Making parts (Extruder module)

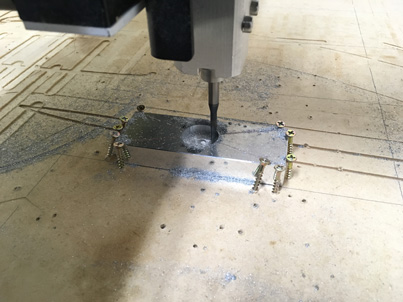

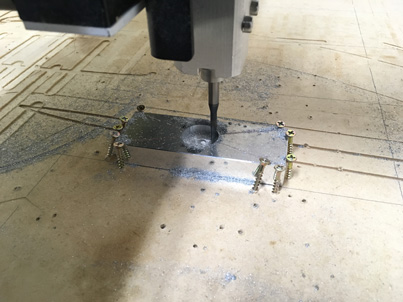

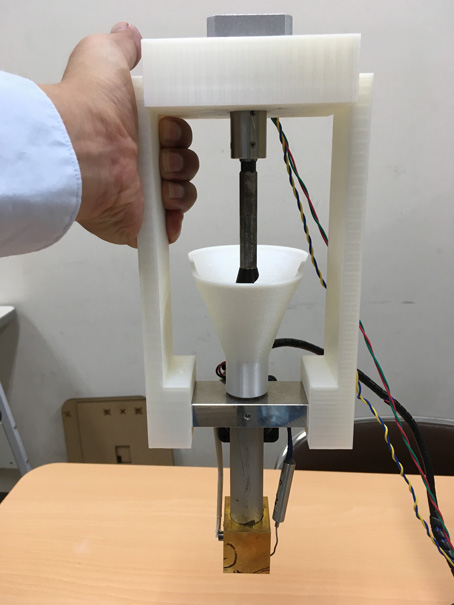

I'v already made hot end parts after the class of Computer-Controlled Machining. Another extruder module parts were made as follows.

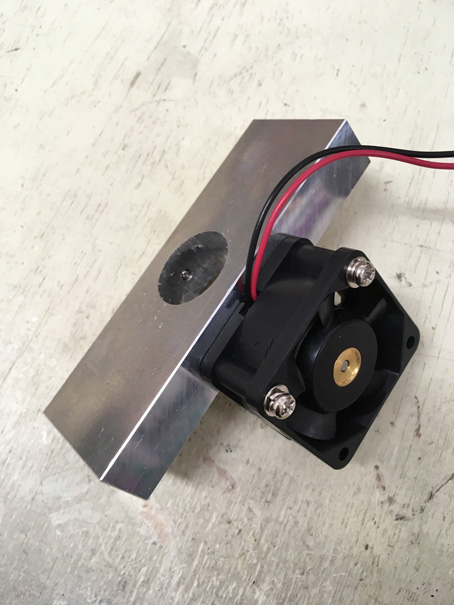

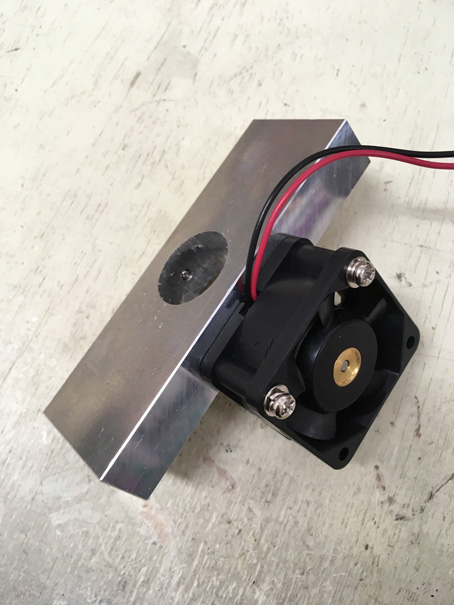

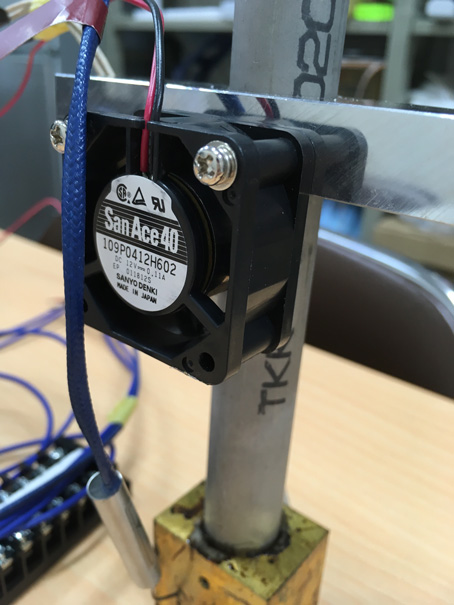

Fan mounting

I thought about making most of body parts with aluminum.

But because I injured my thumb on my left hand few days after from I made the above aluminum parts, it became difficult to handle CNC machine. So, I decided to make other parts with 3Dprinter.

In that case, it is important to insulate from high temperature because the body made with 3Dprinter will be melt in high temperature.

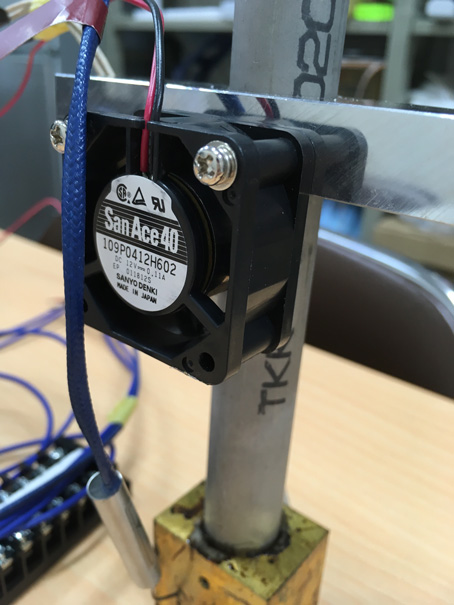

I experimented that to insulate from high temperature by cooling with fan before. At that experiment, I could insulate from high temperature. So, I combined the fan to the parts I made with aluminum.

And using this parts, the experiment was done. Result was not good. Hot end temperature only increased to 270 ° C....

This problem was solved by raising the position to be cooled by the fan by 2 cm or changing heater cartridge from 80W to 120W.

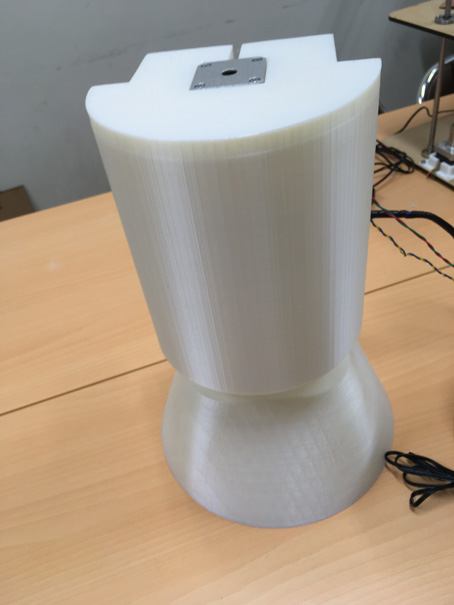

But because I injured my thumb on my left hand few days after from I made the above aluminum parts, it became difficult to handle CNC machine. So, I decided to make other parts with 3Dprinter.

In that case, it is important to insulate from high temperature because the body made with 3Dprinter will be melt in high temperature.

I experimented that to insulate from high temperature by cooling with fan before. At that experiment, I could insulate from high temperature. So, I combined the fan to the parts I made with aluminum.

And using this parts, the experiment was done. Result was not good. Hot end temperature only increased to 270 ° C....

This problem was solved by raising the position to be cooled by the fan by 2 cm or changing heater cartridge from 80W to 120W.

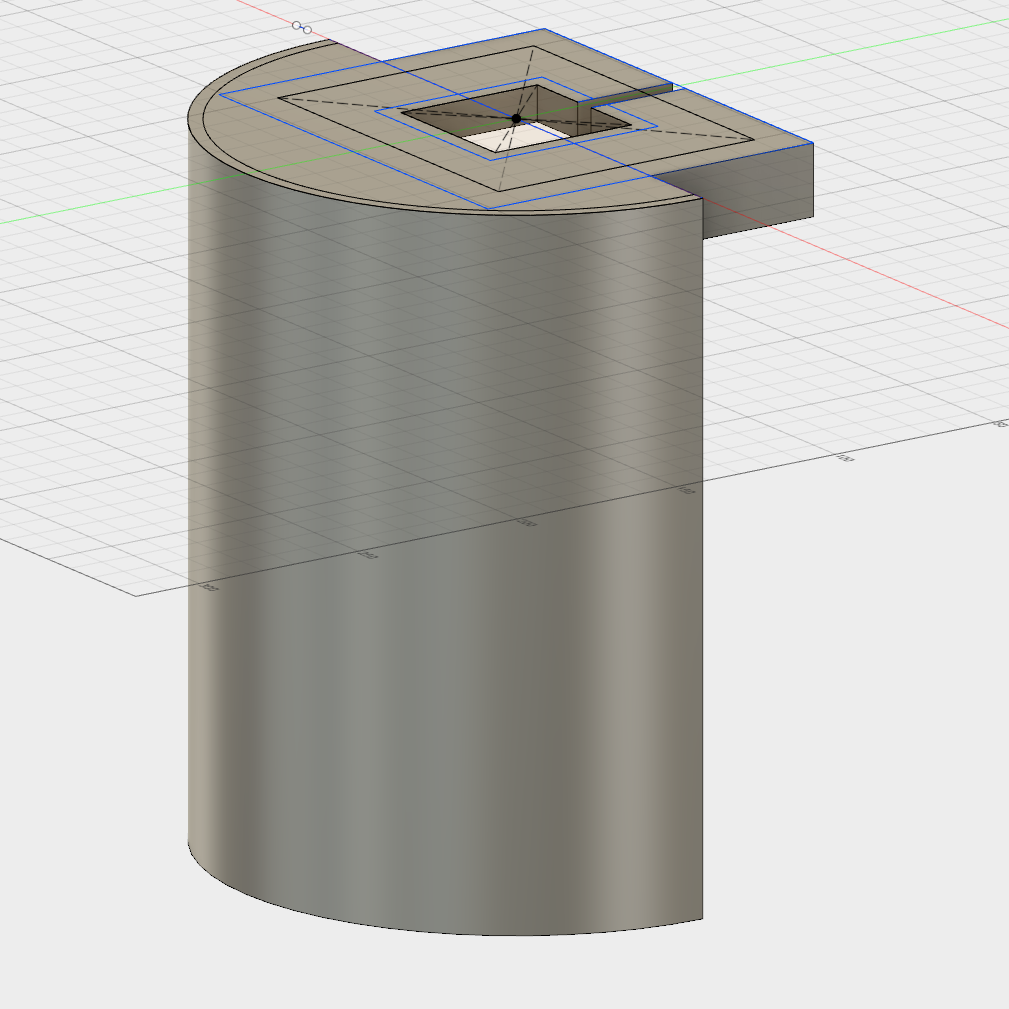

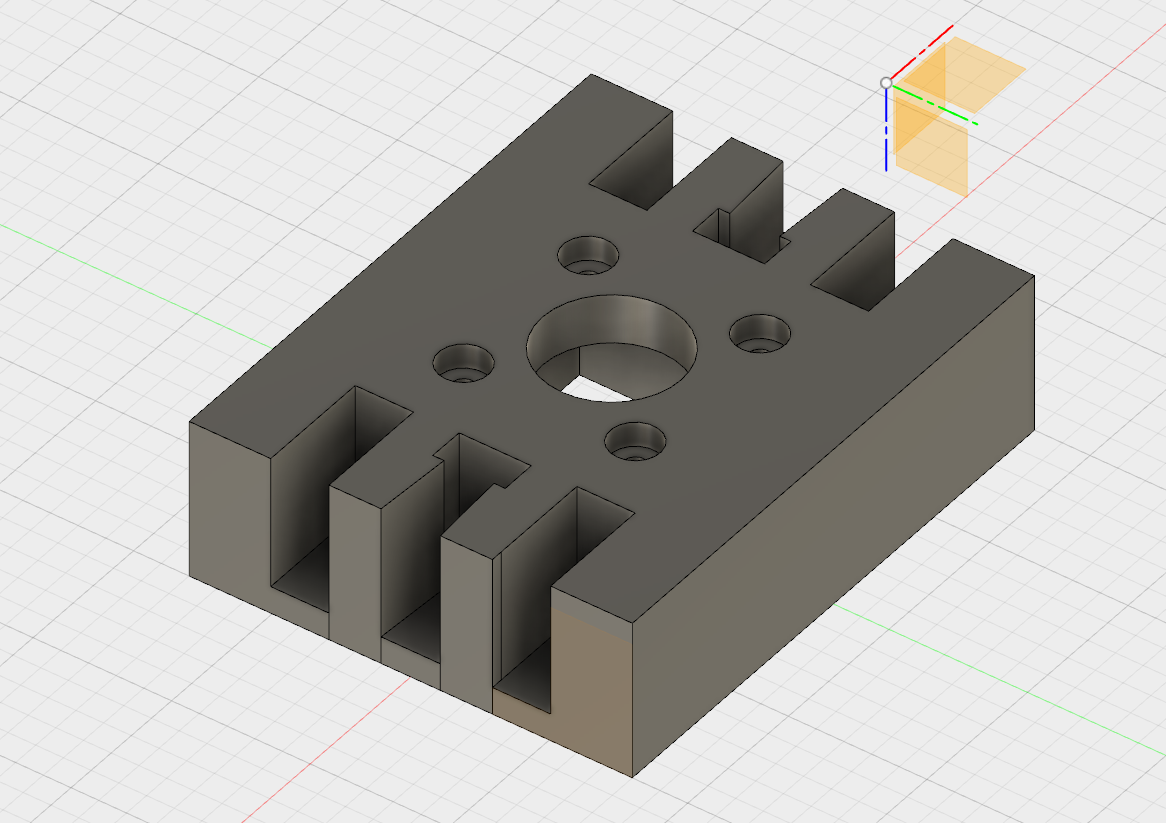

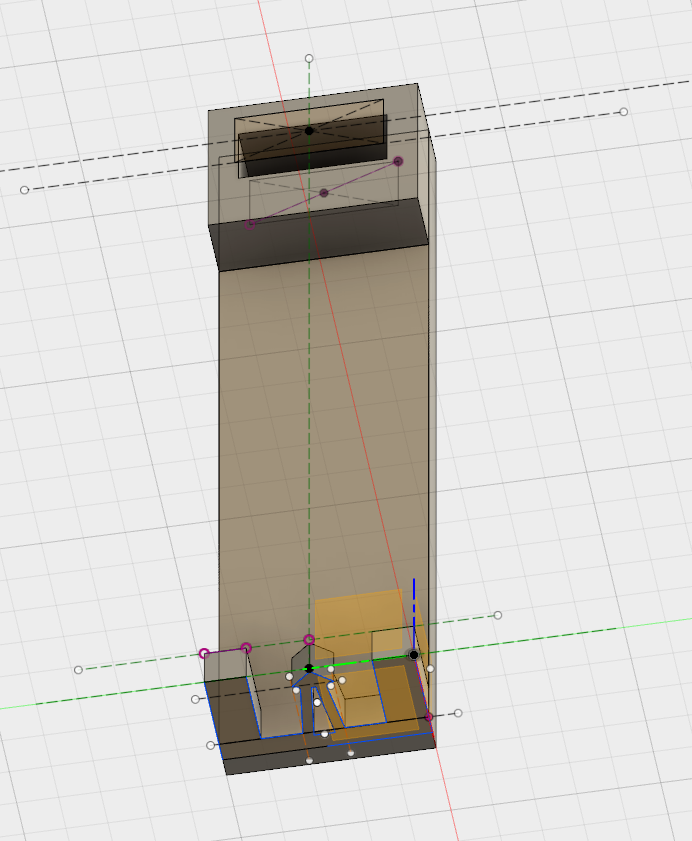

3D desigin with Fusion360

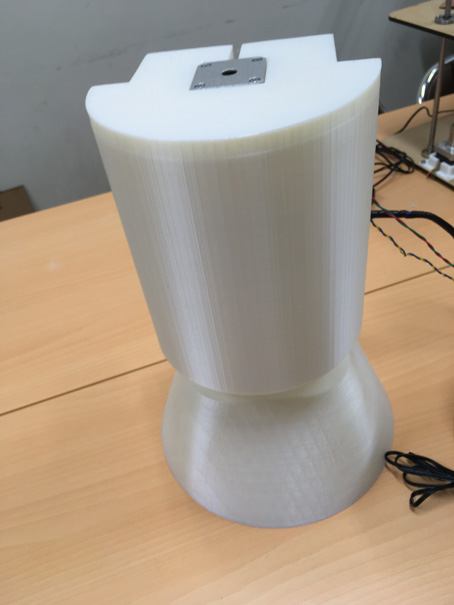

I made a other parts with 3Dprinter.

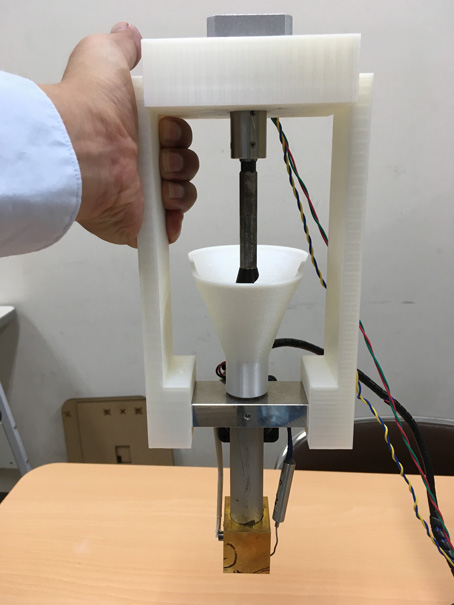

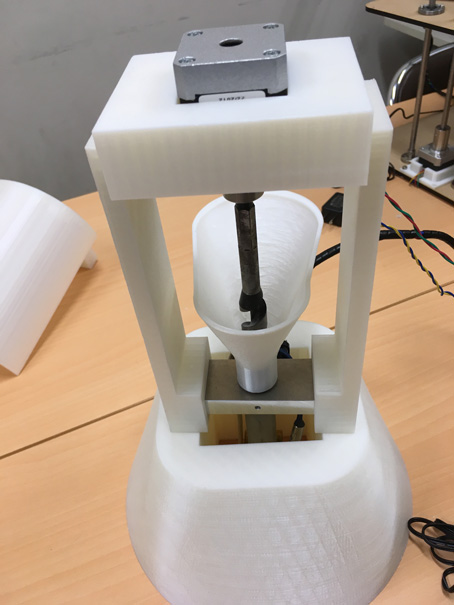

upper parts

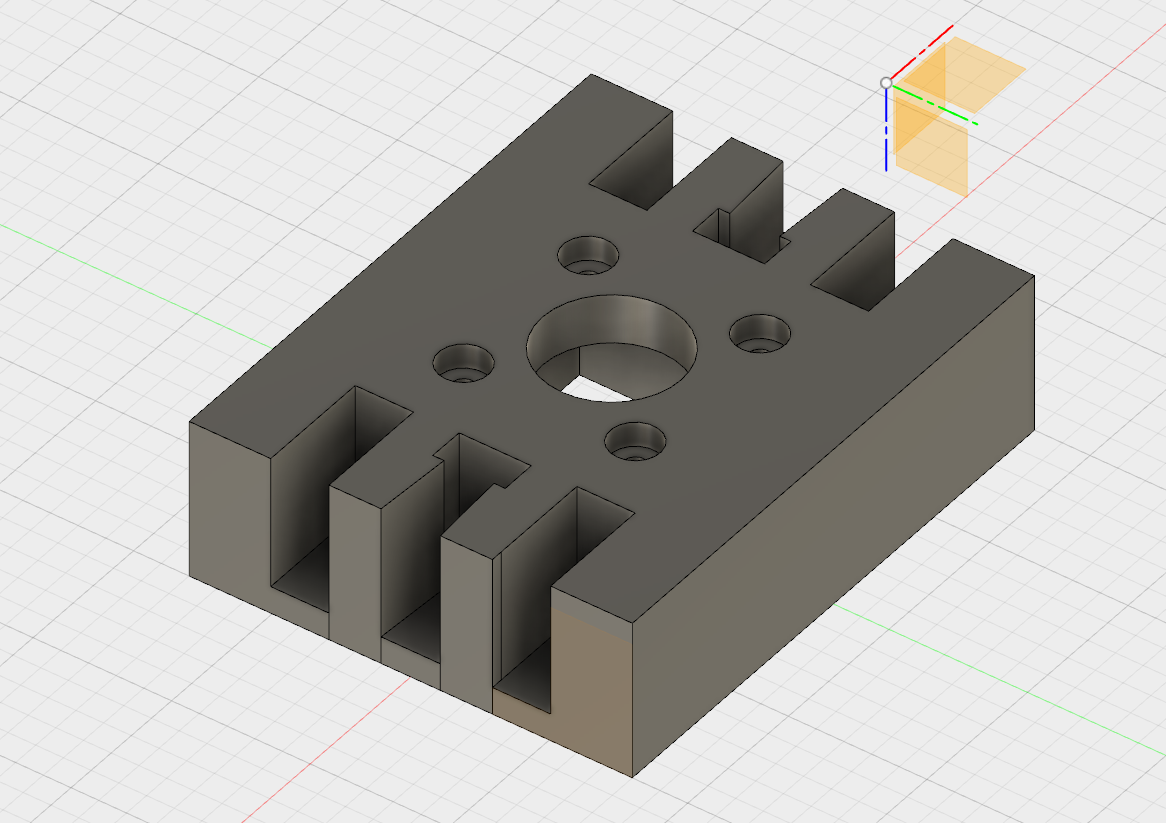

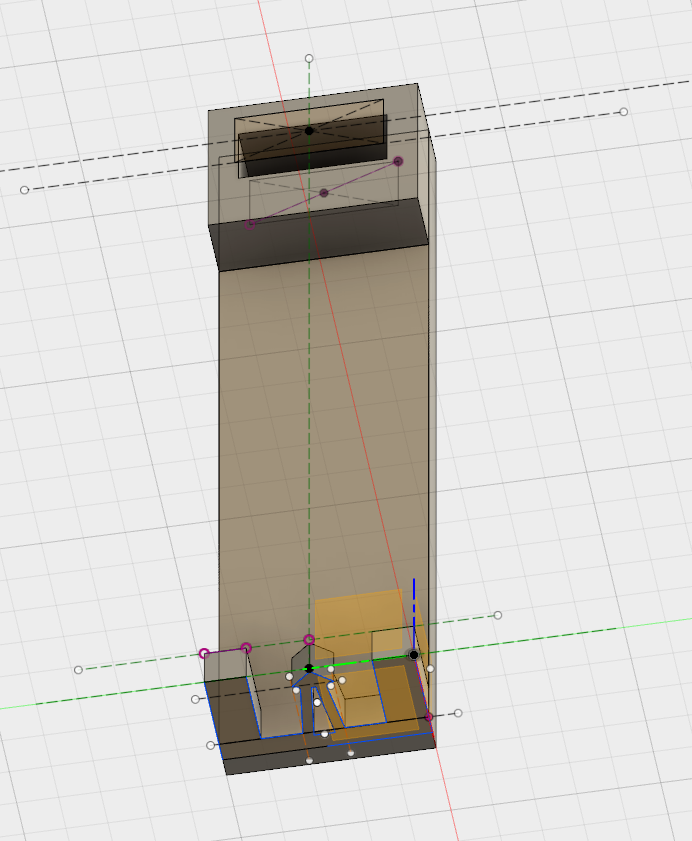

side parts

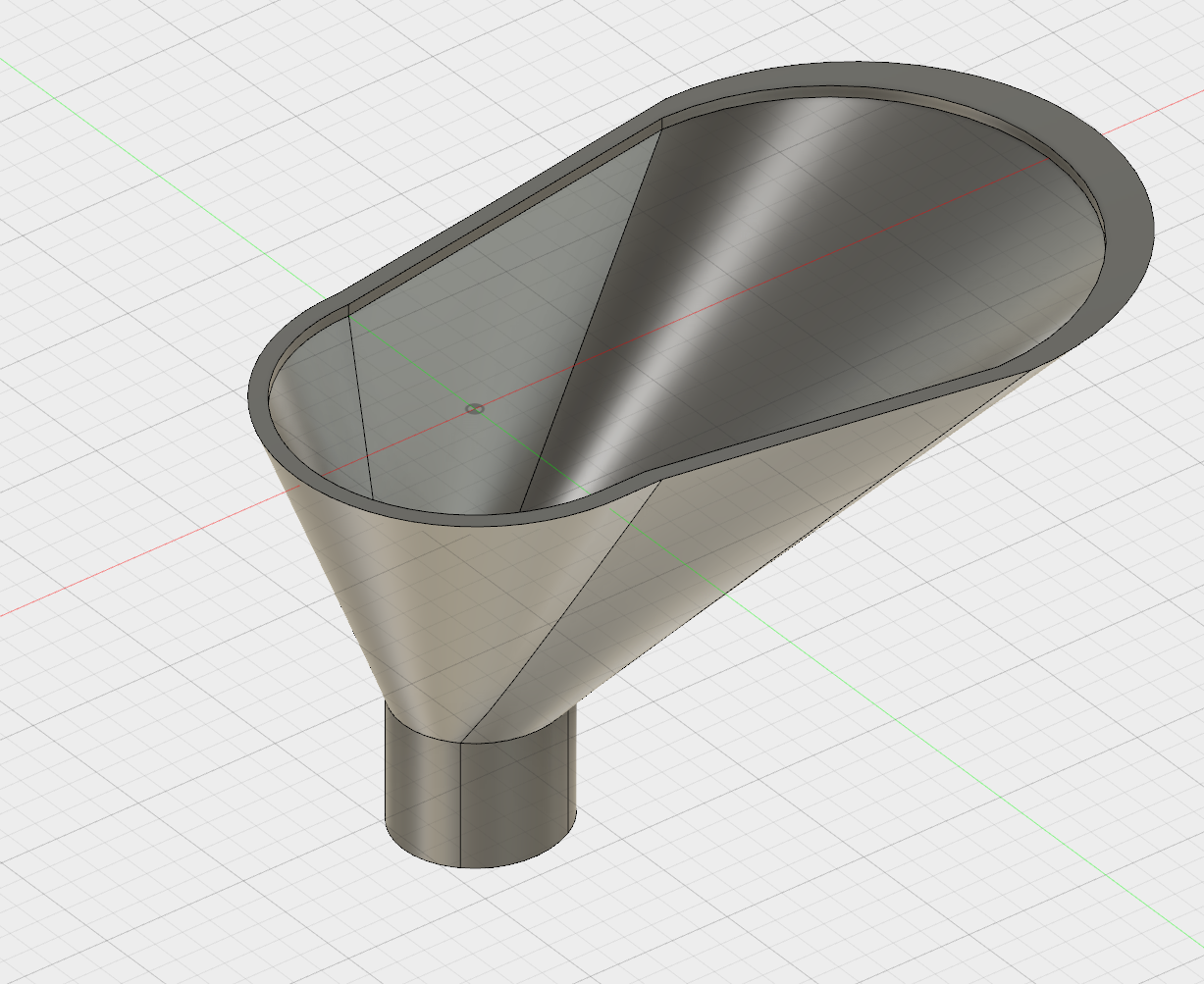

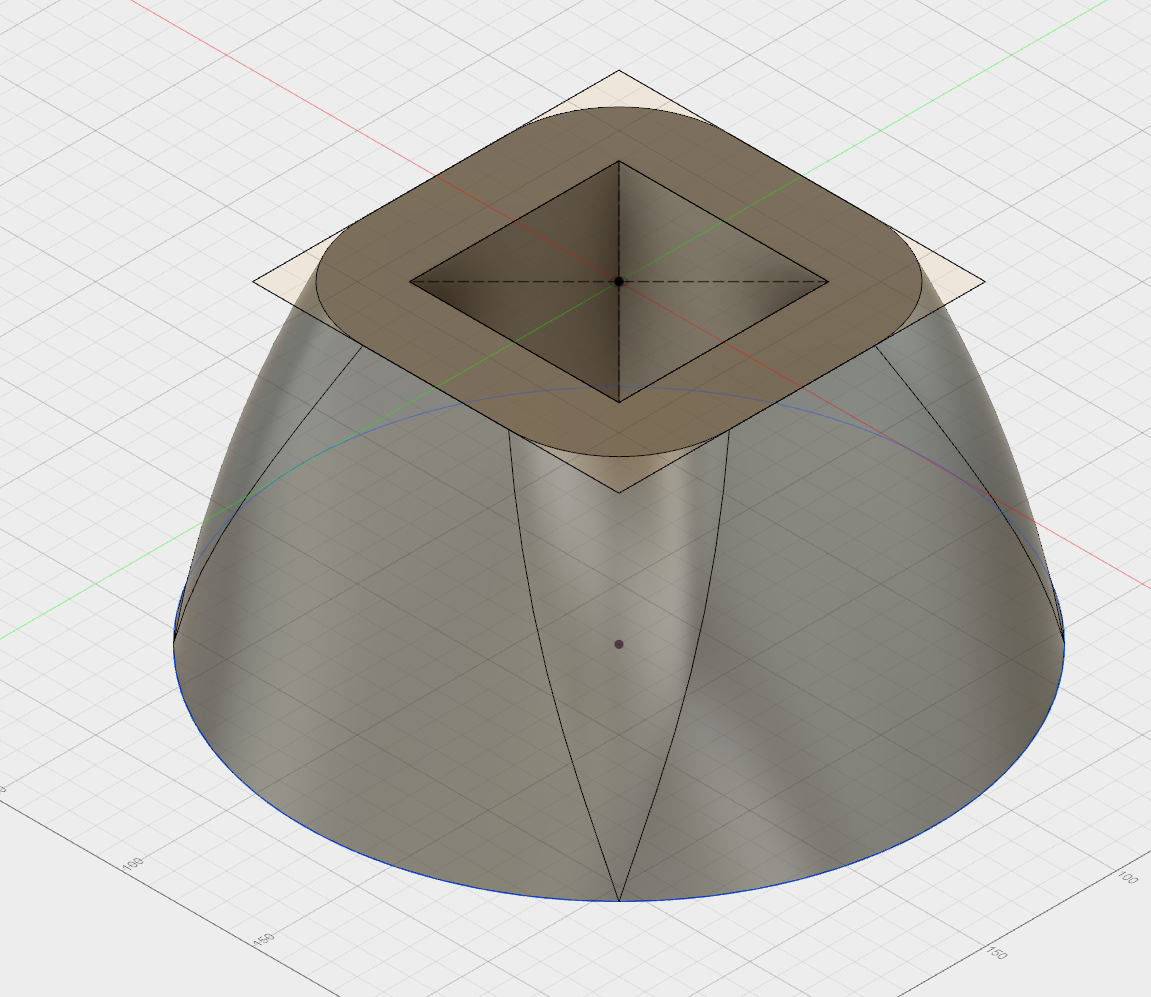

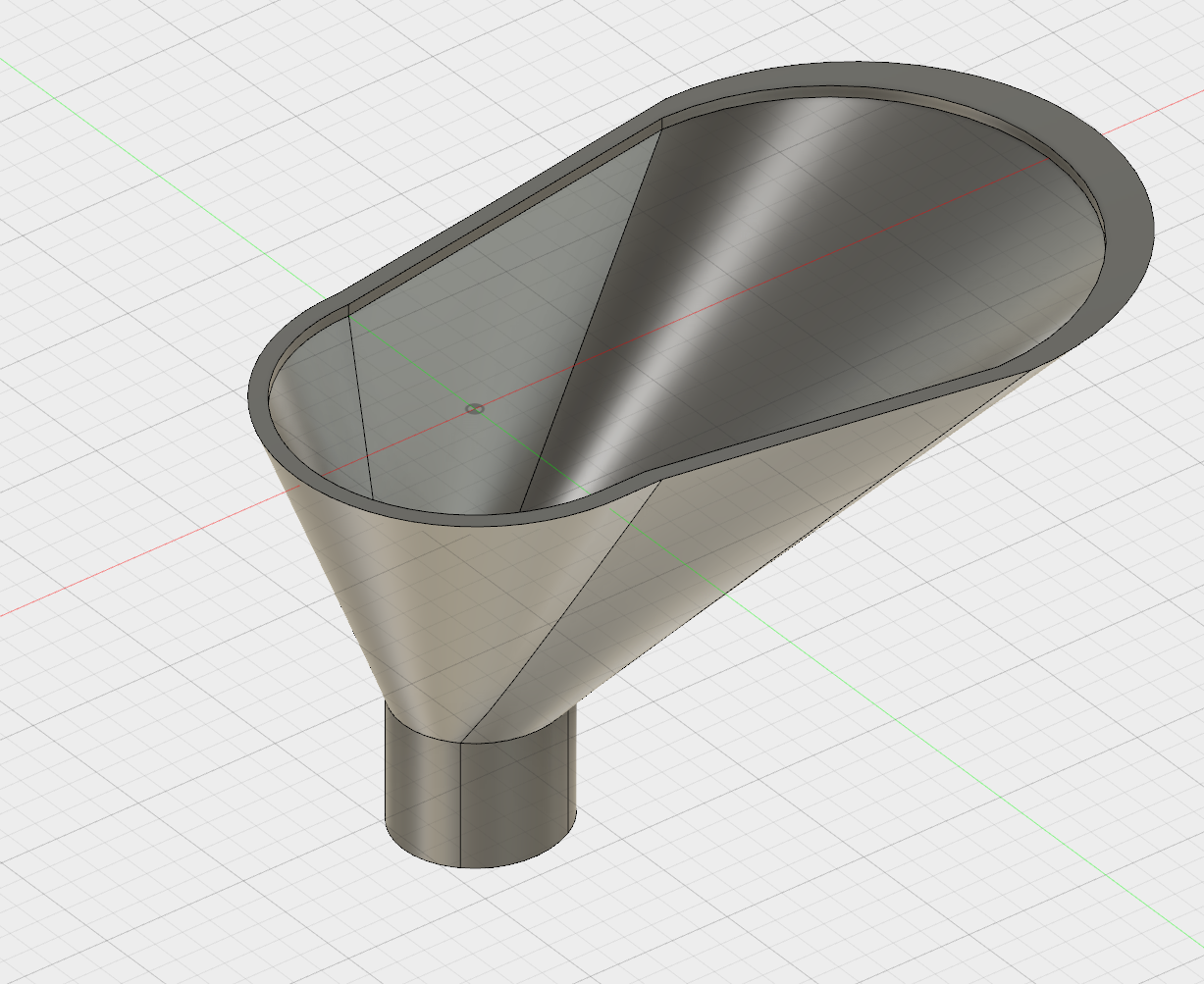

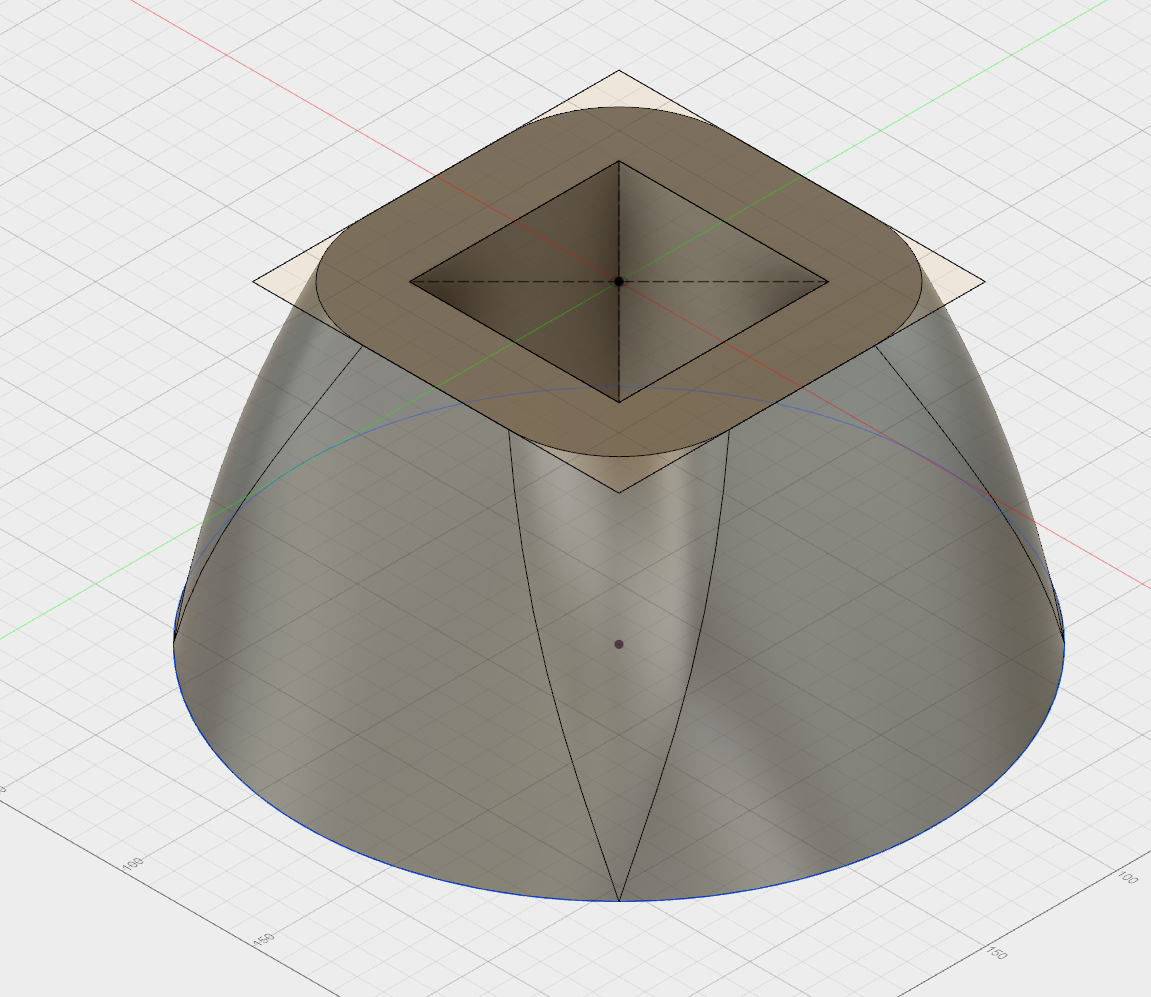

hopper

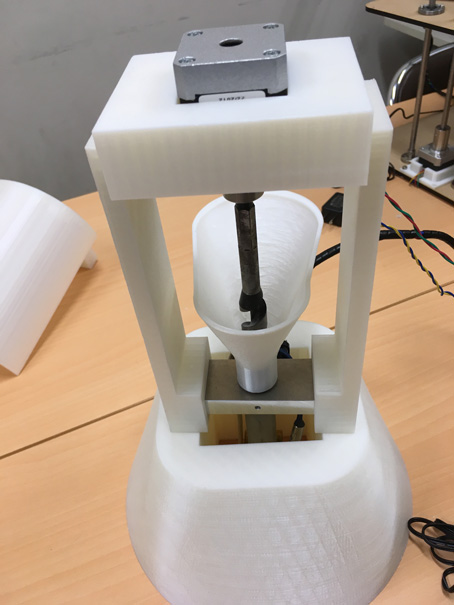

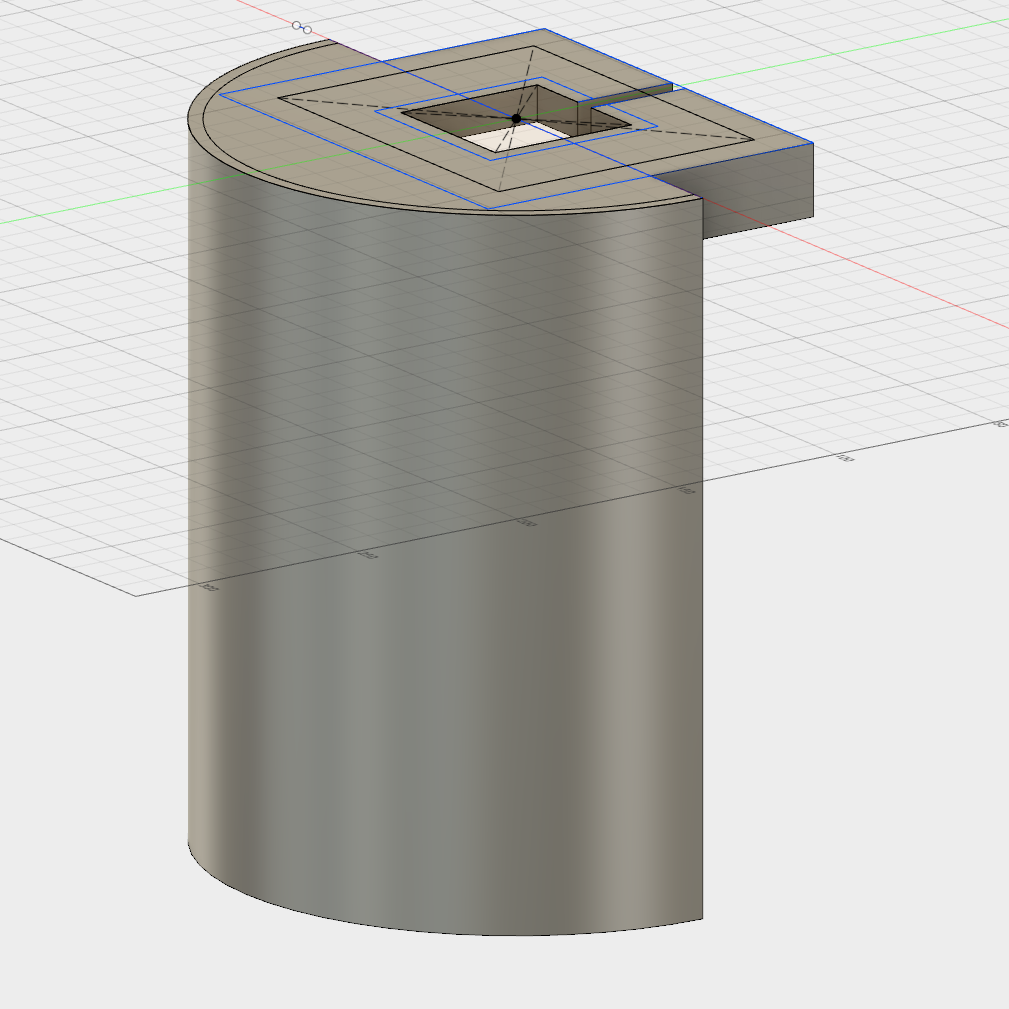

It seems well. But it needed a table to put this extruder module when it was not used. Then, I designed table for extruder .

I tried this exturder, it worked well, but sometime the pellet in the hopper may splash by the rotation of the drill.

upper parts

side parts

hopper

It seems well. But it needed a table to put this extruder module when it was not used. Then, I designed table for extruder .

I tried this exturder, it worked well, but sometime the pellet in the hopper may splash by the rotation of the drill.