final project -- about me -- weekly assignments -- fab academy

What to make, and why

A good first step for a new project is to collect what you want to do and why. That way, you end up with a more productive list than the list of what you hate about the status quo. I started that list. It's not complete yet, though.

The List

A placer that is electrically driven, but manually controlled.

Why? A lot of why here, actually.

First, why an electrically driven system for a simple task? One of the main hassles with out manual placer is getting the parts to end up in the right place. Getting a component down (against the spring pulling the axis up) without moving it sideways is an art. They put in brakes, so precisely placing a component ends up a time consuming, complicated process. Which is roughly the opposite of what I want. Having stuff move at the input of a joystick and stay put when you let go sounds a lot better. Also, given time and effort, it could be expanded to do fully automatic placing.

Second, why manually controlled, when it's already supposed to be electrically driven? Mostly, that's a problem of time. Getting a fully automated system done is a lot more work, and it pulls in a lot of new problems (like knowing where to pick up parts, knowing where the PCB is, ...). I might start some parts of the automation if I end up with too much time on my hands, though.

Have a camera on the placer to look at what I'm doing

Why? Not much to say here. Having a camera in there is rather normal, but our placer doesn't leave enough space to position it near enough to the vertical axis to actually align components with it. So while just mounting a camera on the placer is simple enough, getting the whole system built in a way that lets you see where you're pointing your component will require building the placer around the camera, while keeping it functional.

A dispenser for solder paste or glue

... that can be mounted on the placer and controlled through it.

Why? It would save me from buying stencils for almost every PCB. Given the amount of paste extruder projects out there, it should be possible to do that one quite quickly, I still see it as a stretch goal.

Other stuff

Given that I'm already working on a project to build small, cheap servo drives, I will look into using servos instead of steppers. A good first step will be to get them running.

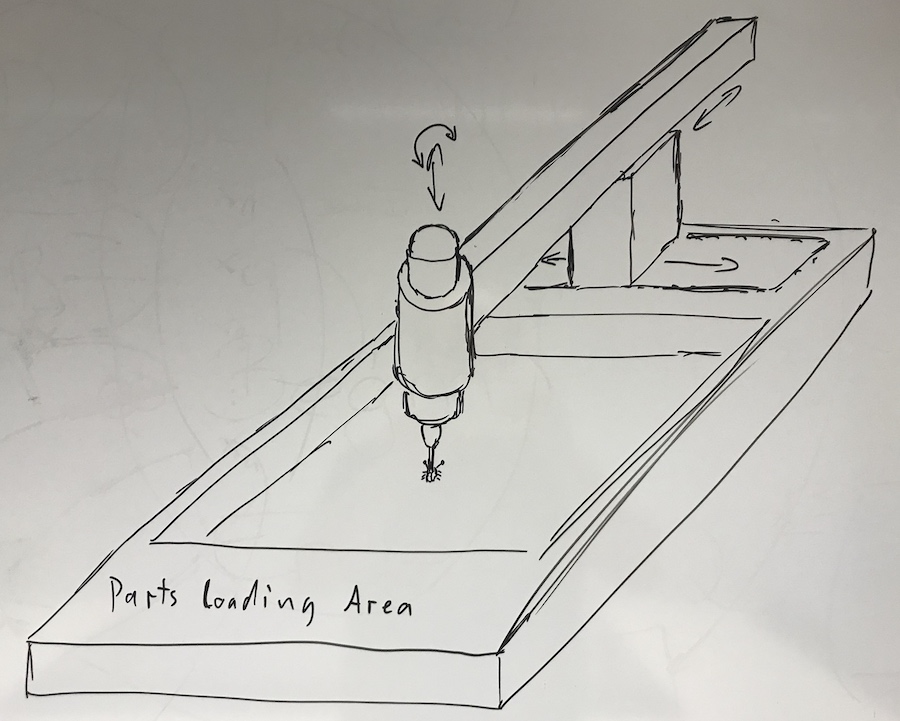

The Image In My Head

While the exact look can and probably will change, this is a first rough idea of what it could look like. Not complete in any way (Where would the camera go? Should the camera rotate with the parts? So many questions...), but a first impression. I wonder if it will be stable enough not to shake like a leaf when built like that, but it looks just so cool that way... And it leaves a lot of open space to put your hands into in case you need to.

final project -- about me -- weekly assignments -- fab academy