1

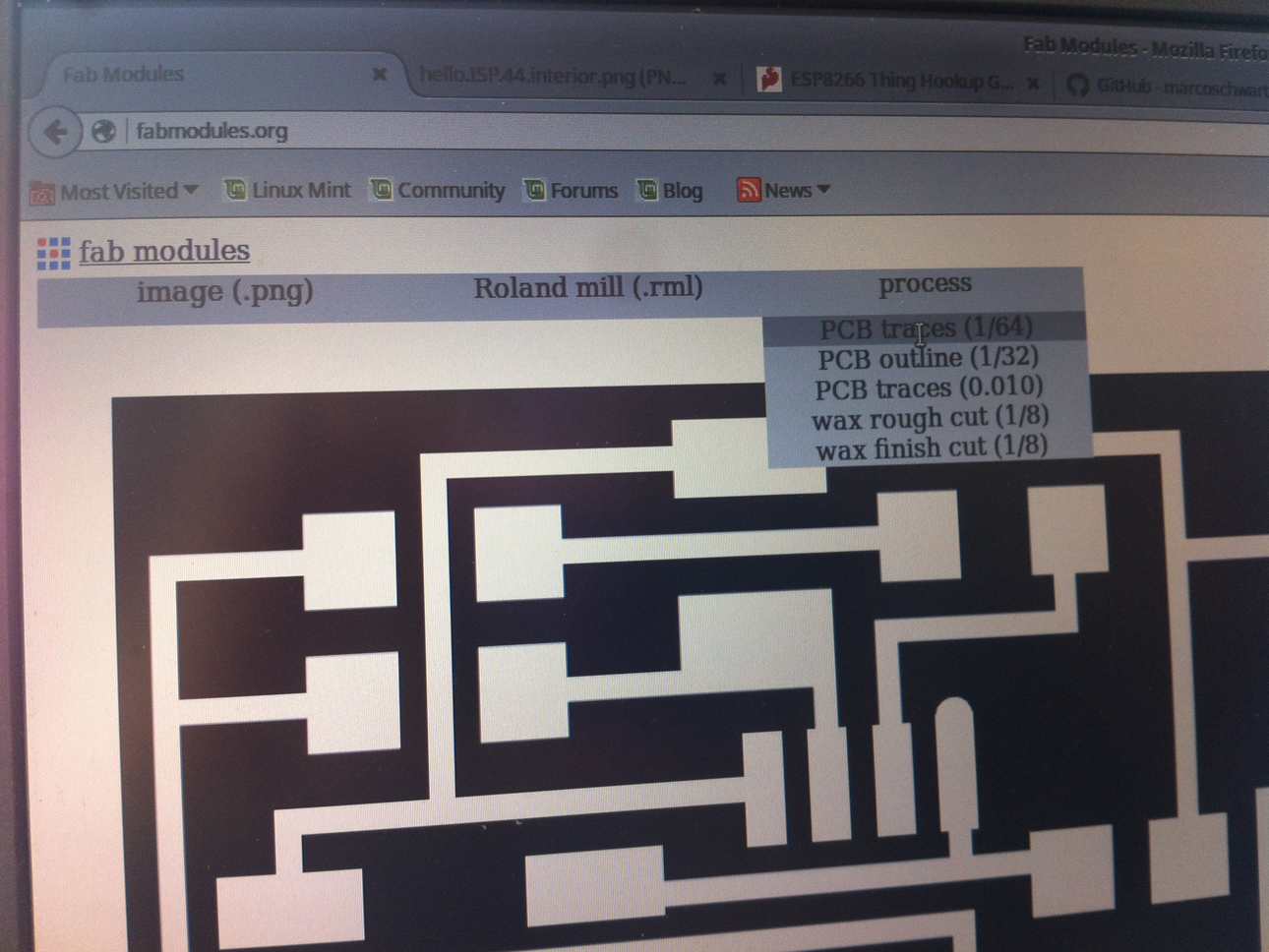

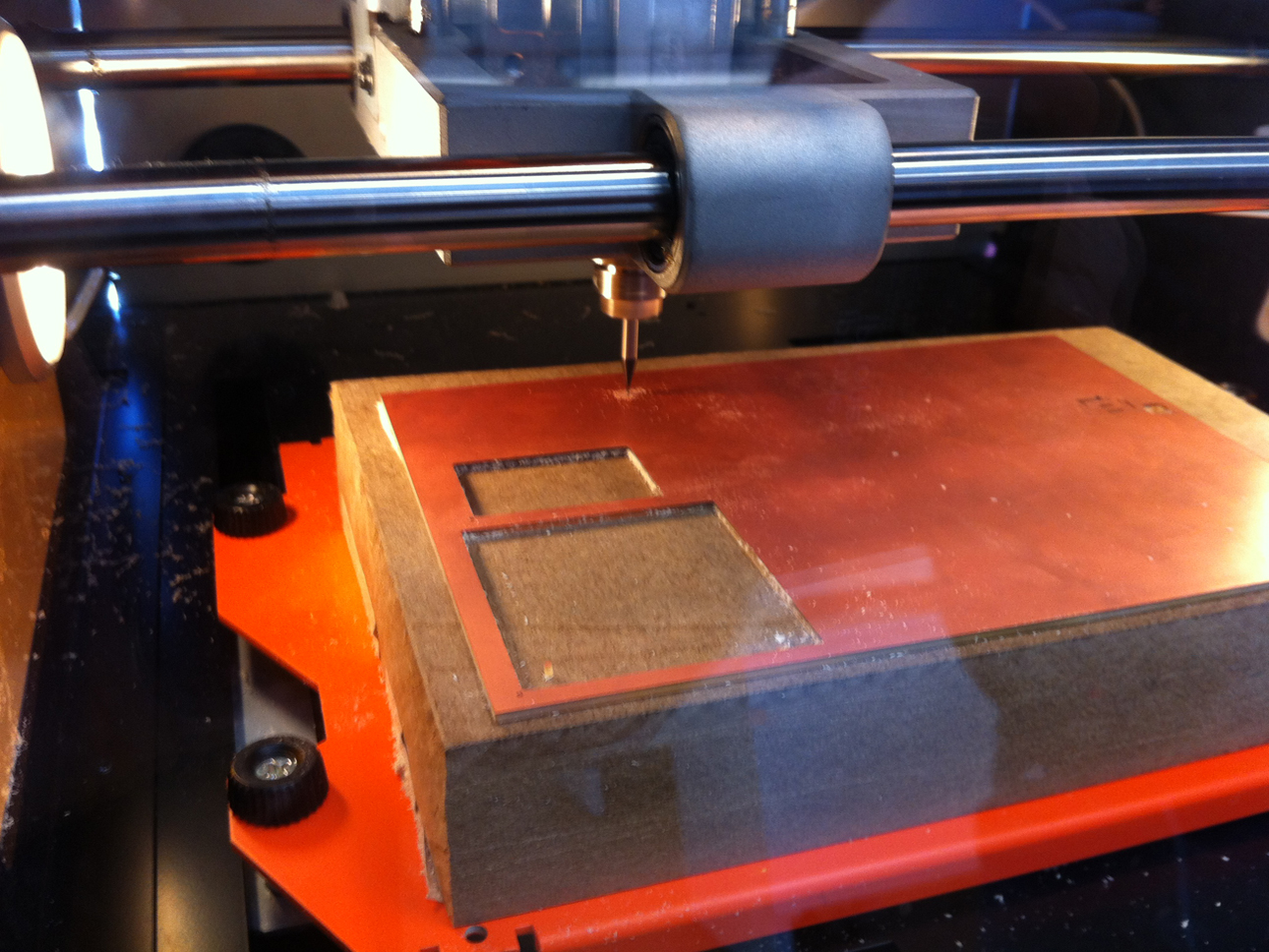

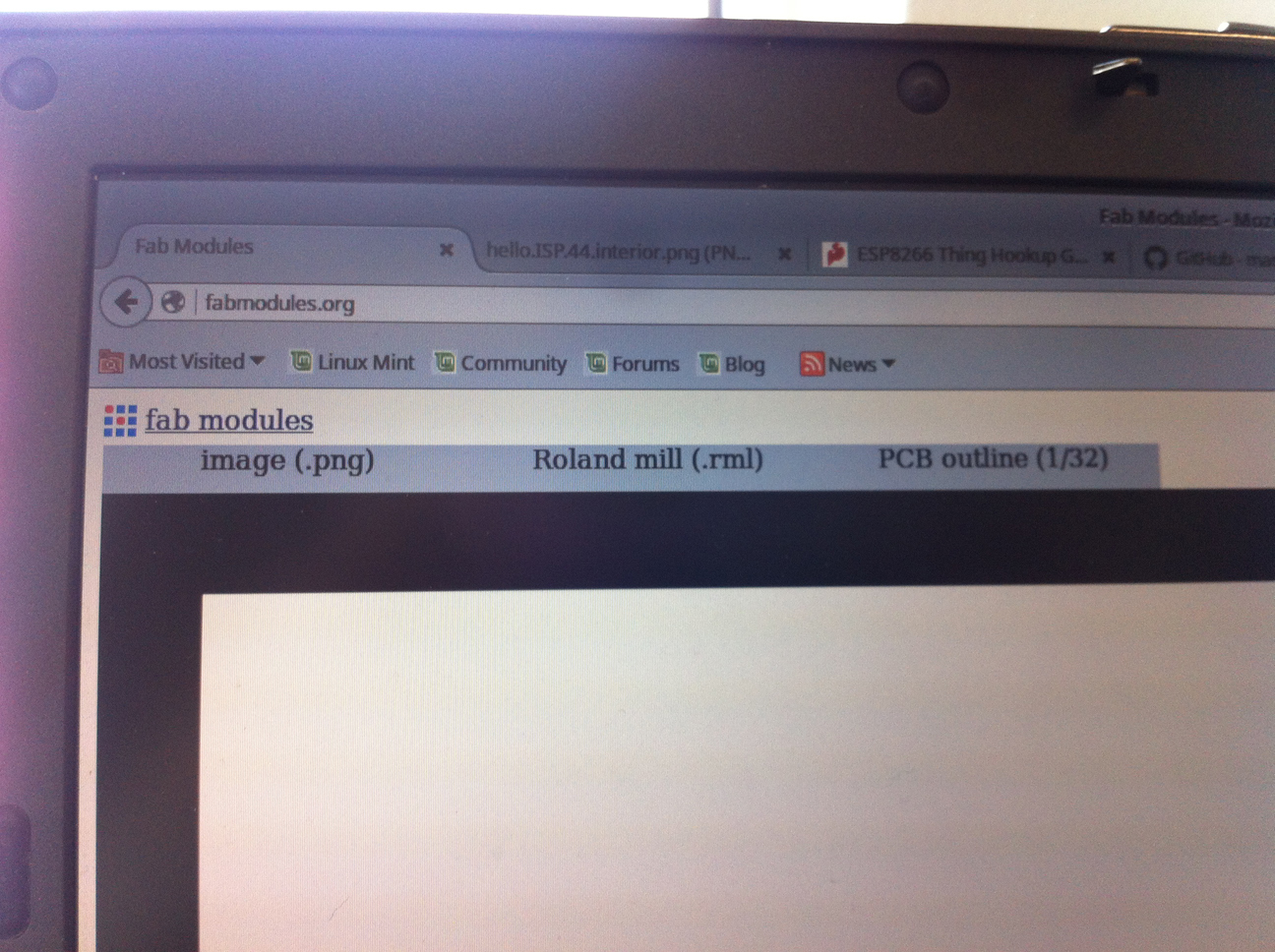

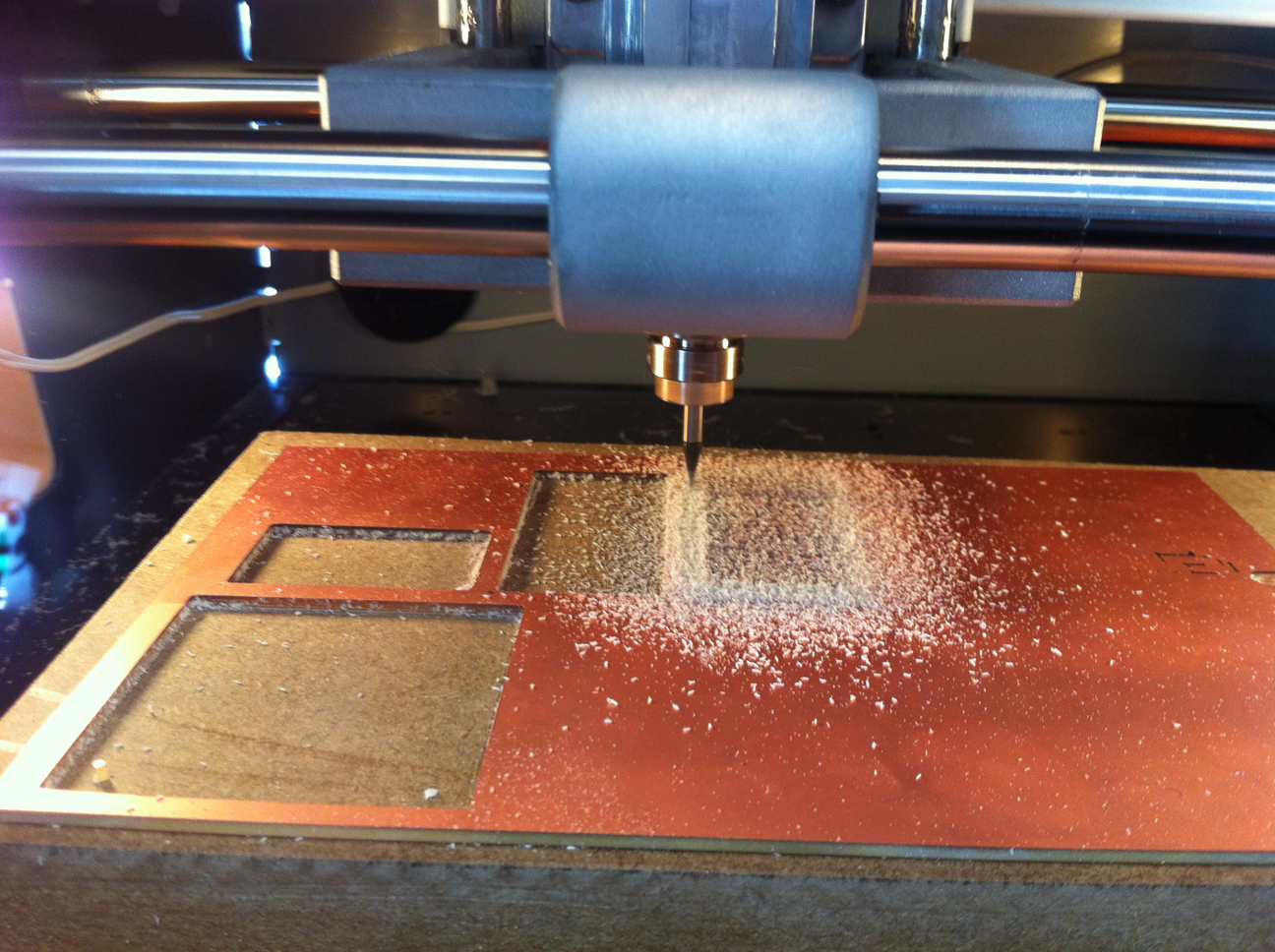

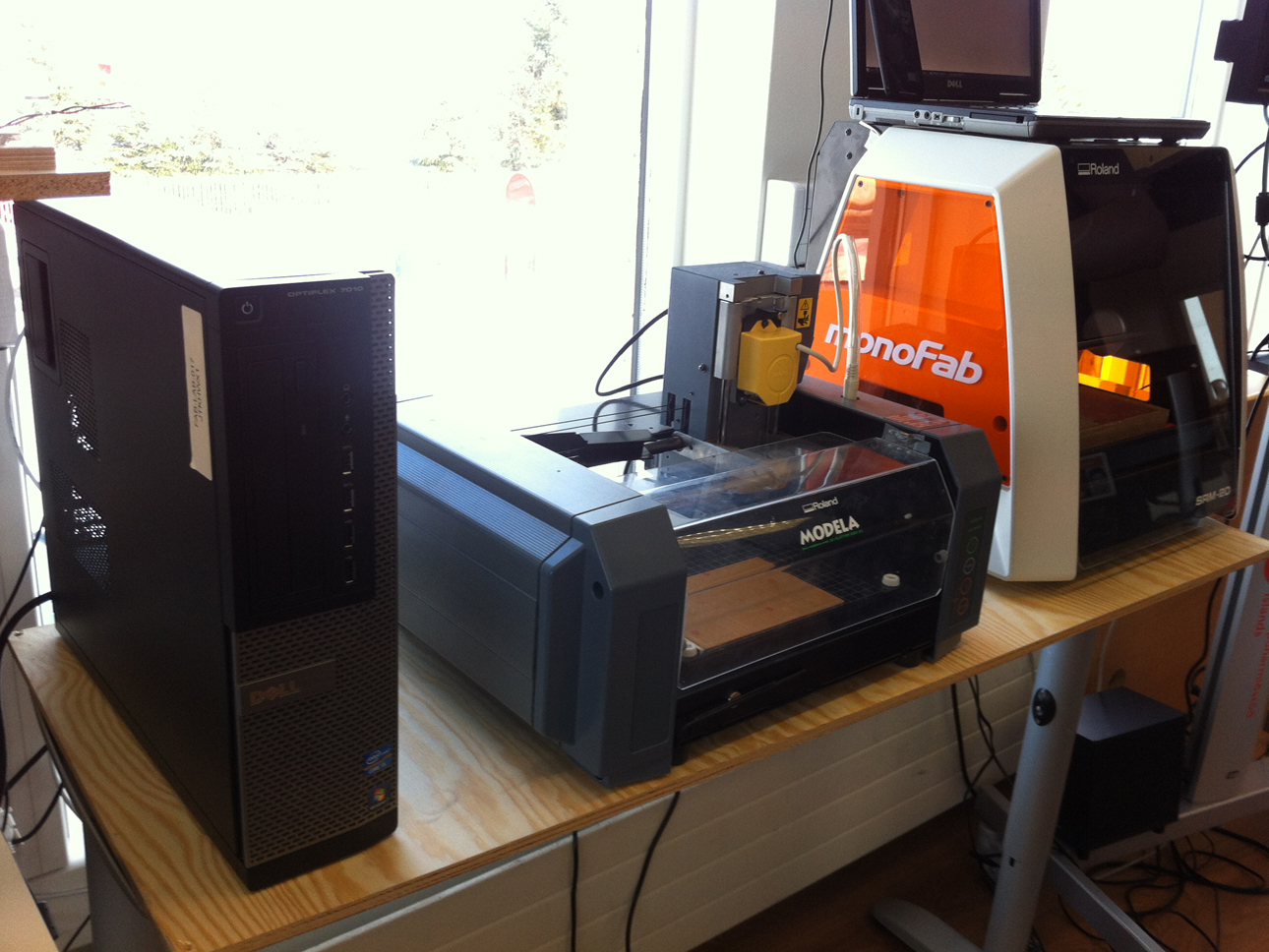

This week we learned to use the Roland Modela and SRM 20 milling machines. After switching on the machines and connecting to the server, first look if the right tool is in it: 1/64 for traces; 1/32 for outline. Switch tool if needed. (Careful: when loosening the screw, support the tip of the tool with a finger at all time in order to not drop the tool!)

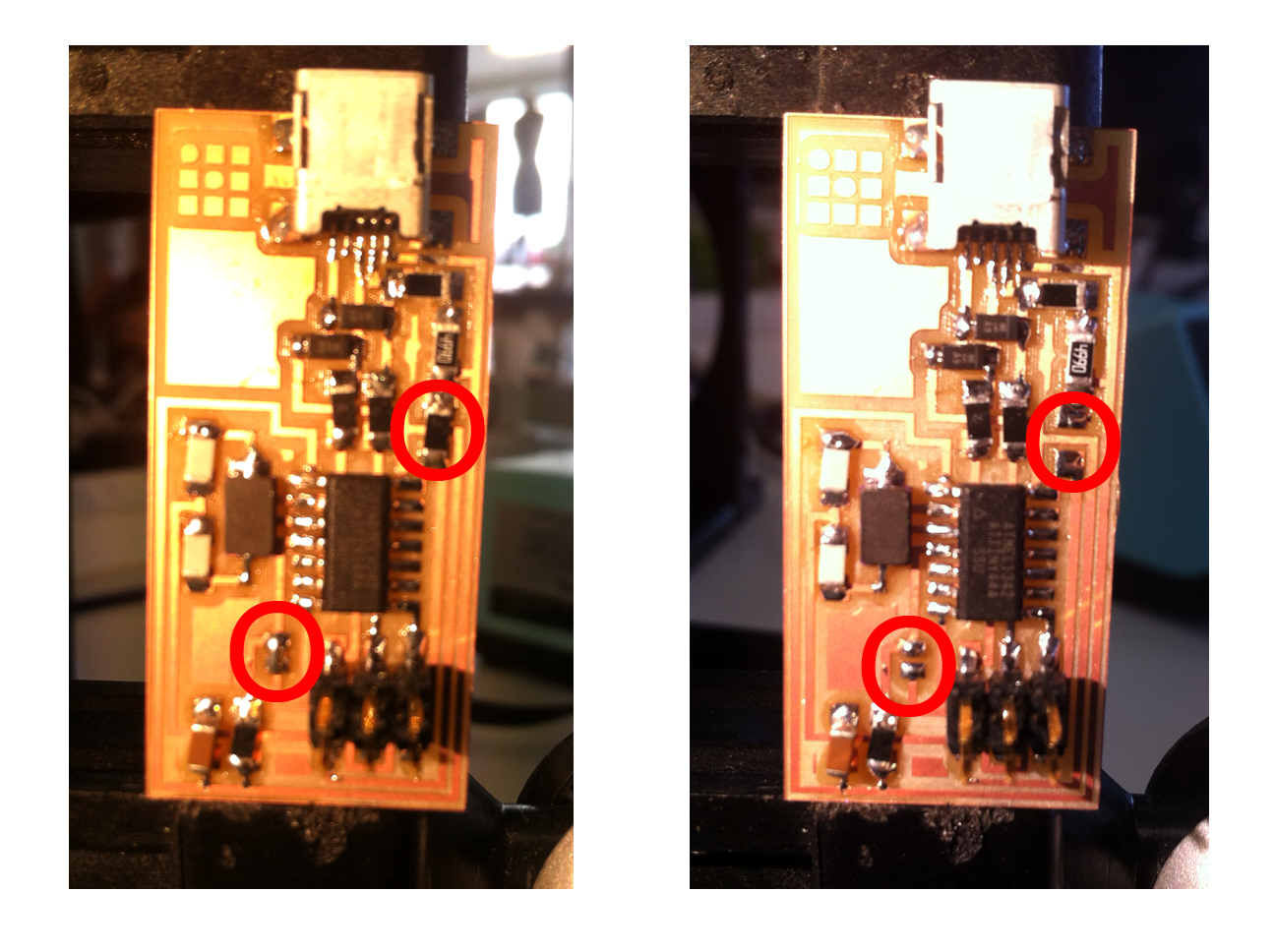

7

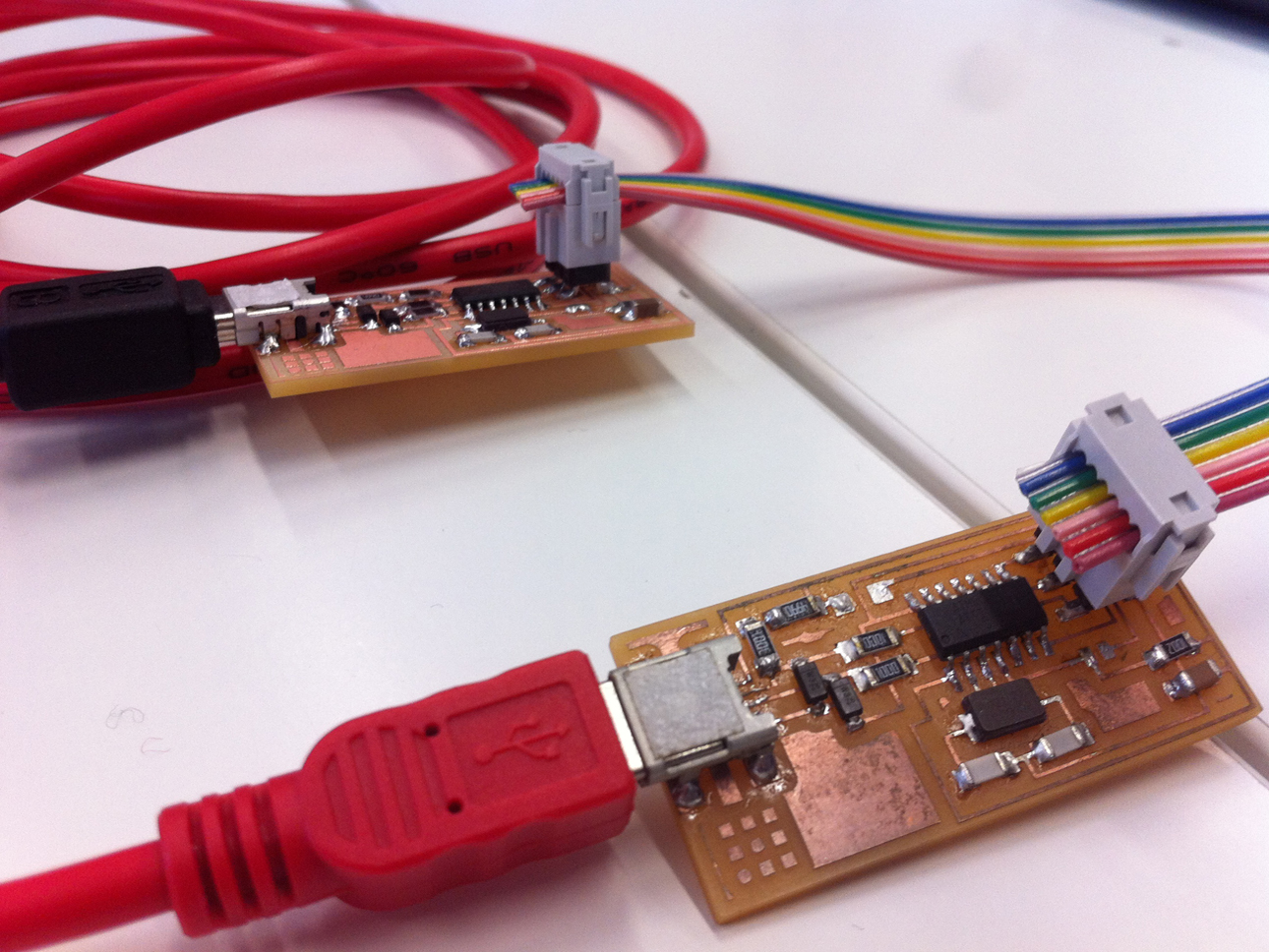

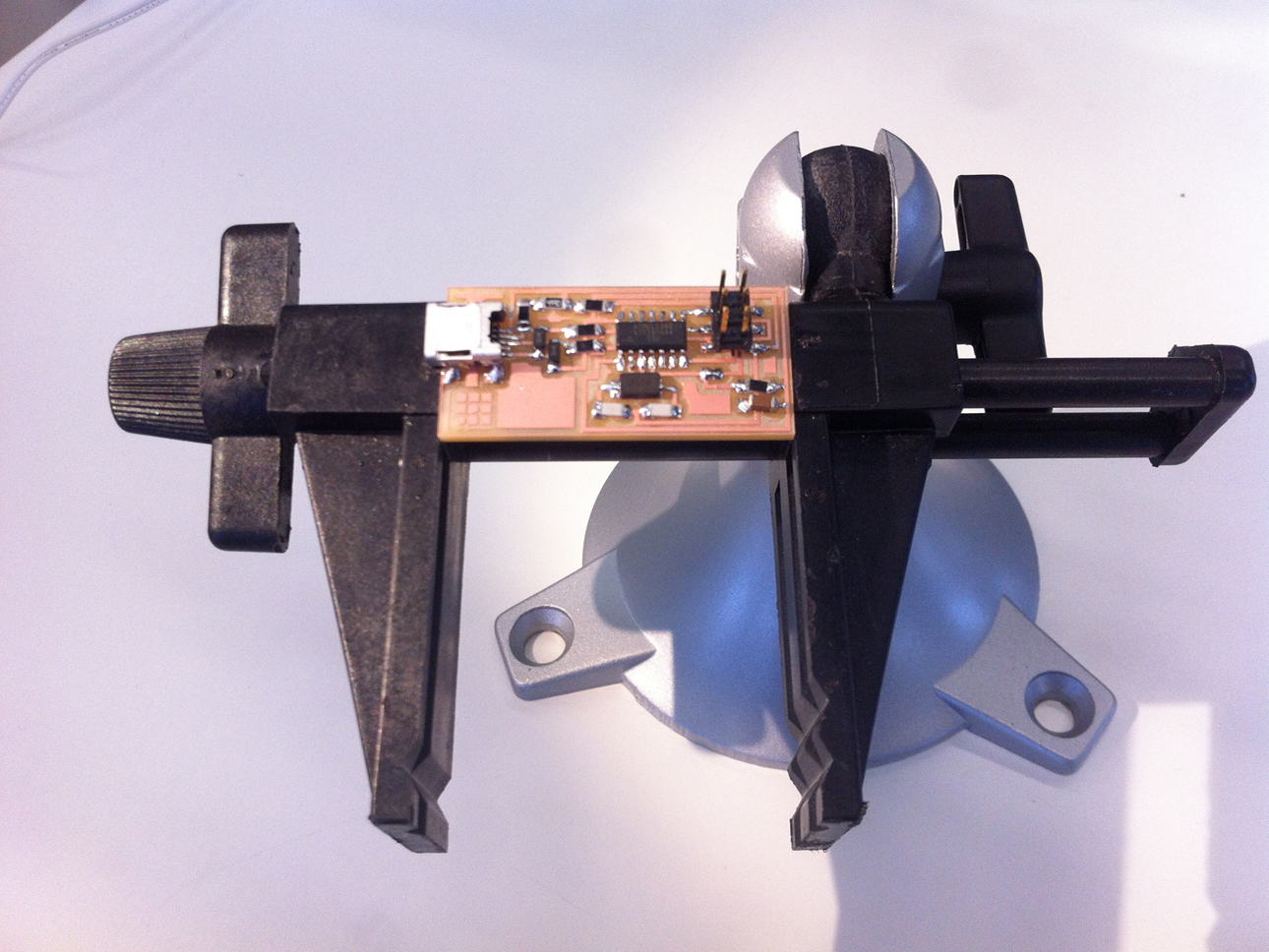

The picture shows how to fixate a tiny board like this in the stand. Also needed: a really strong magnifier, a soldering station that shows the right temperature (300 degrees Celsius) and a nice young class mate to help you out in case you panic because you still cannot see some of the SMD components, let alone their orientation marks!

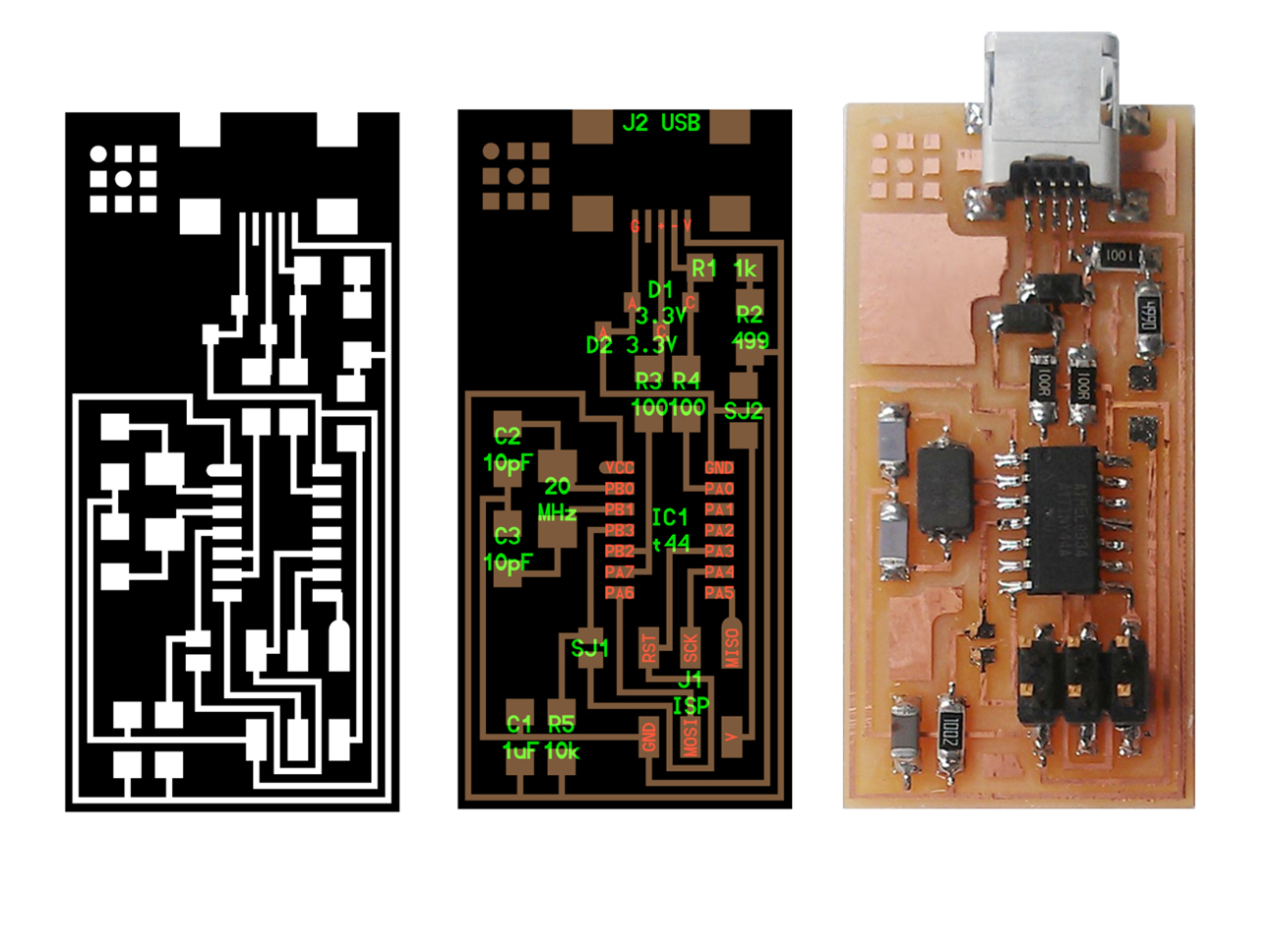

8

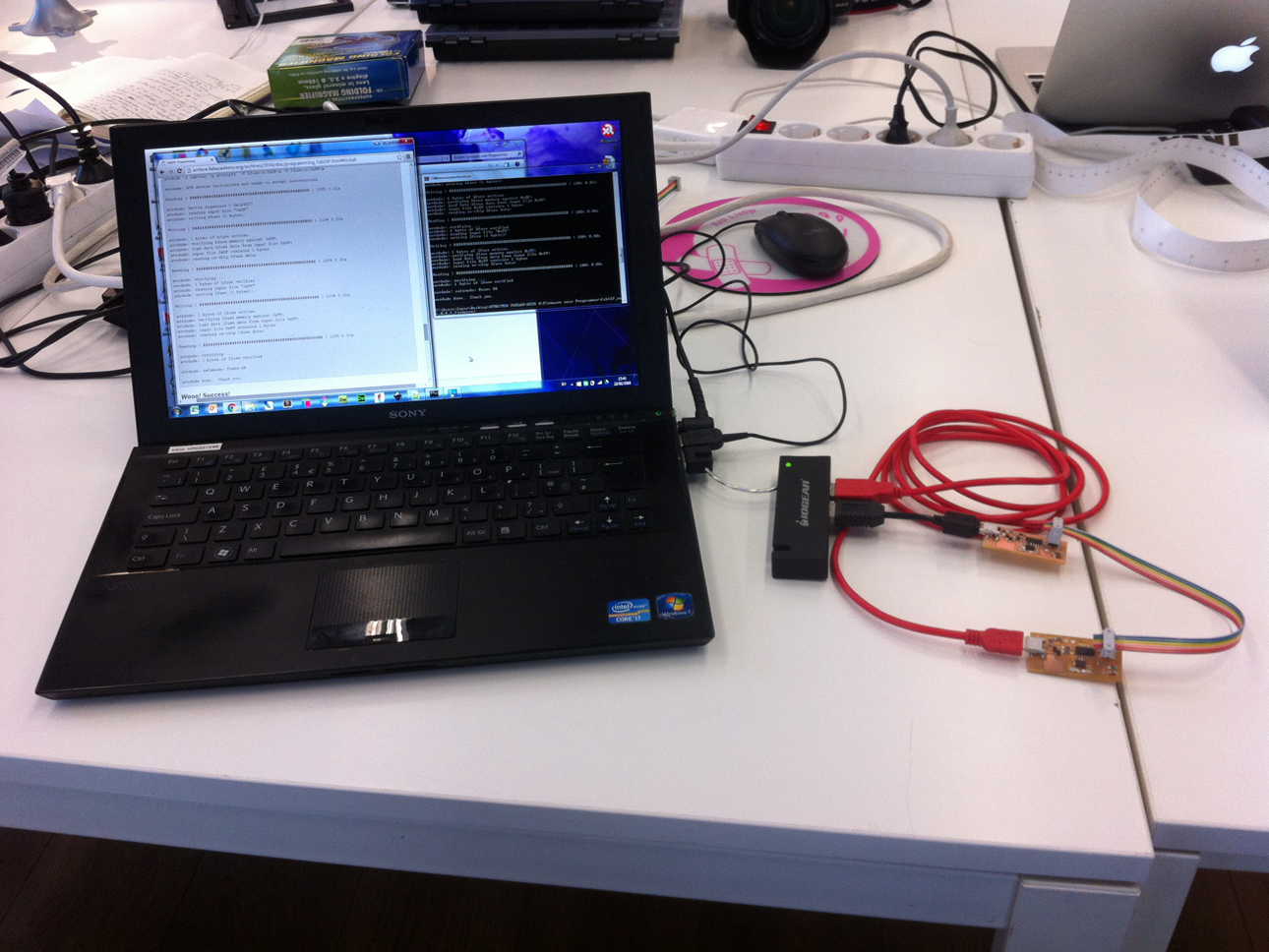

Three versions of the ISP programmer. Soldering done! What follows is the Smoke test. This is really a smoke test: hook the board to your computer and see whether or not smoke is coming out. If you get a message that a USB device is not recognized: that is no smoke and totally to be expected: there is no program in the processor yet!

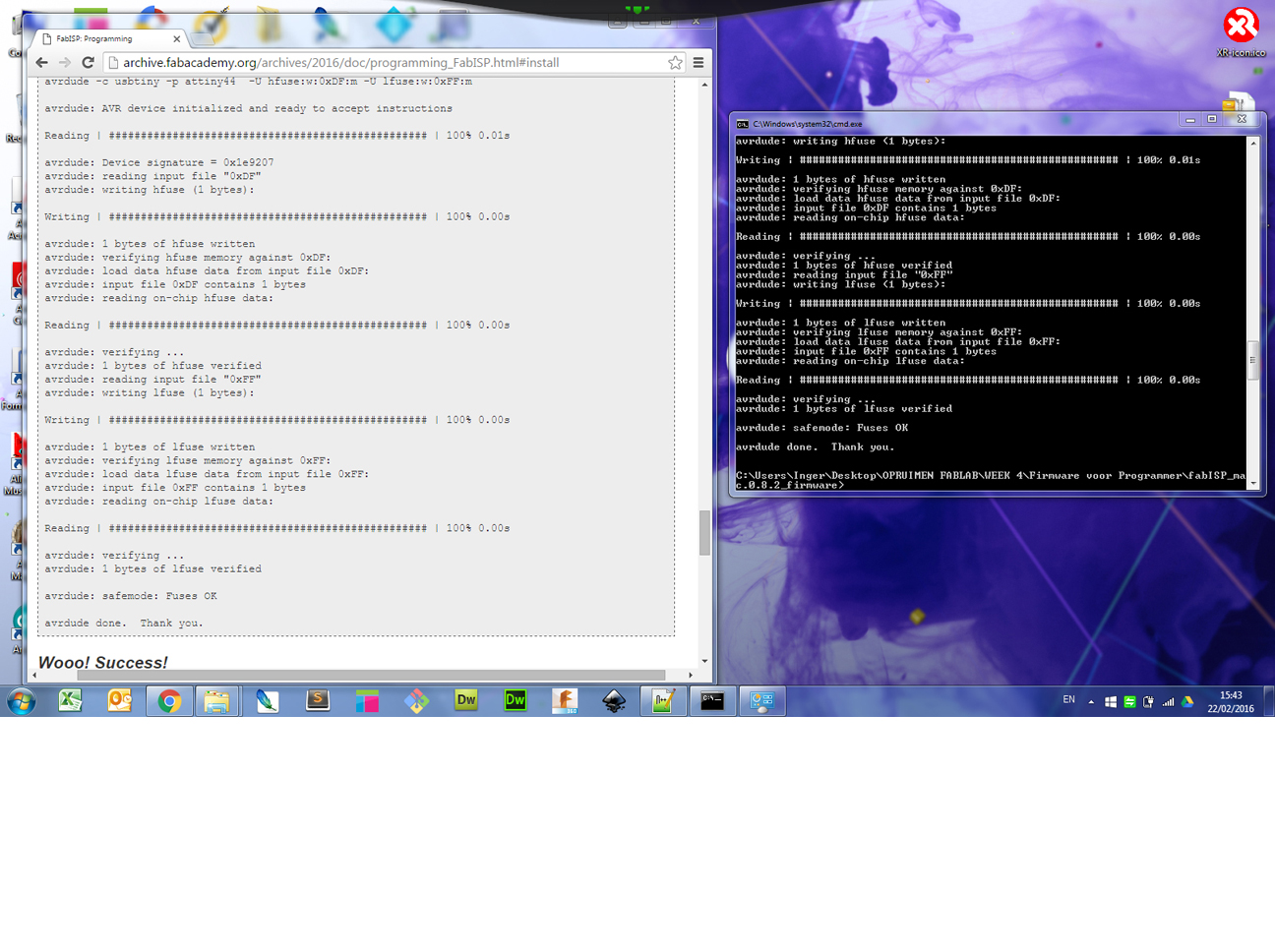

11

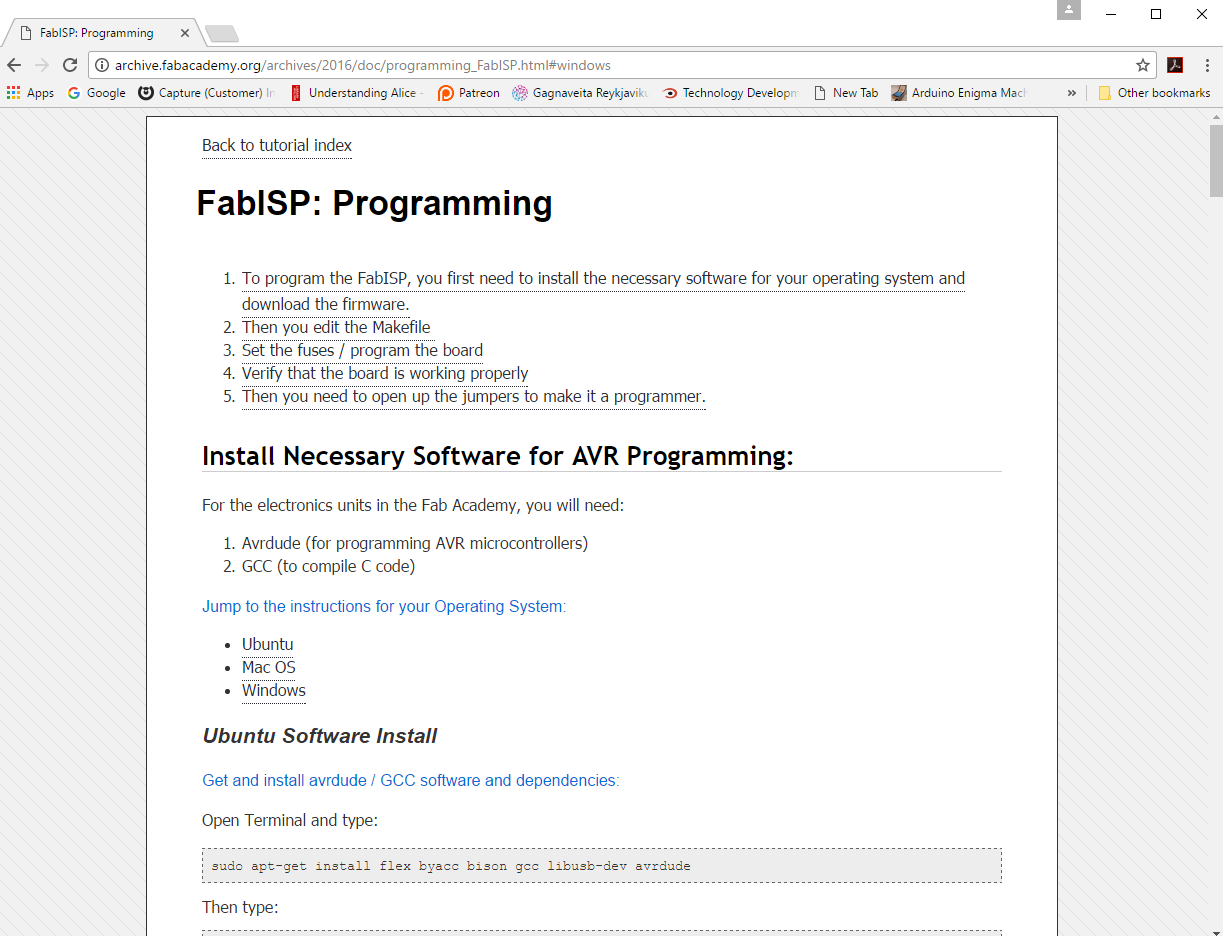

I had some advantages still having a Windows 7 Pro machine: no fixes or patches were needed. All I had to do was follow there FabISP Programming instructions.