- Assignment 03

Computer-Controlled Cutting

This week is dedicated to the use of machines working in 2D.

Vinyl Cutting

The tools that i used are Solidworks to design, Silhouette Studio like CAM and my Silhouette Cameo.

Design

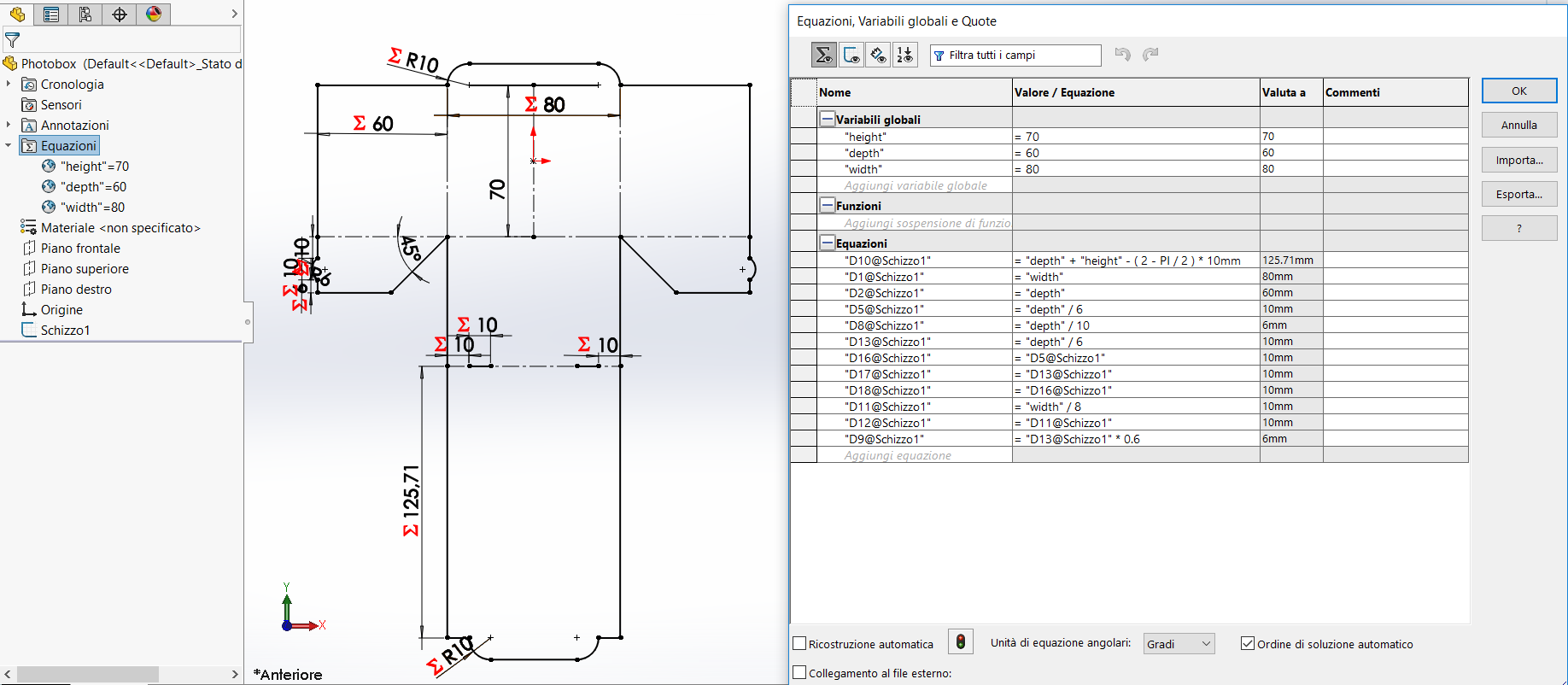

I designed a parametric photo box using Solidworks. I have parameterized so that I can easily change the dimensions of the box.

download Photobox 64,3 kB (.sldprt)

Figure 01. Drawing in Solidworks

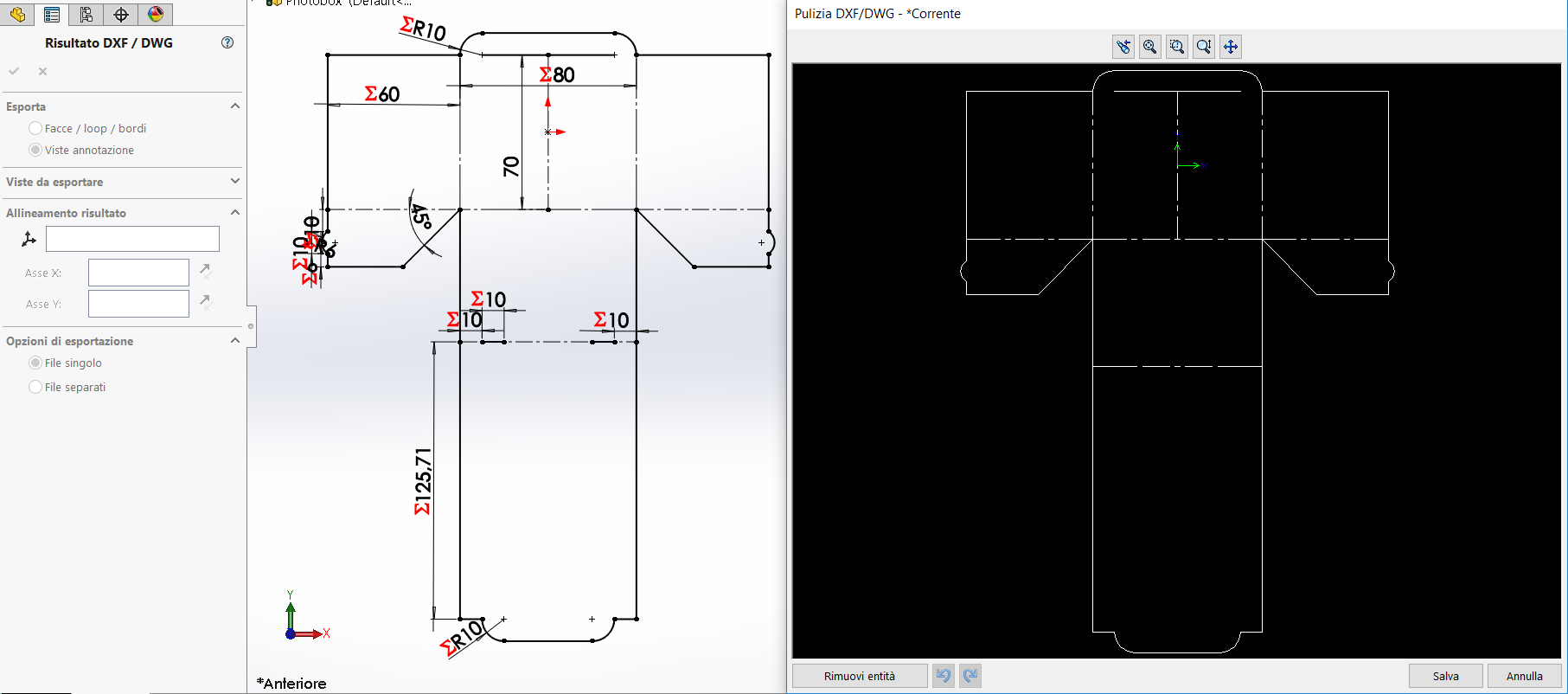

For the next step I exported the sketch in dxf.

download Photobox 27,6 kB (.dxf)

Figure 02. Export by Solidworks

CAM

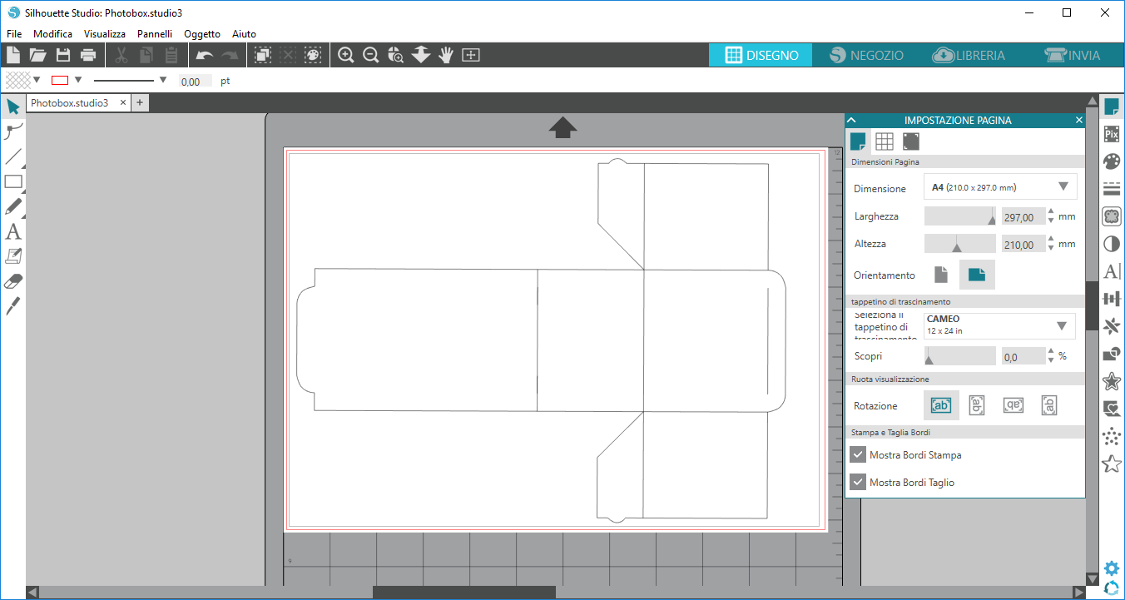

I imported the dxf in Silhouette Studio, set A4 landscape as paper and converted the dashed lines into continuous lines.

Figure 03. File after fixing

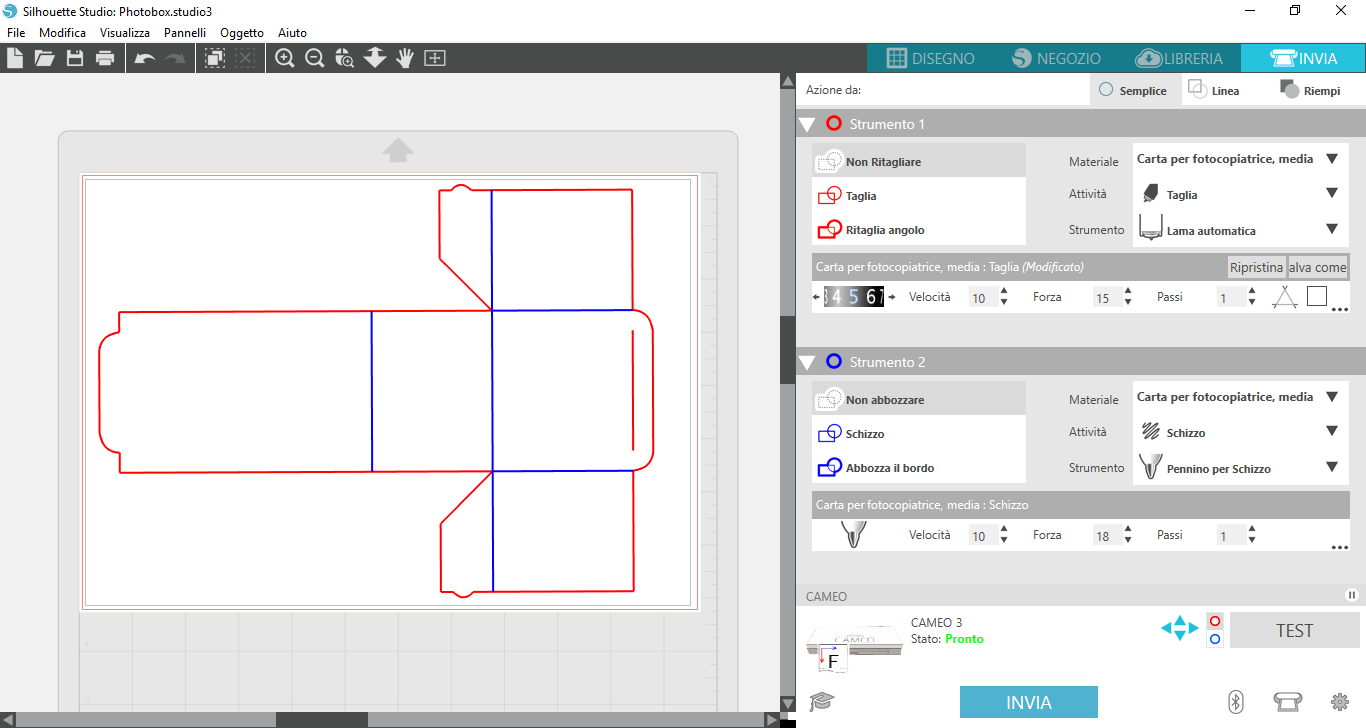

The machine had mounted two heads, one for the cut and one pen. So I set the red lines for cutting and the blue lines for drawing.

Figure 04. All settings

Cutting

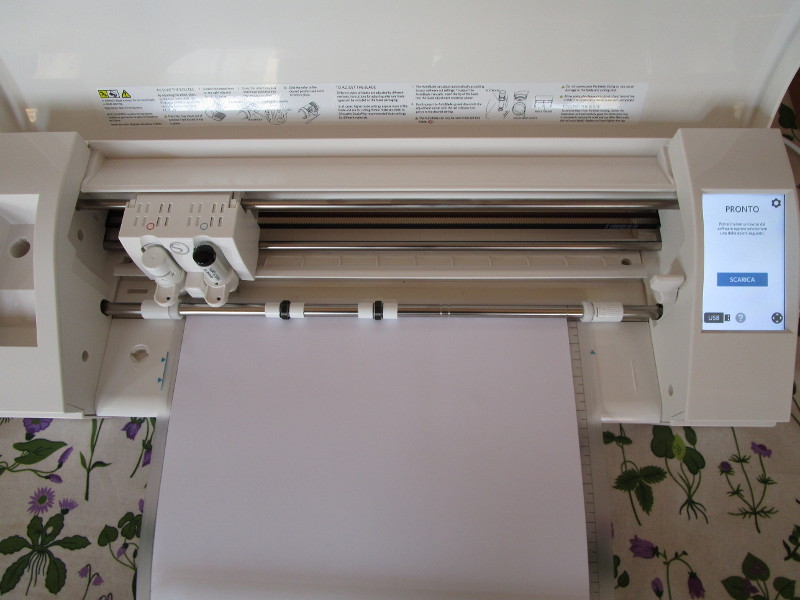

The machine is equipped with an adhesive sheet on which I affixed the paper sheet to cut (A4, 200

g/m2).

Afterward I placed it against the wheels of the machine. Before proceeding I moved the right-hand wheel for

adapt it to the size of the adhesive sheet,

the difference between Figure 5 and Figure 6 can be seen.

Figure 05.

To insert the sheets I pressed charge (CARICA) on the screen. Now everything is ready for cutting.

Figure 06. Ready to cut

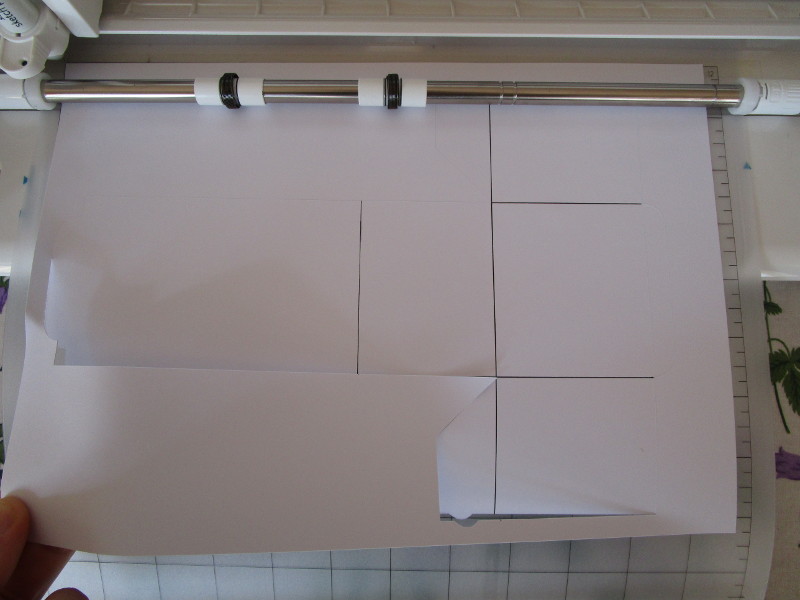

From the screen visible in Figure 4 I pressed send (INVIA). The cut was successful.

Figure 07. The cut was successful

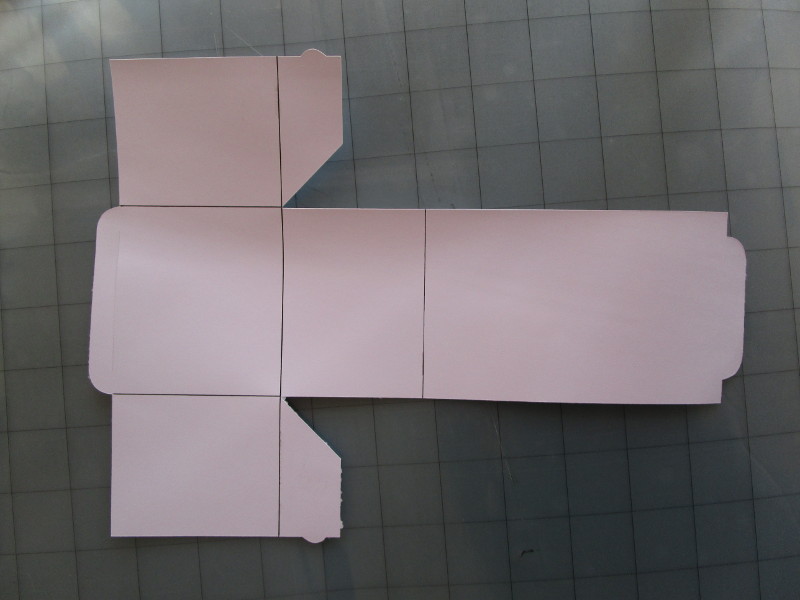

This is the final result after I removed everything

Figure 08. The result

Assembly

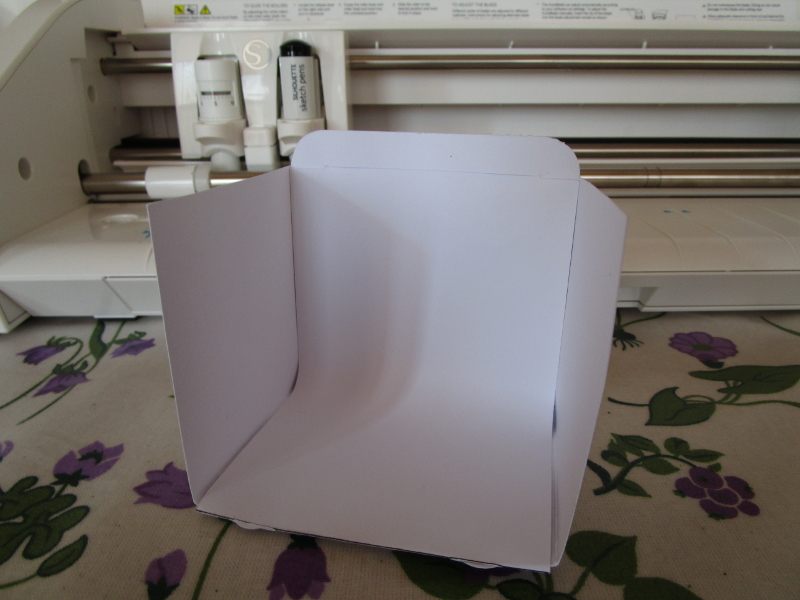

Following the pen lines I bent the sheet to give it the desired shape.

Figure 09. The final result

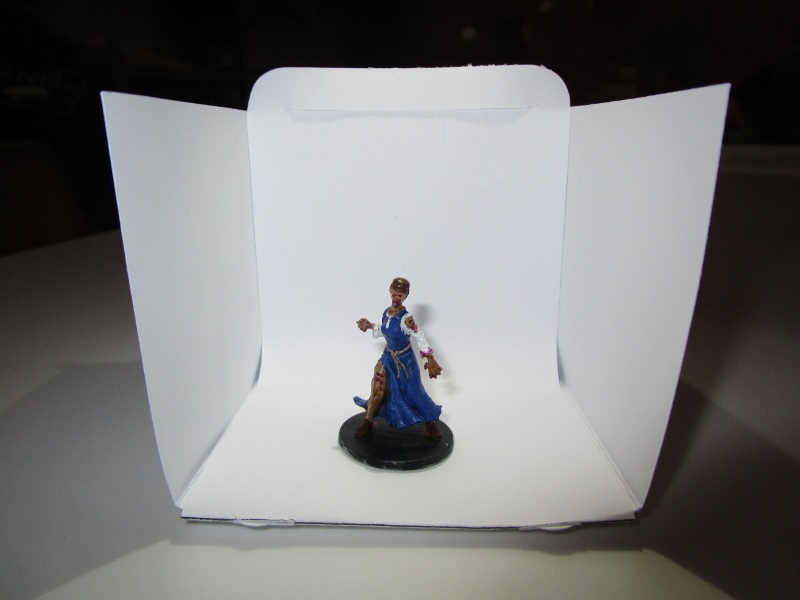

And this is a photo test with a miniature painted by me.

Figure 10. The original photo

Figure 11. The cropped photo

Other

Using the same process, but without using the adhesive sheet, I also made a vinyl sticker using a file made last week with Inkscape.

Figure 12. The Fabacademy sticker logo.

Figure 13. The sticker on my PC.

Laser Cutting

For lasercutting I decided to design a Rubik's Snake to cut with a SpiritGLS by GCC.

Design

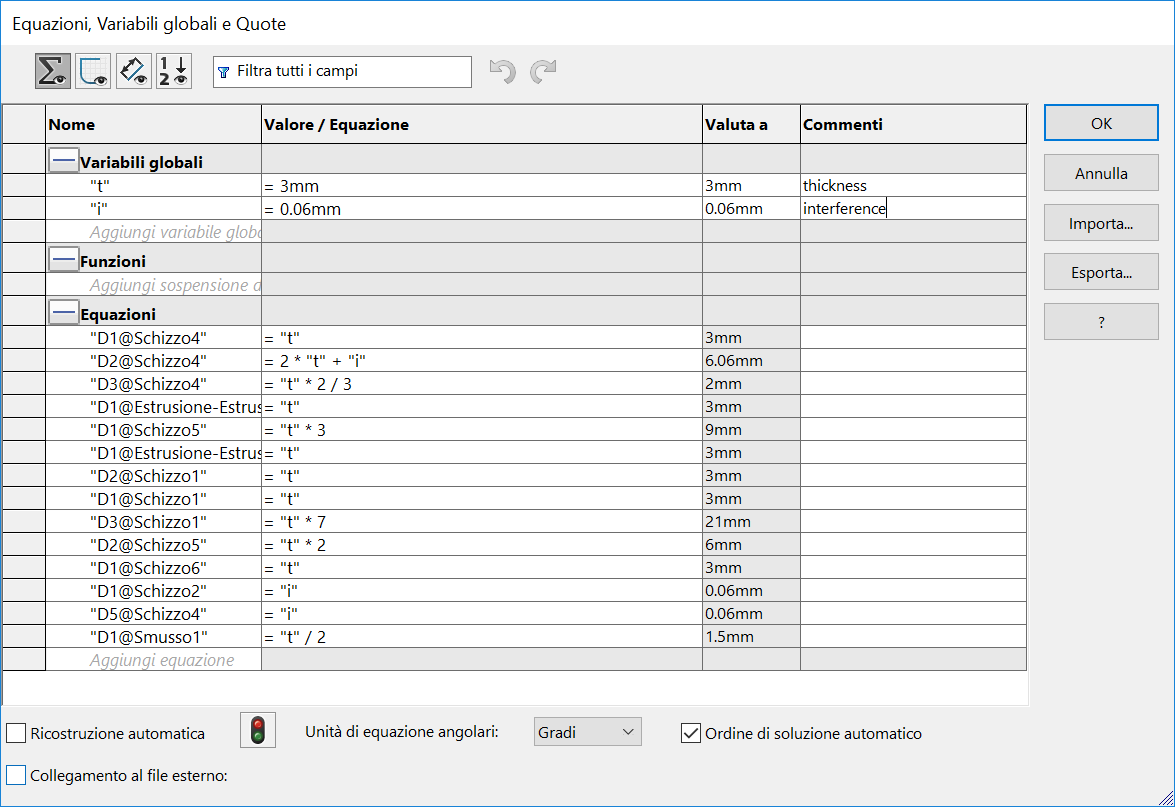

Also with Solidworks I designed the project and parameterized it with the thickness of panel "t" and the tolerance for the joint "i".

Figure 14. Equations

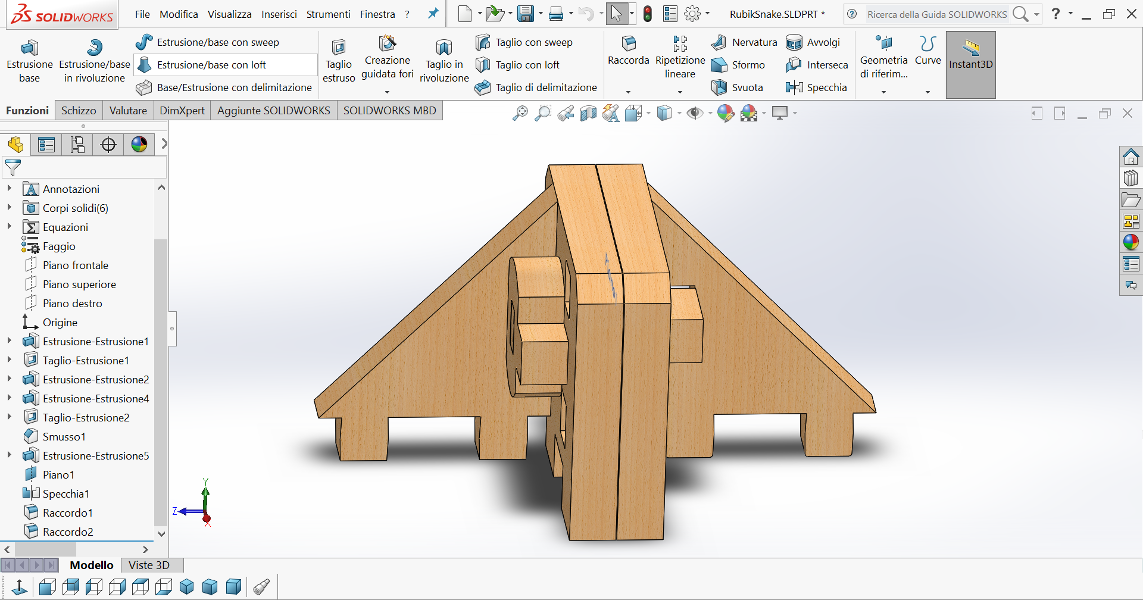

The design is unique and divided into 4 different bodies, two of them, which I mirrored, are repeated twice for each segment of the snake.

download RubikSnake 347 KB (.SLDPRT)

Figure 15. Drawing in Solidworks

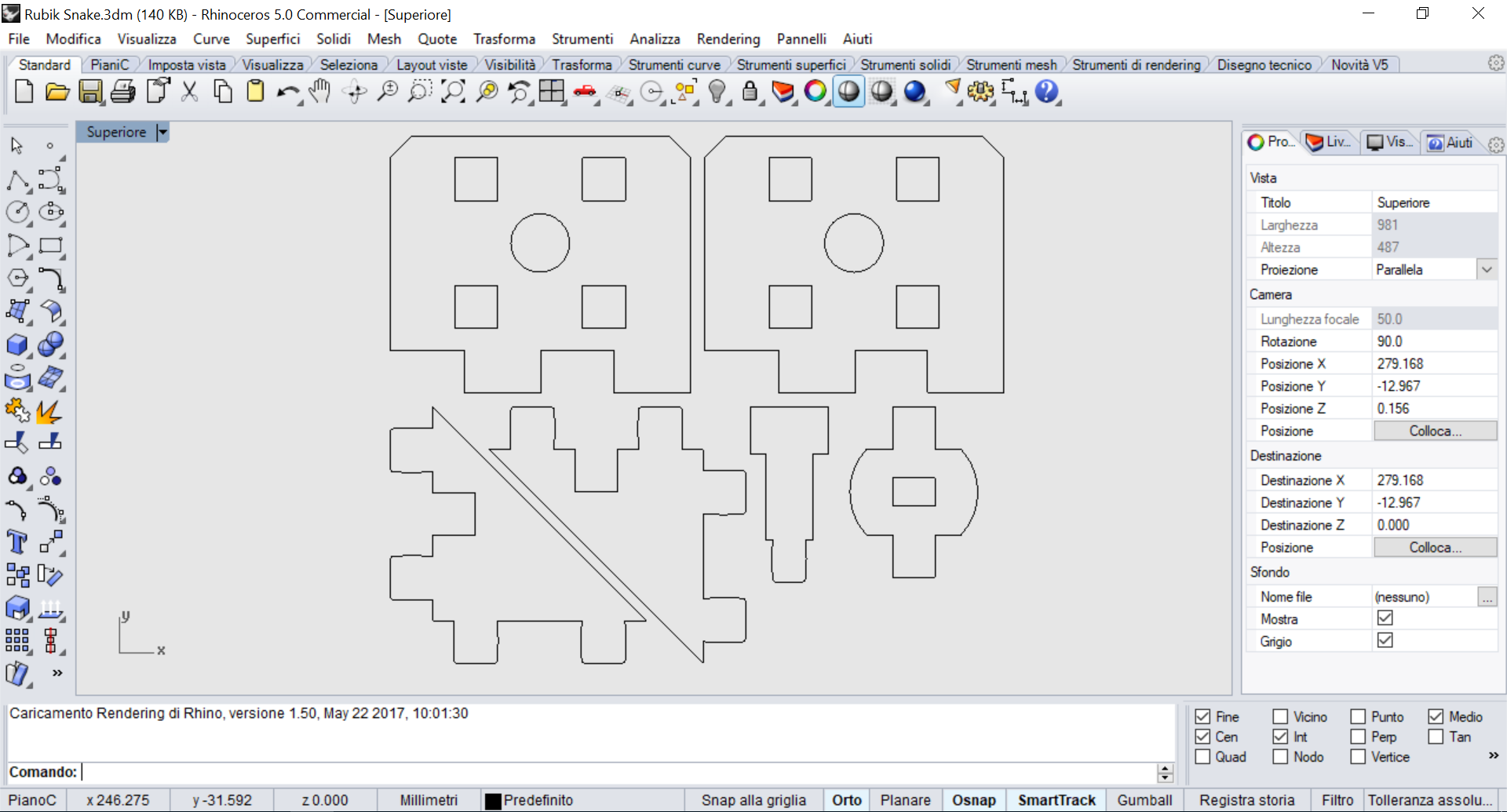

Separately I exported the faces in DXF and with Rhinoceros I made the table and add a 0.1mm

kerf with Offset command. Since the program I used later to send the file to the lasercut

is always Rhinoceros I saved in its native 3DM format.

For completeness also attached the DXF.

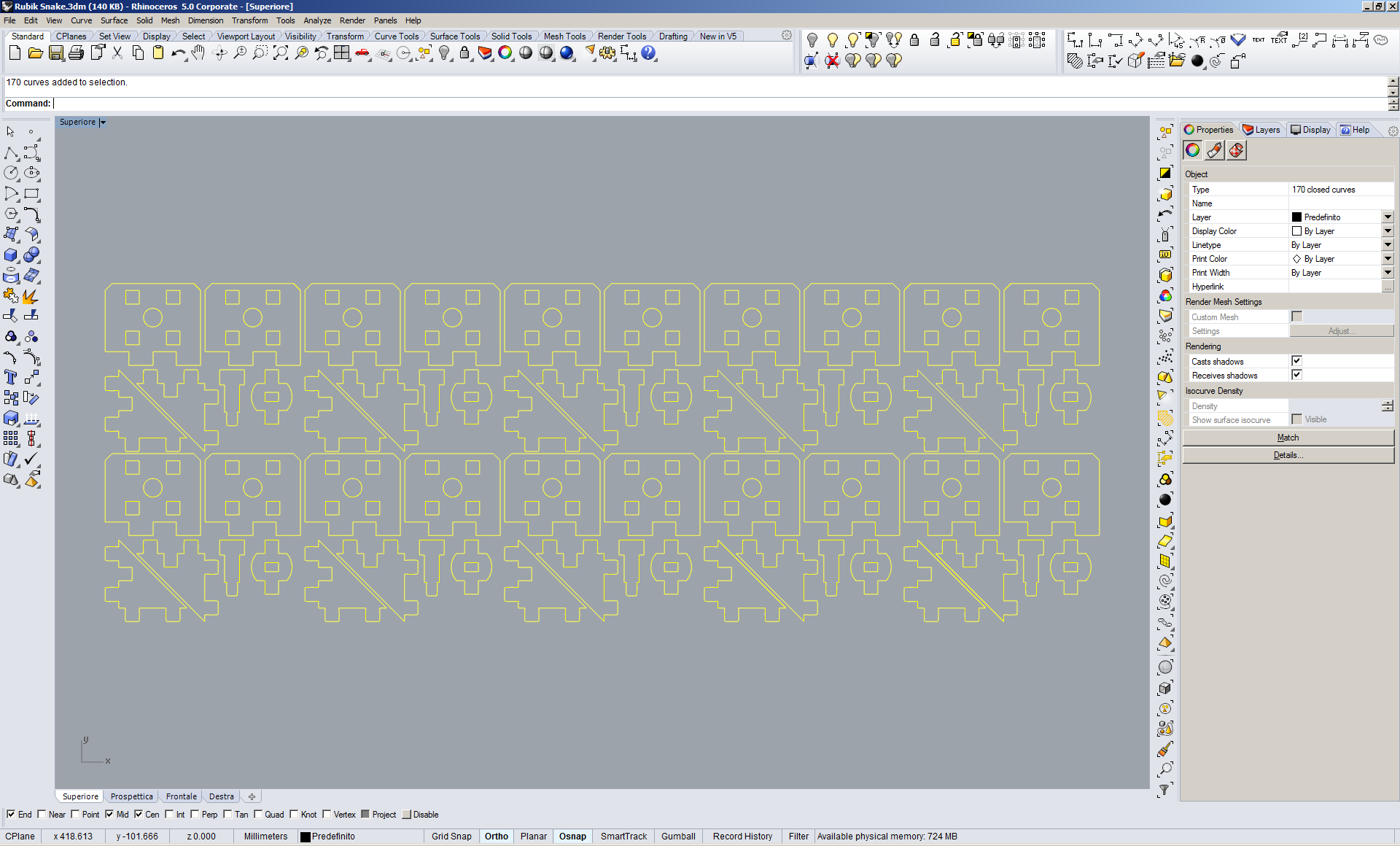

Figure 16. Table in Rhinoceros

download RubikSnake 140 KB (.3dm) download RubikSnake 190 KB (.dxf)CAM

On the computer connected to the lasercut I opened the 3DM file, cloned the segment a few times and in the Properties I made sure that they were all defined as By Layers to prevent lines from getting thick.

Figure 17. Ready to cut in Rhinoceros

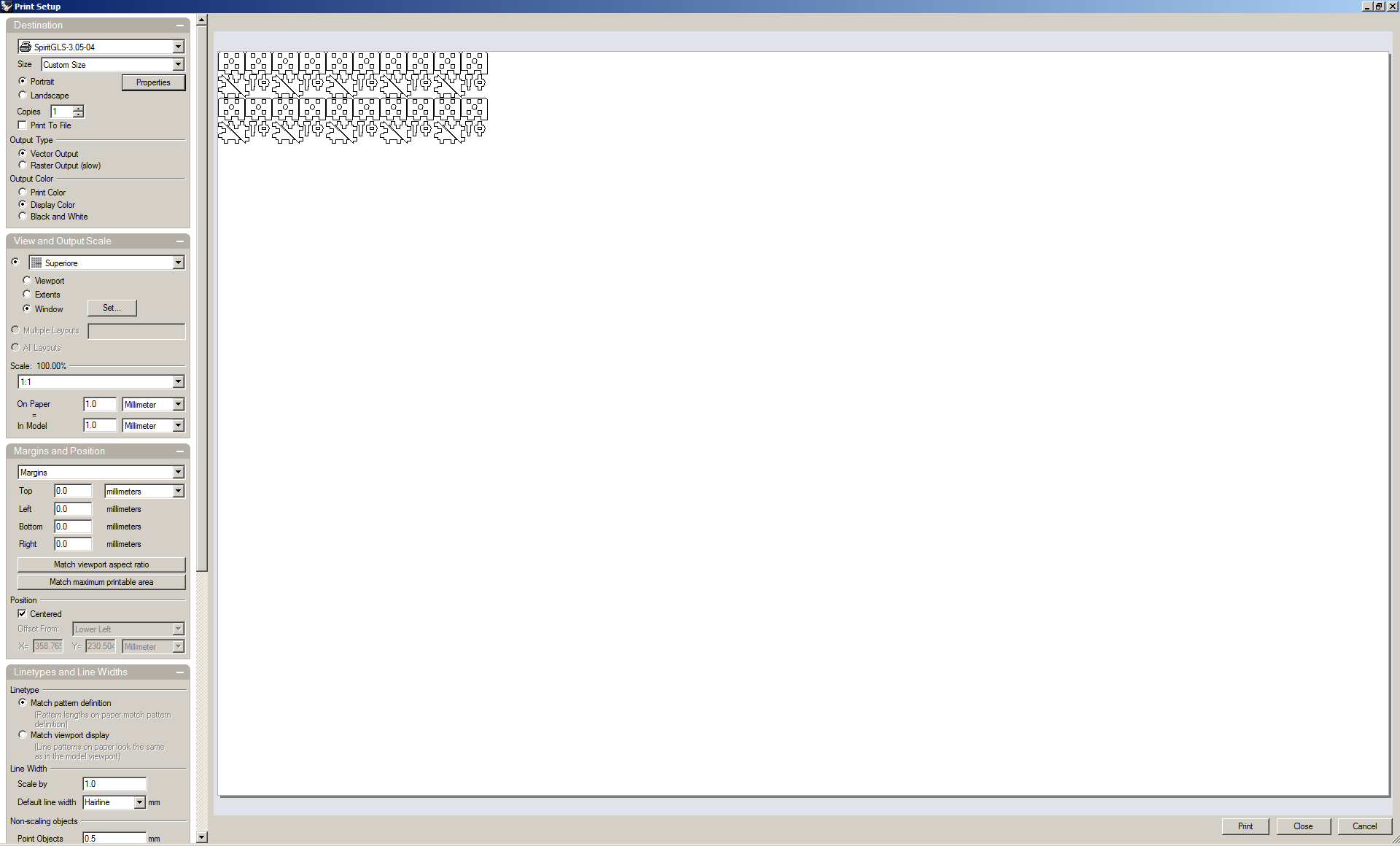

The program sees the lasercut as any printer so I did File -> Print to open the CAM interface.

Figure 18. The print screen

In View and Output Scale I clicked Set... to set the virtual workspace. Then I opened the Properties to set the cutting parameters.

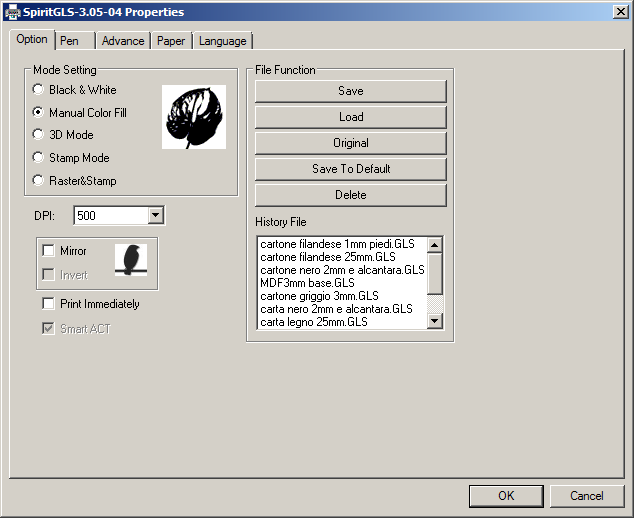

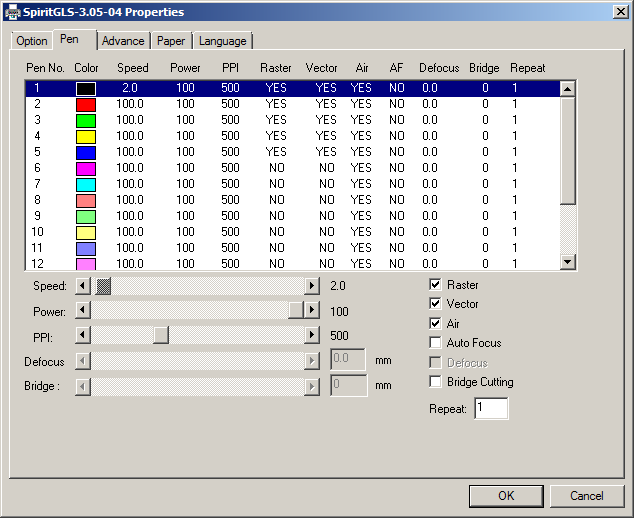

Figure 19. Option

In Pen I reduced the cutting speed to 2.0 mm/s.

Figure 20. Pen

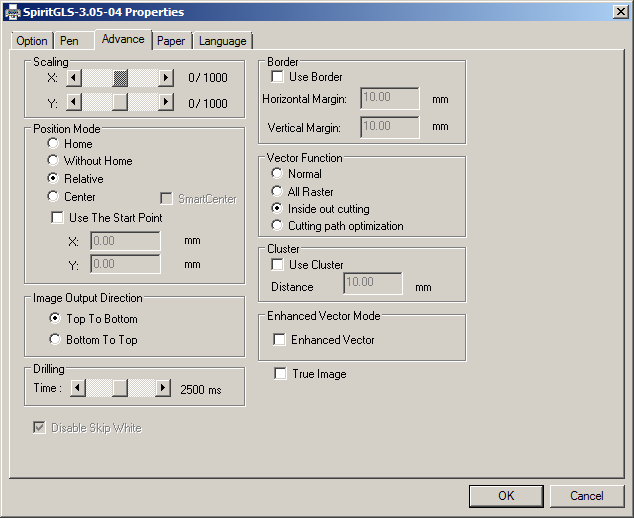

In Advance I set the Position Mode to Relative to start cutting from the top left corner of the drawing starting from the laser position in the machine.

Figure 21. Advance

Therefore I clicked on OK and Print to send the file to the lasercutter.Cutting

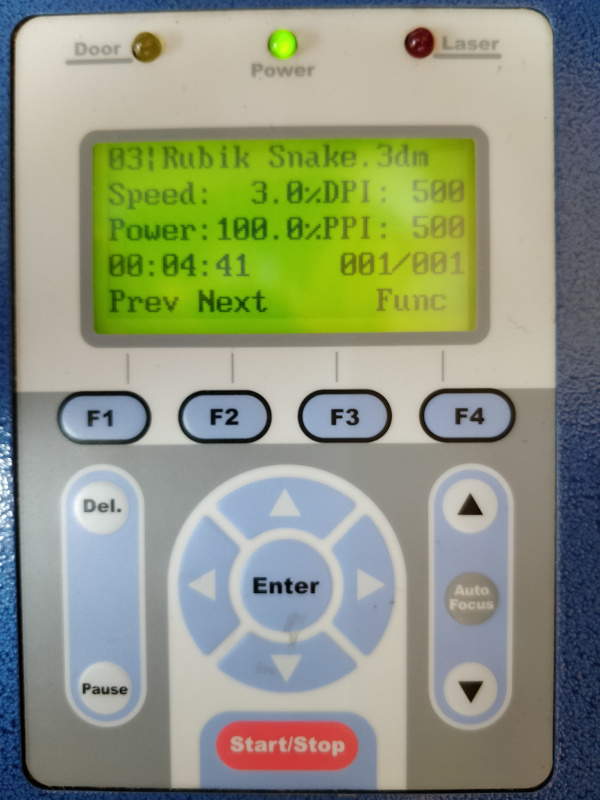

The lasercutter is a SpiritGLS by GCC with a 960x610 cutting area. I placed a 3mm MDF panel under the machine head and from the control panel I pressed Auto Focus to adapt the table top to the thickness of the material to be cut.

Figure 22. The controller

The head from which the laser comes out can be moved by hand, so I placed it in the top right corner for panel and, after closing the protective cover, I pressed on Start.

You can see the laser cutting through the protective cover.

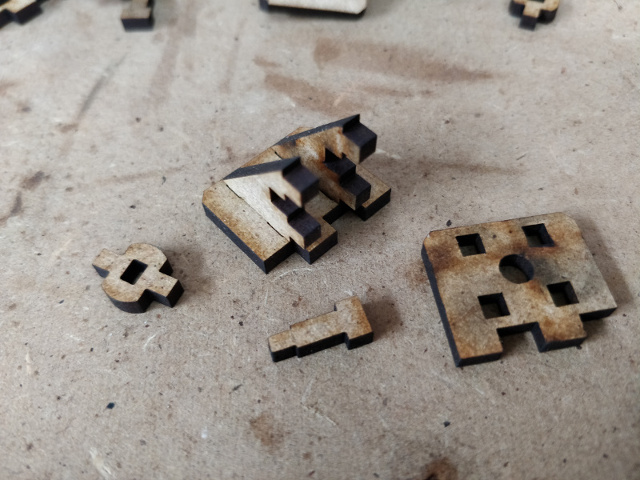

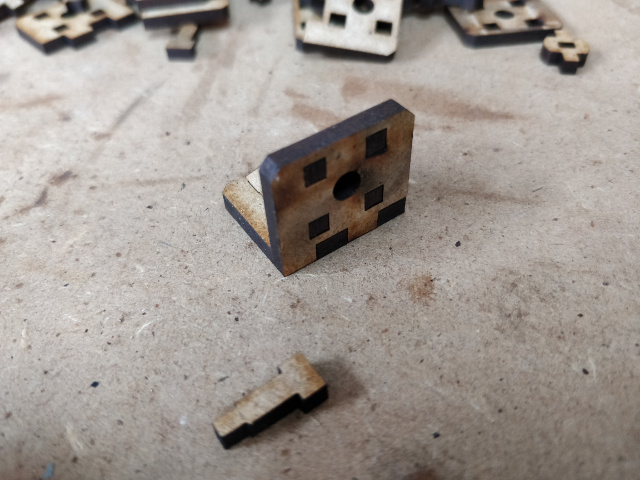

This is the result once the machine is finished.

Figure 23. After cutting

Figure 24. Some pieces

Assembly

This is the assembly sequence I followed.

Figure 25. Step 1

Figure 26. Step 2

Figure 27. Step 3

Figure 28. Step 4

Figure 30. Step 5

Figure 32. Step 6

Figure 33. Step 7

Figure 34. Two joined segments

Figure 35. Two joined segments

All the pieces fitted perfectly without the use of glue, but for safety I put some vinyl on the outer sides.

This is my Rubik's snake with 14 segments!

Figure 36. My Rubik's snake

Figure 37. The dog figure

Group Assignment

More info on the Opendot group assignment page.