Week18

Applications and Implications

Assignment: Propose a final project that integrates the range of units covered, answering:

Training of Trainers for Fabkit

Intro: What will it do?

Intro: What will it do?

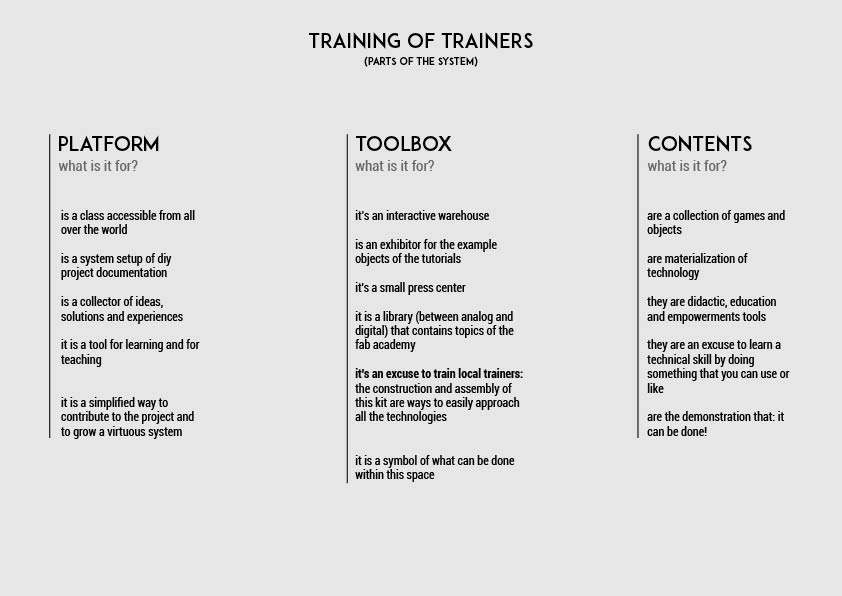

PLATFORM: The platform is a large documentation container. I imagined a way to make accessible the contribution of those who want to upload a tutorial. Even if we talk about technical skills, it seemed necessary to build a tool that would simplify the loading of content. I asked Ludovico Russo

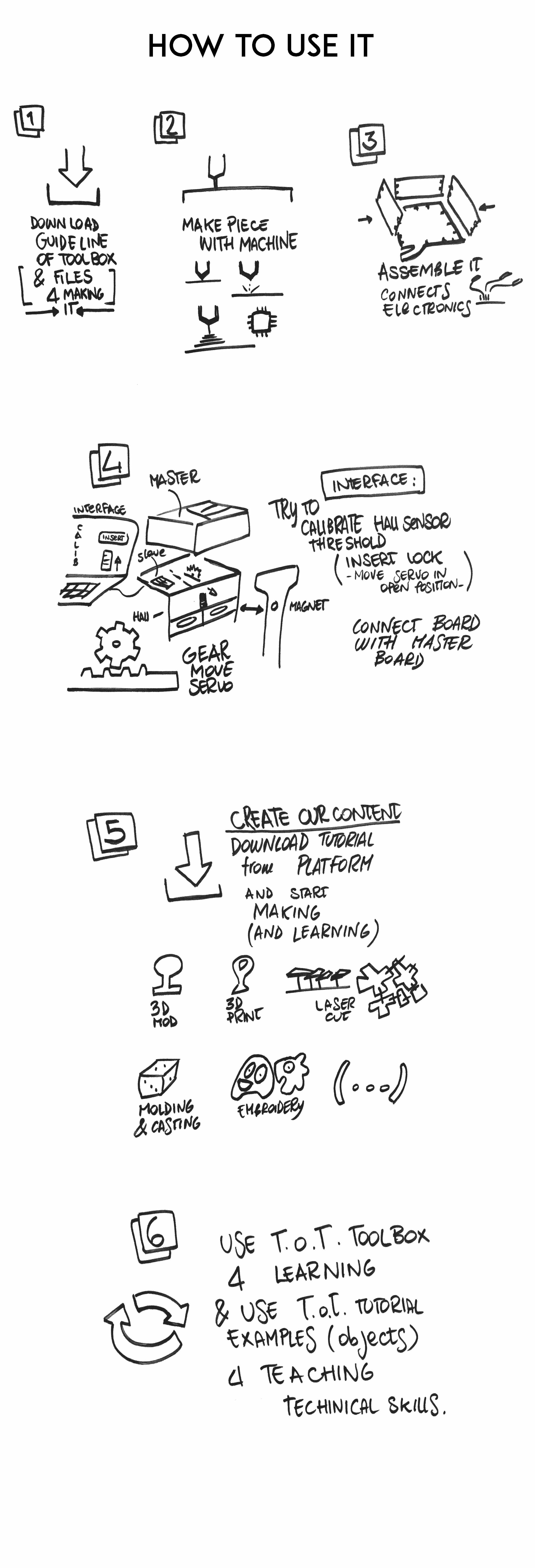

for help on this part. He developed a very usefull "generator" based on my templates that allows you to easily document even those who do not know the htlm. You can try it on this link in beta.TOOL BOX: Training of trainers tool box isn't just an interactive "container". It's the first pretext to teach digital fabrication. This product is designed for self-construction: for introduce and passionate those who are building it to technologies and to understand the potential of a fablab.

CONTENT:contains a series of examples and tutorials to reconstruct, thus learning one step at a time the technical skills to design in a fablab.

CONTEST AND USERS

CONTEST: It is designed for a very particular context, in the development attention is paid to costs and materials easily available are chosen. See more at this LINK.

PEOPLE: In addition to the context, during the design I took into account all the people who integrate with the tool box and its contents. I divided them into two macro categories: trainers and users. this product system will have to take into account their needs, be simple from a cognitive and rewarding point of view from an emotional point of view: it will therefore have to be simple and fun. I expect it to become an opportunity for:

COMMUNITIES'S CONTRIBUTION: The other point of this product system is that it grows with everyone's contribution: the idea is to include it within the Fabkit (humanitarian project) to include a part of the contents in addition to the machines. But for how it is thought it could be interesting a possible development inside the schools.

Who has done what beforehand?

Platform and tutorial:

there are lots of interesting examples about educational platforms to teach technical skills and digital fabrication, the ones I liked the most are:

Toolbox (design ispiration):

Toolbox (tecnology ispiration):

Toolbox (tecnology ispiration):

Concept and global idea:

But surely the most complete idea with the one developing it is that of Jean Baptiste Natali, a barcelona student!

He found me among the students of this year and we made contact to understand if we could collaborate and if our visions were similar.

Unfortunately we managed to meet and talk in person only last month, when we discovered that not only the solution we were developing was very similar, but also the initial problem, even if in very different contexts, the reasons that convinced us to develop it, they are very similar. We weren't able to collaborate for develop a group project during the academy but we will be happy to try to integrate our projects later.

What materials and components will be required?

In addition to the electronic components necessary for the board (which can be found on the input and output page), the tool box is simply made of milled wood.

the contents instead are very versatile based on the tutorials you decide to do.

There are some 3dprinted parts and indicators made with the vinylcutter, but let's say that the assumption is that all the material is available within a fablab.

Where will they come from?

The idea behind the project is to give priority to materials that are readily available on site.In the BOM will be indicated with "local". for the other materials a suggested link will be available as a reference.

How much will it cost?

Within this count, the cost of materials is considered as a priority, the machine and production costs are neglected because it is assumed that these costs can be easily absorbed in the project purpose. Electronic costs will amount to 10 euros. The costs for the necessary wood (15 and 8 mm thick plywood) for a chest of drawer of 8 drawers and space for the rest of the material, will amount to around 60 euros

What parts and systems will be made?

What processes will be used?

FOR TOOLBOX:

FOR TOOLBOX:

What tasks need to be completed?

to do | PLATFORM:

to do | CONTENTS:

to do | DOCUMENTATION FOR FABACADEMY:

What other questions need to be answered?

The whole system would have to be integrated with a series of guidelines: assembly and use for the toolbox, design guidelines for good documentation, guidelines for icon design.

What is the schedule?

the program is as follows:

How will it be evaluated?

It is a very simple project from the technological point of view but that works a lot on the acquisition of skills in a gradual way. It could have a lot of room for development and optimization and entice people to use it in their laboratories. Behind the ""banality" of the solution there was a great simplification process to make this object accessible to everyone.

In-depth analysis of the type and structure of the contents

FABKIT is a project started by GHL and supported by the fablab network. The main objective is to create a low cost, replicable and “open” fablab to be deployed in refugee camps or developing areas to empower local communities. To support local users, the package will include:

- The machines (mainly to be assembled and producible in a Fablab)

- The structure (reusable as furniture\enclosure of the machines)

- Contents (material that can be used by the instructor and by local trainers).

Contents: training of trainers tool box

Within this section there are different types of educational and training contents. These are followed by a template and some design guidelines to allow an open contribution without losing the continuity of the system. There are:

- VADEMECUM: summary tables containing design information about the topic, general rules and best practices.

- INTRO AND CHECKLISTS: printable web page that contains: general information and glossary about technology and all step to do to use it or to rely a project: setting of the files, process management interaction between softwares or between machines, safety information.

- TUTORIALS: It’s a guide for the construction of a symbolic object explained step by step on a web page, with the goal of learn and apply technical skills (i.e. 3D modeling, lasercutting, reading a sensor, etc.), with different difficulty levels and are target. The output is a “object-excuse”: something fun to make or useful to understand the potential, but not necessary co-designed.

- LESSONS: It’s a brief class, that aim to work on the soft skills (how to do a brainstorming, problem solving, spiral development, etc.) The outcome is still a “object-excuse” or a “project-excuse”. It’s probably done in group and lead by the trainer. It’s divided in two: brief theoretical intro, and activity + support of notes (like a cheatsheet).

- MANUALS: summary tables containing design information about the topic, general rules and best practices.

--- this part will not be developed during the Fab Academy ---

--- to be defined with machine team ---

chest of drawers:training of trainers tool box

We imagine that part of this content has a "physical" correspondence inside a container that for the moment we will call "brainbox" that will be feasible on site with the technologies present in FABKIT. This container has an integrated thermal printer and a series of drawers that contain the example objects and a series of QR or RFID codes that allow you to reconnect directly to the dedicated page of the site.

Templates and examples

- VADEMECUM: this board is designed to be laser cut and inserted into the top of physical chest of drawers kit with the "example box" (in this case) already mounted.

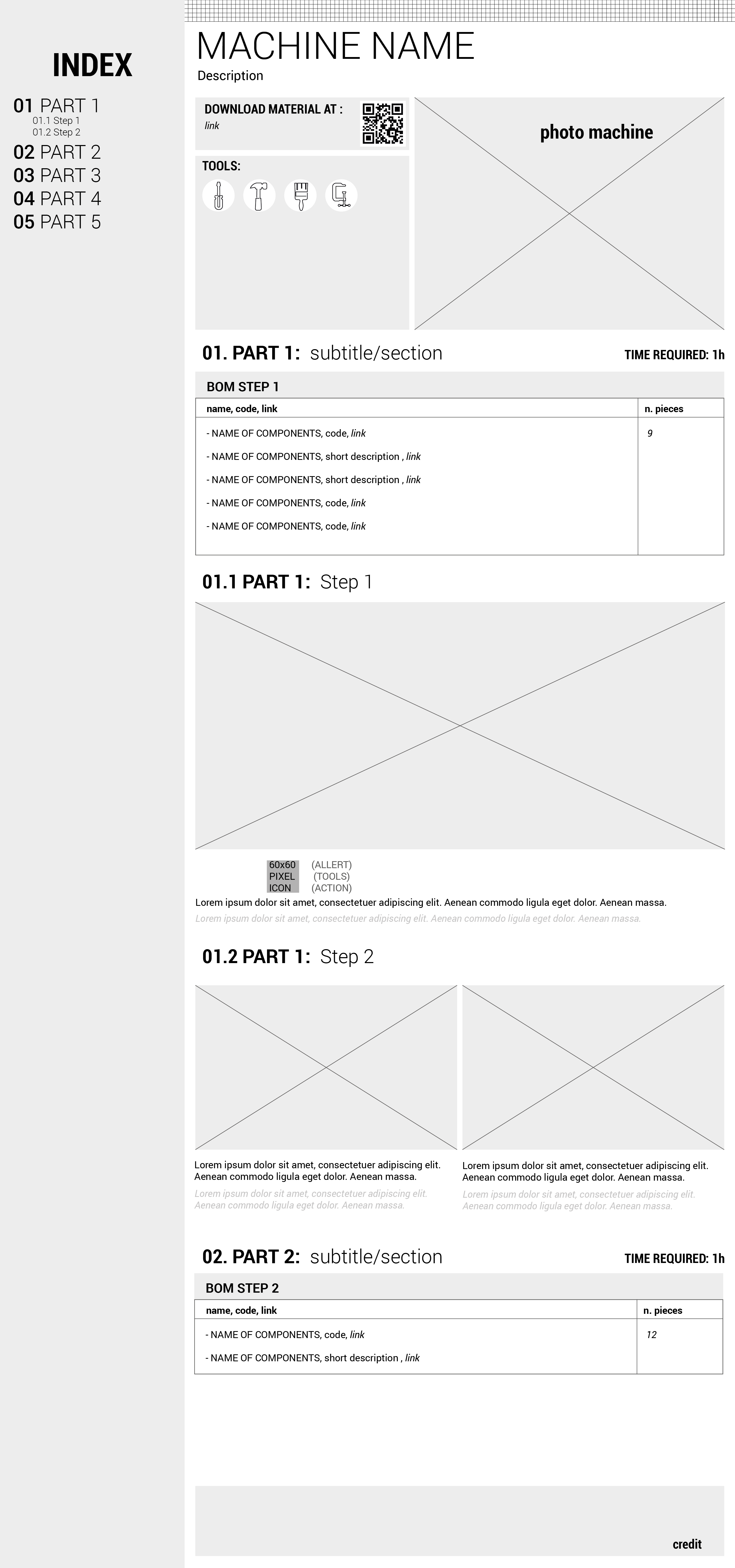

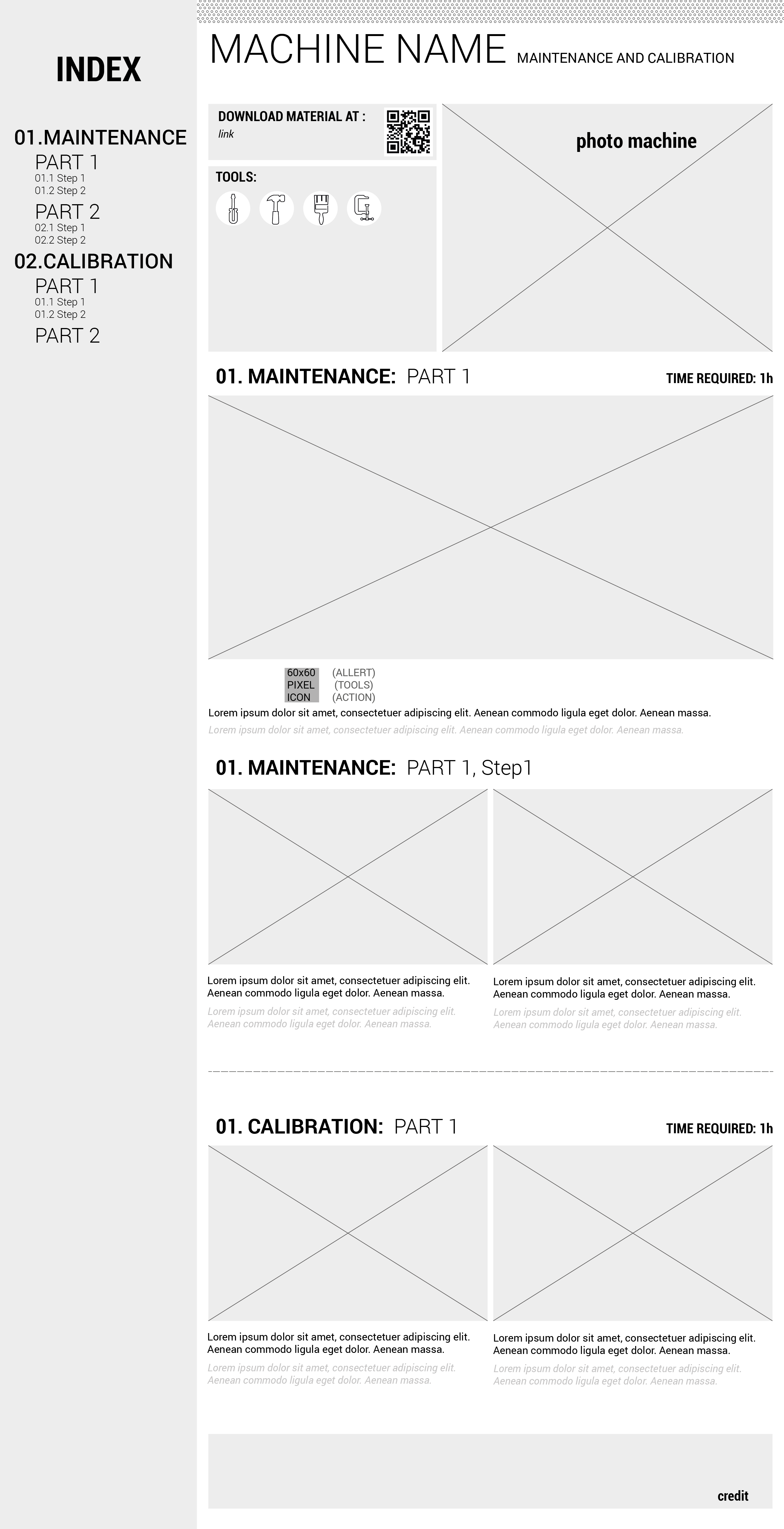

- TUTORIAL: this is a template for web tutorial's webpage. It's responsive and printables. For reduce the complexity, the idea is to write in Markdown and create a system for convert and apply the style in HTML. For each tutorial there is a drawer (physical) inside the Brainbox which contains: the example object already created, the technology vademecum and the QR code to connect to the site page (and eventually print it).

- MANUALS: there're two different templates for assembly and maintenance.