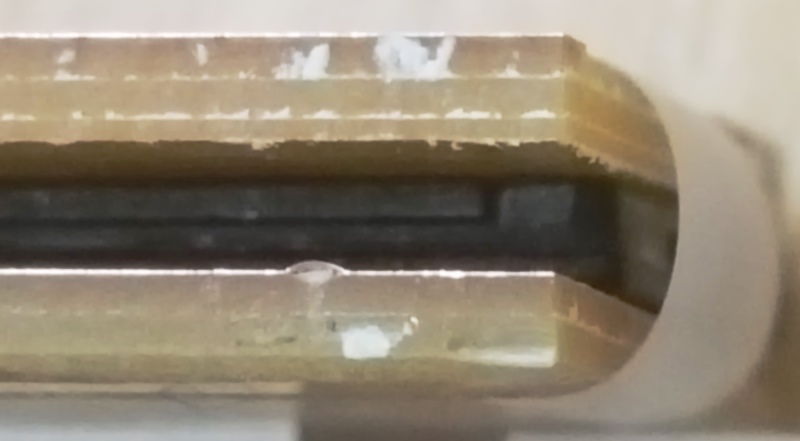

I realize 3 times cut to mill through depth, for under cutted 1st pcb still hold near plate,

so it's hardly to get off cutting pcb. Also I found broken parts remain near plate.

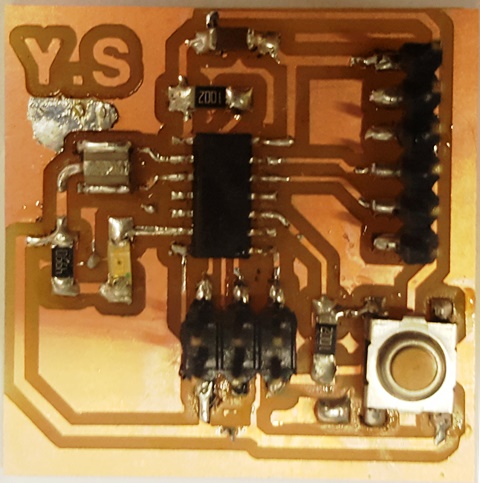

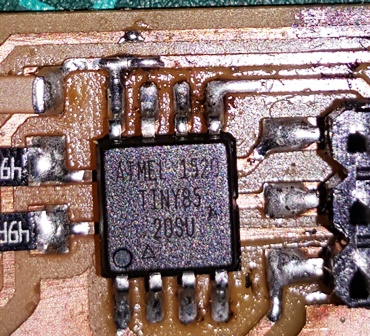

Soldering

3. Programming and find a result

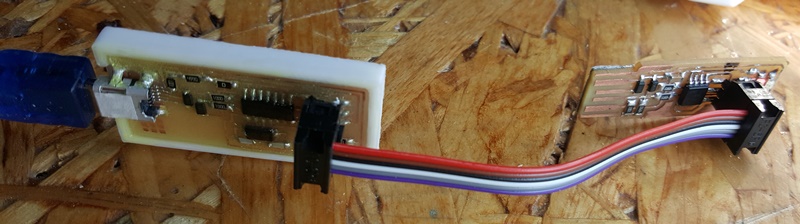

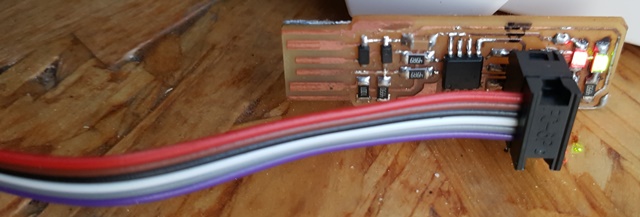

Prepare fabisp module

Detail process on computer, I'll descrive go back to week5 assignment section.

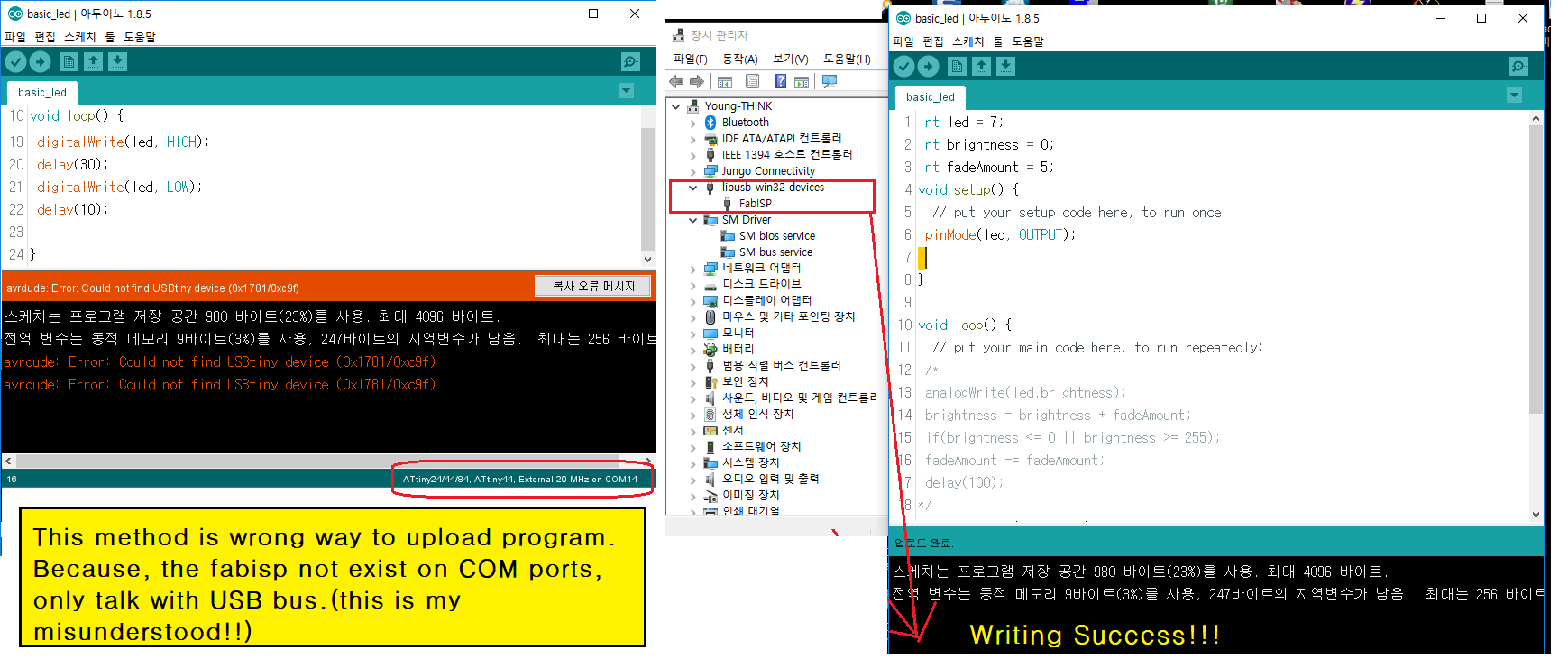

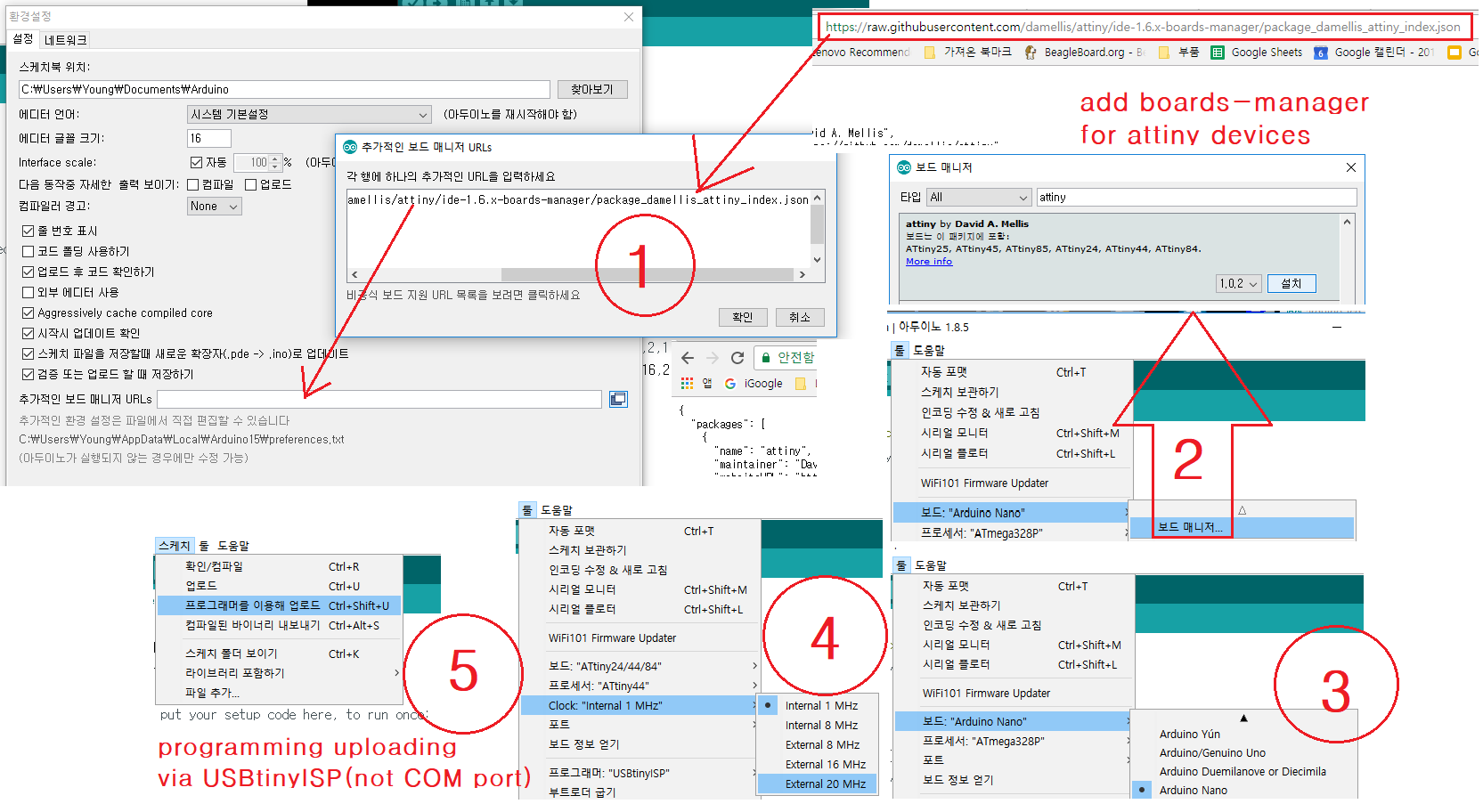

Fabisp plug-in to Arduino IDE 1.8.5

Programming, download and result.