Week 1

Principles and practices

Assignment

Plan and sketch a potential final project

Check Points

sketched your final project idea/s

described what it will do and who will use

Contents

1 Project idea

2 Sketch of project

3 Features of product

4 Working principle

5 Problem analysis

6 Fabrication techniques used

7 Project development cycle

Idea 1 -A solar panel cleaning system for residential surface mounted Roof top solar plant

Working Principle

A system consist of rotating microfiber brush which rotate over the panel to wipe out dust and while moving forward on panel dust get accumulated in dust collector attached for cleaning , after moving on one array machine move to the direction changing station where wheel rotate vertically and move forward to next array and clean second array ,similarly move to next array

Features of solar panel cleaning system

Features of solar panel cleaning system

Water free

Water free cleaning system will work with any climatic condition and avoid cost of water

Effective

Regular cleaning of panel will increase annual energy production capacity by 10 % to 25 % use of microfiber brush to Remove dust will reduce this

Autonomous

Clean the solar panel by the preset time automatically,it also have option to control manually

Problem identification

The solar PV modules are generally employed in dusty environments, the dust gets accumulated on the front surface of the module and blocks the incident light from the sun. It reduces the power generation capacity of the module. The power output reduces as much as by 50% if the module is not cleaned for a month and use of solar panel in residential sector is increasing day by day which generate requirement of efficient cleaning system as life of solar panels are generally from 20-25 years

Fabrication Techniques Used

1 3d printing - For printing motor couplings and wheels

2 Computer control cutting - laser cutting for motor and brush holding

parts and vinyl cutting for making sticker of

of on-off switch , diction indication

3 Computer control machining - for making dust collector and direction

changing station and structure to hold panel

4 Electronics production - for controling motion of motor

5 Input and output devices - In end switch for control limit of motion

Project development cycle for project planing

1 Design Cad model of machine

2 selection of motor and brushes on basis of model size test using manual

cleaning

3 Make structure for holding brush and motor

4 make couplings and wheels

5 assemble machine

6 make motor control board

7 make structure of one panel and clean single panel using machine

8 make one array of panel and than clean that

9 make multi array structure and than clean that

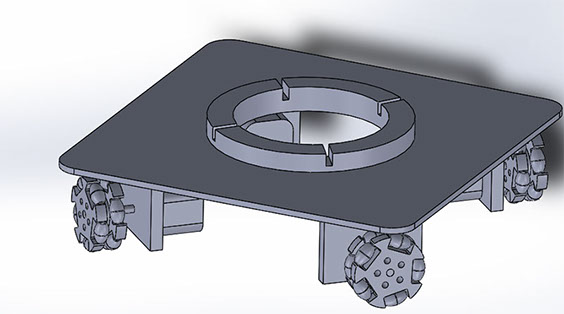

Idea 2 -making omni bot which can we use for multipurpose cleaning operations and other utilities

Considering size and scale of development of project , i decided to make omni bot which is itself as host bot with multiple attachment / end factors having utilities in cleaning floor , drawing random sketches on floor and lot more as per user need you can modified it

Features of Omni Bot

1 omni bot is bot which can move in both x-y axis independently with blue-tooth control mobile application

2 multiple attachment to bot which allow us to use it for floor cleaning and scrabble drawing bot etc

3 opportunities to modify bot for using it for different purposes

Why omni bot

Considering the utility of cleaning robot for residential demands need for bot which can be use for more than one purpose as they may use it for dusting floor , mobbing the floor with detachable attachments which can be easily cleaned and replaceable and have low cost considering its utilities omni bot is perfect solution to this

Model of omni bot

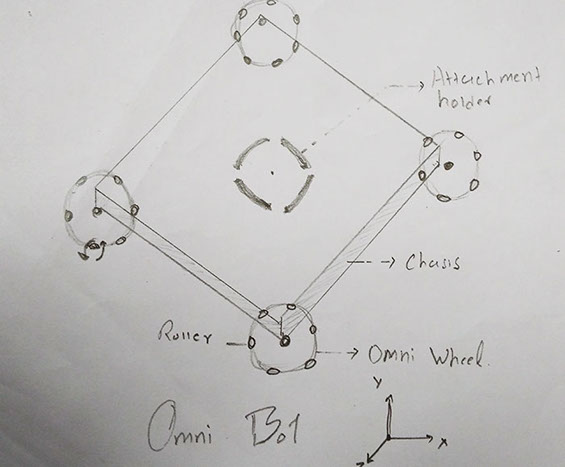

Sketch of Omni Bot

in sketch i just want to show what actually omni bot have that is four omni wheels and the end factor attachment holder which will be in the center of bot as shown

Cad Model of Omni Bot

AS, i finalized this idea after my design week , so i Make cad model for presenting project as this is first cad model of bot developed for understanding the design and location of various components i.e motors , wheels , attachments etc

The detailed analysis of this Project regarding manufacturing techniques used , material etc are mentioned in Week 18 page

This work by Gaurav wadhwa is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.