Experiments (Final Project )

I used the soldering Iron to test if my code is reading the correct temperature and if my thermocouple is working properly.

As you can see the Serial monitor is displaying the temperature that is set on the soldering Iron. So everything is working properly.

The leadscrew is connected to a DC motor that is also connected to an H-bridge and my board is programmed to make it rotate clockwise then counter clockwise.

I used a ready H-bridge because the lab inventory was missing the smd component (Just to testing)

that was in OUTPUT device week

.

Before assembling the system, I wanted to make sure that everything was working properly, so I run the system and tried to extrude filament from shredded plastic. It all worked perfectly.

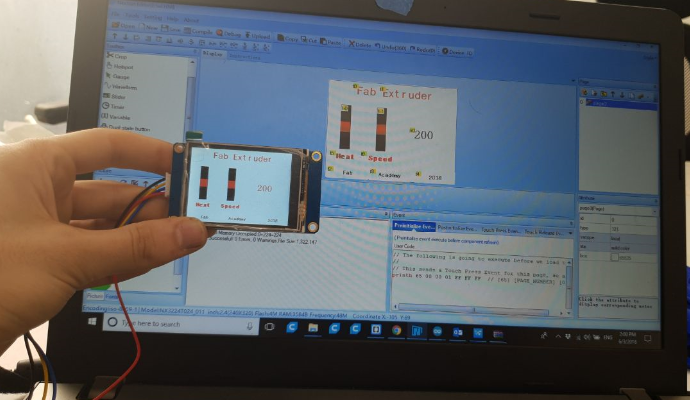

I decided to use a fancy touch screen instead of using an Nextion

LCD Display and a keypad to control the system. The touch screen I used is the nextion touch screen and you can design the user interface and program to do a certain action when a certain button is touched.

The above photo shows my design and the touchscreen.

The above video shows another experiment I did to get recycled filament, as you can see the diameter of the result filament changes depending on many parameters such as the speed of extrusion, cooling the filament and the speed of pulling.

I managed to extrude good results for an experiment and the closest thing to the actual filament diameter I got was 1.71mm.

Last result

The above photo shows the best result I got from my Fab Extruder. It should be 1.75mm and I managed to get 1.71mm.

That difference is due to the fact the filament produced can change depending on many parameters such as the speed of pulling the material and the cooling.

In my opinion the cooling plays a major role in the result. I will work on a cooling mechanism in the future to produce better results.

But I managed to put in a 3D Printer and it got extruded perfectly.