Final Project 01: Concept(s) & Sketch(es)

Motivation

This [Final Project] is your opportunity to demonstrate synthesis of skills you developed in the previous weeks... Each student, whether working individually or in a group, must prove mastery of the skills gained during the program.

Learning Outcomes:

- create your own integrated design

- demonstrate 2D & 3D modelling capabilities applied to your own designs

- select and apply appropriate additive and subtractive techniques

- demonstrate competence in design, fabrication and programming of your own fabbed microcontroller PCB, including an input & output device

Source: Fab Academy Assessment - Final Project Requirements

My Process

Exploration

I have many ideas for projects popping around my head at any given time. In order to get a sense for what other students have done, I spent several hours perusing past final projects in the archive. I wish now that I had kept a list of some of my favorites, because there were many that I loved, and several which were inspirations.

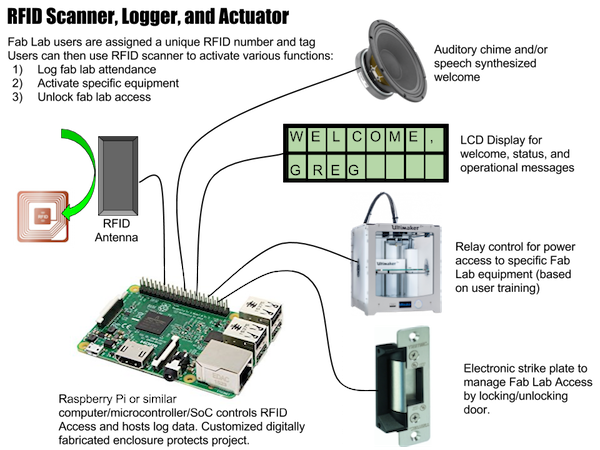

First Idea & Sketch: RFID Scanner/Logger

The first idea I began to flesh out and sketch was an RFID Scanner/Logger for my Fab Lab. Each Fab Lab user would be assigned an RFID tag (probably attached to or embedded in their Fab Lab nametag). The RFID tag would be coded with a unique user identification number. They would then swipe the card on the RFID Scanner/Logger each time they enter the Fab Lab. The Scanner would validate that they are authorized users and could perform various functions: e.g. unlock the main door, allow power-up to certain equipment (based on user certfication level), and log the user's presence at the lab. This system could give us detailed data about Fab Lab and equipment usage and act as a quick, easy way for users to sign in.

I realize now that Raspberry Pi would not be an appropriate board to use, and I would have to make my own board in accordance with the Commercial Boards Policy. I think a revision would be to have a custom PCB microcontroller that reads the RFID and then talks to a central server (either a Raspberry Pi or just a desktop computer in the Fab Lab or even in the cloud).

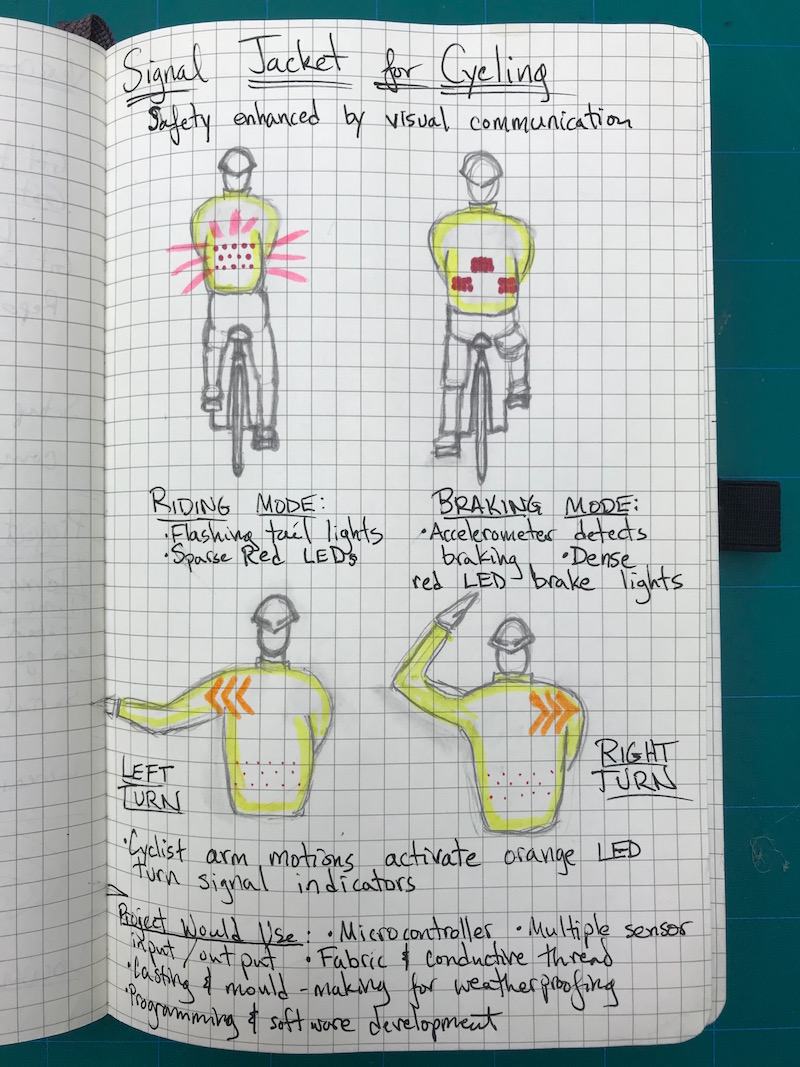

Second Idea & Sketch: Signal Jacket for Cycling

The next idea was inspired when talking casually with my course mates about their ideas for final projects. Oye mentioned an idea for a textile or jacket-based project, and the idea popped into my head: why don't I add turn signals and brake lights to my biking jacket?

The idea here is to enhance the safety of people on bikes by increasing visual communication with other street users (especially people in cars). The jacket would include a Riding Mode, which would entail a flashing sparse array of red LEDs. An accelerometer in the jacket would detect deceleration (braking) and change the light pattern to Braking Mode: a dense, solid red LED pattern (similar to a car's brakelights). A set of orange left and right directional turn signal indicators could be activated either by standard user hand signals or the accelerometer to engage Left Turn and/or Right Turn mode. I would want to make the jacket ambi-dextrous and symmetrical so that users in left-side driving countries (e.g. the U.K.) could use it just as easily. (This would have the added benefit of allowing all users to signal with either arm.) Note: I had initially thought about using pressure sensors in the hands to detect brake application, but I saw an accelerometer-based bicycle brake light in a past Fab Academy final project and thought that was a much better idea! Go find that project again and link it here. Also: go do some research to see if there is something like this commercially available already

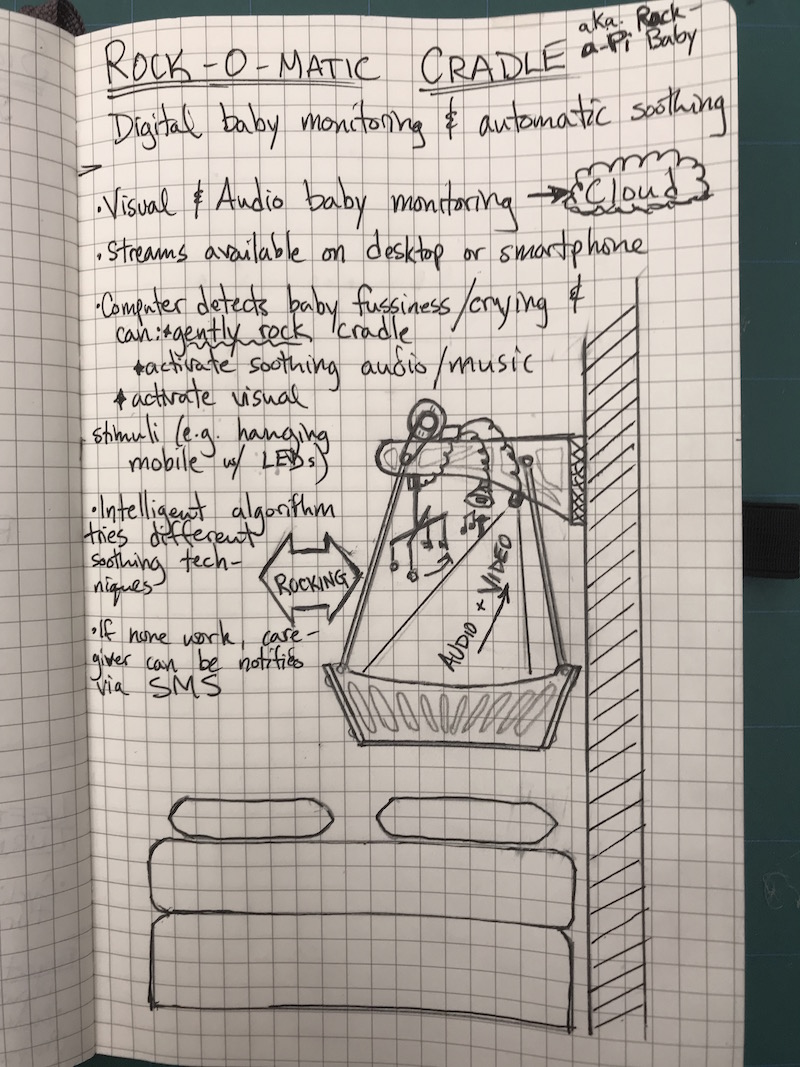

Third Idea & Sketch: Rock-o-Matic Cradle

My partner and I are expecting our first child in May (!) and so I have been thinking about what I might be able to make in Fab Academy that will help us with this new endeavor. Some friends of ours have a small child, and they had a hanging cradle above their bed. When the baby fussed or cried in the night, they could gently rock the cradle with their feet. My idea is to take this one step further, and add a digital fabrication twist:

The cradle itself and the bracket for hanging it from the wall will be CNC cut out of a sturdy flat stock, such as baltic birch plywood. The bracket would house a computer and/or microcontroller board which would enable the following functions.

- Visual and Audio baby monitoring, with streaming to the cloud

- Streams available for viewing on desktop, smartphone, or tablet

- Computer automatically detects baby fussiness and/or crying and in response it can:

- gently rock the cradle

- activate soothing audio or music (such as a lullaby)

- activate soothing visual stimuli, such as a hanging mobile and/or soothing LED lighting

- Intelligent algorithm tries different soothing techniques and can learn what works best for the child

- If nothing works and the child is still fussing, care-givers can be notified via SMS (though of course, the care-givers should be close by anyway)

I believe I remember hearing about a Fab Lab project from Brazil that had a similar scope using a baby-rocking stroller. Go find that project and link it here

Final Thoughts

Each of these three projects is interesting to me, and I think any of them could be fleshed out to make a good final project. I think I will move through the semester with an open mind, keeping in mind "supply side" time management principles and "spiral development" as I work on each week's assignment. For example, I think I could work on making the hanging cradle (sans sensors, microcontroller, etc.) in the CNC milling week. This would still be a great outcome, even if I don't add the "O-Matic" features (automatic rocking, baby-monitoring, etc), and just have a rocking cradle. I will keep this website up-to-date with my progress!