|

|

|

|

Week10. Molding And Casting

group assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

individual assignment:

design a 3D mold around the stock and tooling that you'll be using,

machine it, and use it to cast parts

1. Review MSDS of Mold and Casting Materials

Mold : Mold Star 16 FAST

- property : silicones

- low viscosity

- no needs Vacuum degassing

- mix ratio : 1A:1B by volume (no weighting scale)

- pot life : 6 minutes

- cure time : 30 minutes

- heat resistant(in cured) : ~ 450'F(232'C)

- storege and used methods : cool and dry environment

- mixing tool and cntainer : metal,glass or plastic

- wear : safty glasses, long sleeves and rubber gloves

- release agent : not usually necessary.(Ease Release 200)

- ambiant : light mist

- dry : 30 minutes

- Measuring and Mixing : pre-mix PartA and PartB separately.

add part A to part B into mixing container(1A:1B).

scrape the sides and bottom of the mixing container several times.

- Pouring : uniform flow, liquid level off at least 1/2"(1.3 cm) over the highest point

of the model surface.

- Heat curing : 140'F(60'C) ,10 minutes in oven chamber

- Curing : at least room size space needs ventilation.

Cast : TASK 2

- property : casting resins

- low viscosity

- no needs Vacuum degassing

- mix ratio : 1A:1B by volume (115A:100B by weight)

- Color : White

- casting thicknesses : designed for up to 1/2"(1.27 cm)

- capacity : trial kits, 1-gallon, 5-gallon, 55-gallon drum

- storege and used methods : warm environment(73'F/23'C)

- mixing tool and cntainer : metal,glass or plastic

- wear : safty glasses, long sleeves and rubber gloves

- release : release agent applied onto all surface will contact the plastic

with lightly brush, use soft brush.

- ambiant : light mist

- dry : 30 minutes

- Mix and Pouring : add part A to part B, do not delay between mixing and pouring

a uniform flow will help good quality

- for best result : pressure to 60 PSI(4.2kg/cm2) in cure chamber

- Curing : at least room size space needs ventilation.

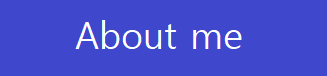

2. Mold frame Design

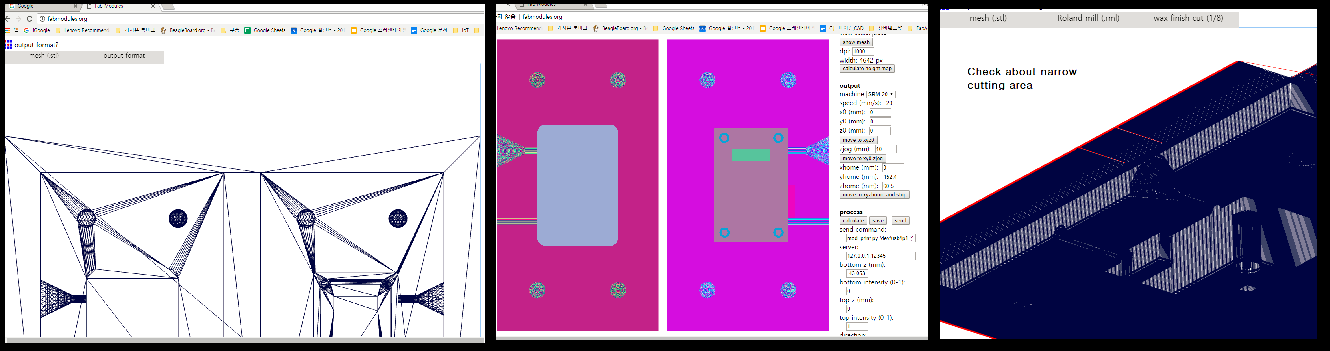

Step1. modeling and export stl format from FreeCad

download file: test_mold3.zip(stl file)

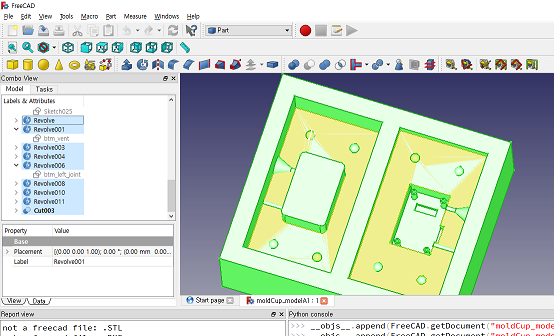

Step2. create roughcut-toolpath

Load stl file to on-line fabmodule to create roughcut-toolpath and save to rml format.

Step3. create finishcut-toolpath

Again load stl file to on-line fabmodule to create finishcut-toolpath and save to rml format.

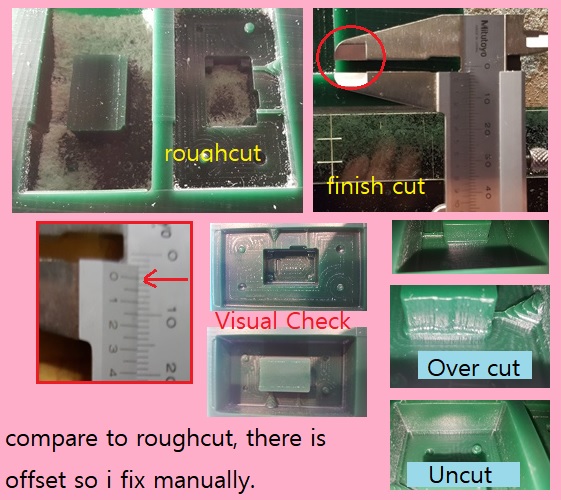

3. Machining

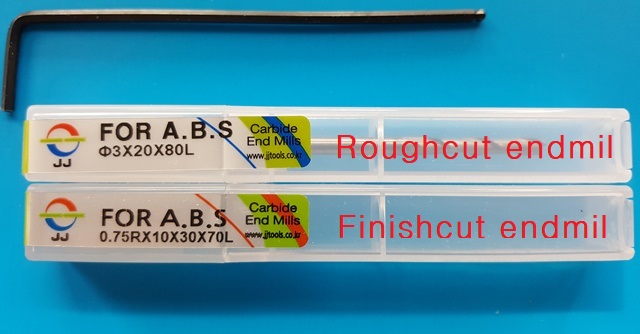

Step1. endmil select

Select the 3mm endmill to make roughcut and 0.75mm ball endmill to make finishcut./

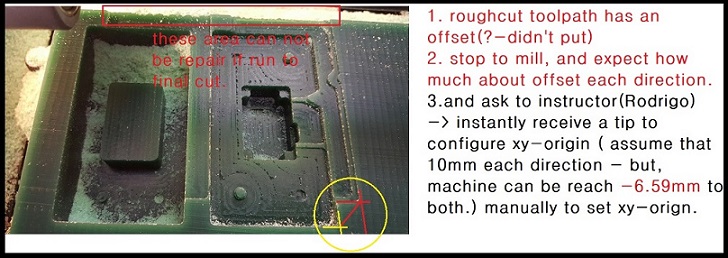

Step2. First cuttings

Problems while in roughcuttingThere are some unexpected that startpoint was not intended position.

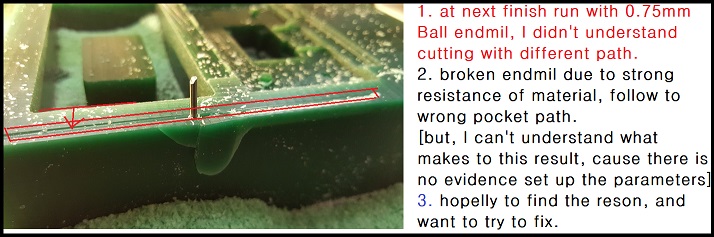

Problems while in finishcutting

It was my fault, if make to avoid this problem, must be done air-cut before to mill.

Step3. error check and rerun on milling

Process for fixing errors

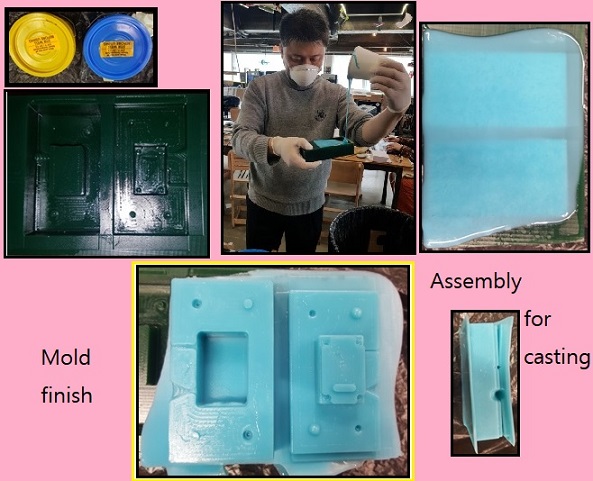

4. Molding

Mold processing

Prepare for environment to molding process, make the silicon resins about 150g.

Pouring to milled molding wax with slow and gently, if fullfill the frame and grab the frame

than several weakly knock to the work stage for vent the air pockets. Stay on air 2 or more hours.

After that, check about the state of hardness than take off the molded silicon frames.

5. Casting

Prepare for casting, reads and prepare as in MSDS for cast resin(prefer to TASK2 MSDS of 1.)

Combine ratio 1:1 by weight to make about 120g of resin.Quickly combine and pour in silicon frame

slowly till come out of air pocket hole.(for the good shape of casting, the press force spread out of

whole area over of bending zig.)

Here I have a result of casting. I want it to use a small electronics case.

Results Shot What I learn about casting

1. Too many air bubbles :

The possible resons are two things one is wrong mixing methods the other is not

enough ventilation for injection to silicon cast frame.

(I was discussed for these problems with instructor(Rodrigo).It helps me to think about 'Mix and Pouring' process in MSDS of TASK2. )

**Solution:

a. Mixing : It needs more slower speed to combine but shake more illregular pattern for mixing.

b. Pouring and ventilation : After injection with a syringe , several times knock to the stage with hold cast frame by hands.

2. The color :

It looks like a some transparently, the correct color is white as followed MSDS even though the thickness is some slitely thinner.

The possible reson is the ratio between of addhesive and hardness is not uniform such as mentioned in MSDS, especially for the smallist and thin structure.

** Solution:

For the good result, improve the mold frame structure for epoxy casting such as more thicker the wall thickness and, needs more ventilation ports added.