Computer controlled machining

This week's tasks are:

- Design something big

- Fabricate it using CNC router

For this assignment I decided to design a stool which can also be used as a table.

Step1:Design the Stool

I used Fusion 360 for designing .The designing technique was to make it 2D and used the DXF file for machining, 2D file was dwarn using only lines, constrains and dimensions tools. For more detailed instructions on how to use different tools in fusion 360 check Computer Controlled Cutting week.

I made this design for MDF 18 mm thickness

I made the height of the stool around 65 cm and the width around 40 cm.I designed the legs to be pairs of two that

These pairs can be fitted together through two tabs from the oppositie directions.

I designed the base of the stool where I can sit or put stuff to be around 45 CM X 45 CM.

The whole design is so simple and from only 3 parts.

I exported the sketch to DXF to use it in cutting.

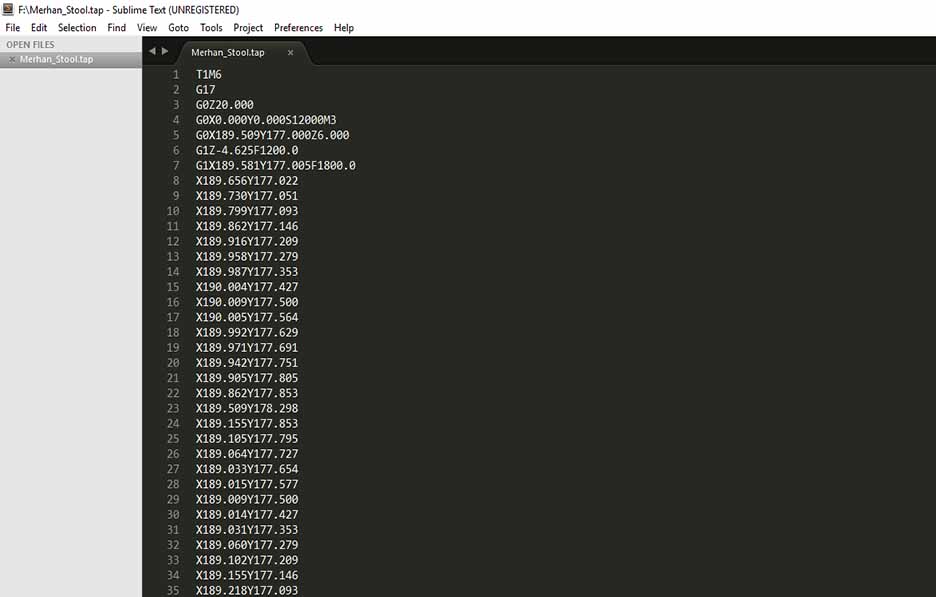

Step2:Prepare the tool path for the CNC milling

The tool path is basicly how the CNC machine will move to create the object and it is set in the form of G-code.There are so many platforms and software that could be used even fusion 360 can be used to create the tool path but I prefered to use the software that is used here in Fab Lab Egypt to learn it which is Aspire.

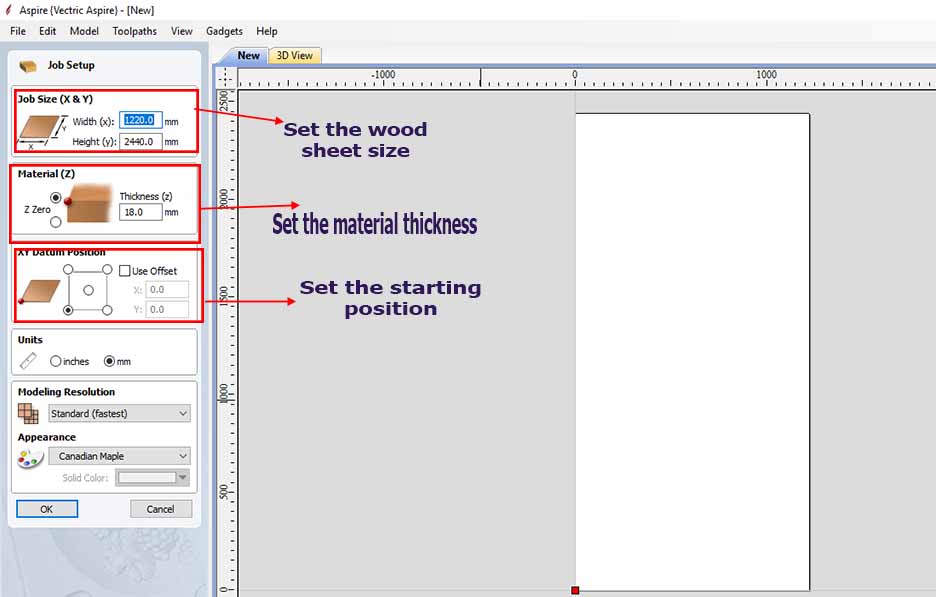

Create a new file and set the dimensions of the MDF sheet ( width, height and thickness) and the starting position to be lower left.

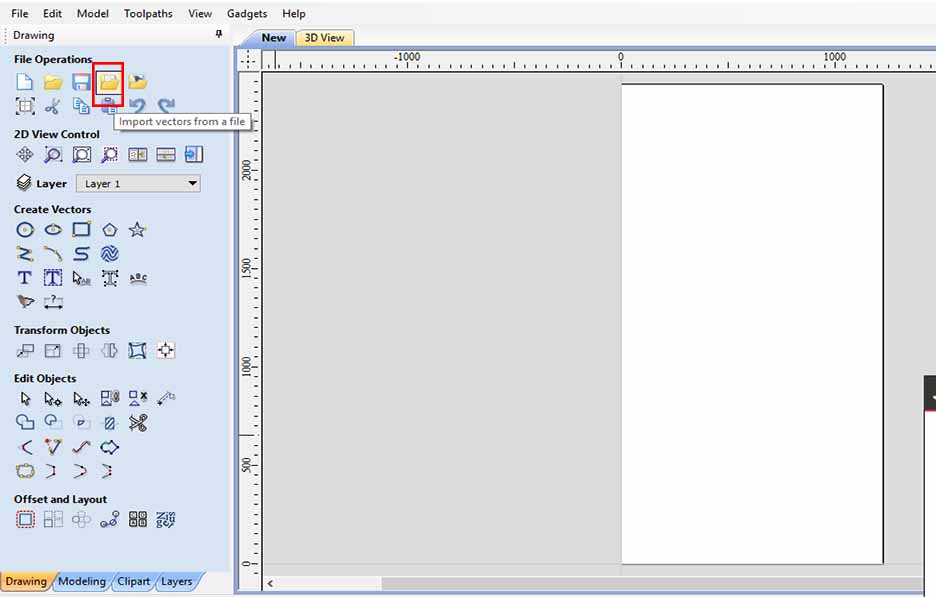

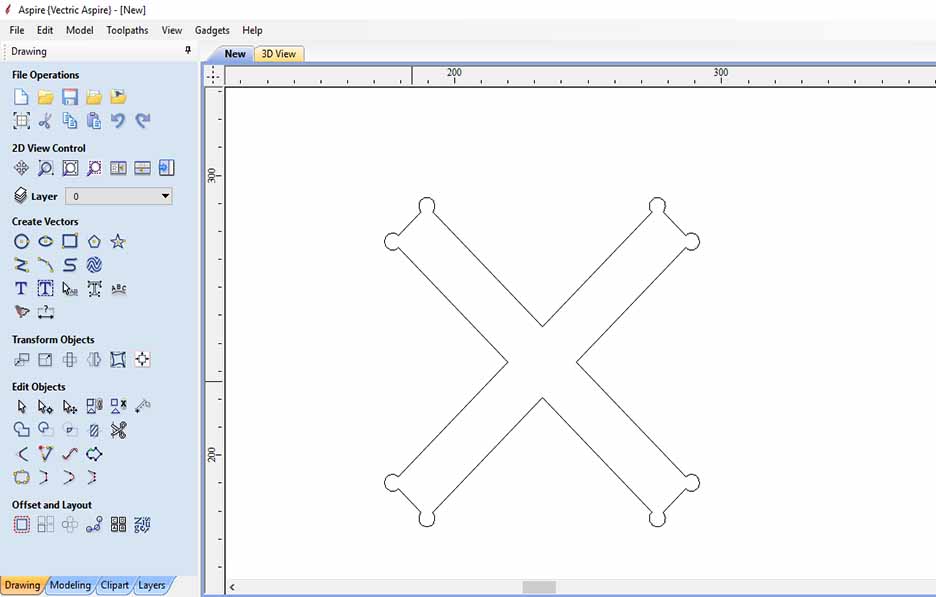

Select (import vector file ) to open the Design in DXF.

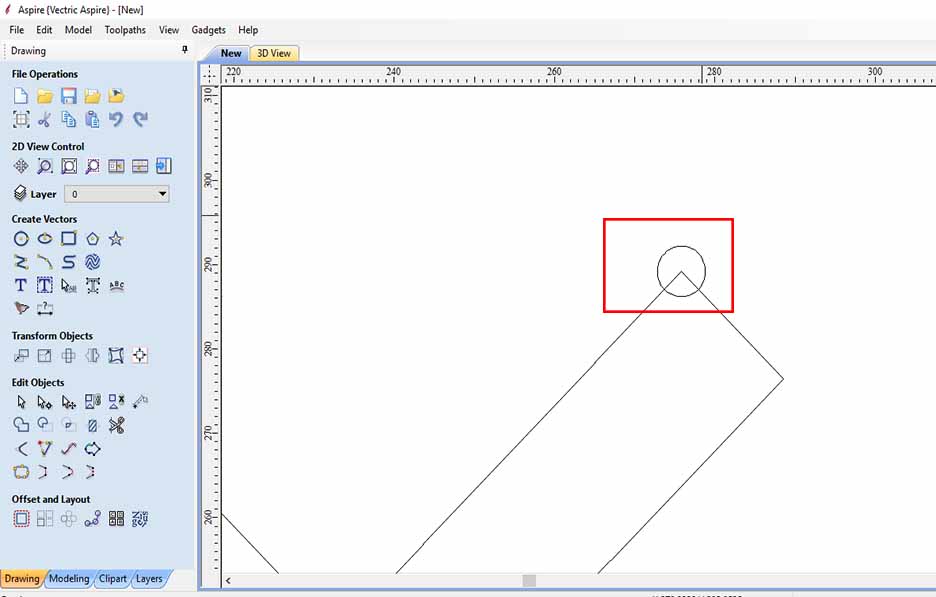

There is a common problem with CNC that corners can't be reached with runded bits! Read more about this issue on this link.This is fixed by making dog bone corners.It is a way where we round the corner to outside till the unreachable areas is covered.

Draw circle with the tool diameter and put it over the corener.

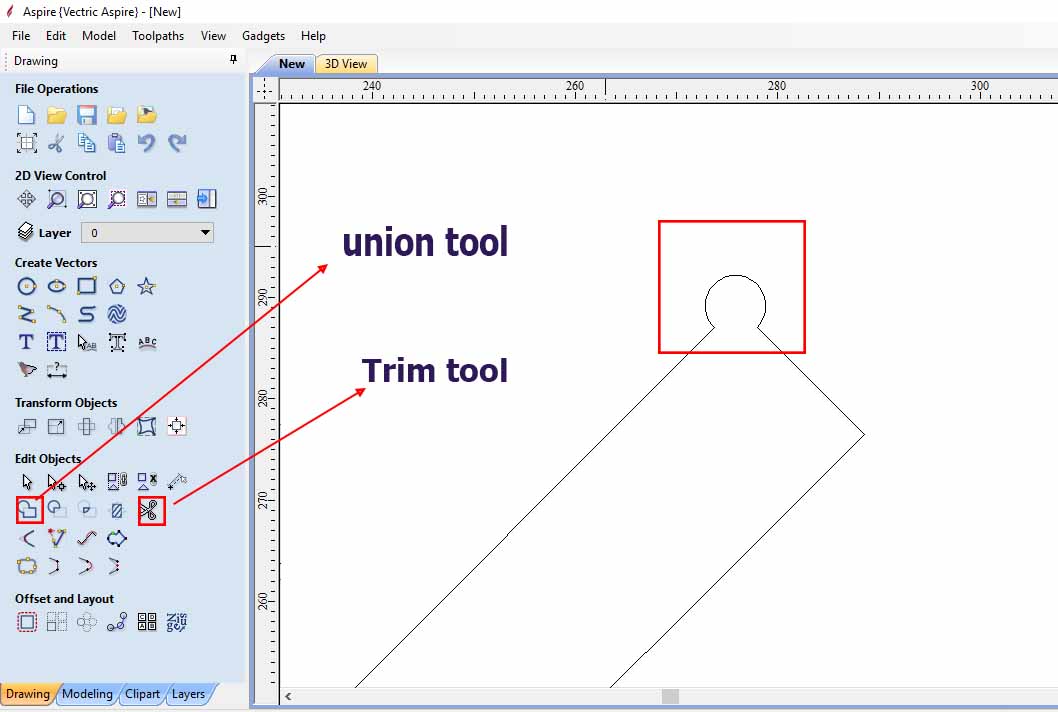

Use the union tool or trim tool to delete the inside part of the circle and leave the outside part.

All corners and tabs should be like this ( this is dog bone).

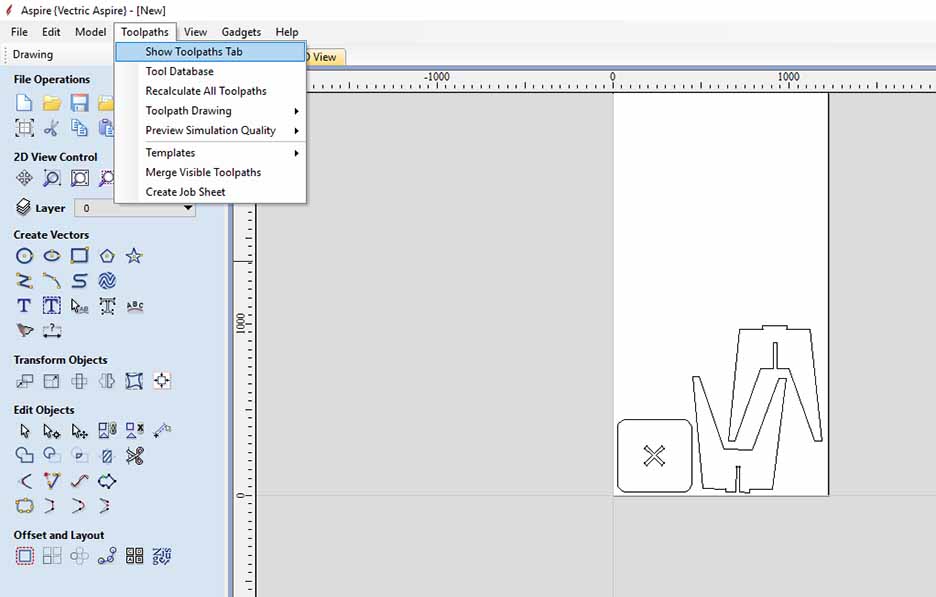

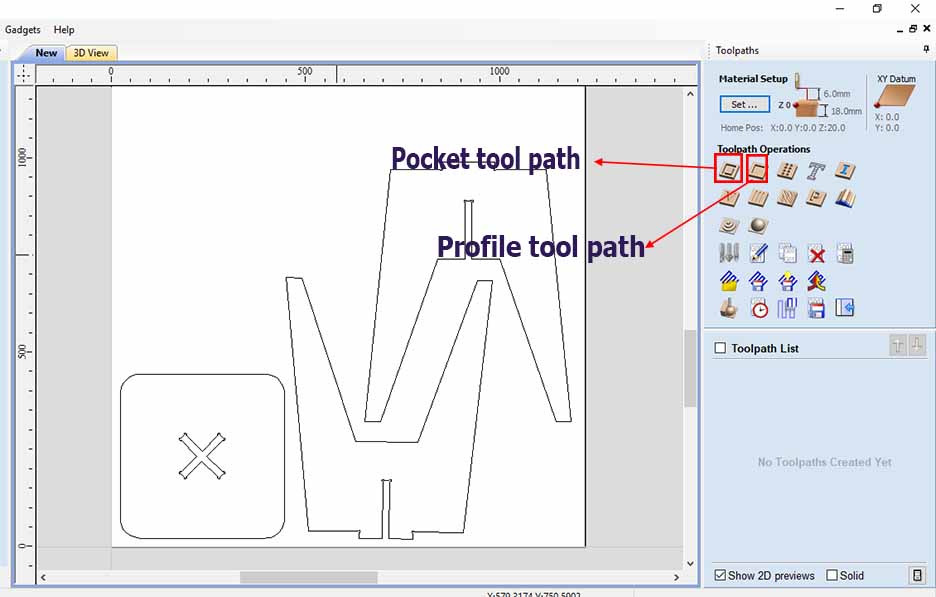

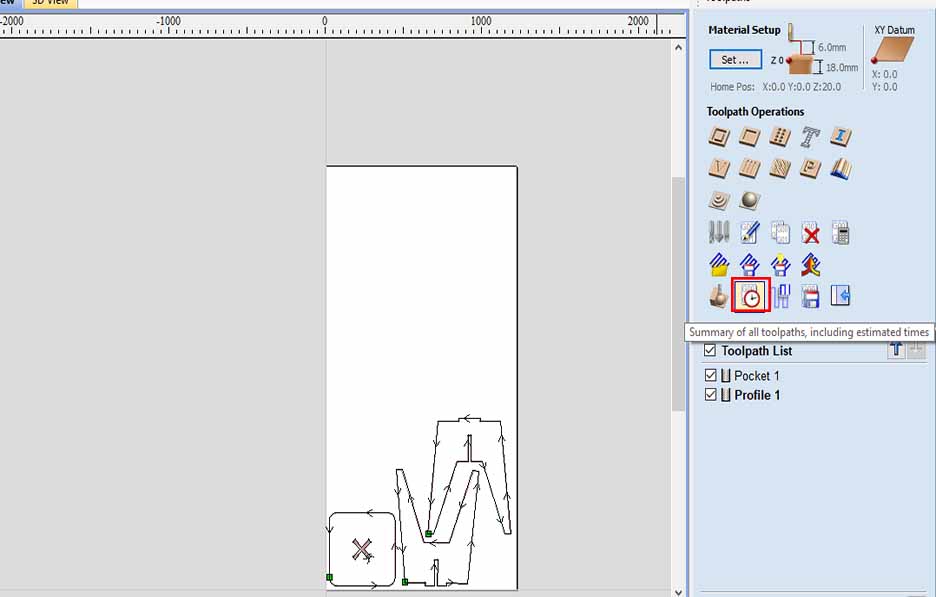

Start creating the tool path by showing the tool path tab.

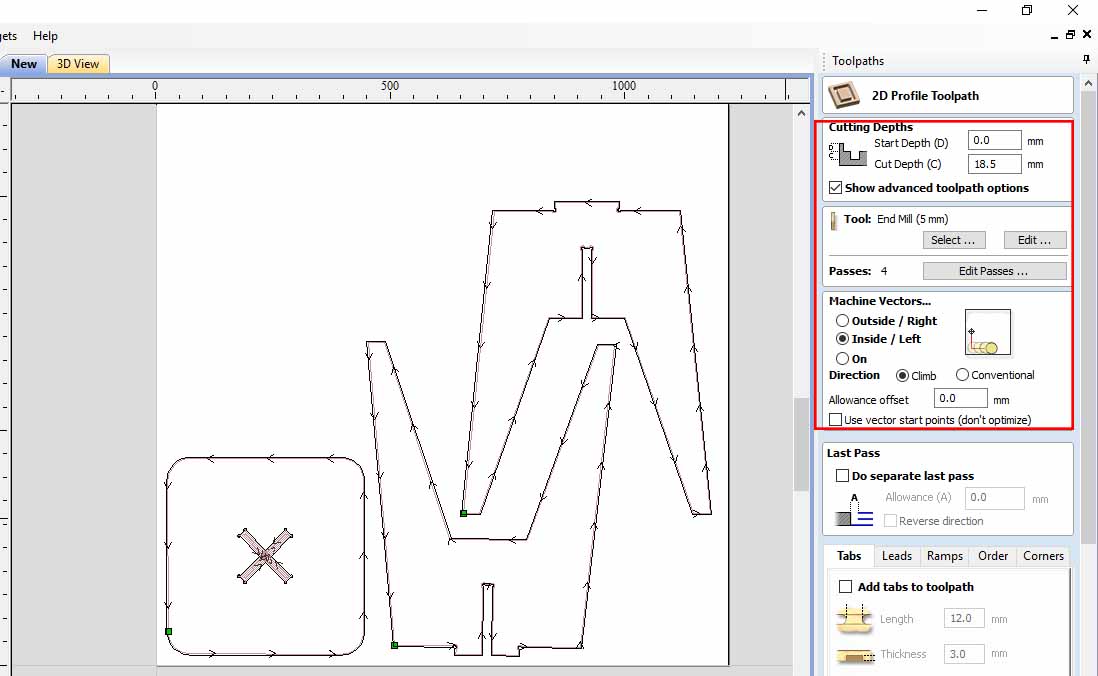

I used two types of tool pathes pocket and profile.

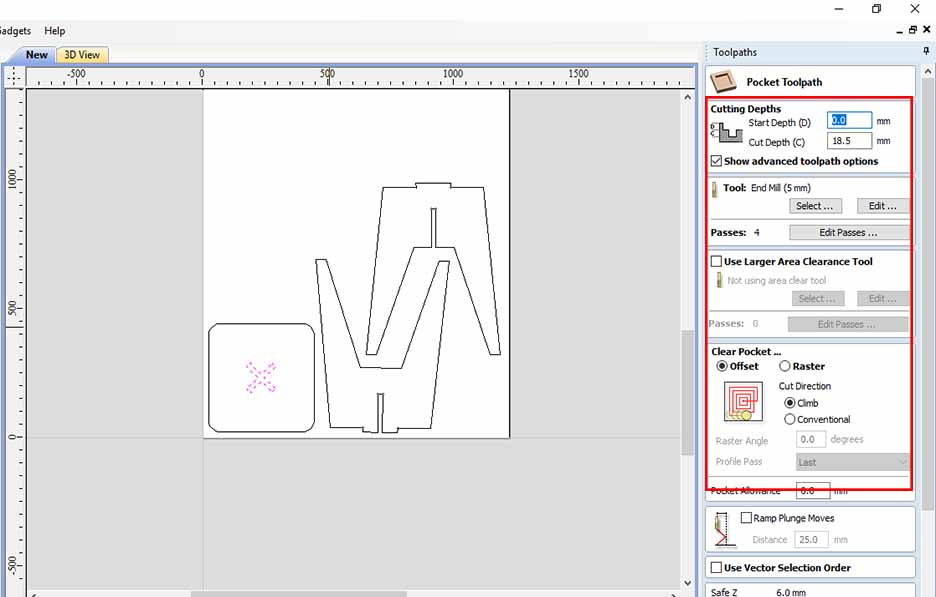

I used pocket for the inside fittings (x shape) only. Set the cutting depth to be 18.5 mm, tool diameter to 0.5mm and 4 processes to cut the material in 4 steps.

Select the profile tool path for the rest of the design except the (x shape).

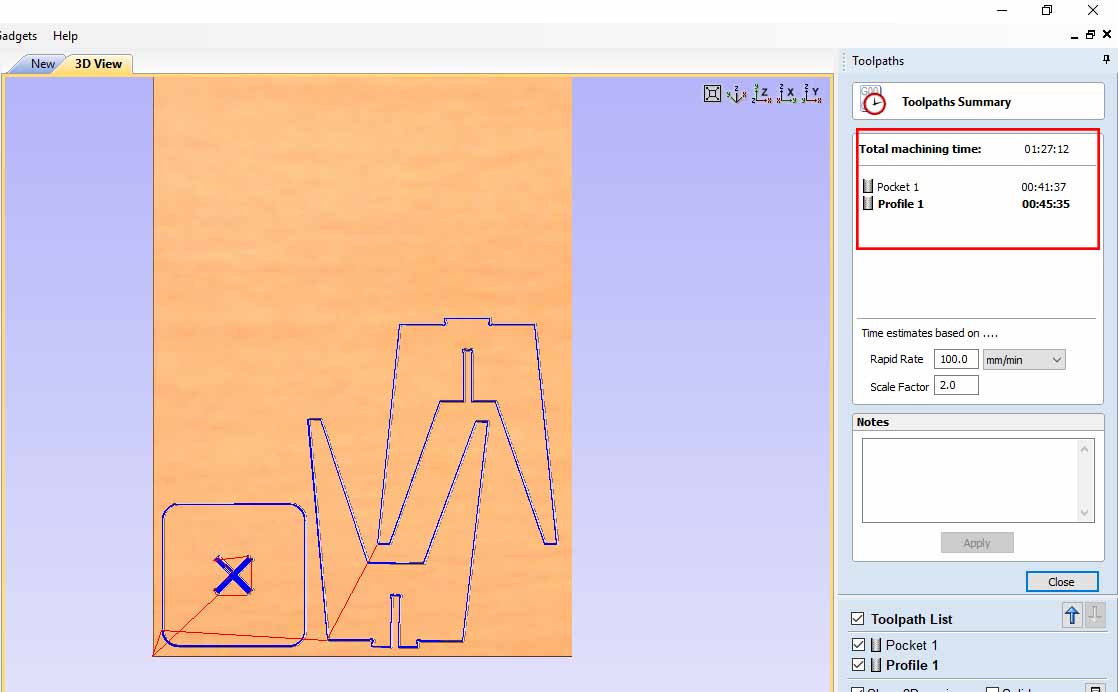

Click on the summery tool path to estimate the time.

The whole stool will take around 1 hour and 27 minutes.

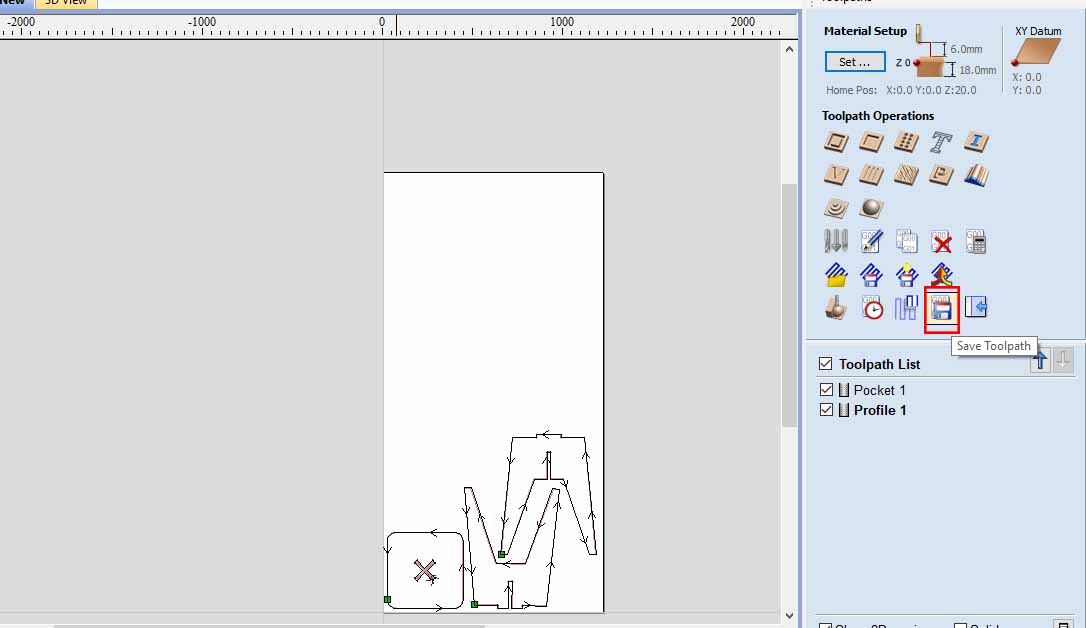

Select save tool path to get the G-code.

Finally I got the G code.

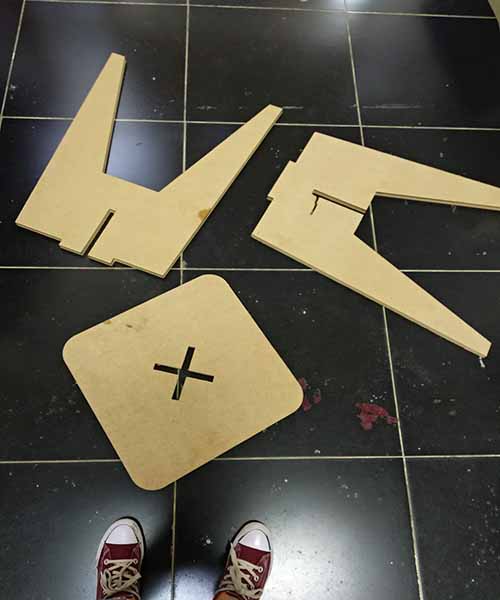

Step3:Cut and assemble

I fixed the MDF sheet on our milling machine and started the milling, then starting to construct it and I had to use the hammer for fixing the base on the legs.

And finally I was able to sit on it :D