-

Assignment

Computer Controlled CuttingComputer Controlled Cutting

I used to use digital fabrication machines since I work for FABLABs' and Makerspaces. I've printed some 2D designs that I made last week using CR-10 3D printer and Epilog mini Laser cutter. I used the following softwares:

1. Inkscape

2. 123D Design

3. Onshape

4. RetinaEngrave

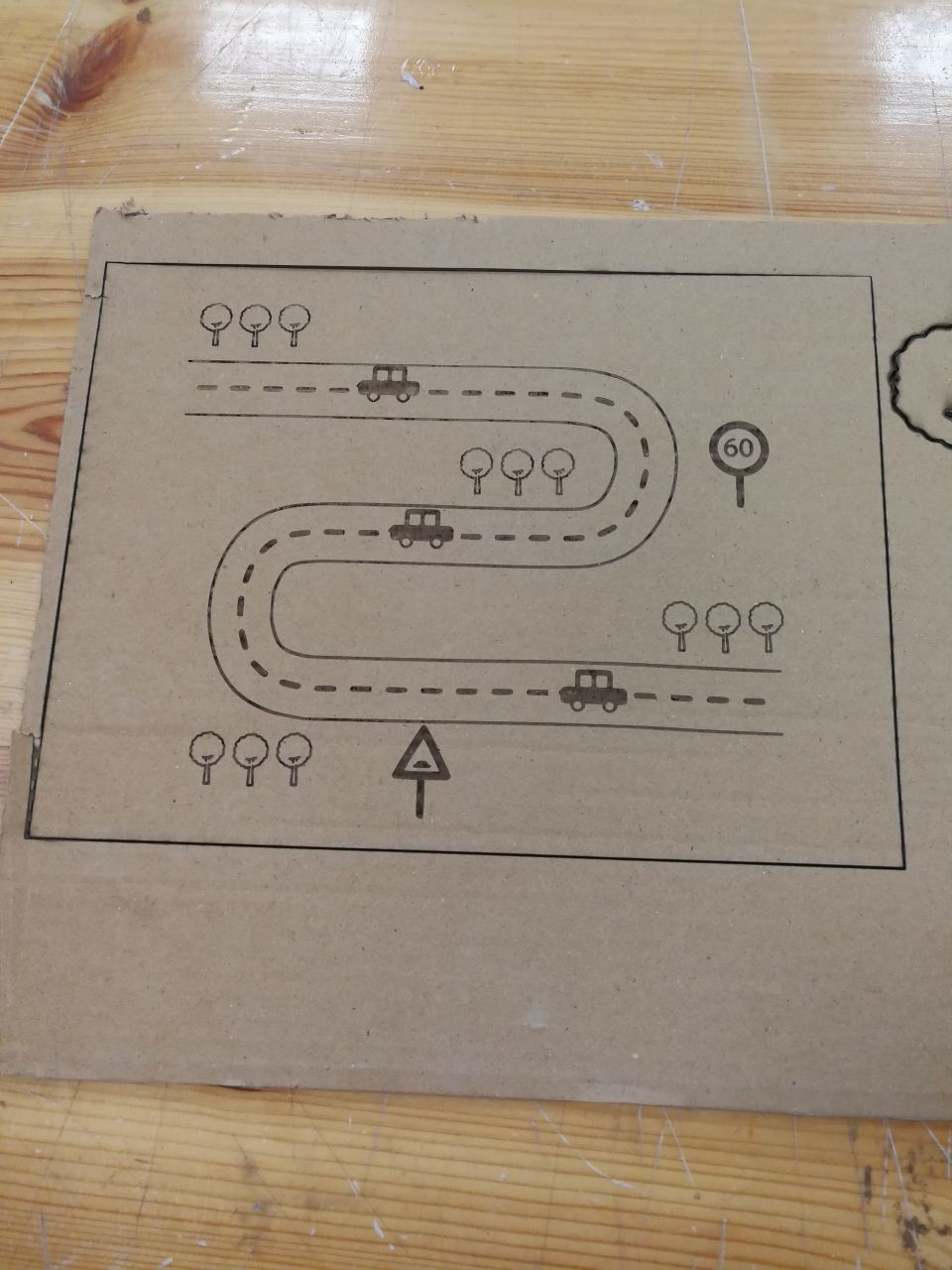

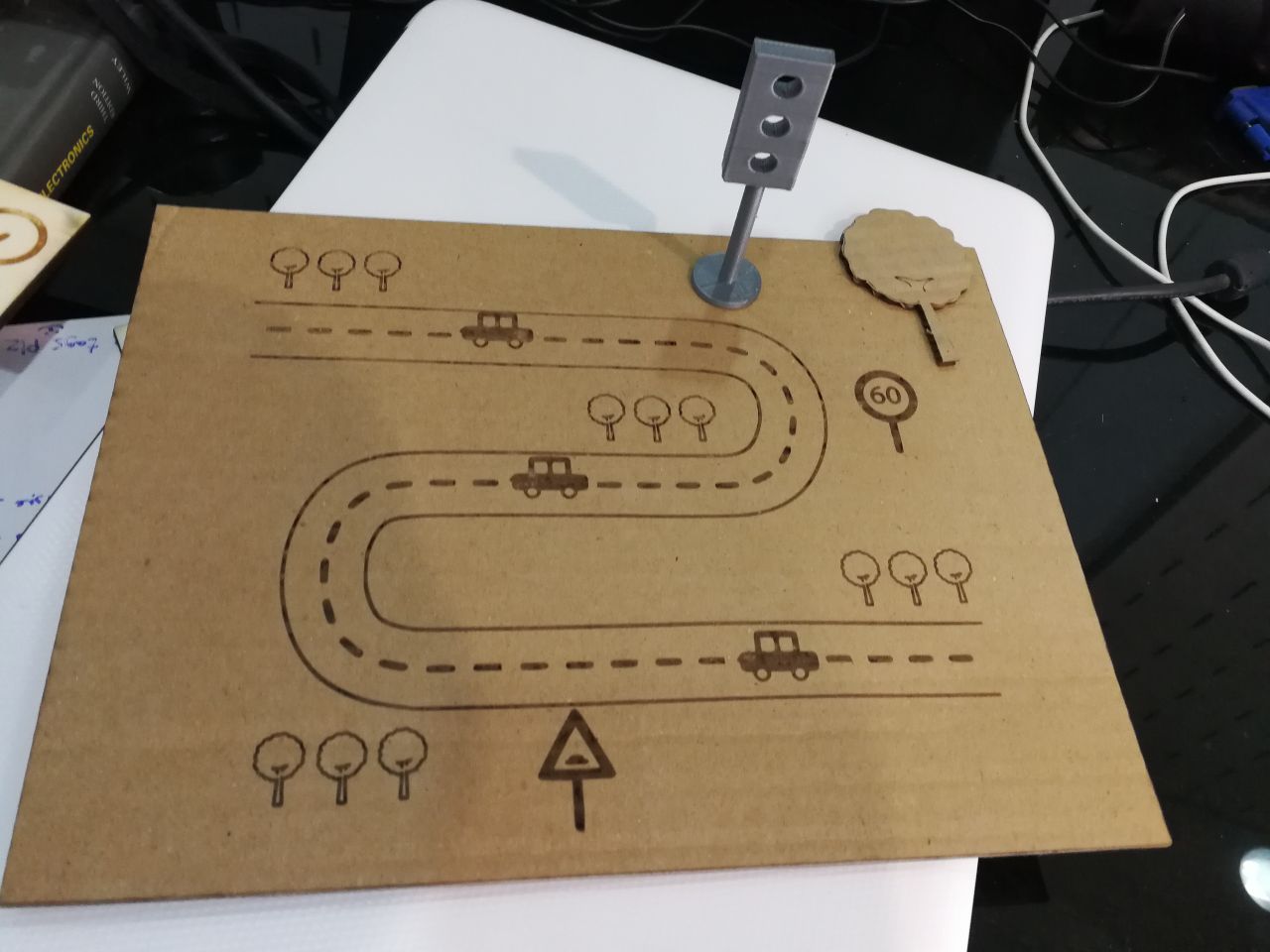

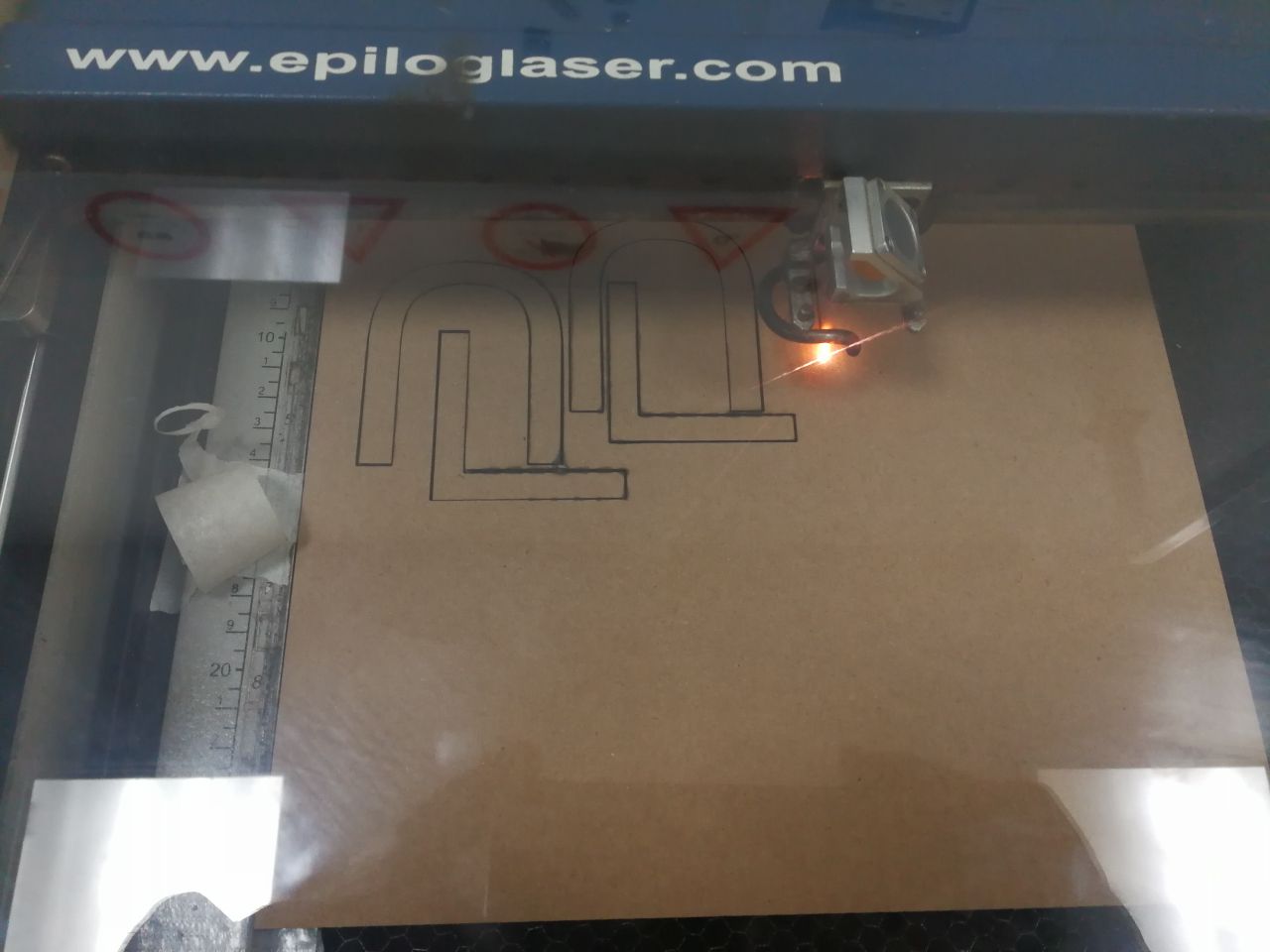

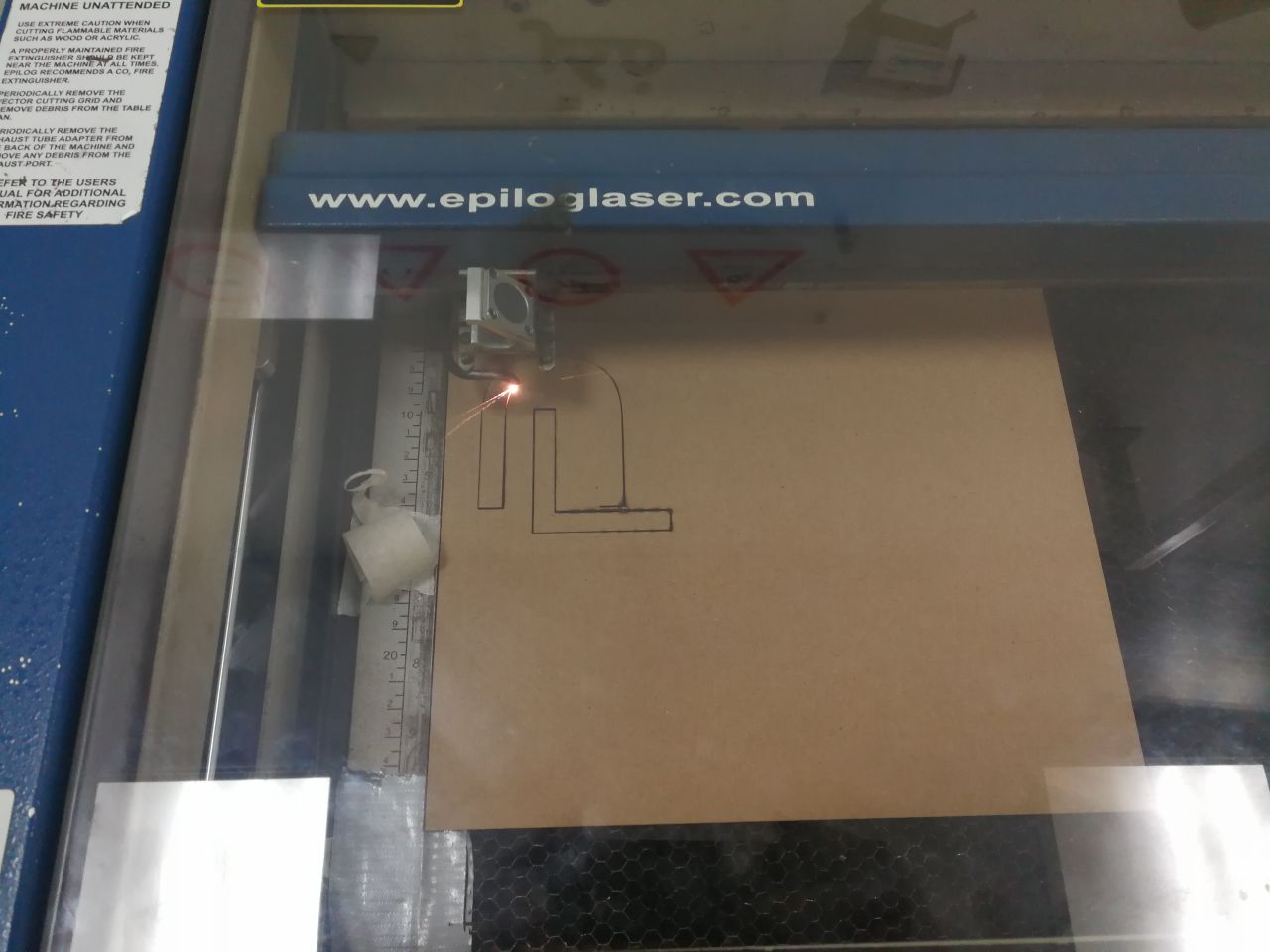

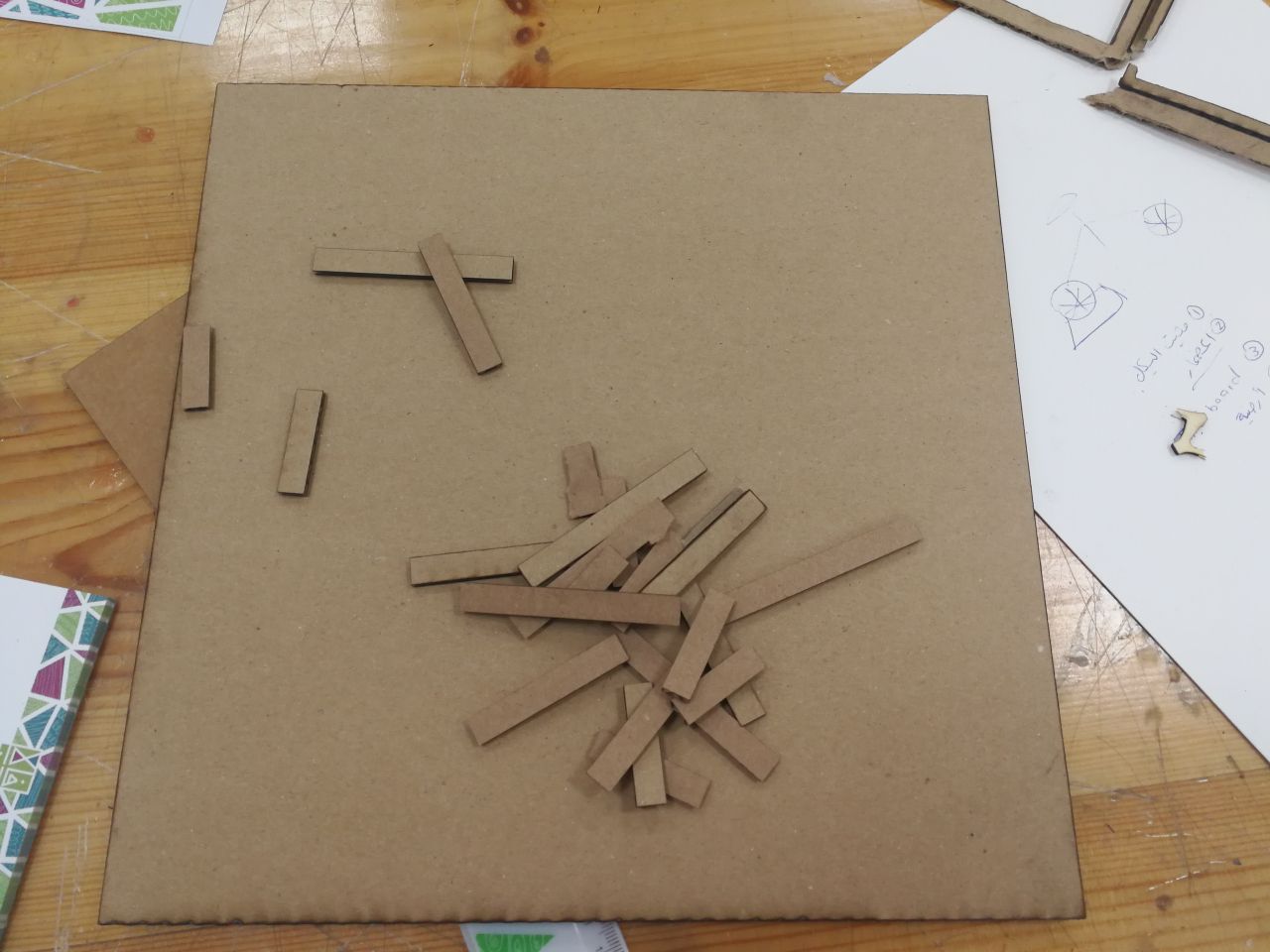

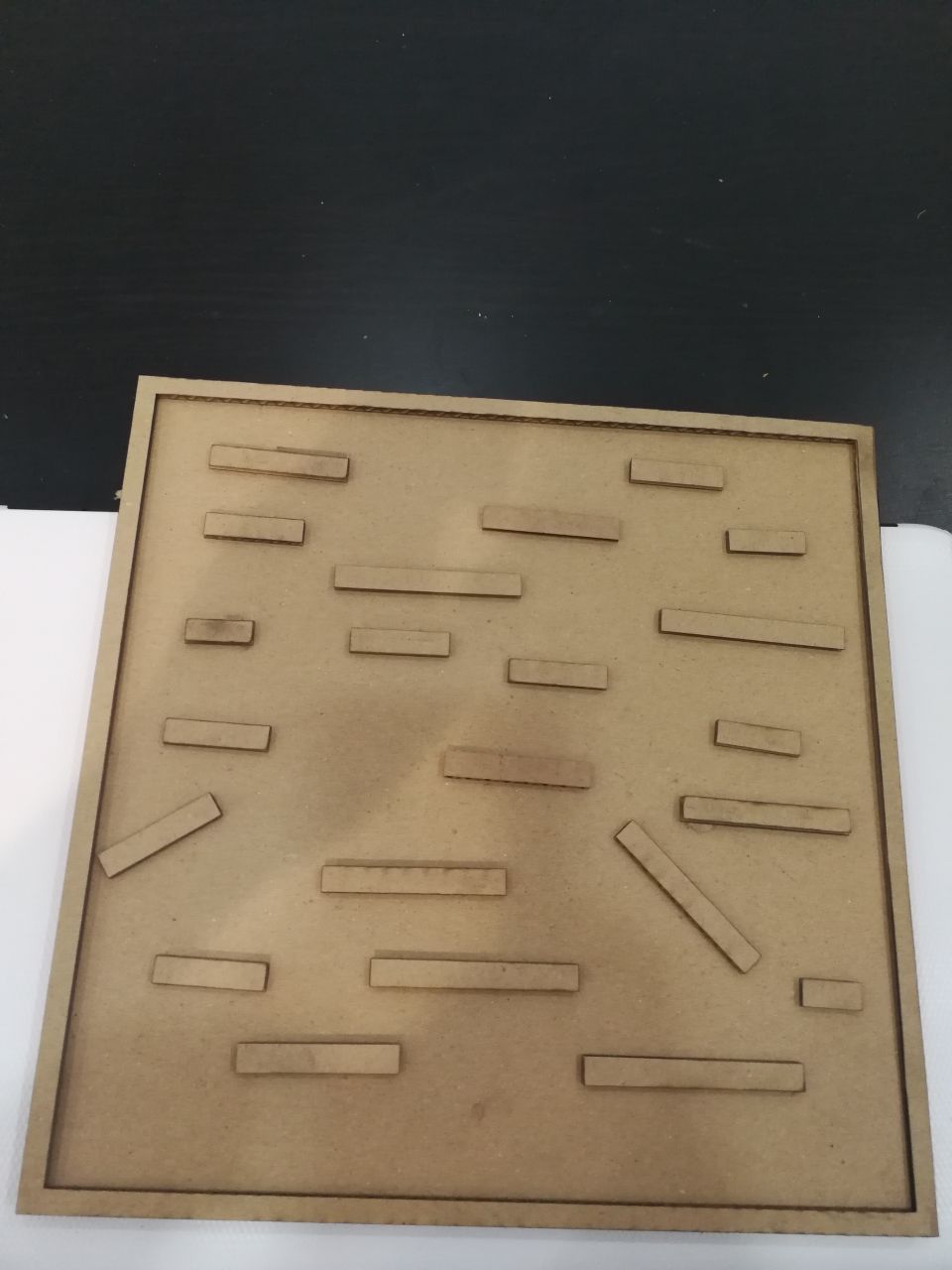

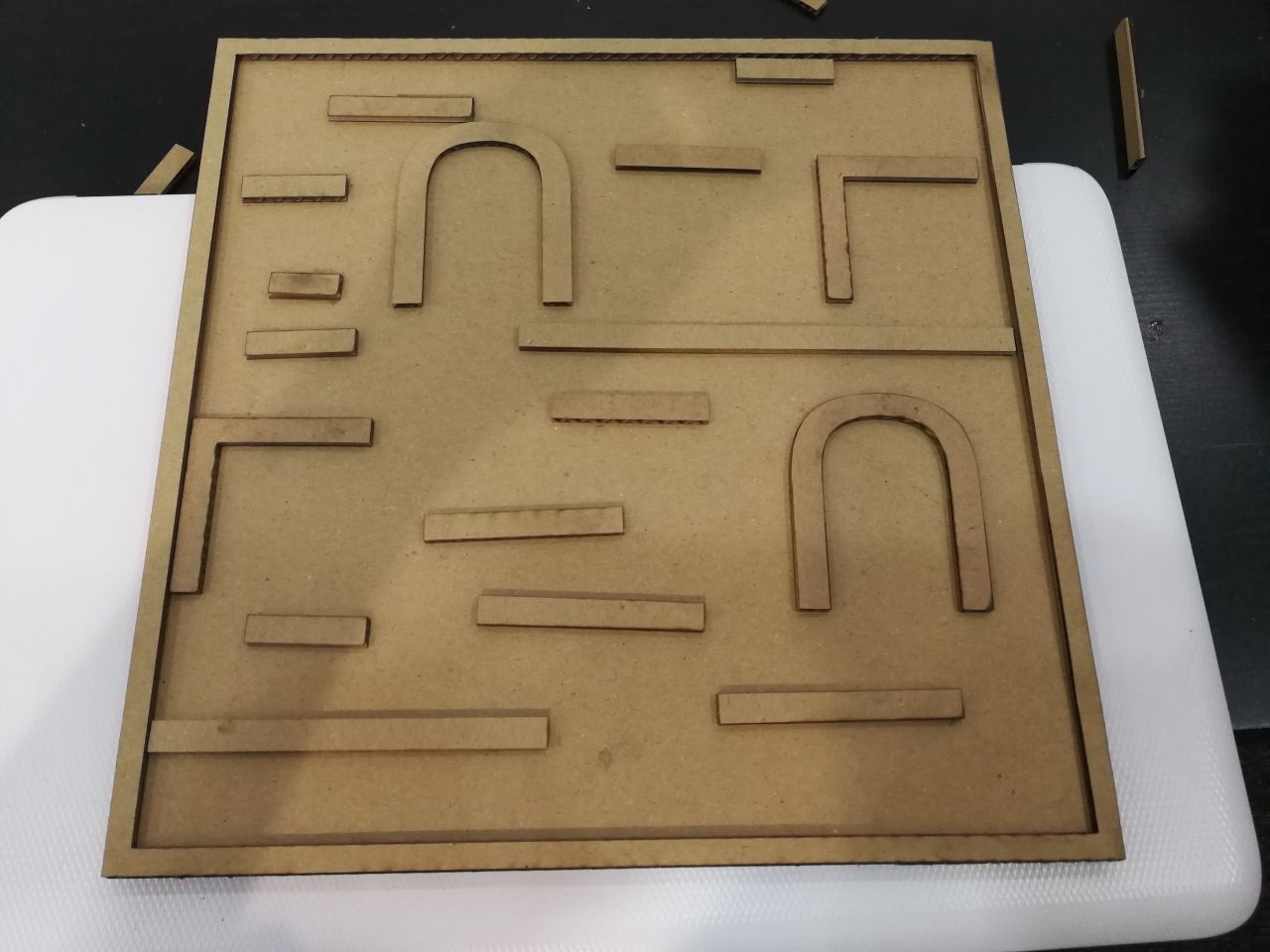

Trying to design and cut the maze using laser cutter

After using Epilog mini 24*12, I moved to try the second laser cutter which is Full spectrum laser cutter. The one that we have here is 5th generation 20*12 (50cm * 30cm working area). This machine uses a special software to do the cutting and engraving. The software is called

it's an open source, easy to use program

I downloaded the program and installed it. The intrface was so easy as shown below. You have two main things: Vector (cut) or Raster (engrave)

Now, I have to prepare the laser to start working on it. I have 3 main parts that should be connected to the laser before doing anything. The first one is water pump or water chiller to cool down the laser tube. The second is air pump, to control the sparks during the cutting. The third part is exhust fan, this part is used to take out the fumes that produced by laser

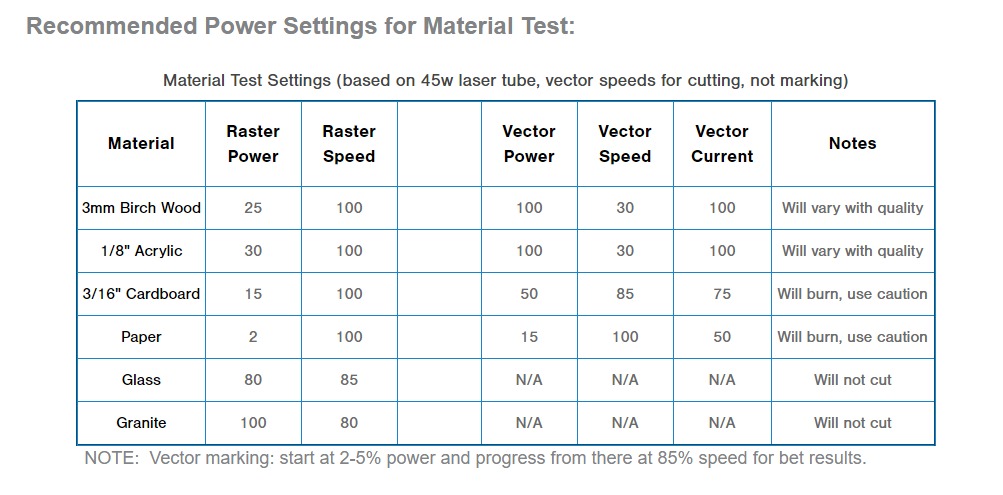

There is a table showing the material settings to adjsut the speed and power accordingly, you can check it below

We have to have the design ready to cut and engrave before I use Retinengrave program. You should keep in your mind the following:

1- for cutting parts: the object should not be filled, and the strock must be red with 0.035 mm as the line thikness

2- for engraving parts: the object should be filled with black and no strock

So, it's the time to start using the machine. First, I connected everyting to the power and run the devices (Water chiller, Air pump, Exhust fan, and laser cutter) moreover, then I opend the laser software, I have to click the box (ignore thin vector) because the software will detect the edges of the engraved parts, but by clicking this the software will detect the 0.035 mm strok

I print the design from inkscape using the machine driver (full spectrum engineering driver). You can do it by pressing ctrl+p

Now, the IP address shown in the machine display should matched the IP address shown in the software. Otherwise, you have to click refresh (the button beside the IP address in the software)

The machine is connected and I will start cutting the robot parts now, I have to select if the design includes Raster only or Vector only or Raster then Vector (both of them starting by raster)