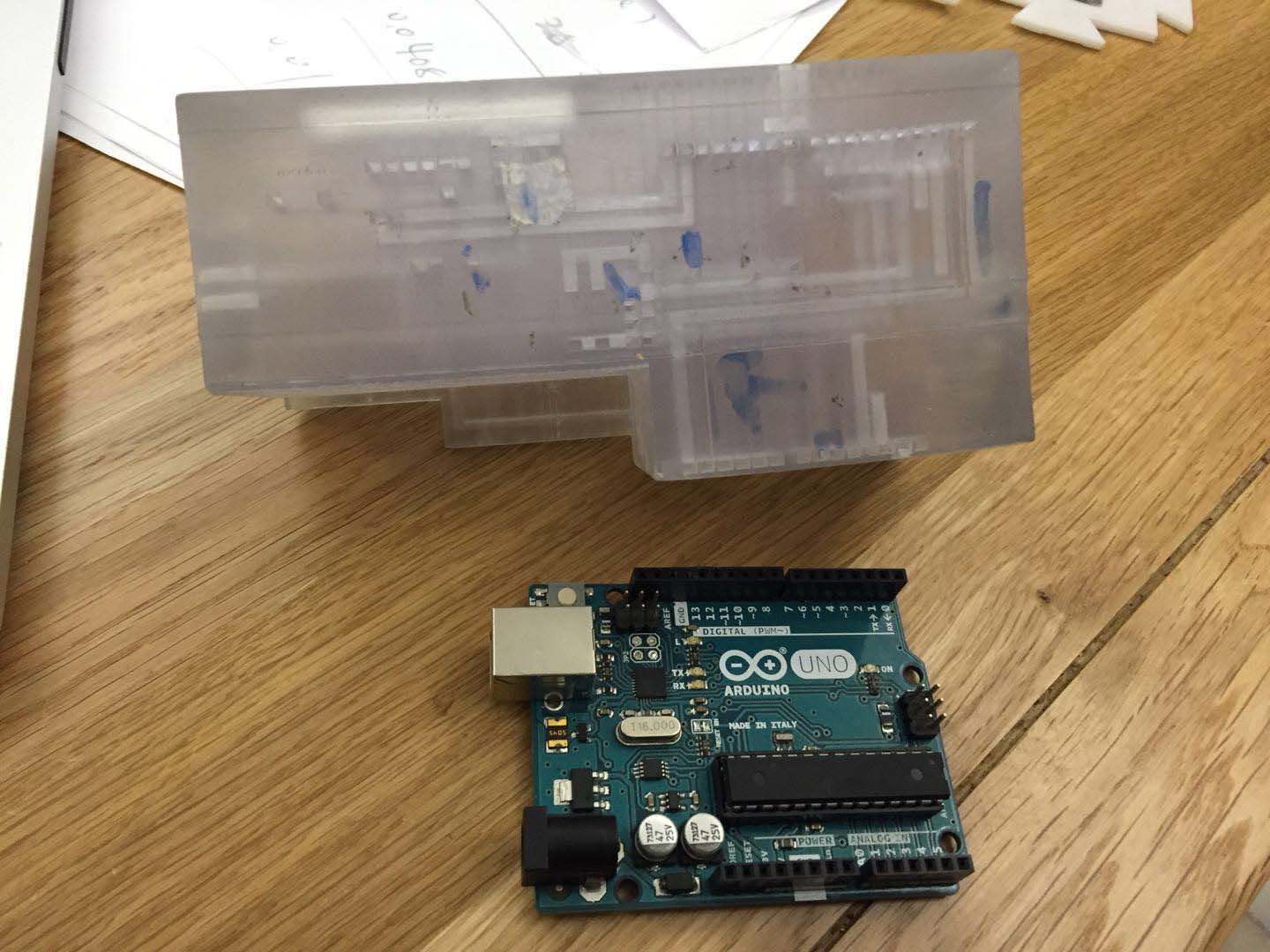

I have do some explore about multi-material 3D printer(I call it DM)which can print plastic(PLA or TPU),and metal(Sn) in one model.

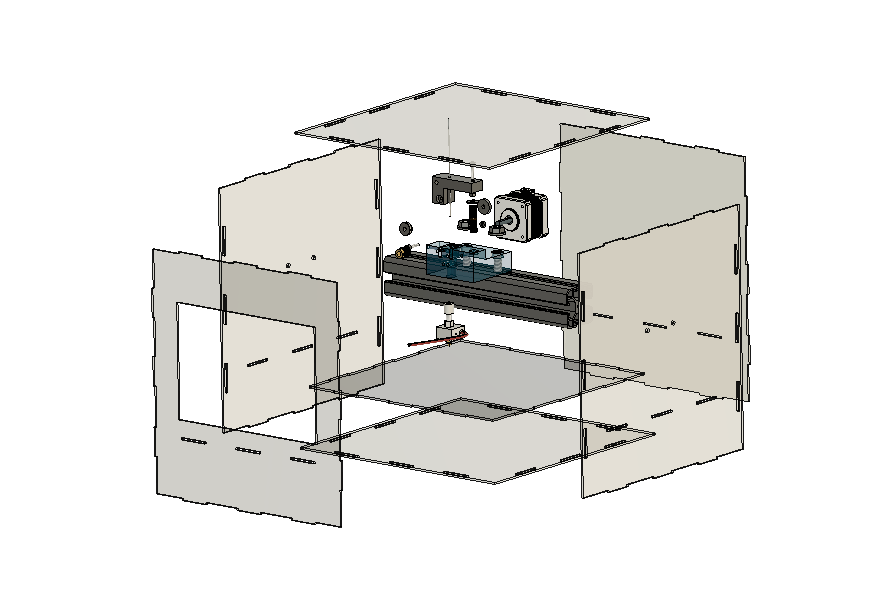

In the meantime I do some basic practice about computer control engraving machine in MECHANICAL DESIGN and BUILDING week

I found the core point in this project is how to control the metal extrude. In Professor Neil 's advice. My finial project's topic change to 3D printing nozzle for Sn.

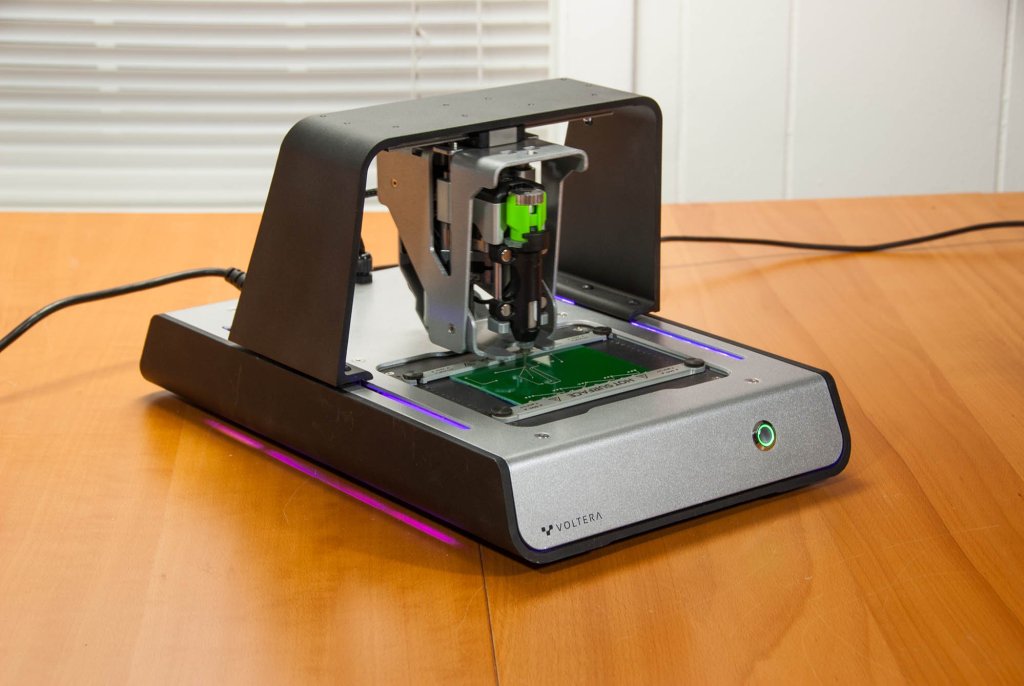

This is a desktop machine,its nozzle can print conductive silver ink on base board, and then maker can use another method to SMT

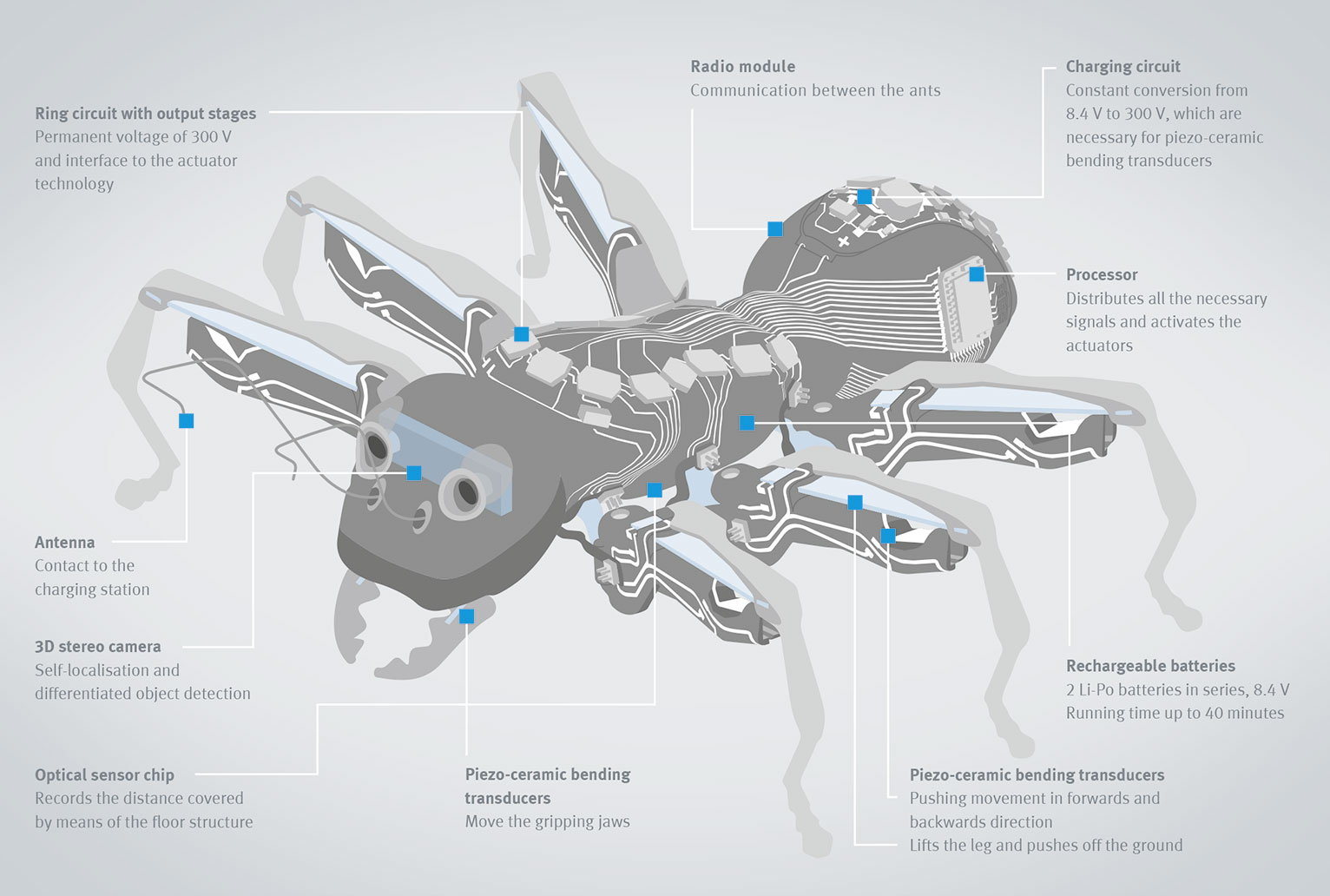

Festo team use 3D MID technology to make a bionicants which can operate similar with the real one.I attach the link: the make of bionicant The basic operate of 3D MID

This website by Bob Wu (based on Twitter Bootstrap) and all its content is licensed under the following license: CC Attribution-Share Alike 4.0 International.