Fablab Seoul

JIN`s Fab Academy 2018:

How to make almost everything

My Project

My project name is `Hot set`. Hot Set is Heart + Safety

I will make CPRband. CPR band is necessary for patients with acute cardiac arrest.

In Korea, 60,000 patients have cardiac arrest. But the survival rate is only 4 percent.

So I will make the CPR band easy to raise the survival rate and make it open source.

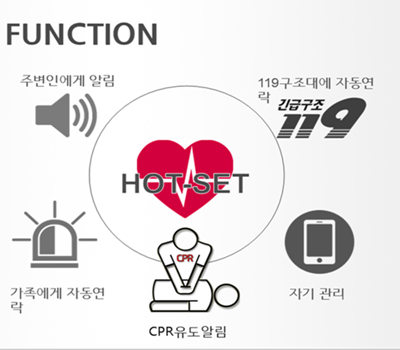

Hot Set Function

1. Announcing Patients to Nearby People

2. Automatically contact your family

3. Contact the rescue team

4. Manage your heart constantly

5. When the public wears it, it will tell you the accuracy when doing CPR

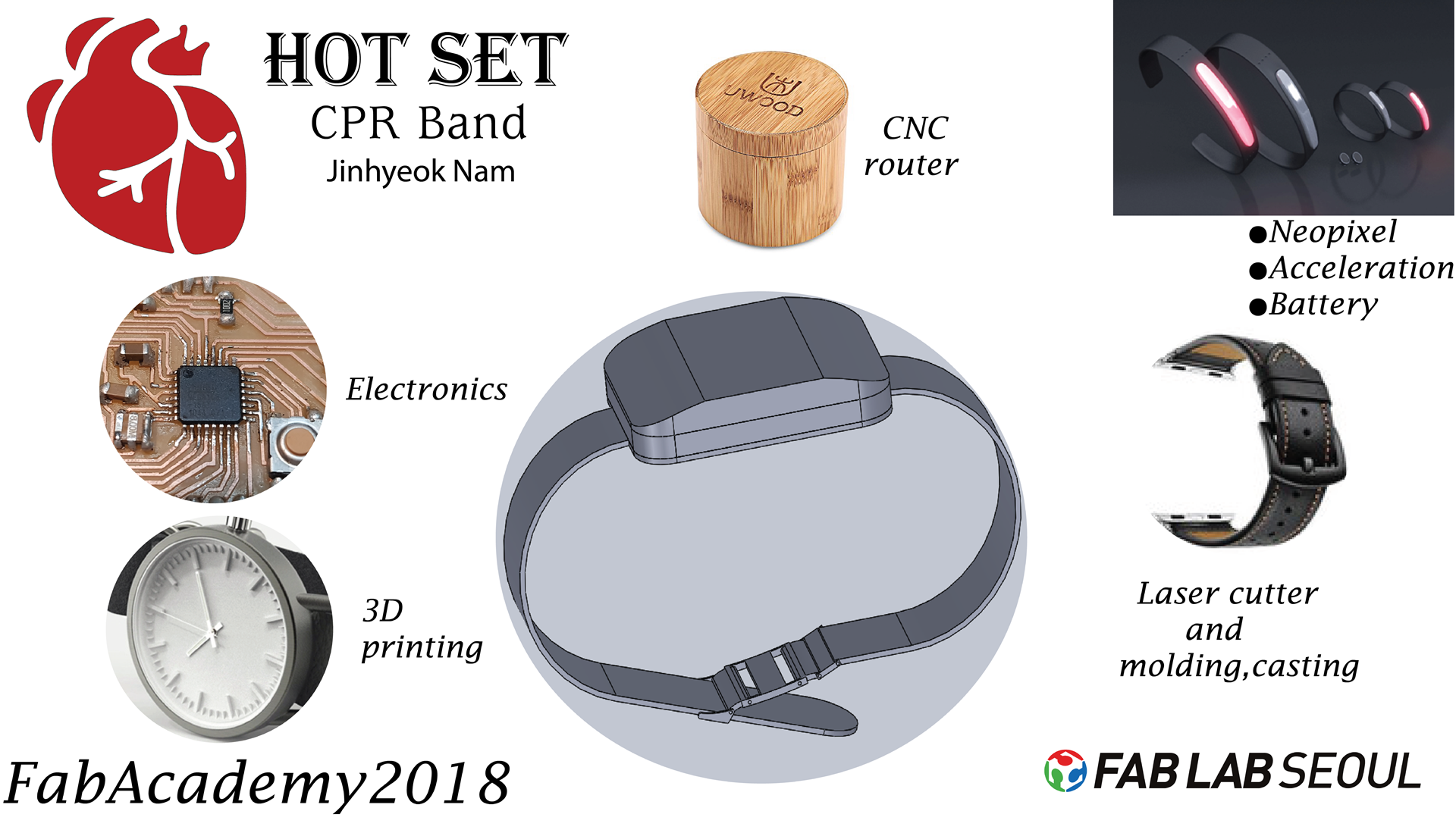

-The appearance of the hot set I painted-

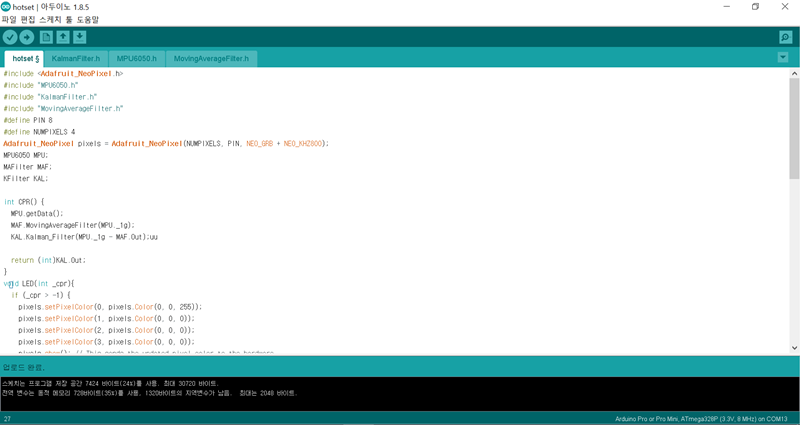

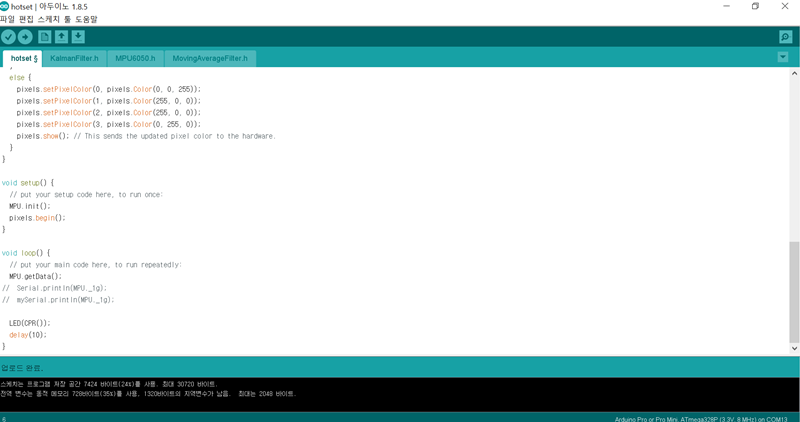

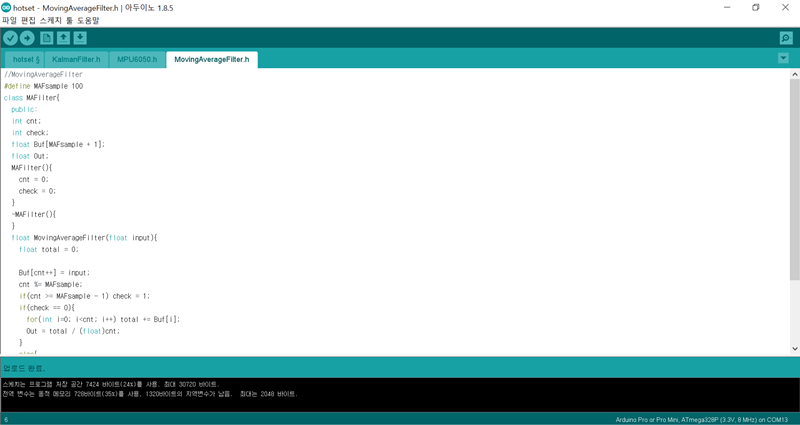

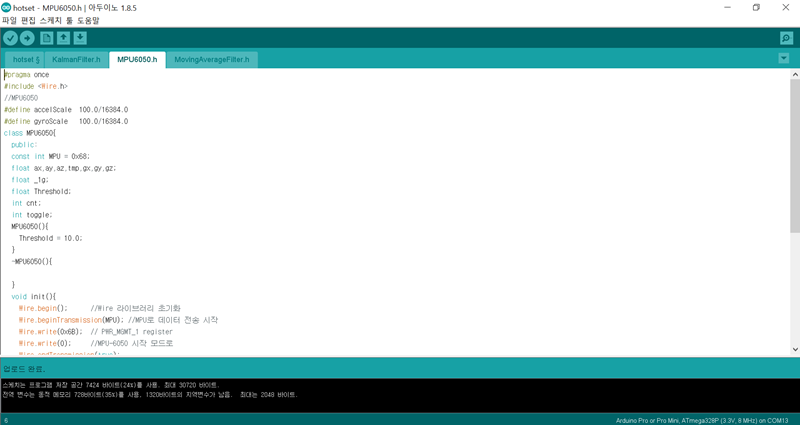

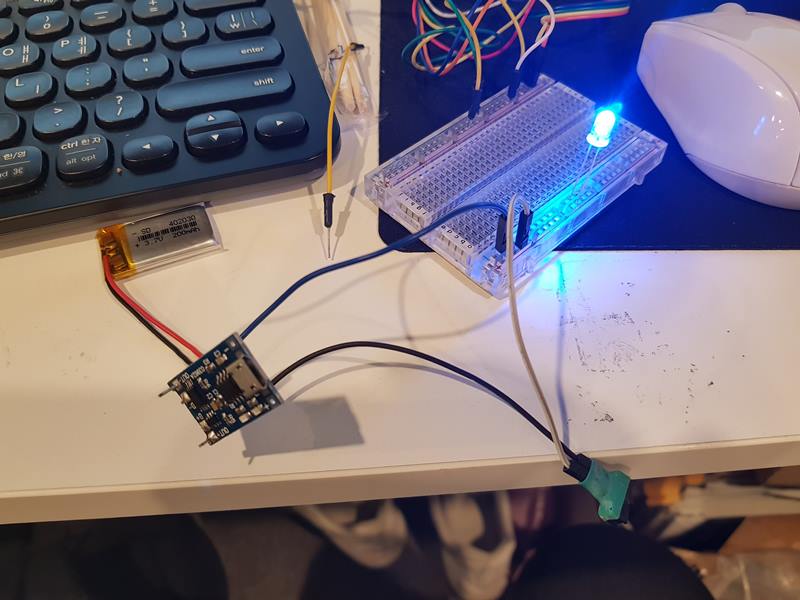

Senor and Cording

I used Neo pixel as output. The acceleration sensor was then used as an input to change the color of the Neopixels

sequentially according to the speed.

Using the Kalman filter, check the acceleration sensor for error.

At first, acceleration sensors had a problem due to high levels of bouncing.

However, the filter holds the value of the acceleration sensor and consequently works well.

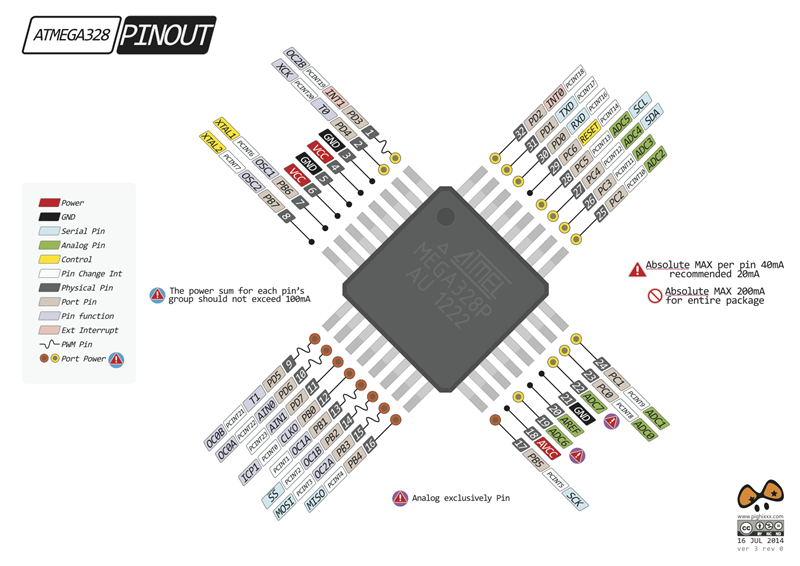

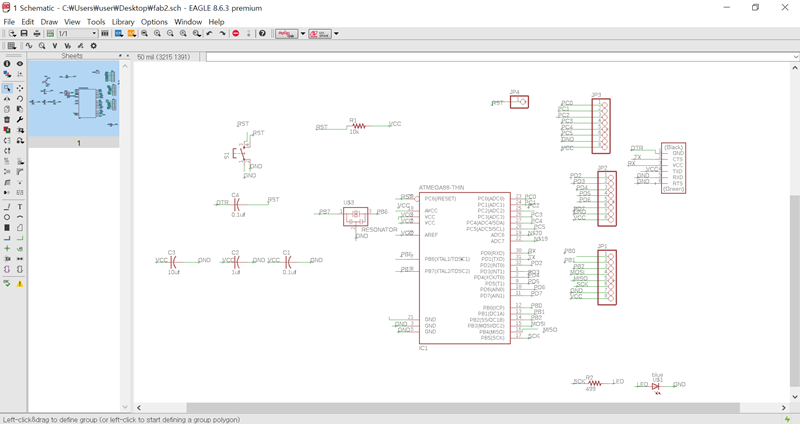

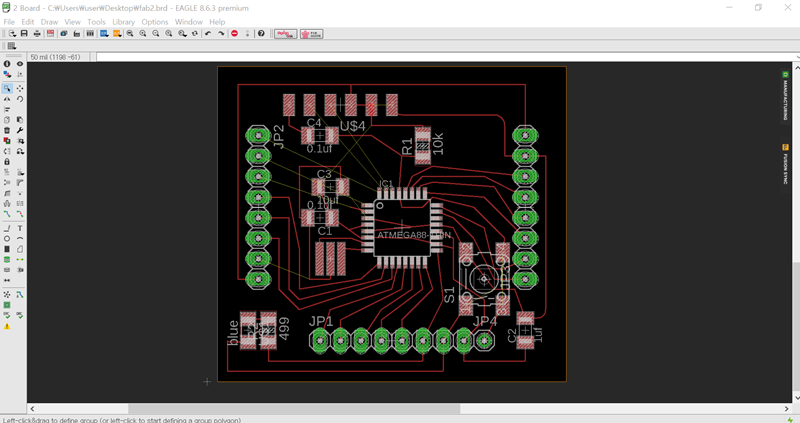

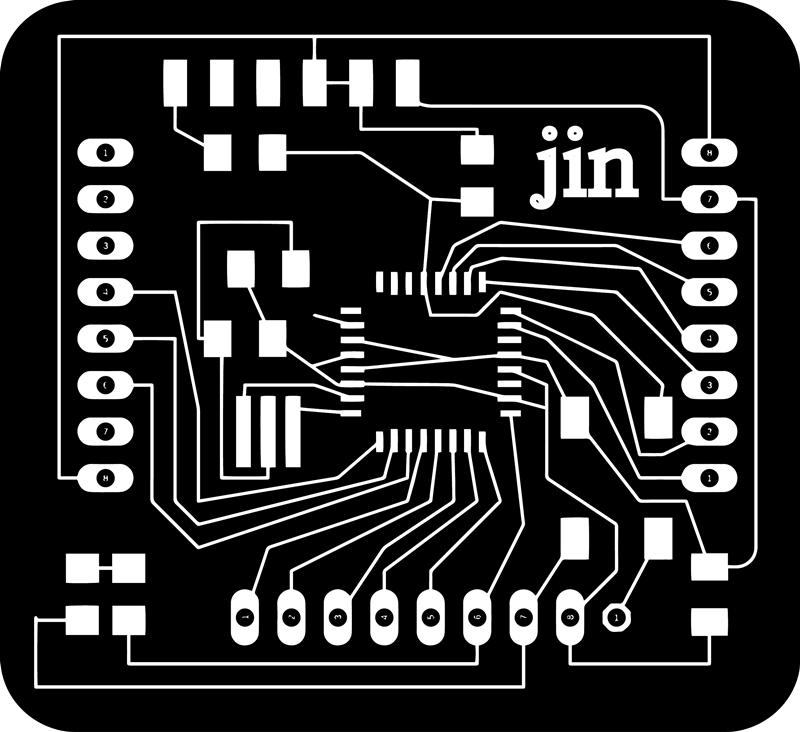

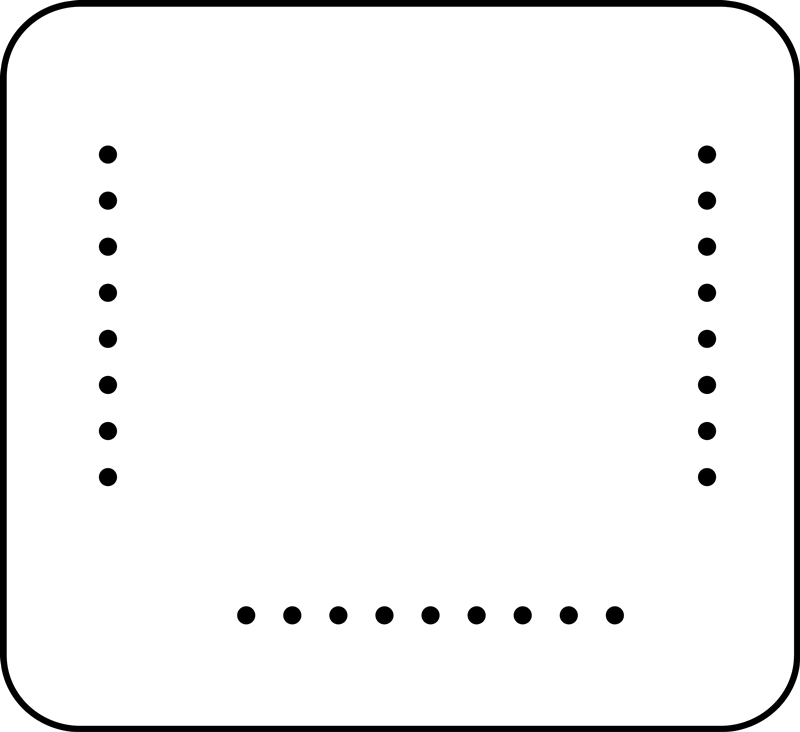

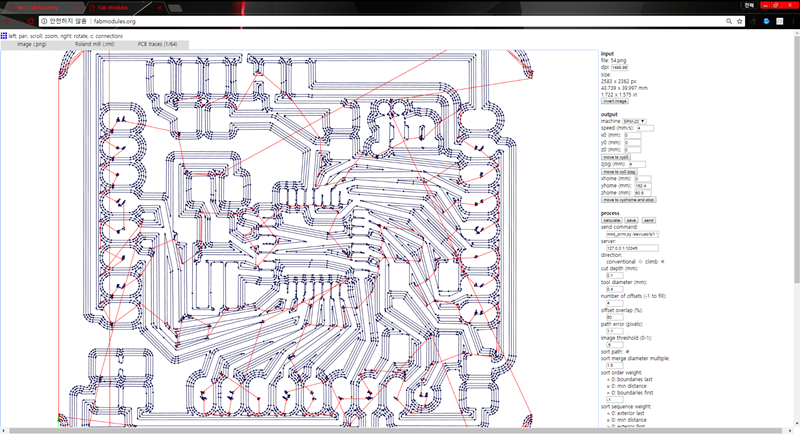

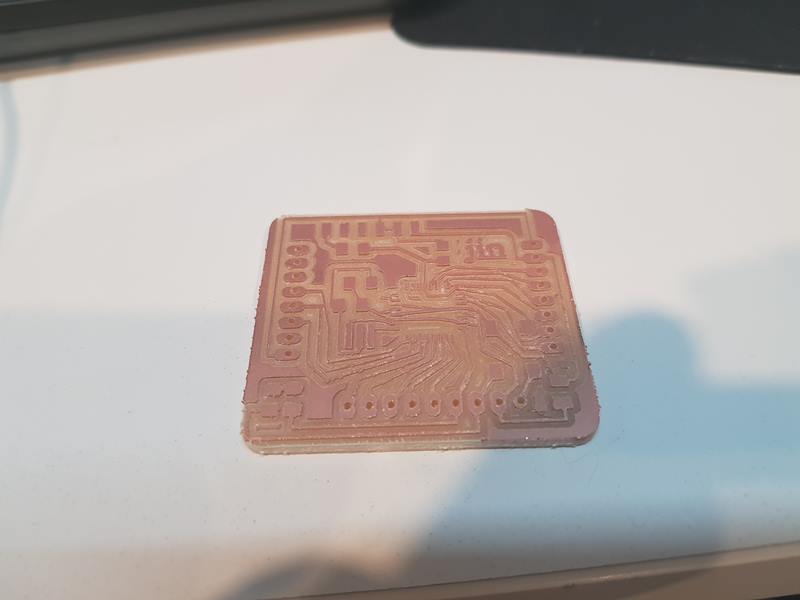

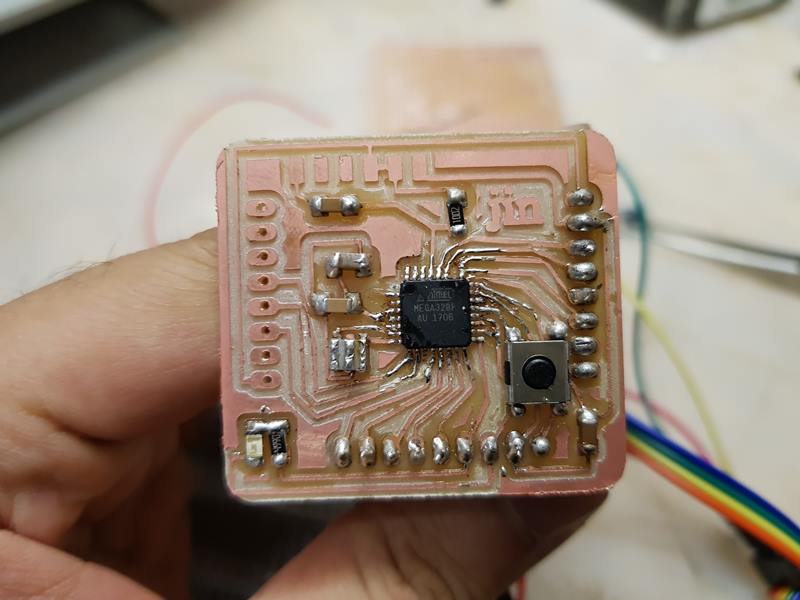

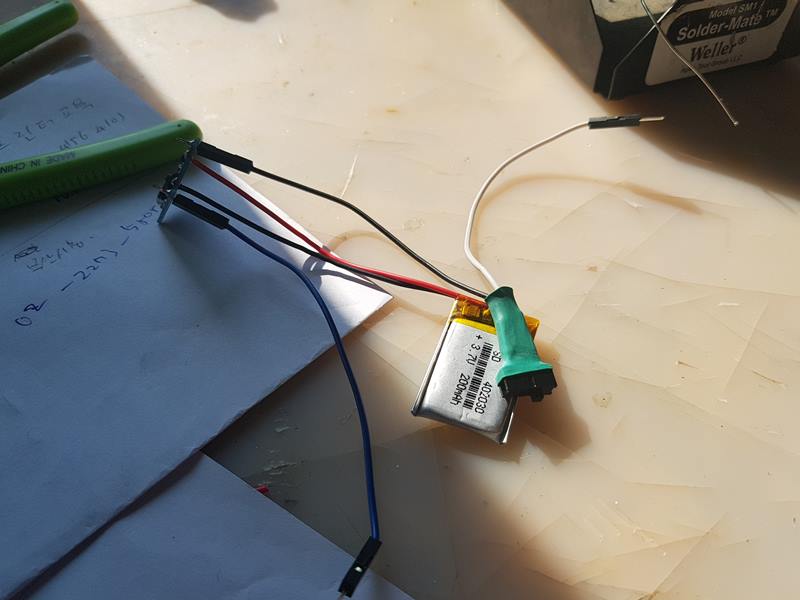

Making my CPR board (Electronics)

I decided to make a board that will operate the acceleration sensor and the Neopixels.

So I used the Atmaga 328 with the main parts. So I made my CPR board by referring to Fakit.

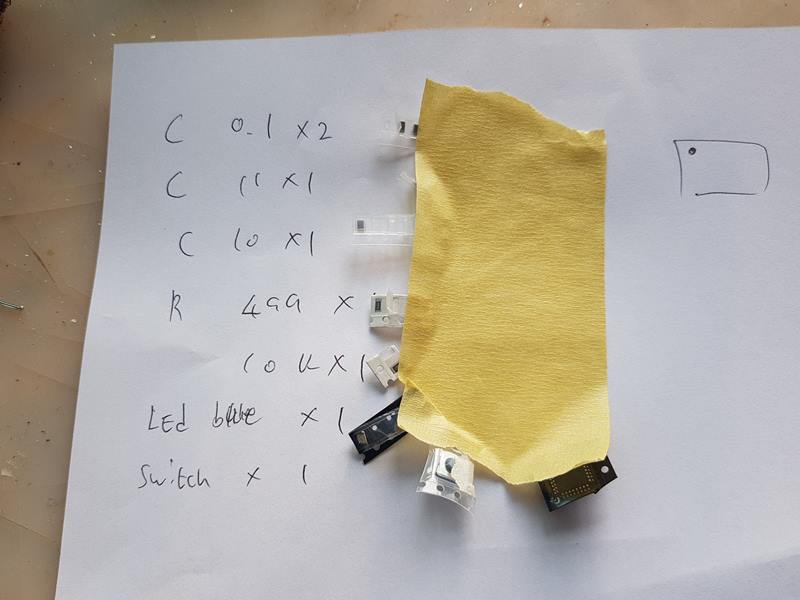

Component

Atmega 328

Crystal 8 MHz (resonator) 535-10004-1-1 ND

Capacitor 10. uF

Capacitor 0.1 uFx.2

Capacitor 1. uF

Resistor 10K

Resistor 499 ohm

Blue Led

Button SMD

It's working too well. I am so happy. I feel like I'm going to cry. It's good !!!

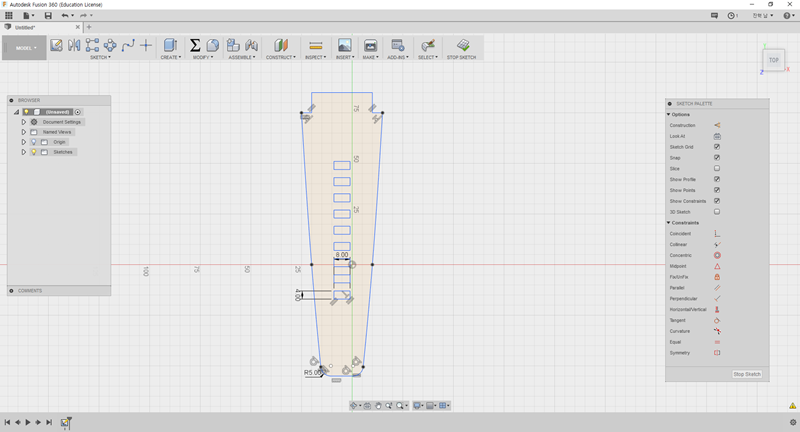

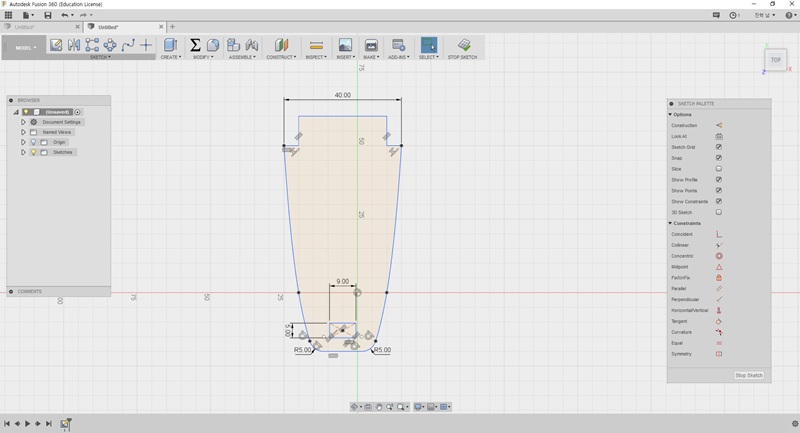

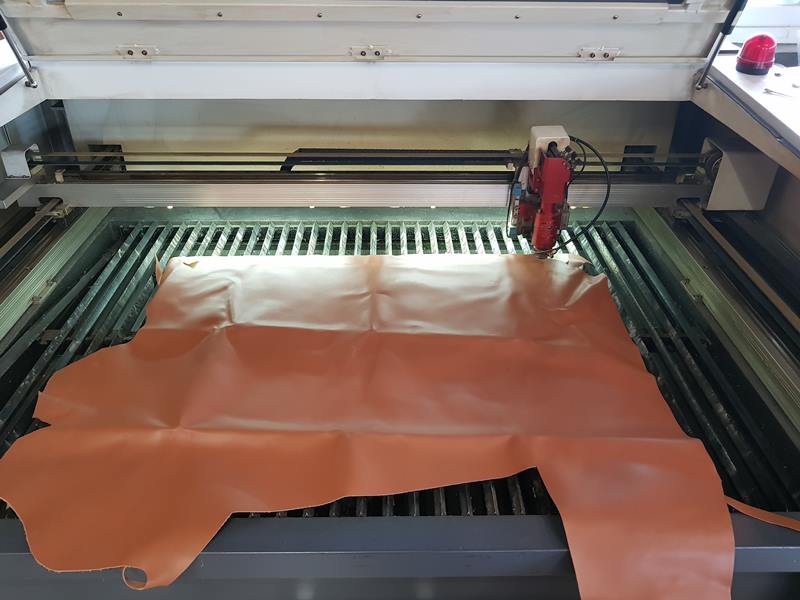

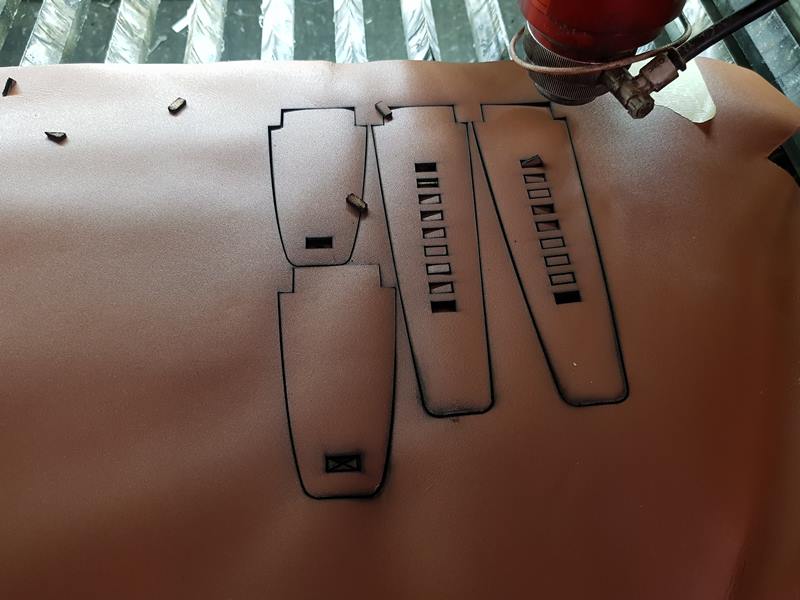

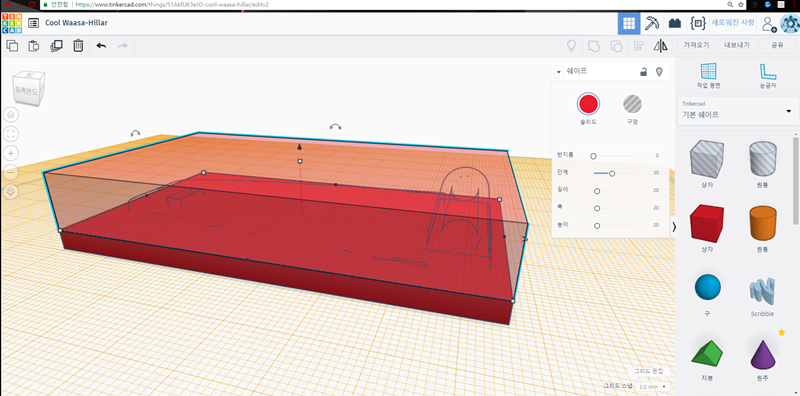

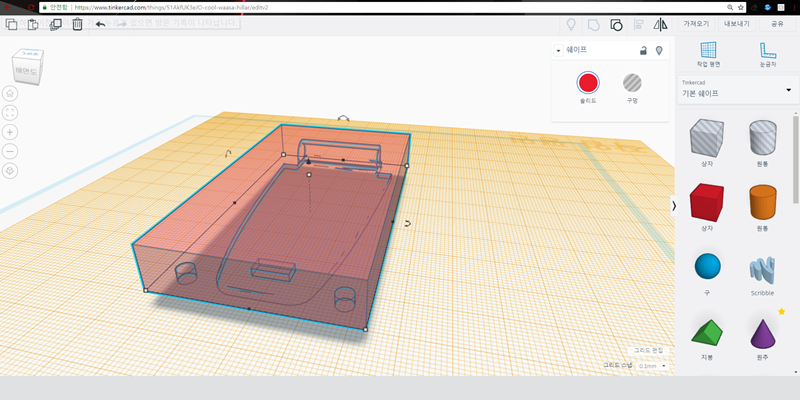

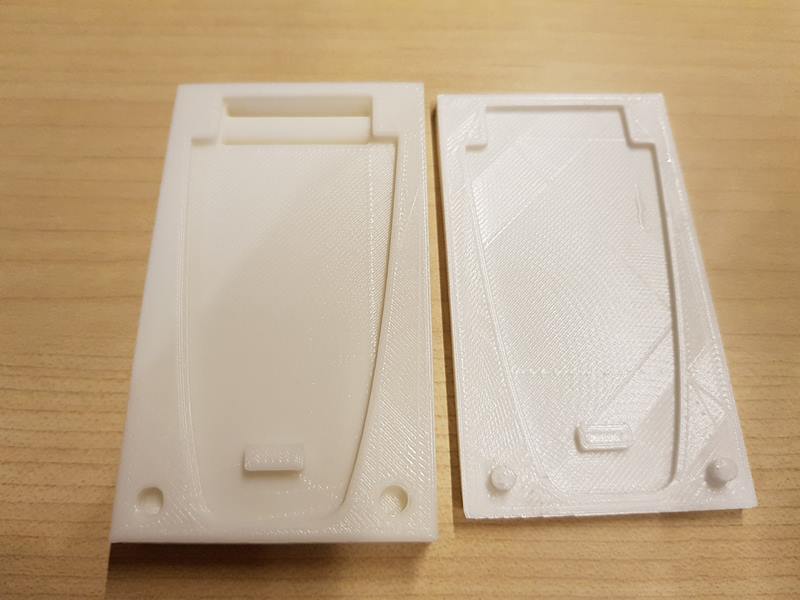

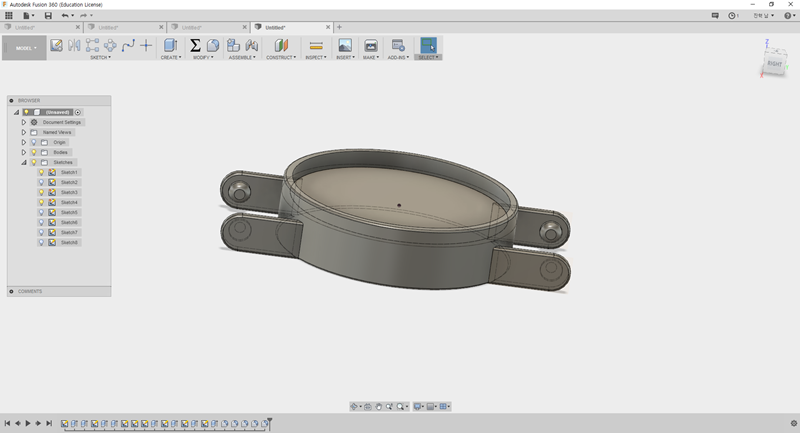

Making watchband (Molding and casting, Lasercutter)

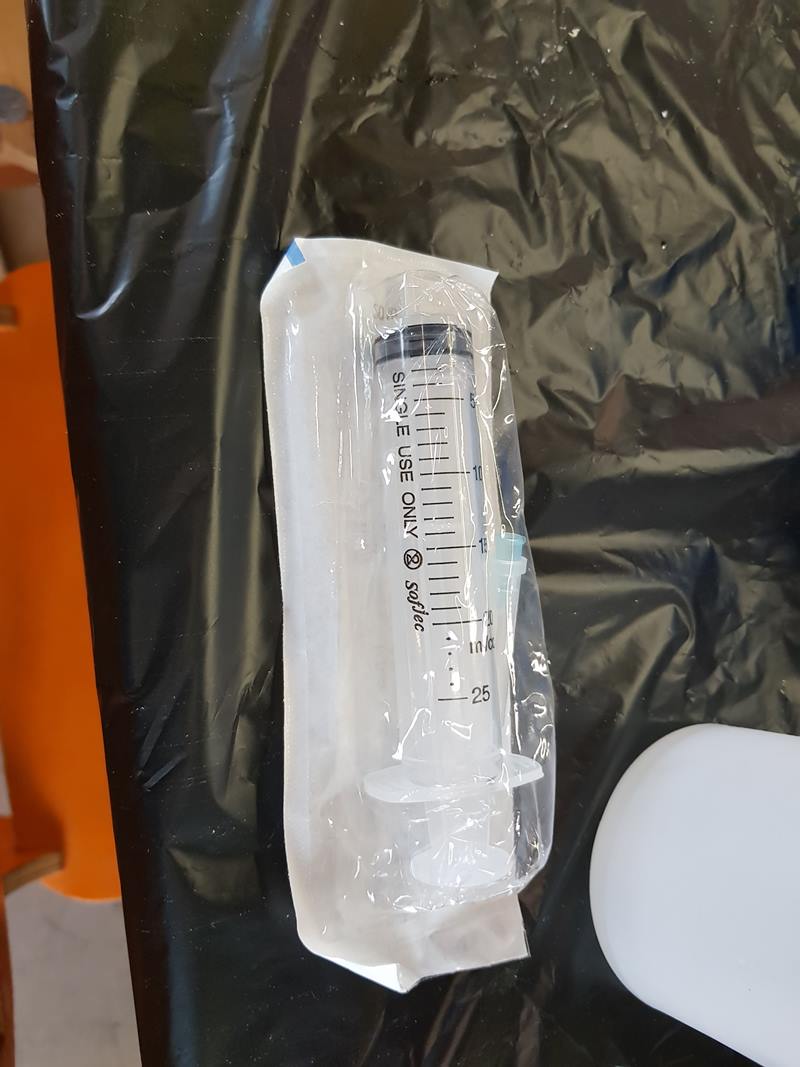

I've been thinking a lot about making a watchband. So I considered two ways. One is to create a molding with a 3D printer and then use Moldstar Fast 16 for casting.

And the other is cutting the leather with a lasercutter to make a leather watchband.

Becasuse the laser cutter can be affected by the stickiness of leather.

Speed : 30ms

Power : 60 % (150 w)

So I used an electric drill to make an entrance.

So I used masking tape to block the gap and left it open at the top.

Because there is a hole for air to come out as silicon enters.

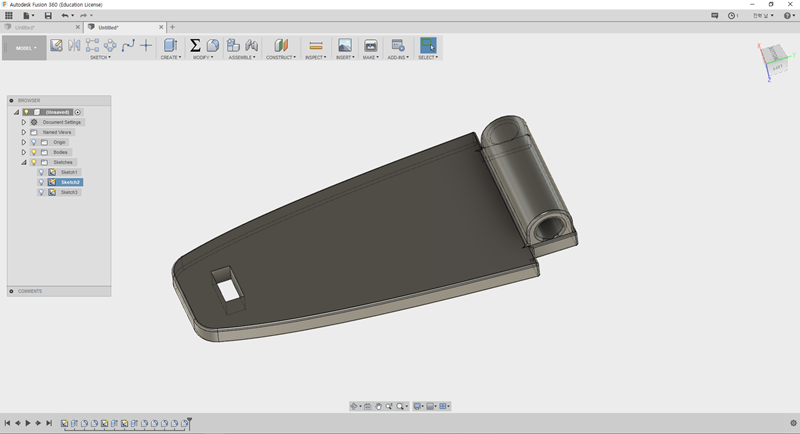

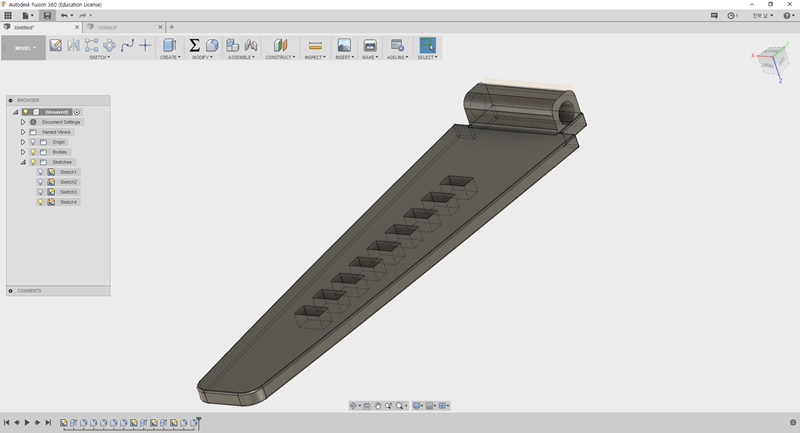

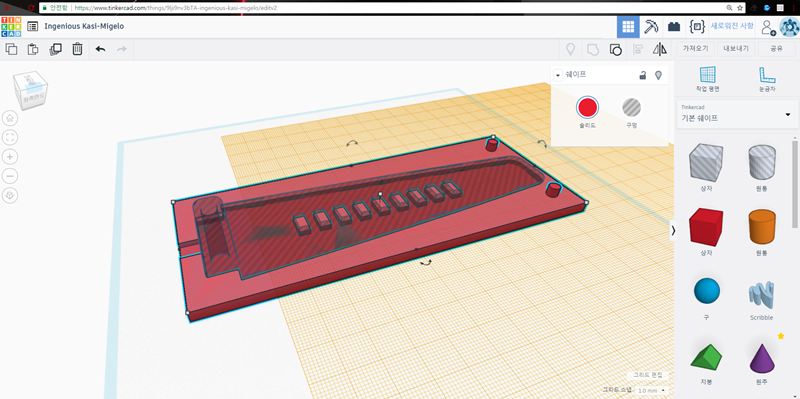

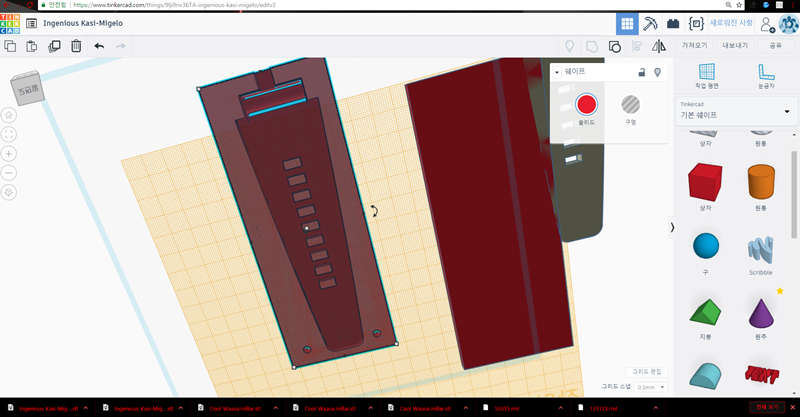

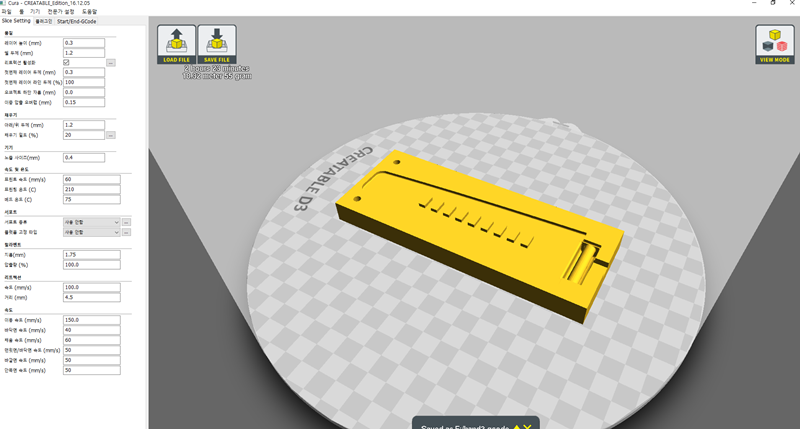

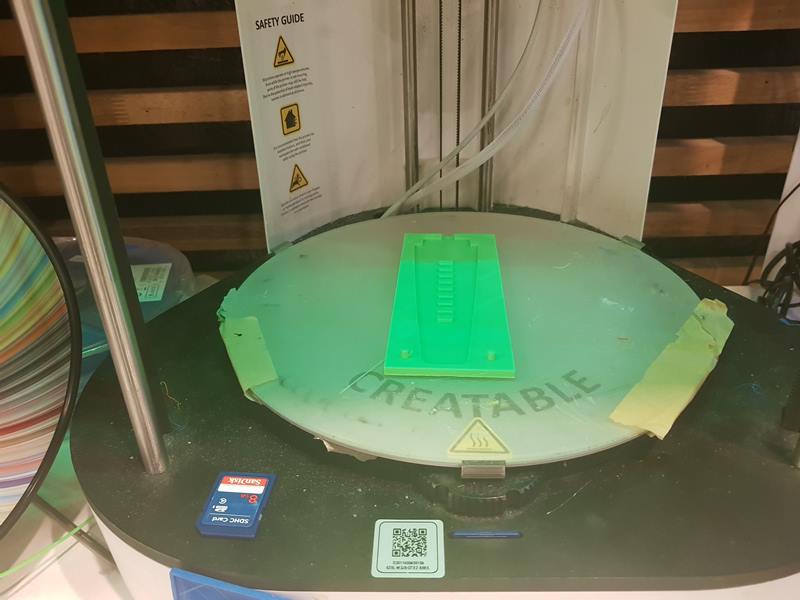

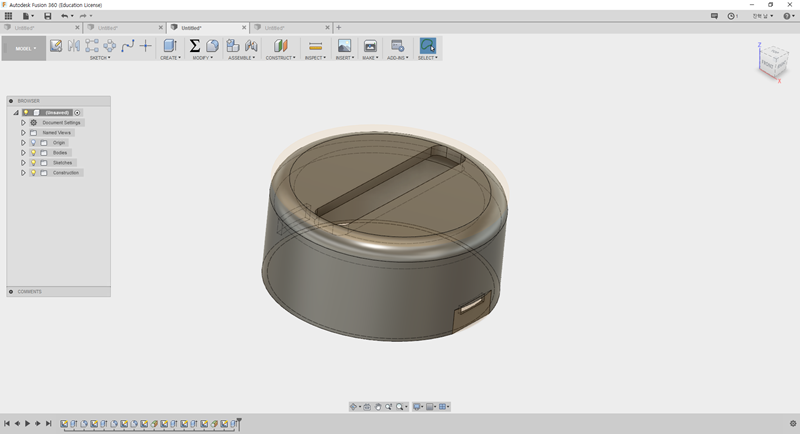

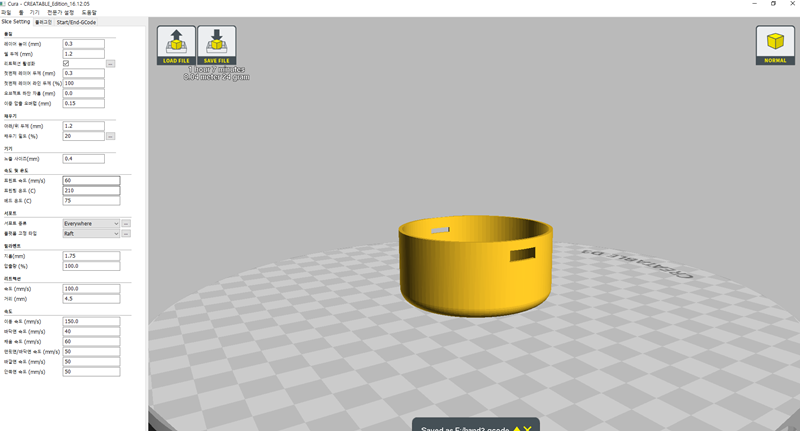

Making watch Appearance (3Dprinting, 3Dmodeling, CNC)

I designed the upper and lower appearannces of the watch as Fusion 360 through Fusion 360.

It is simple to remove as it covers from top to bottom. I made CPRband referring to the appearance of Samsung Galaxy Gear 3.

And I cut it in two ways : 3D printing and CNC wood.

Layer:1.5mm

Shell : 1.2mm

Infill : 20 %

Support : o

Raft : o

RPM : 1000

Feedrate : 100

Endmill:downcut 1F

Making My CPR band (Hot Set)

And the switch has three pins, so be sure to check.

I started with a good concept and finished well. I`m so happy. But there is still a lot to be desired.

I want to make the CPR band smaller and have more functions to save many people.

I hope many people will see the idea of this and think a lot about CPR and acute cardiac patient. Thank you.

-Download File-

cording librariescprboard desgin

cording source

3Dprinting stl file

3D modeling file

board image