A symbol / label can be produced using a Vinyl Cutter such as a ‘Sticker Machine’ or a ‘Craftrobo’. These machines are controlled by a computer and operate similar to a printer. Essentially they cut out shapes in adhesive vinyl. The vinyl can then be stuck onto almost any surface. A vinyl cutter (or vinyl plotter) is a computer-controlled plotting device with a blade instead of a pen. A vector based design is created in a software program (usually Adobe Illustrator or Corel Draw) and then sent to the cutter where it cuts along the vector paths laid out in the design. The cutter is capable of moving the blade on an X and Y axis over the material, cutting it into any shape imaginable. Since the vinyl material comes in long rolls, projects with significant length like banners or billboards can be easily cut as well. The one major limitation with vinyl cutters is that they can only cut shapes from solid colours of vinyl. A design with multiple colours must have each colour cut separately and then layered on top of each other as it is applied to the substrate. Also, since the shapes are cut out of solid colours, photographs and gradients cannot be reproduced with a stand alone cutter.

vinly cutting.

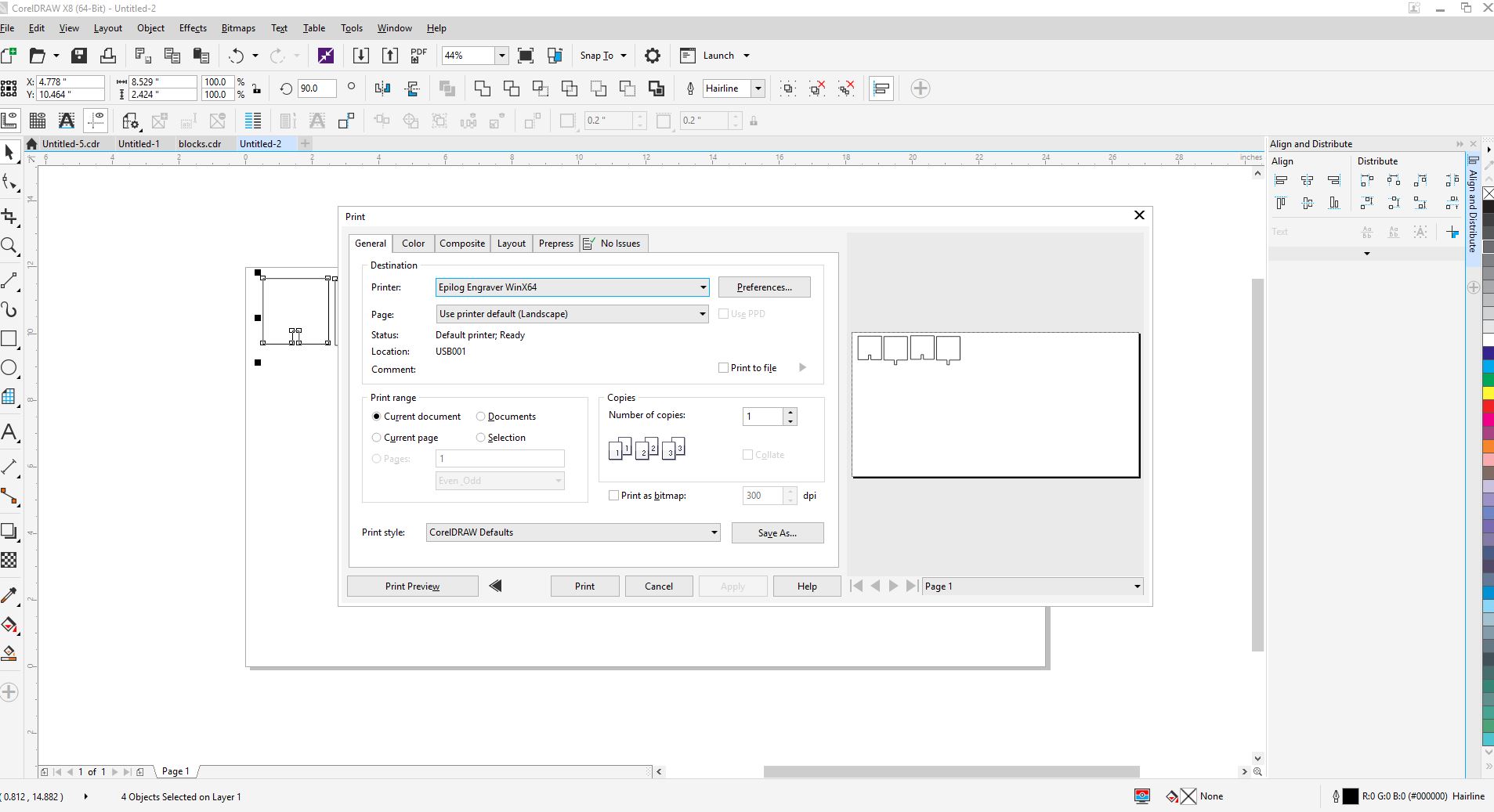

vinly cutter parameters.

Create your artwork.

Aside from simple fonts already in the Windows or Mac operating system, you can purchase additional fonts, or you can purchase artwork that is Vinyl Cutter Ready Vector Art such as the Mega Vector Art Collection.

Bring your artwork into a vinyl cutter cutting program.

Connect up your vinyl cutter.

Load your material.

Select and set up setup your blade.

Create a small line of text that you can send to the cutter.

Weed all the text you have cut.

Cut your artwork.

Remove your cut vinyl.

Weed your vinyl.

Apply transfer tape.

Prepare your target surface.

Apply your graphics.

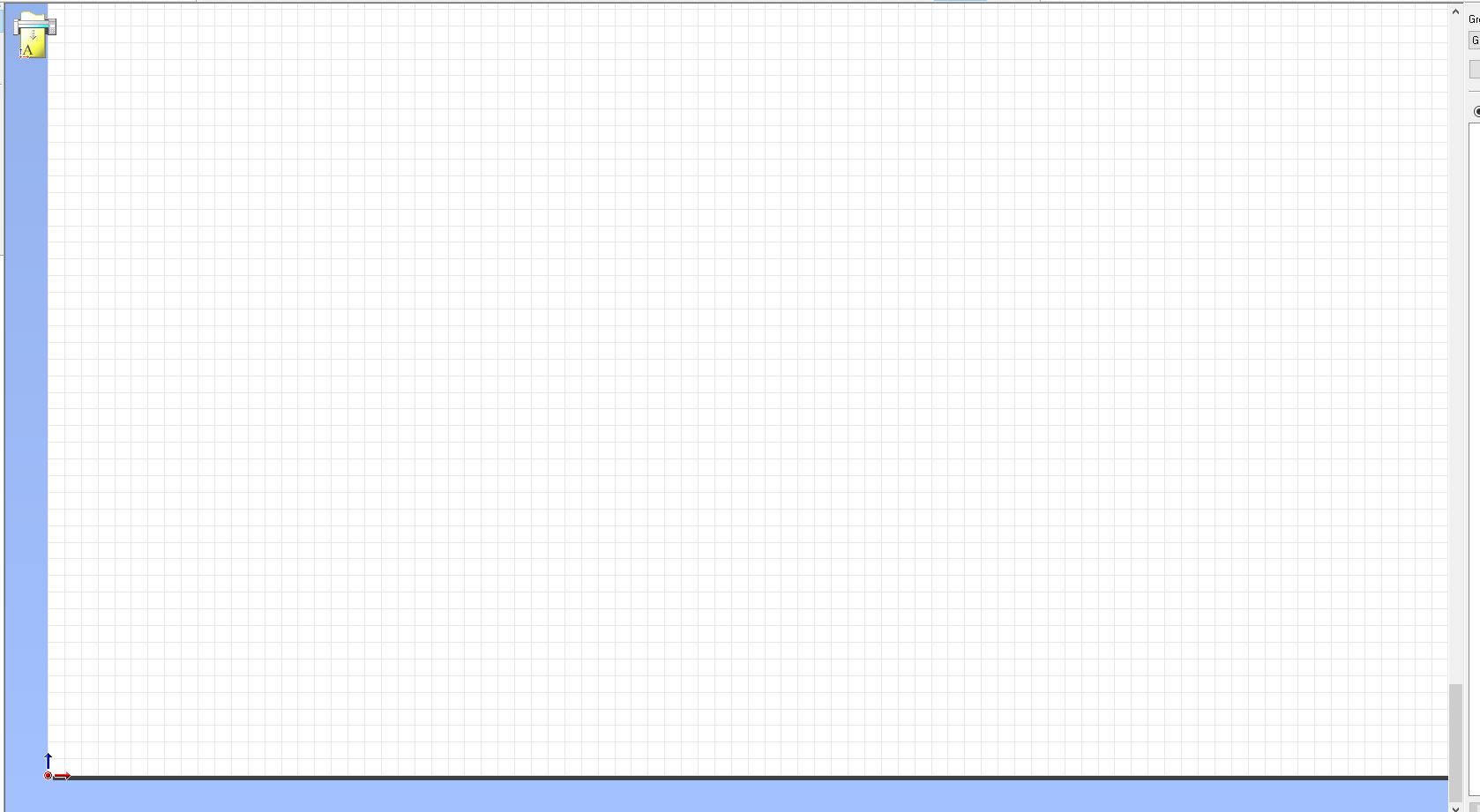

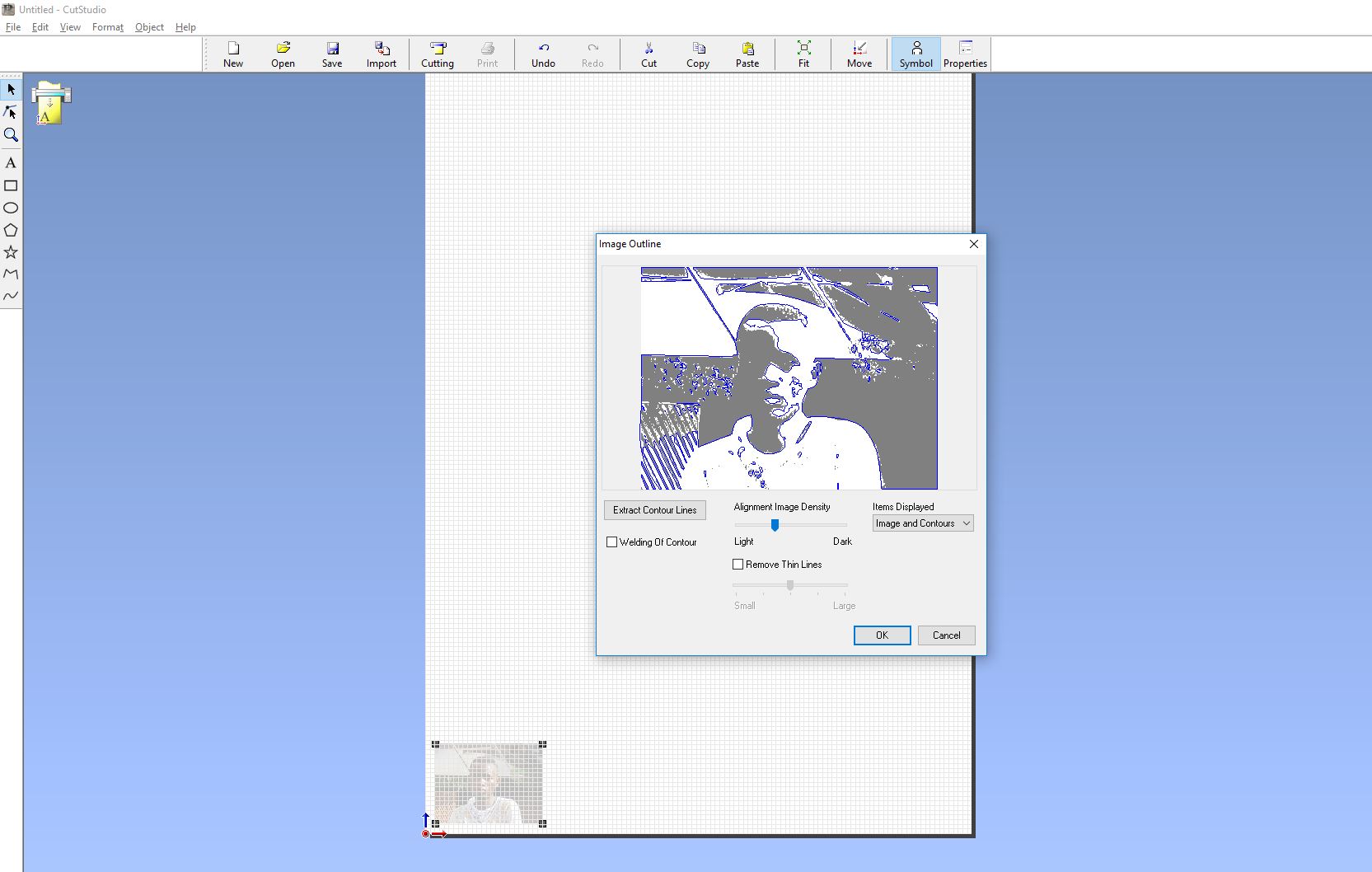

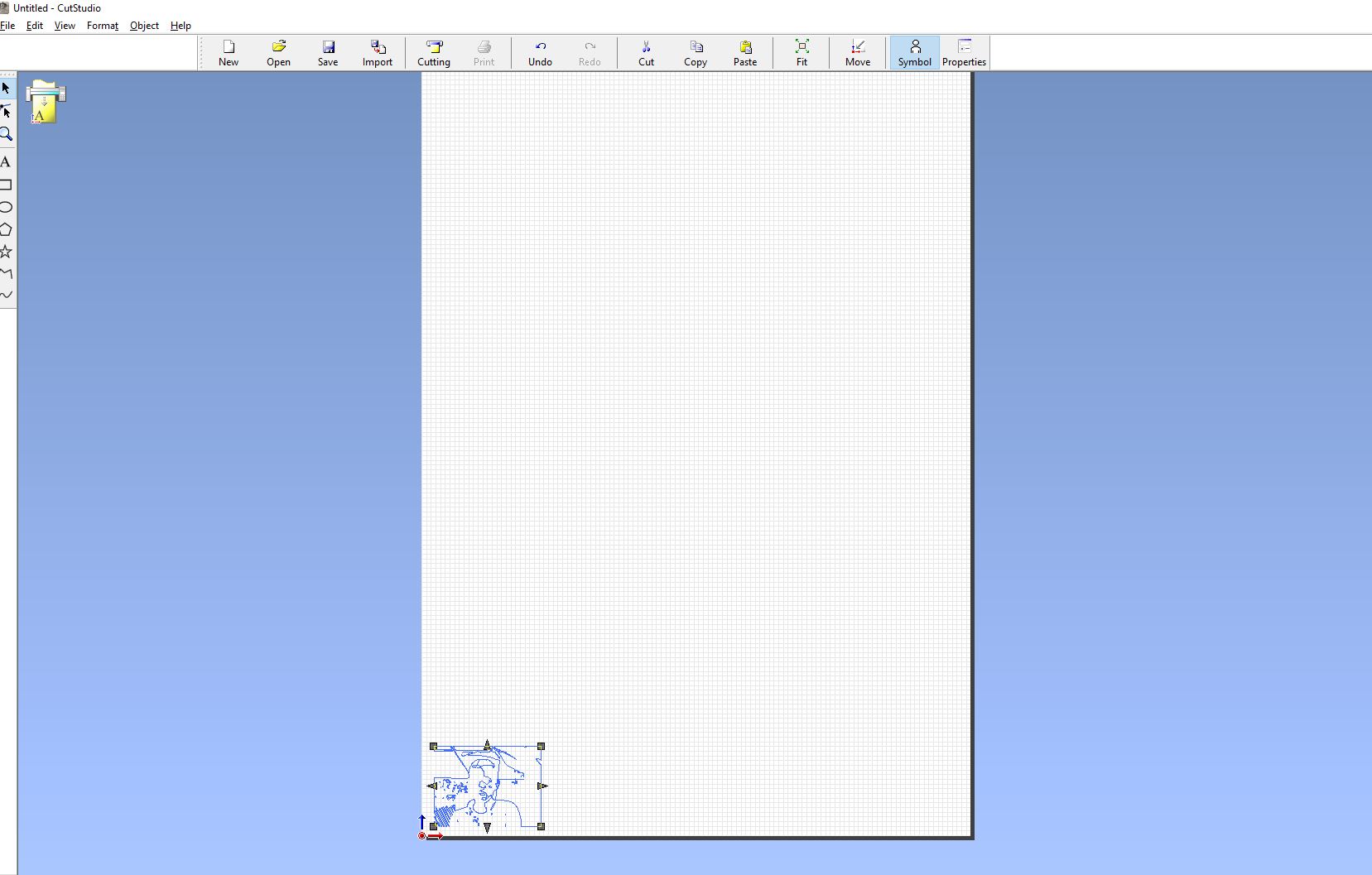

cut studio.

Roland’s powerful CutStudio software provides the necessary tools to design and create professional custom cut graphics for a wide range of applications. The Roland part RASD-CSWIN-01 is bundled with purchases of new CAMM-1 GR and Stika SV vinyl cutters. The software is compatible with all older Roland cutters.

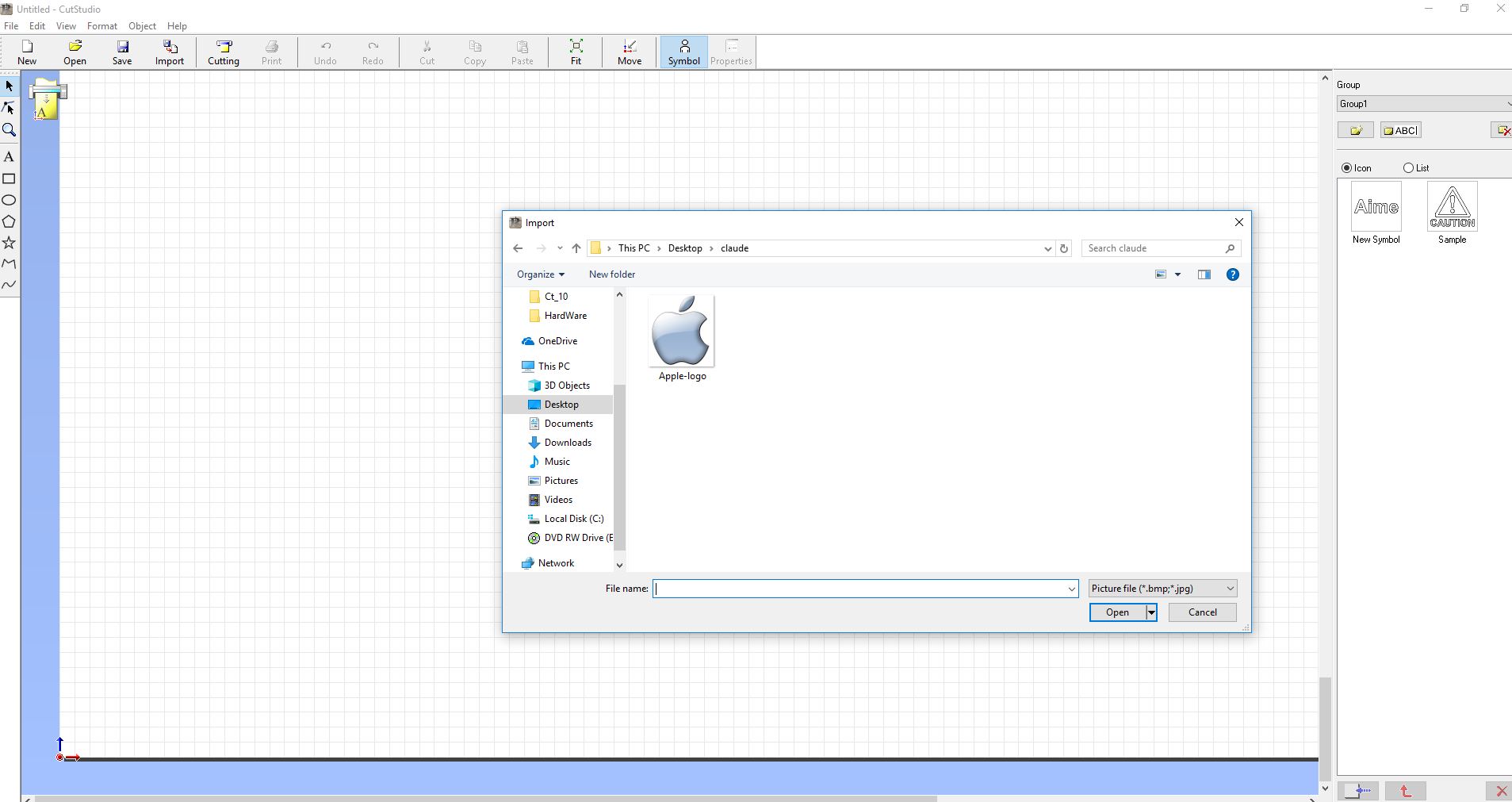

click to the button called import and to select the picture that you want to print.

import the picture that i want to print.

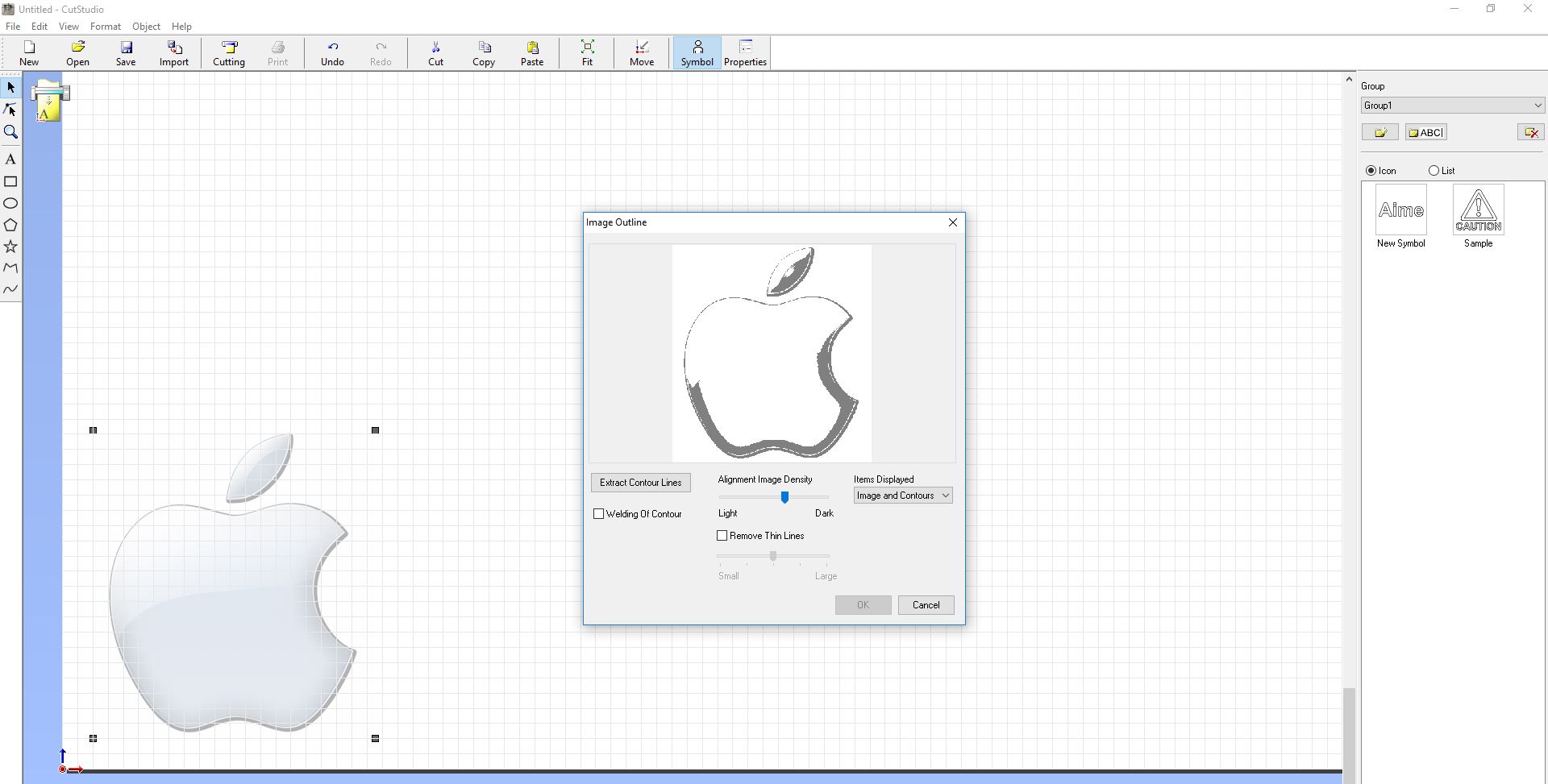

select the object button and click to image outline to convert that picture into the image.

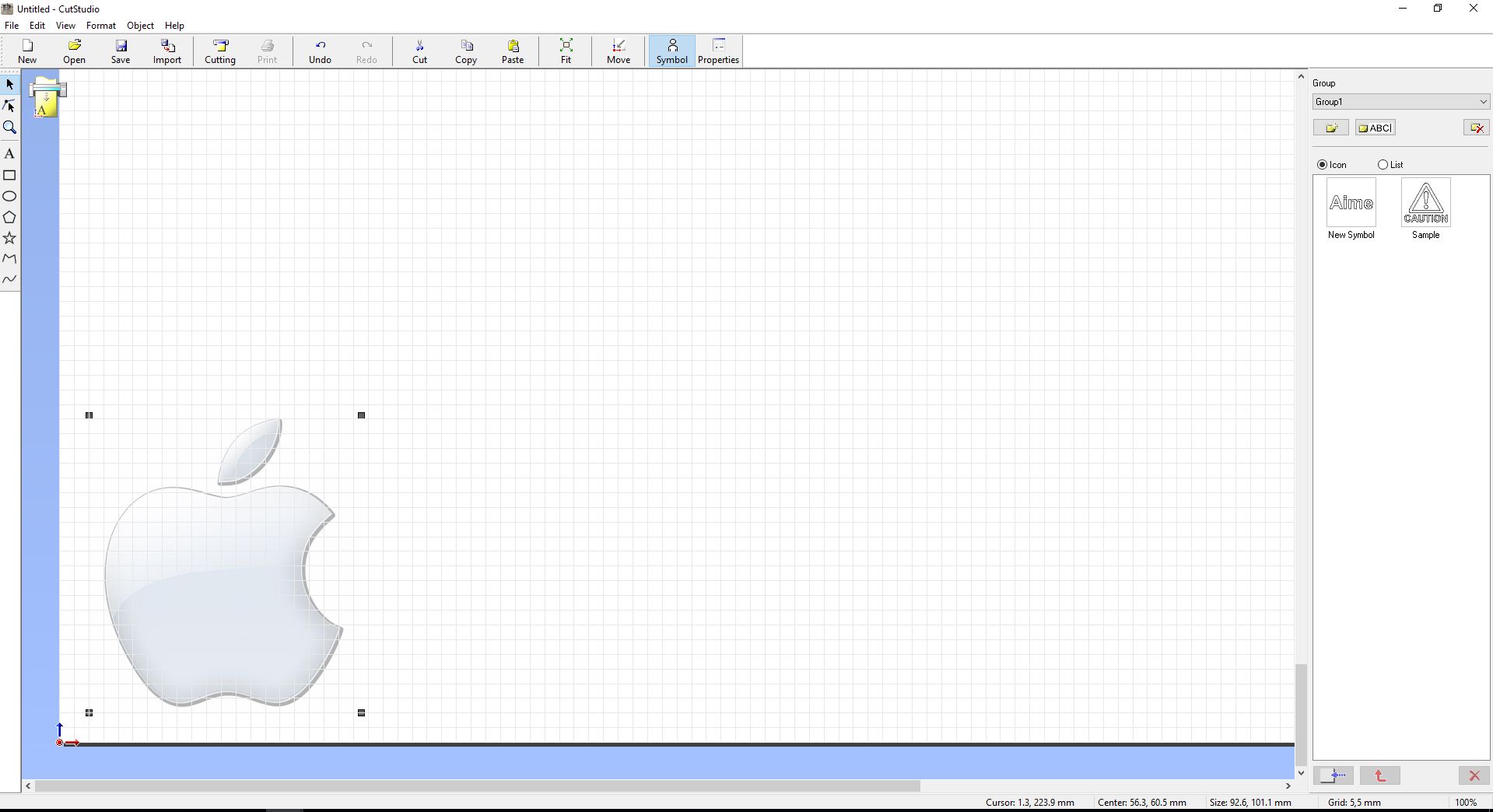

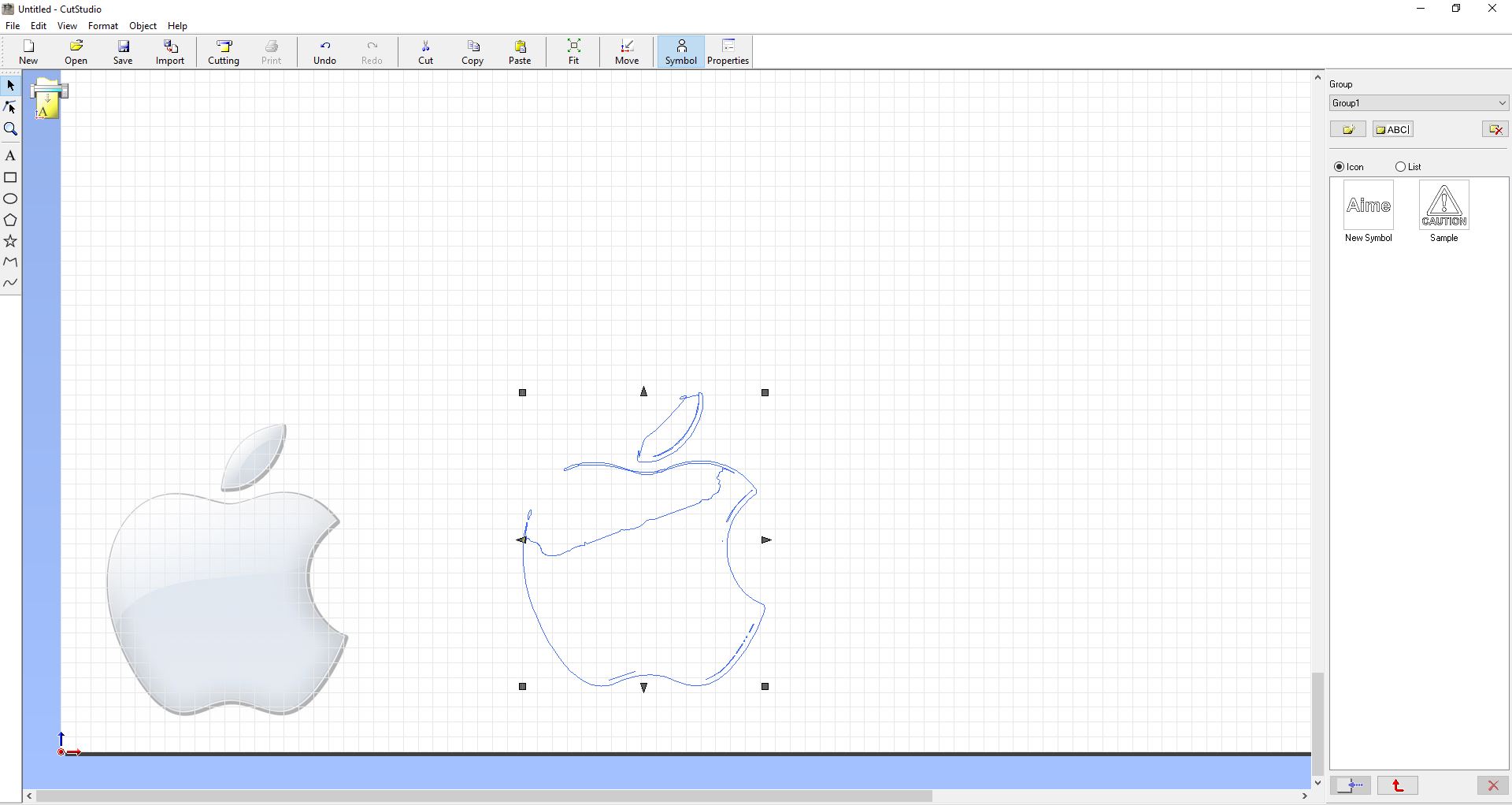

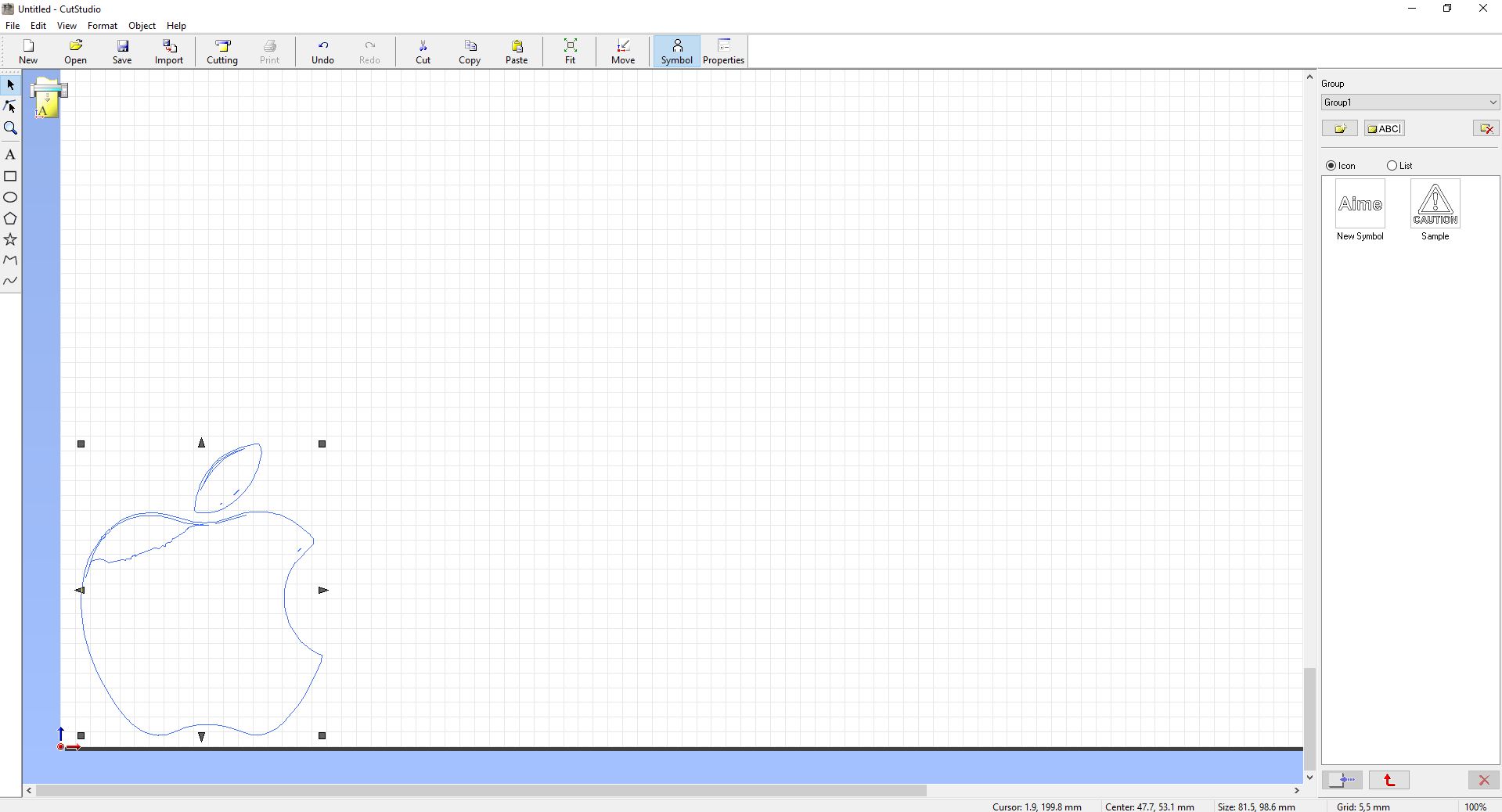

the final image that i want to print.

that are final image that are want to print in cutstidio click to the button called cutting and click OK to print.

in vinyl cutter i try to cut the logo of apple .

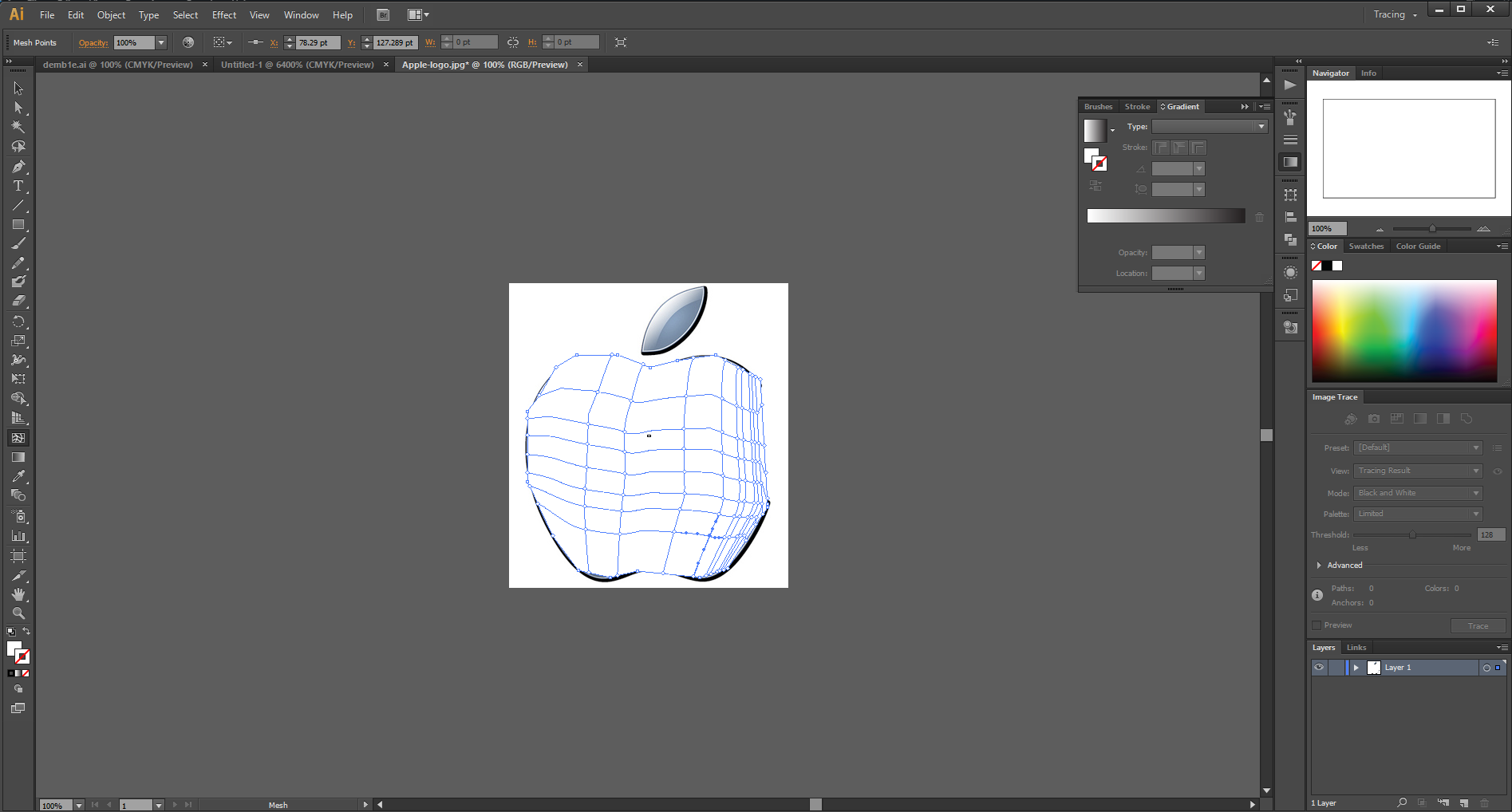

i try to design the logo of apple in illustrator software.

the second is laser cutter machine.

introduction.

laser cutter machine are the machine cutting the image in trees and plastic by using the laser that is laser cutter machine that is so goodThe assignement for this week was to make a press fit kit using laser cutter Laser cutting .is a technology that uses a laser to cut materials. The Laser cutter we use here is Trotec Speedy 100 The first step for making the press kit is the Design.

the picture of laser cutter machine that i have in fab lab Rwanda

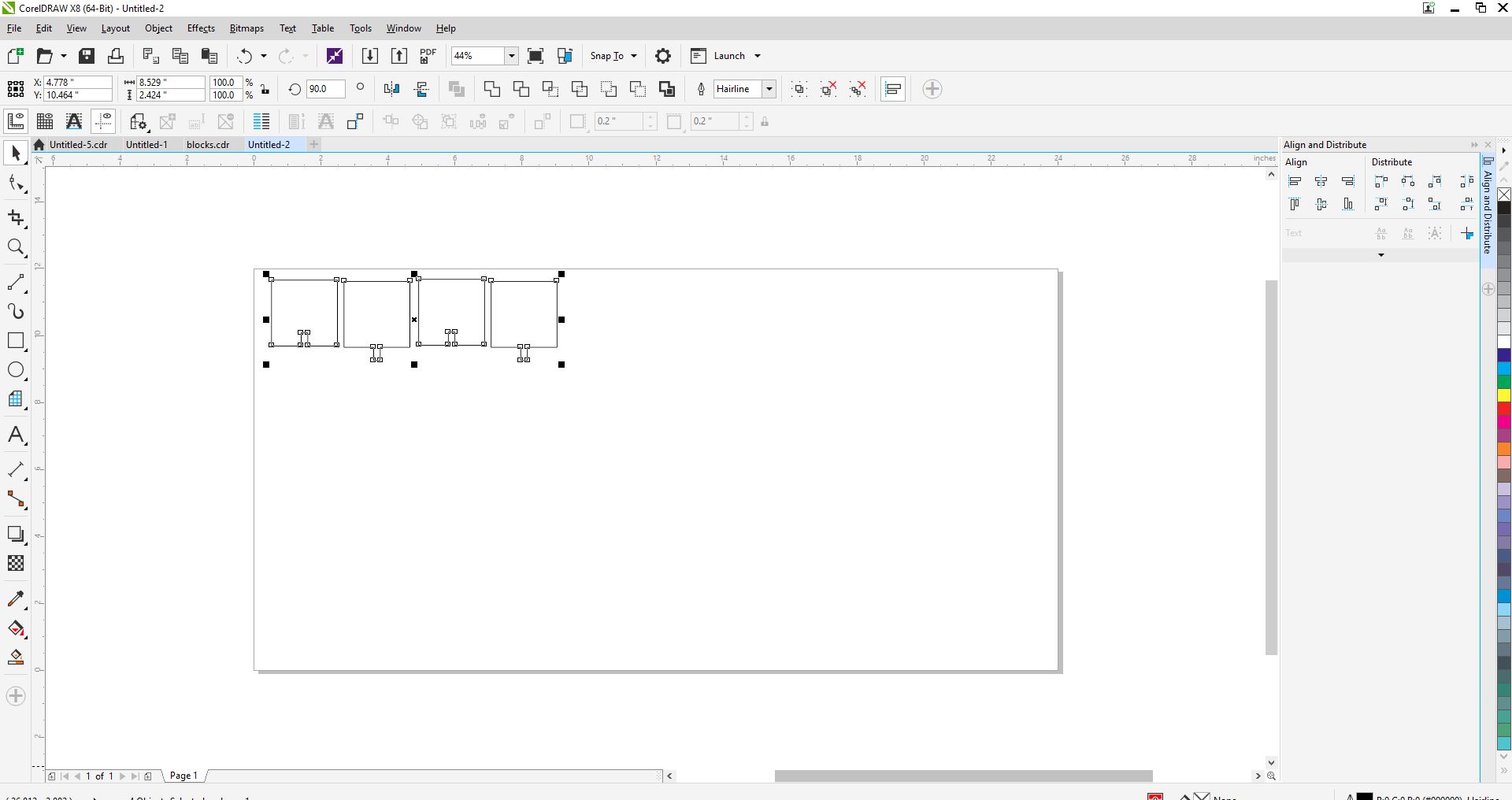

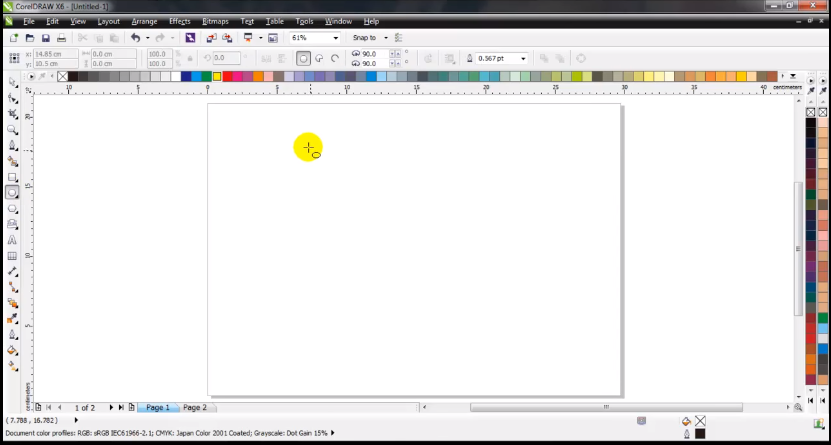

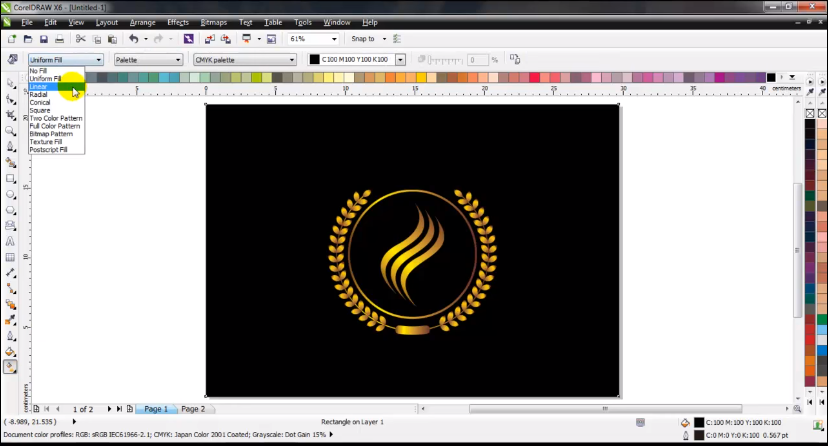

that are the corelDRAW software.

Laser cutting.

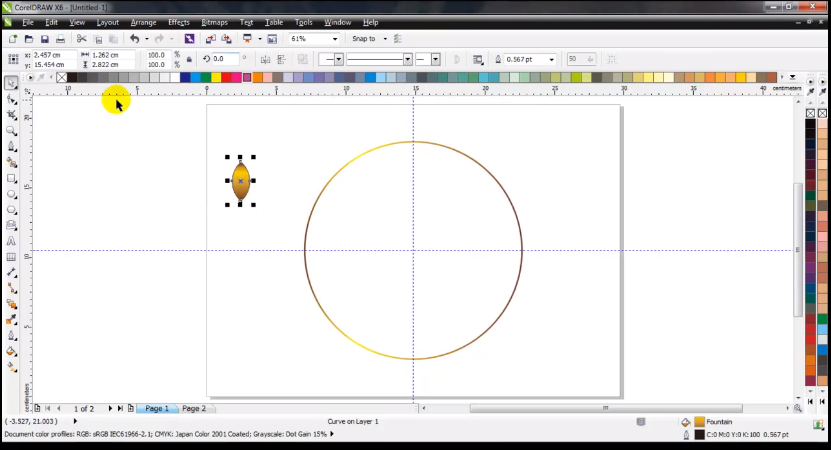

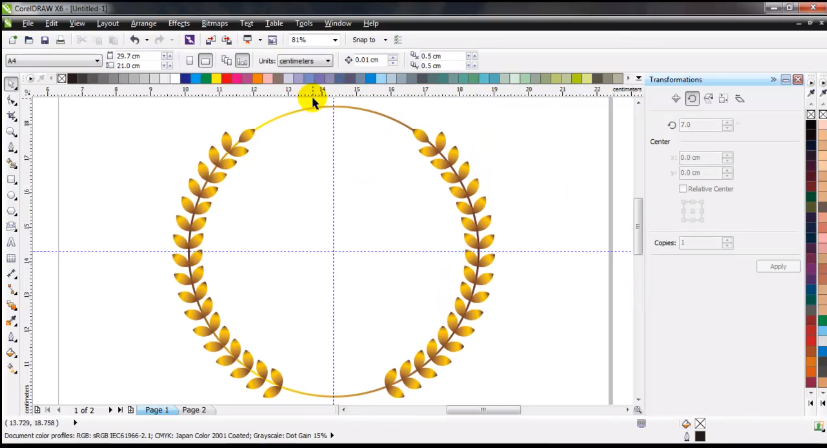

before we print i can start to design the logo in corelDRAW software.

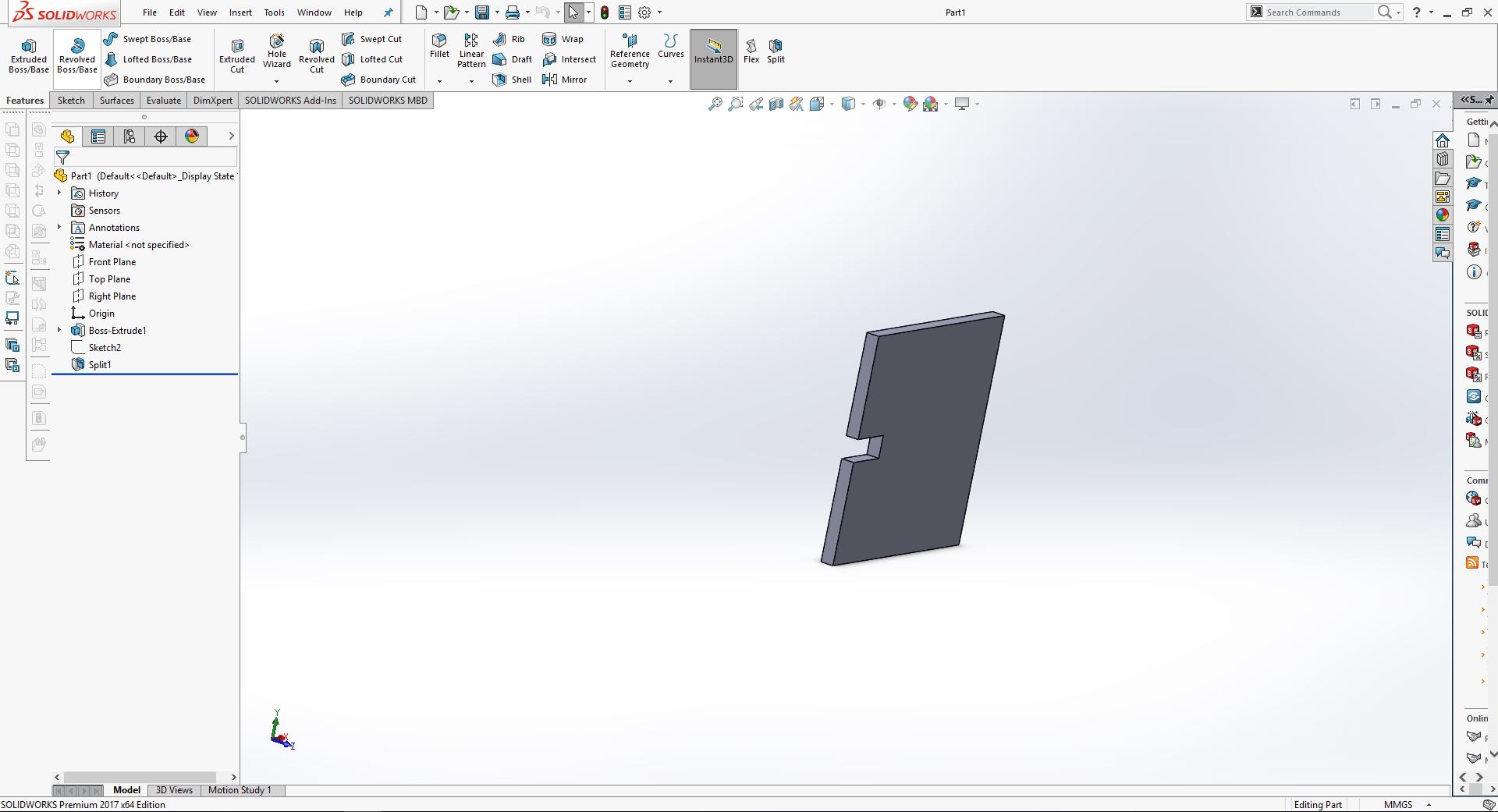

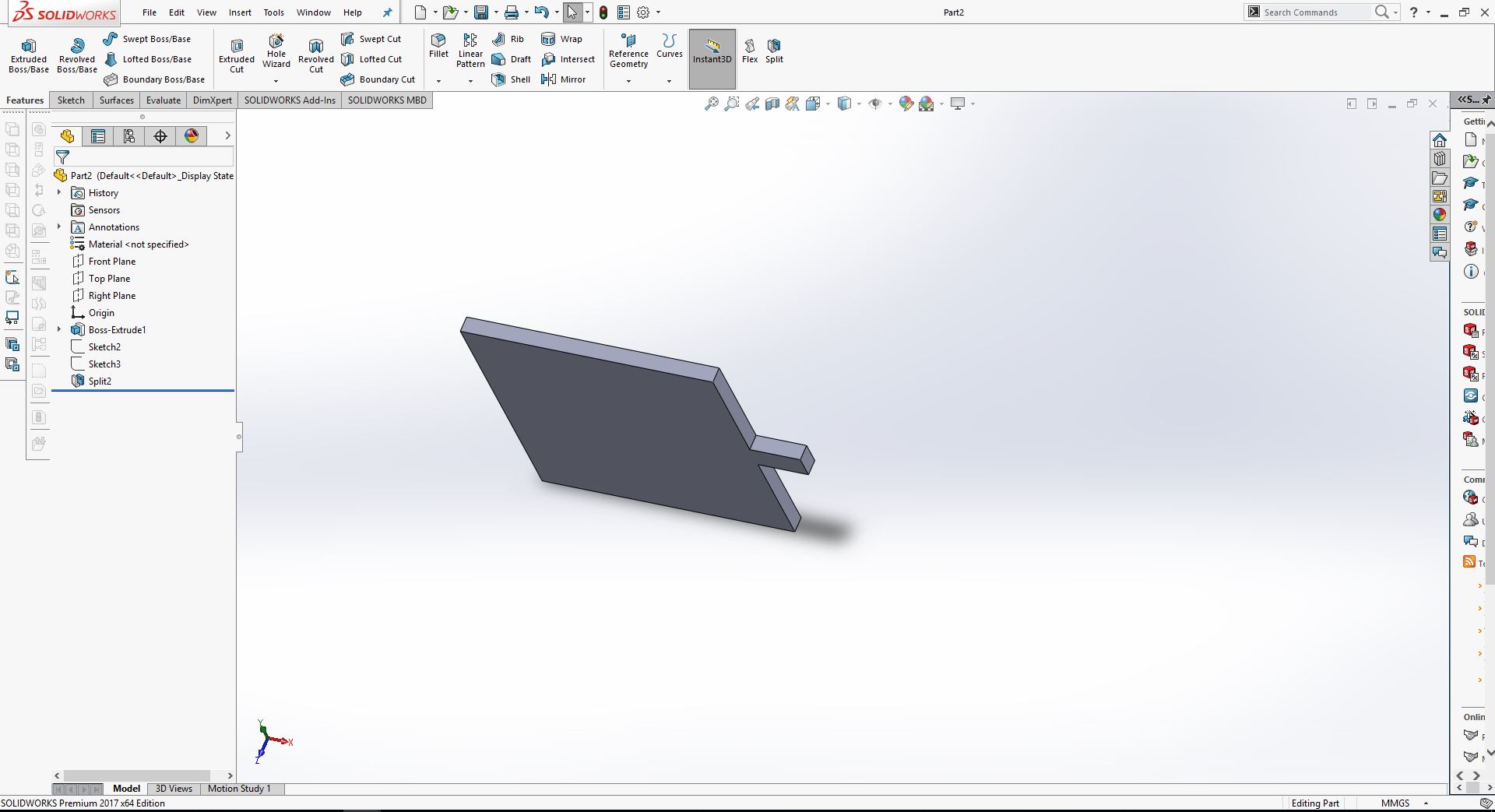

the second i will design by using soldworks.

Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.

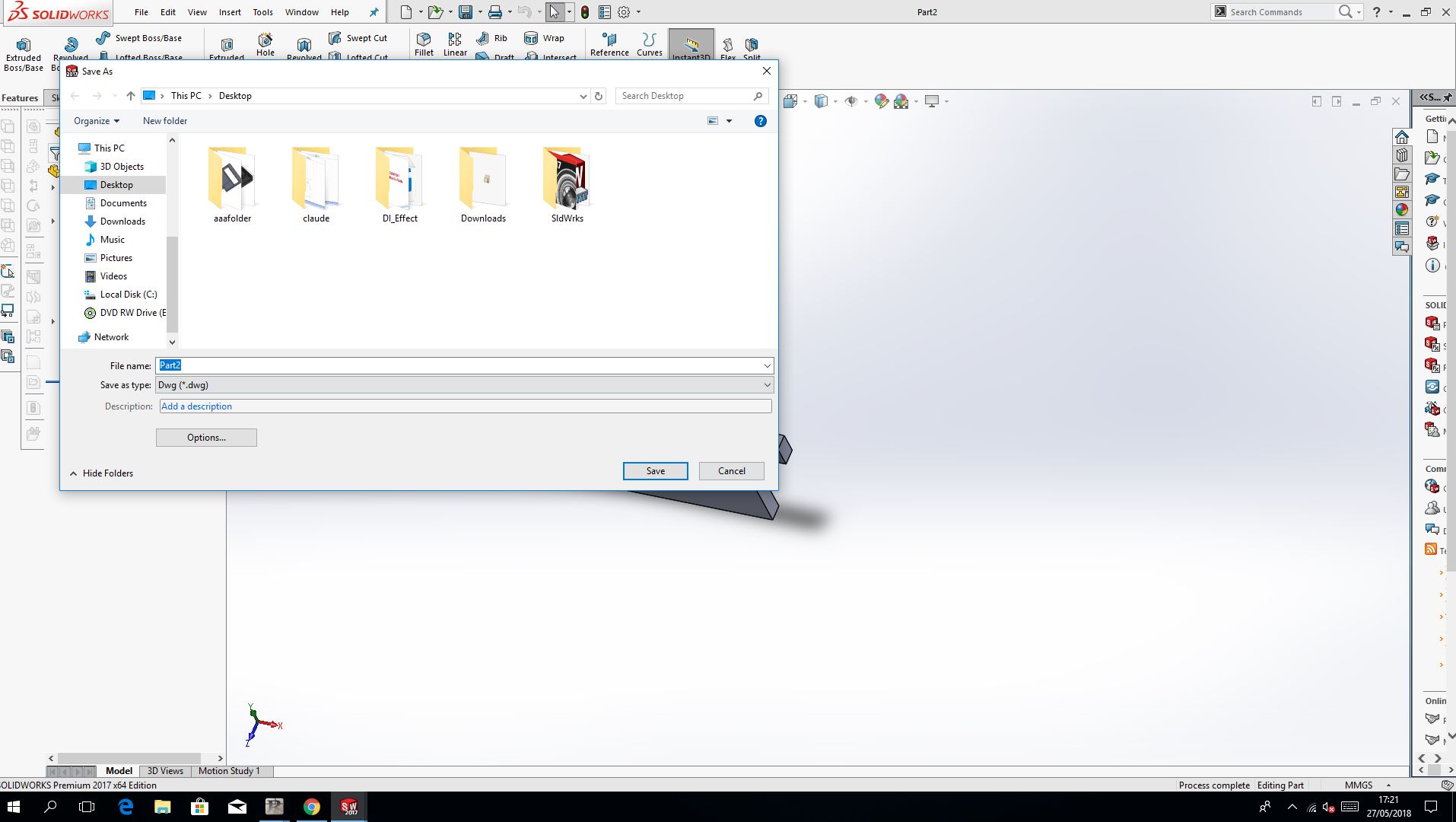

Before i cut on laser first i was design Parametric design in solidWorks.After i save it in dxf file.