Computer Numerical Control Machine Operator (CNC Machine Operator), Computer Numerical Control Machinist (CNC Machinist), Computer Numerical Control Operator (CNC Operator), Machinist

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manuaComputer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by cams alone.lly controlled by hand wheels or levers, or mechanically automated by cams alone.

Make something big

On this week i got chance of making something big. Because there is a customer how bring a job of making office furniture table.Here in Fablab Rwanda we make business. Actually i make that job at the same time as assignment.

Designing.

There a lot of tutorial.available for Onshape in Youtube, which is very usefull.

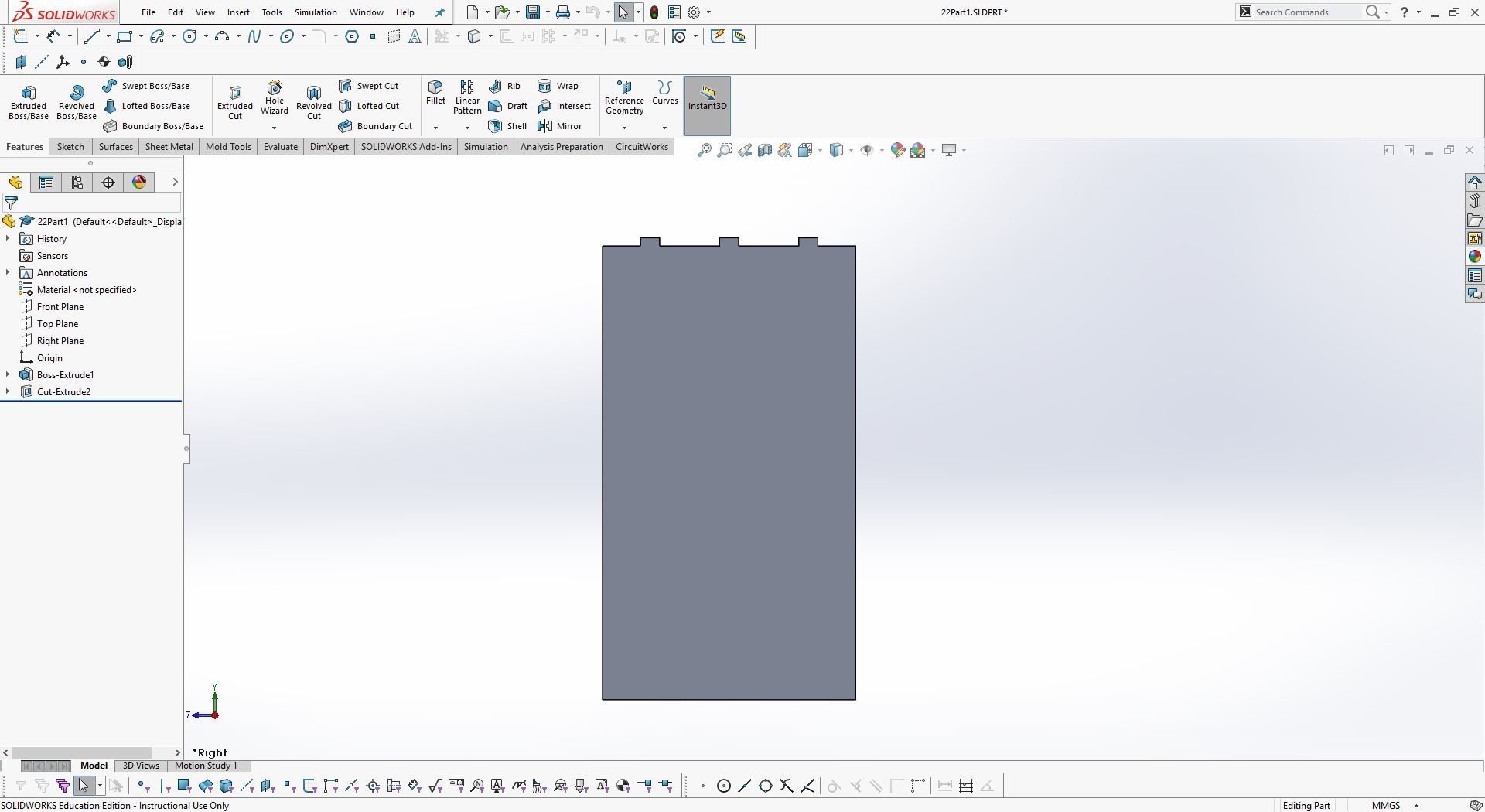

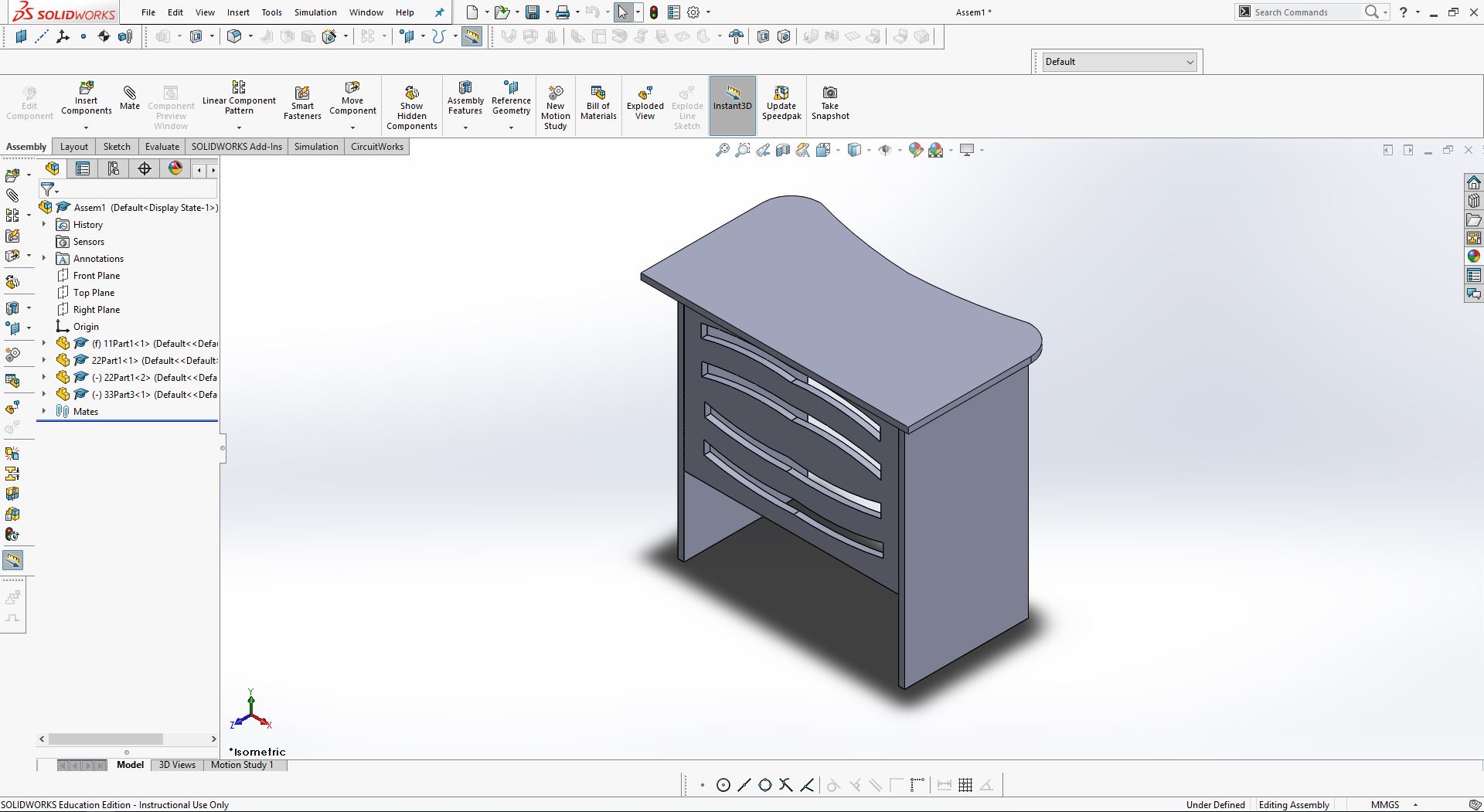

soldworks part 1.

side Extruded boss/base.

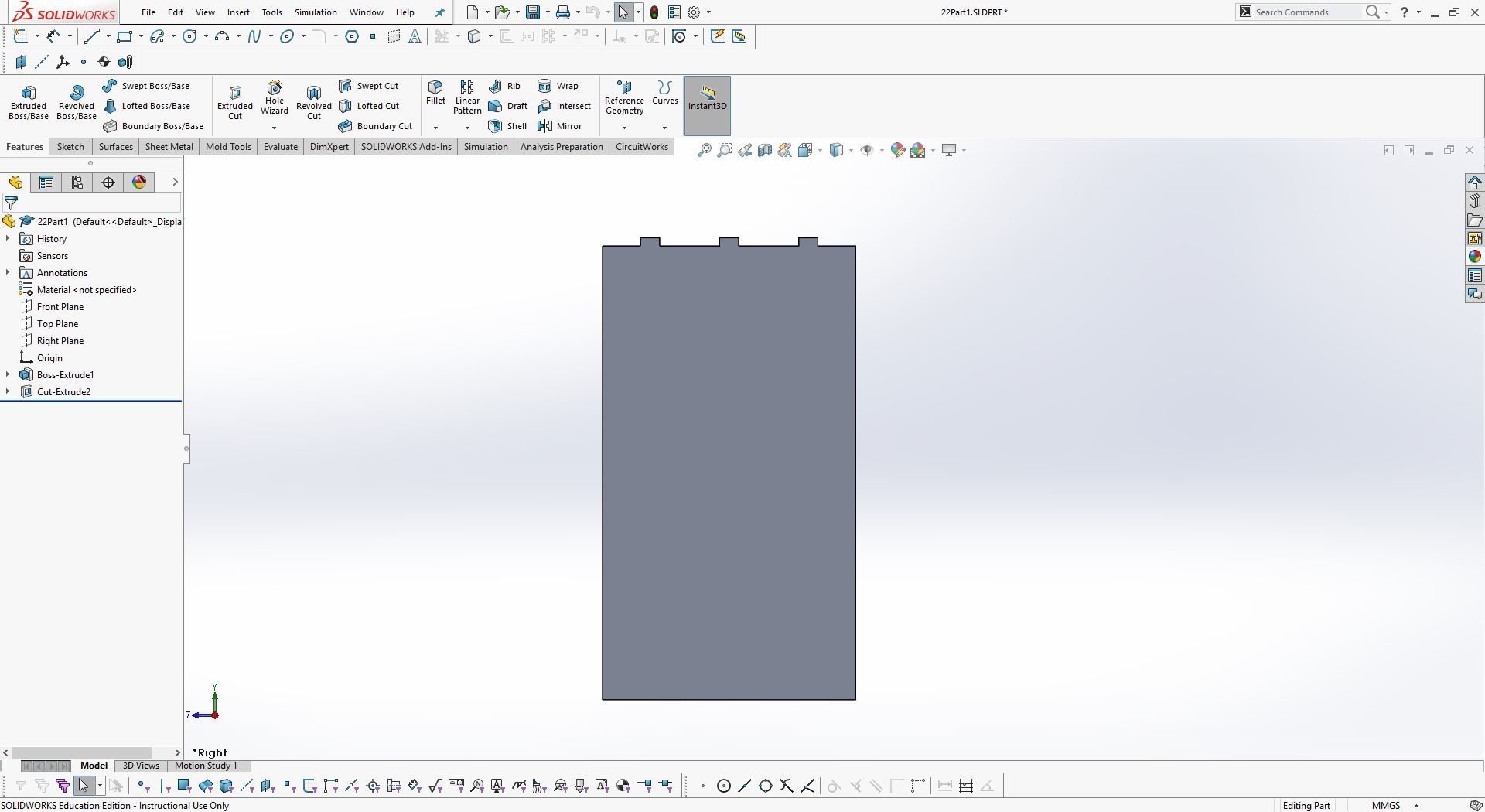

soldworks part 2.

Top extruded cut.

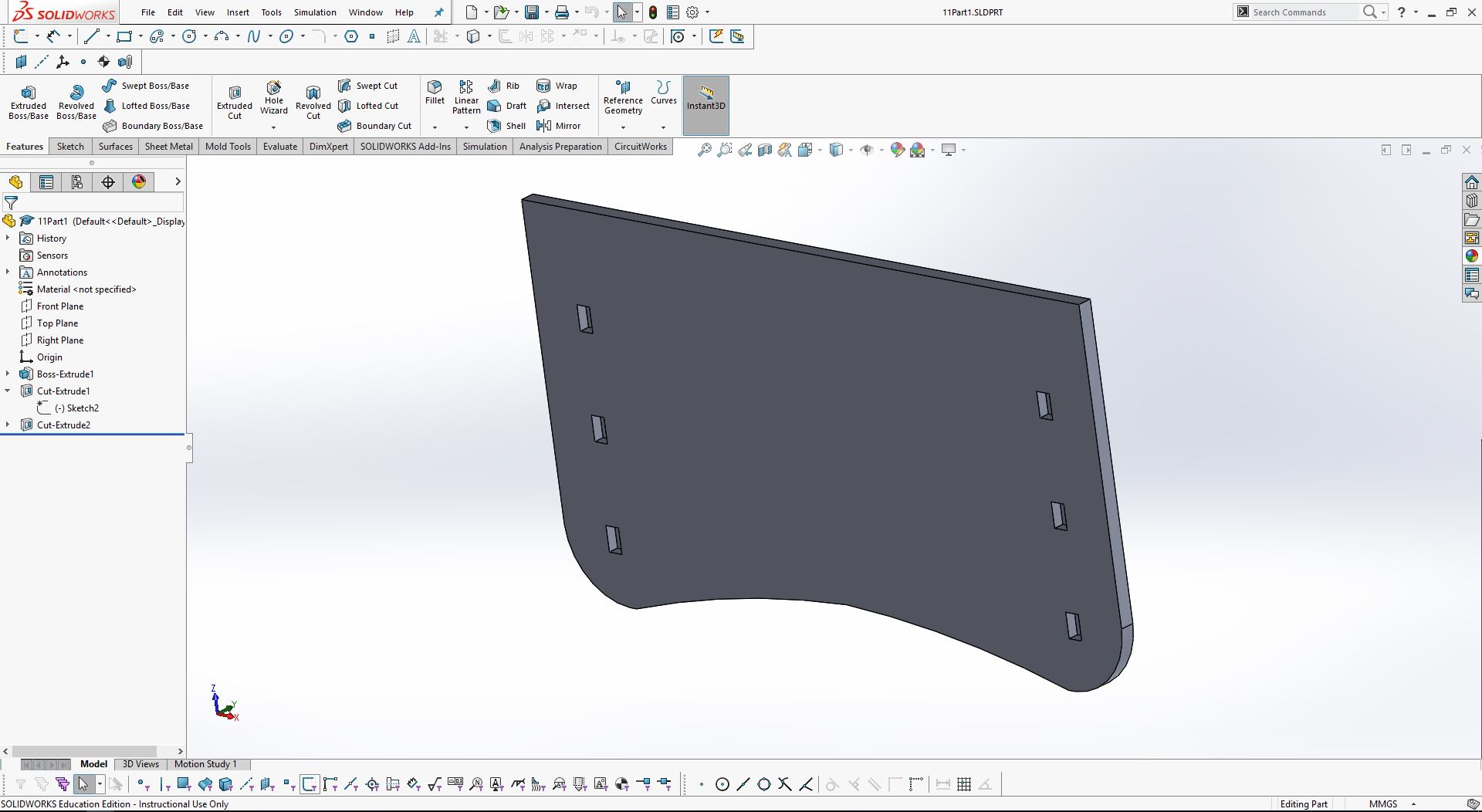

soldworks part 3.

front extruded cut.

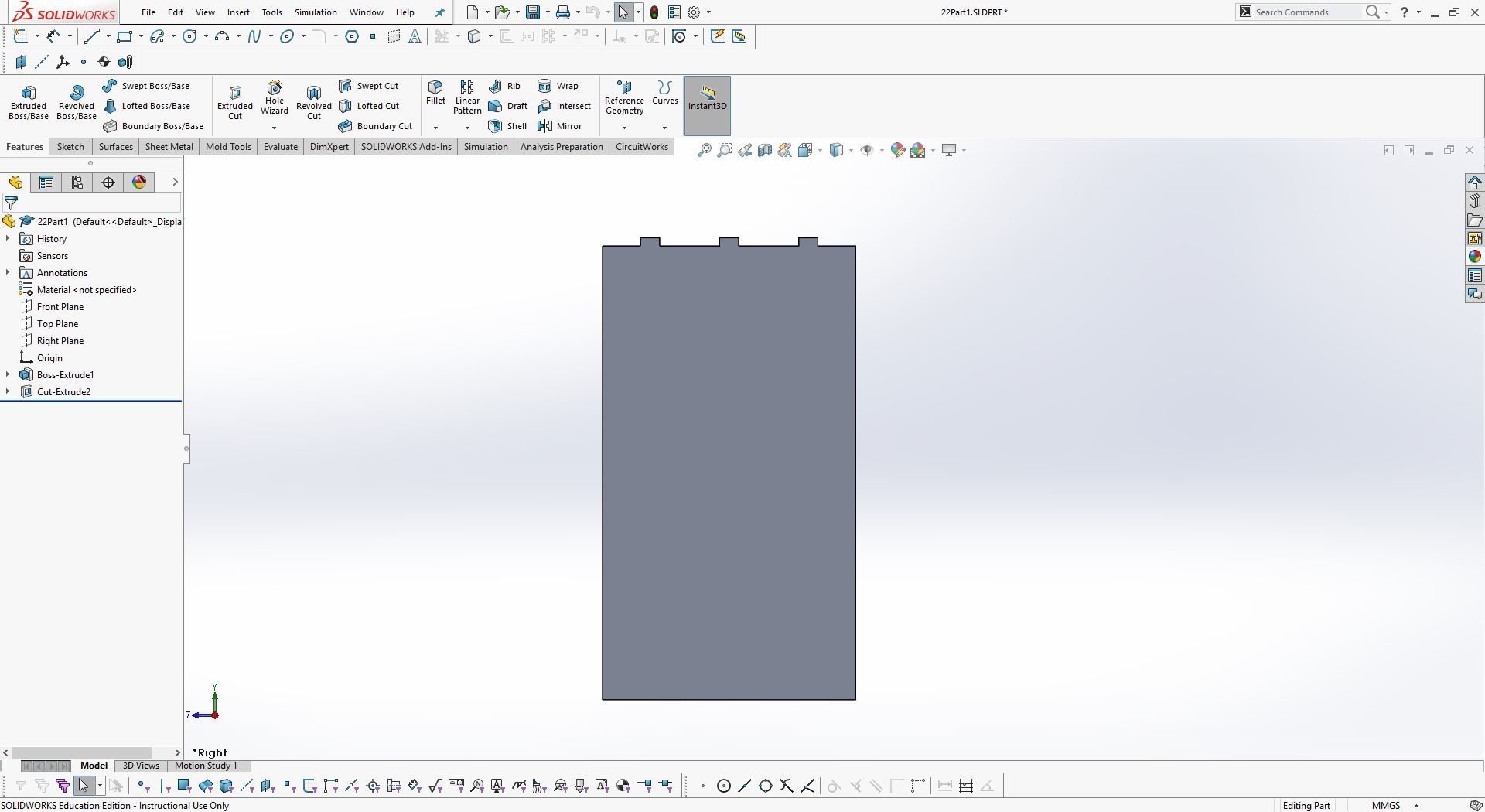

soldworks part 4.

Extruded side boss/base.

assembling all parts in soldworks.

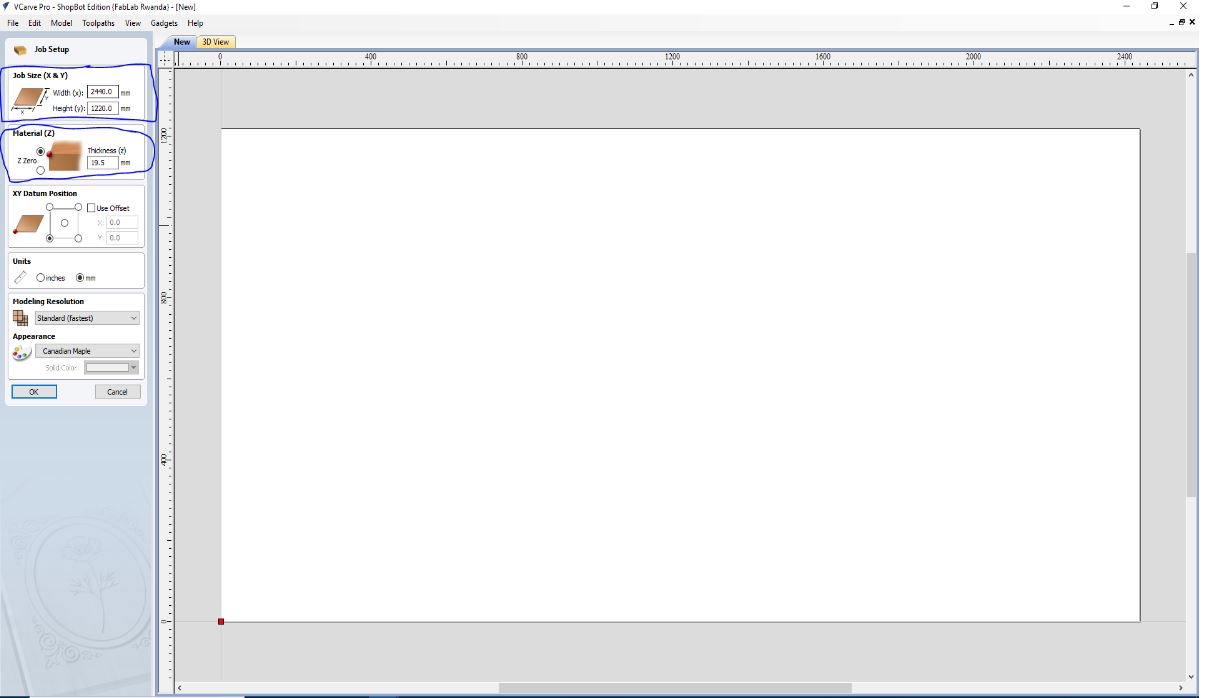

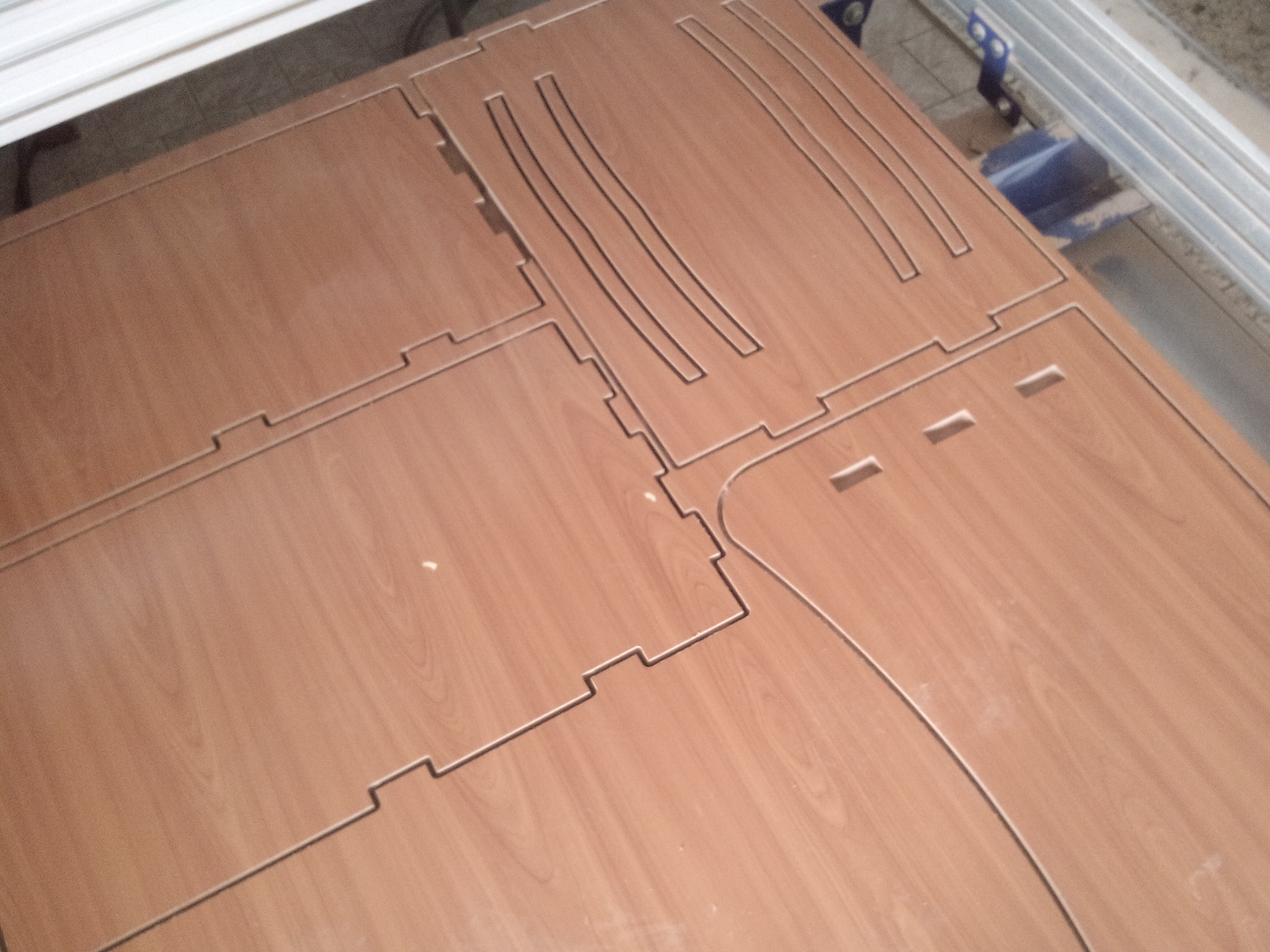

The CNC Router in our Fablab for cutting wood, plywood, etc is shopbot. It has a 8x4 Feet bed size. See our shopbot below:.

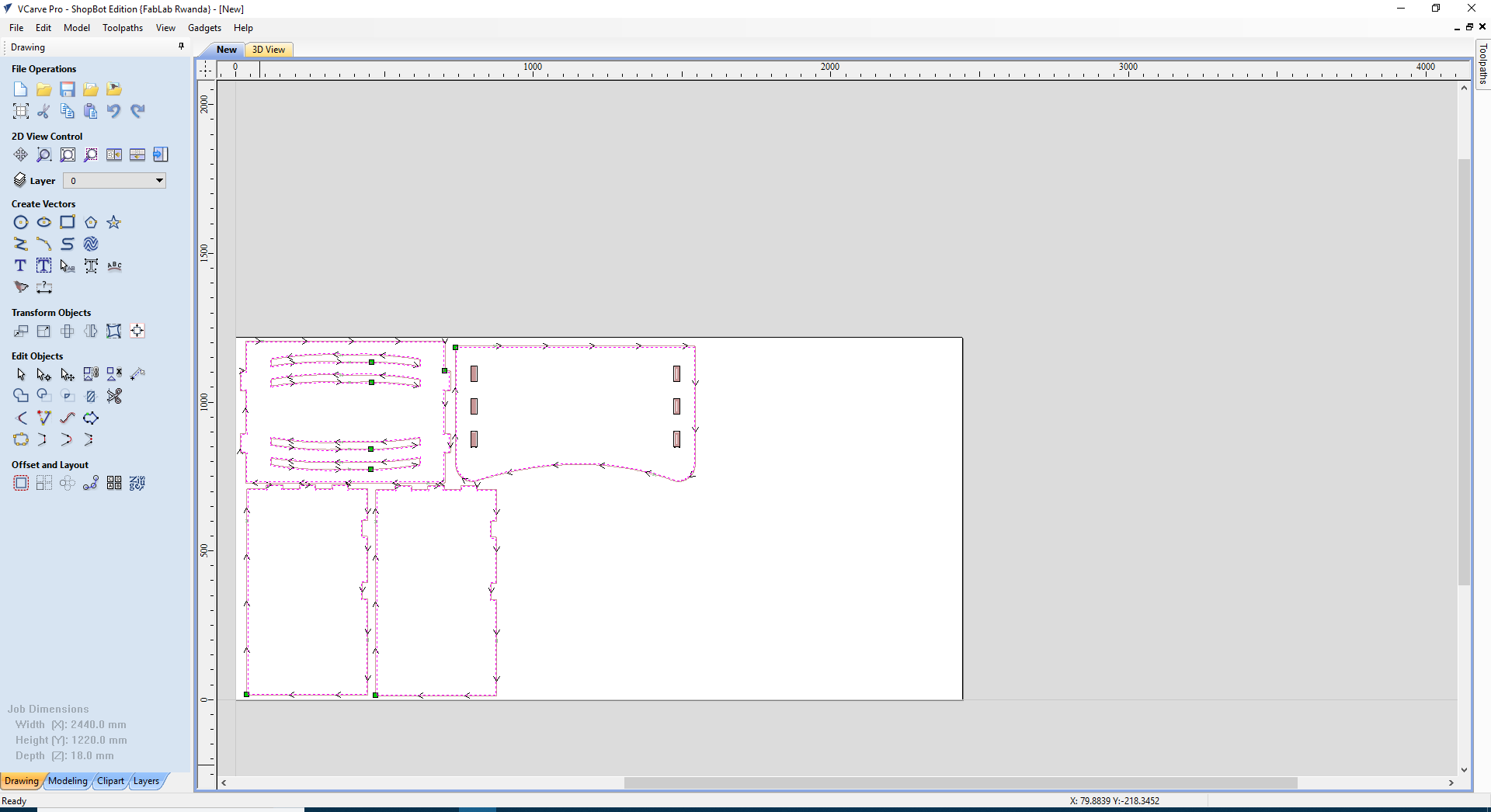

vcalve shopbot editor.

VCarve Pro V9.0 ShopBot Edition provides a powerful but intuitive software solution for cutting parts on a ShopBot CNC Router. There are tools for 2D design and calculation of 2D and 2.5D toolpaths and along with the ability to import and toolpath a single 3D model (STL, OBJ etc.). There is also support to import multiple Vectric Clip Art 3D models (V3M) to create 3D assemblies.

The software can import 2D designs from other programs but also provides a full set of drawing and editing tools.

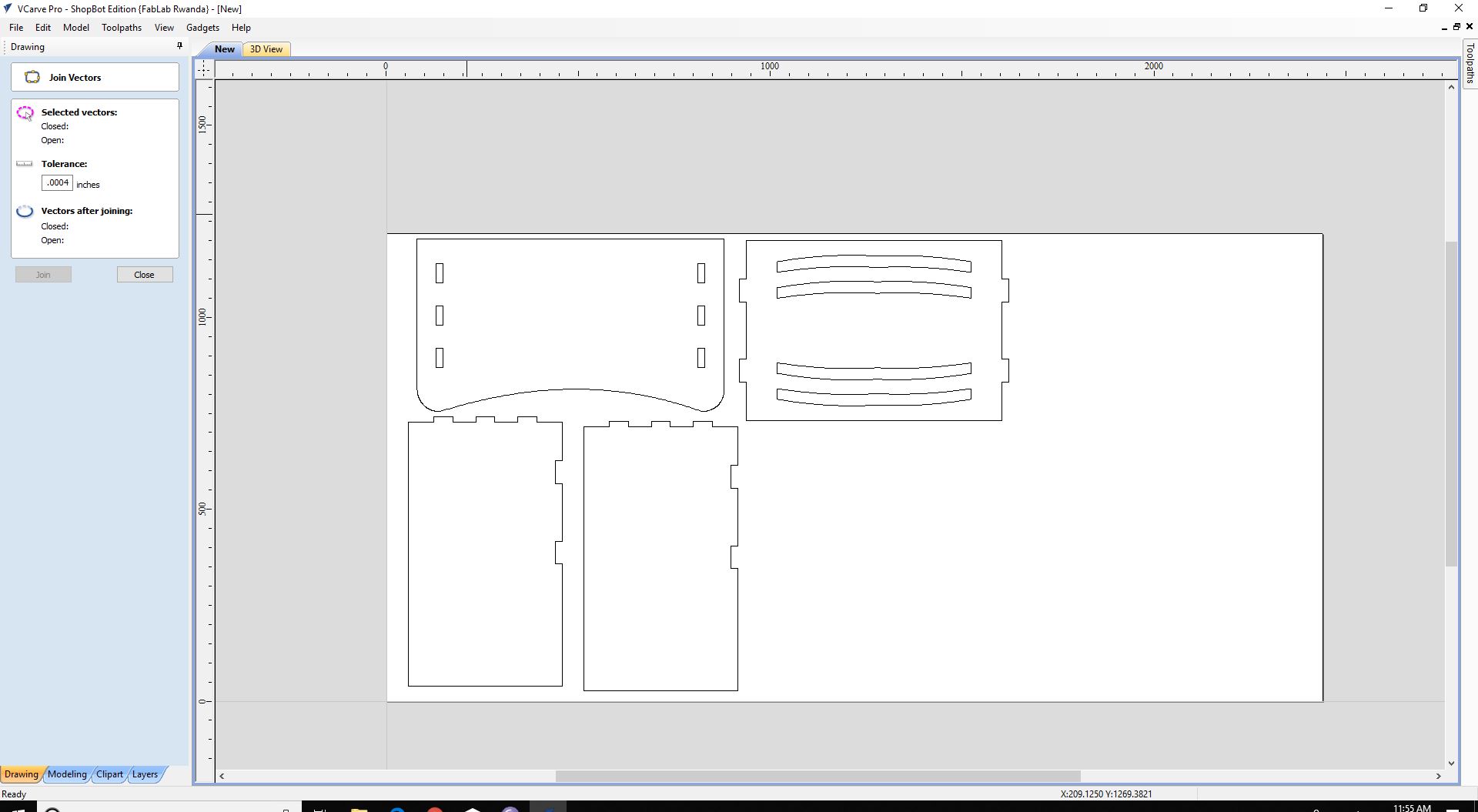

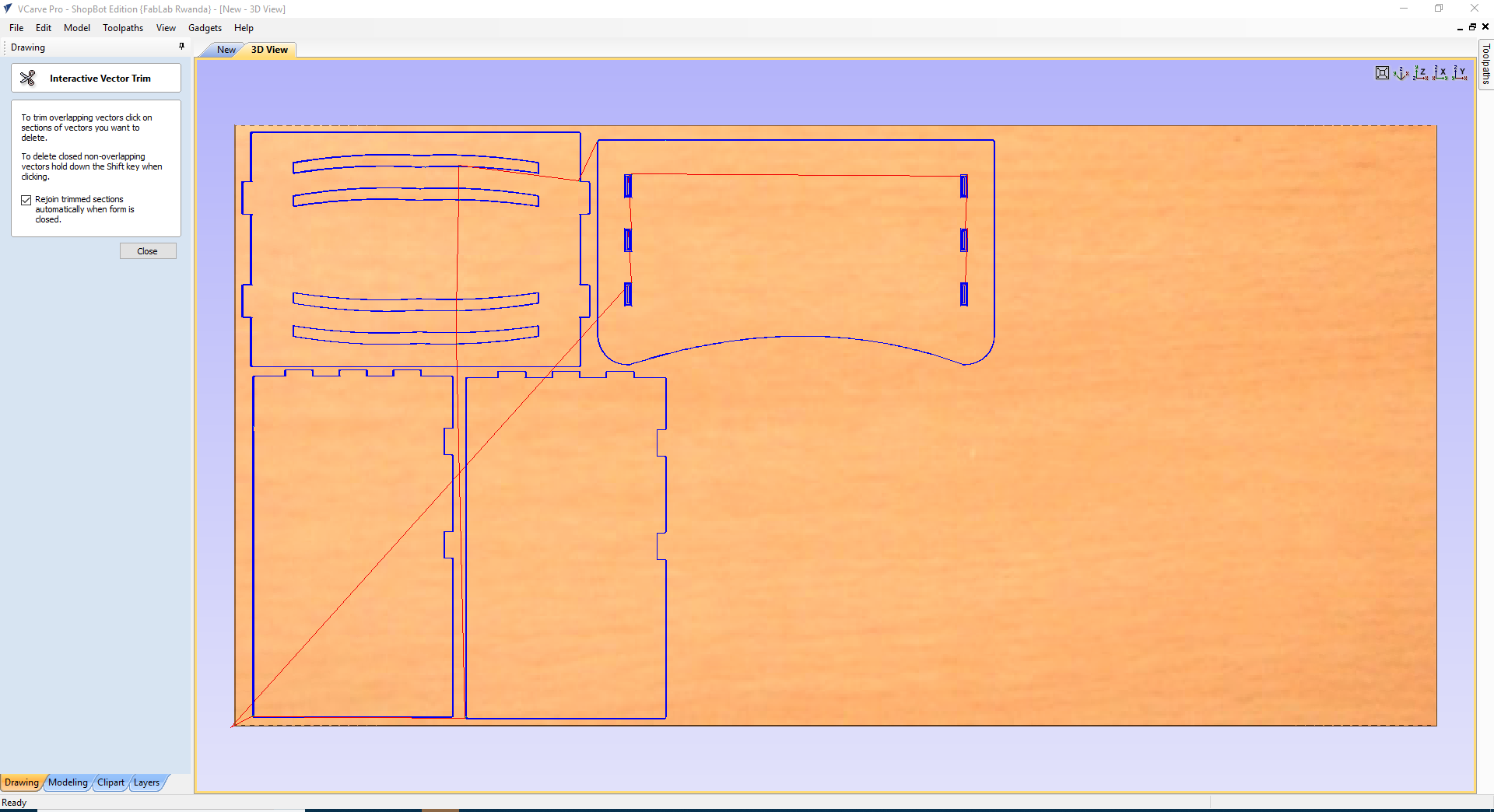

after joining all part DXF file.

Editting tabs in order to avoid bouncing of material.

After calcaluting all profile and pocket.

Switch of control box and display of speed.

Putting and adjusting material.

fixing material.

After adjusting all thing needed i cut all parts.as you seen on the following picture.