Parametric modelling allows the person to modify an entire design by changing only one attributes.

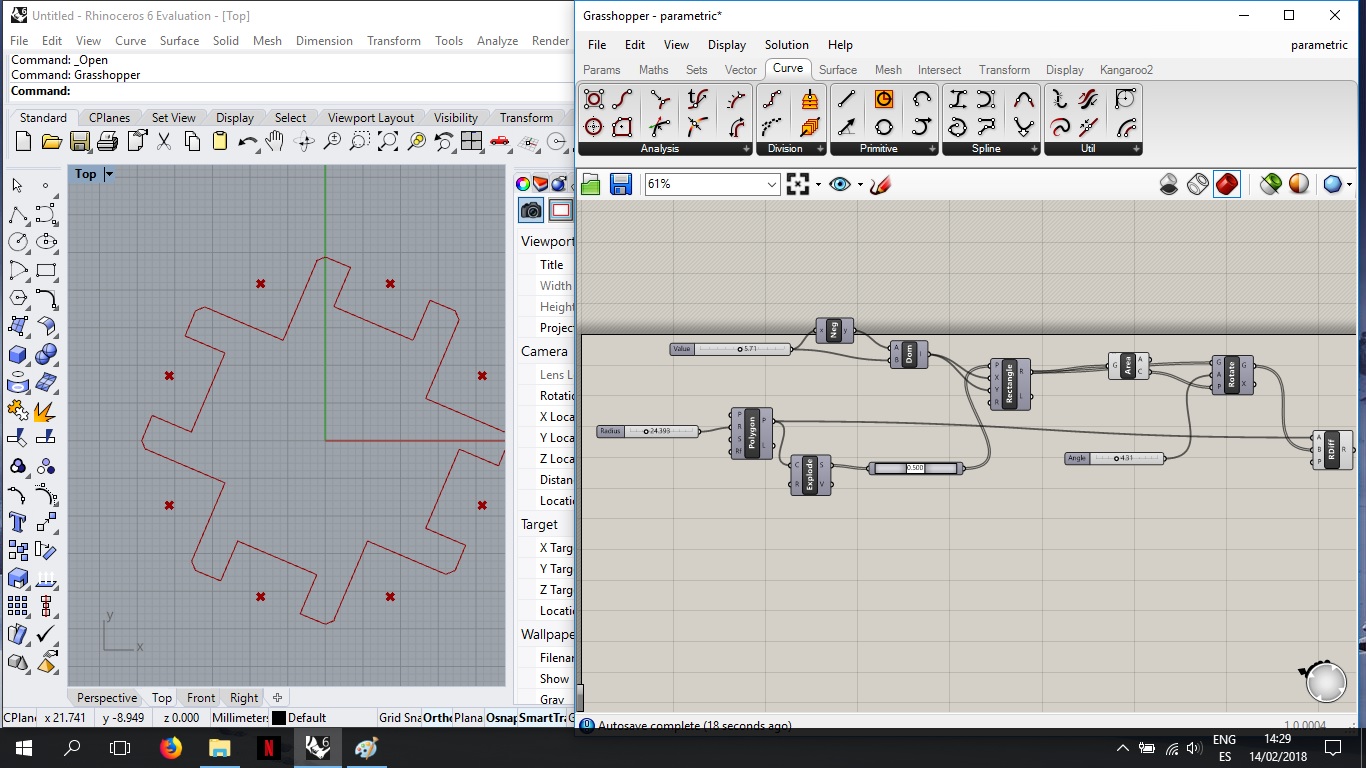

For that I had to use the Grasshopper, that is a plugging to make the Rhino parametric.

In the beginning I was trying to parametrise a design that I created in Rhino, but after a lot of time wasted

I decide to design it direct on the Grasshopper. My main sourse was the class they gave us in Fab Lab Barcelona. The idea of the grasshopper is instead to use the command

and click on the screen to let the software let you know what you want to do, you use “blocks” and connect

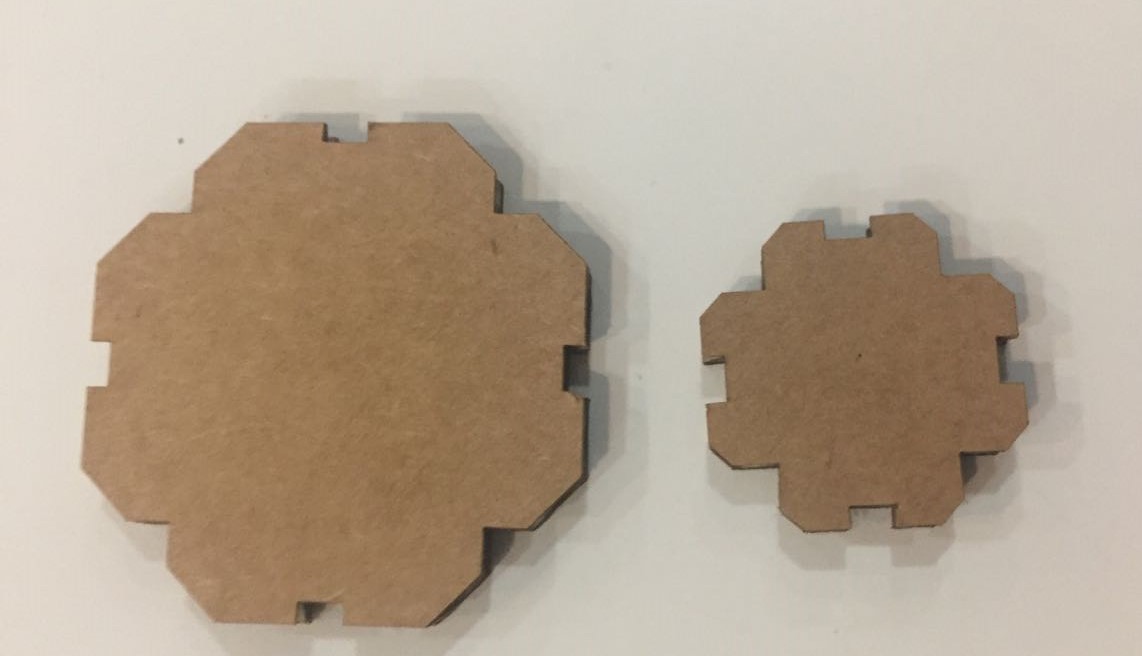

them to make your design. I first started with a simple shape, after I exploded and divided it. In this

divisions I place a feel squares and connected it to when the first shape variate the squares keep the same.

After it I set the size of the connection and baked it in varied sizes. I had a problem with the size of

the connection because when I tried to cute it was double the size, i realise it was the mistake because i could i could fit 2 pices perfectly on one whole. So, I when back to the program and add

a division on it.

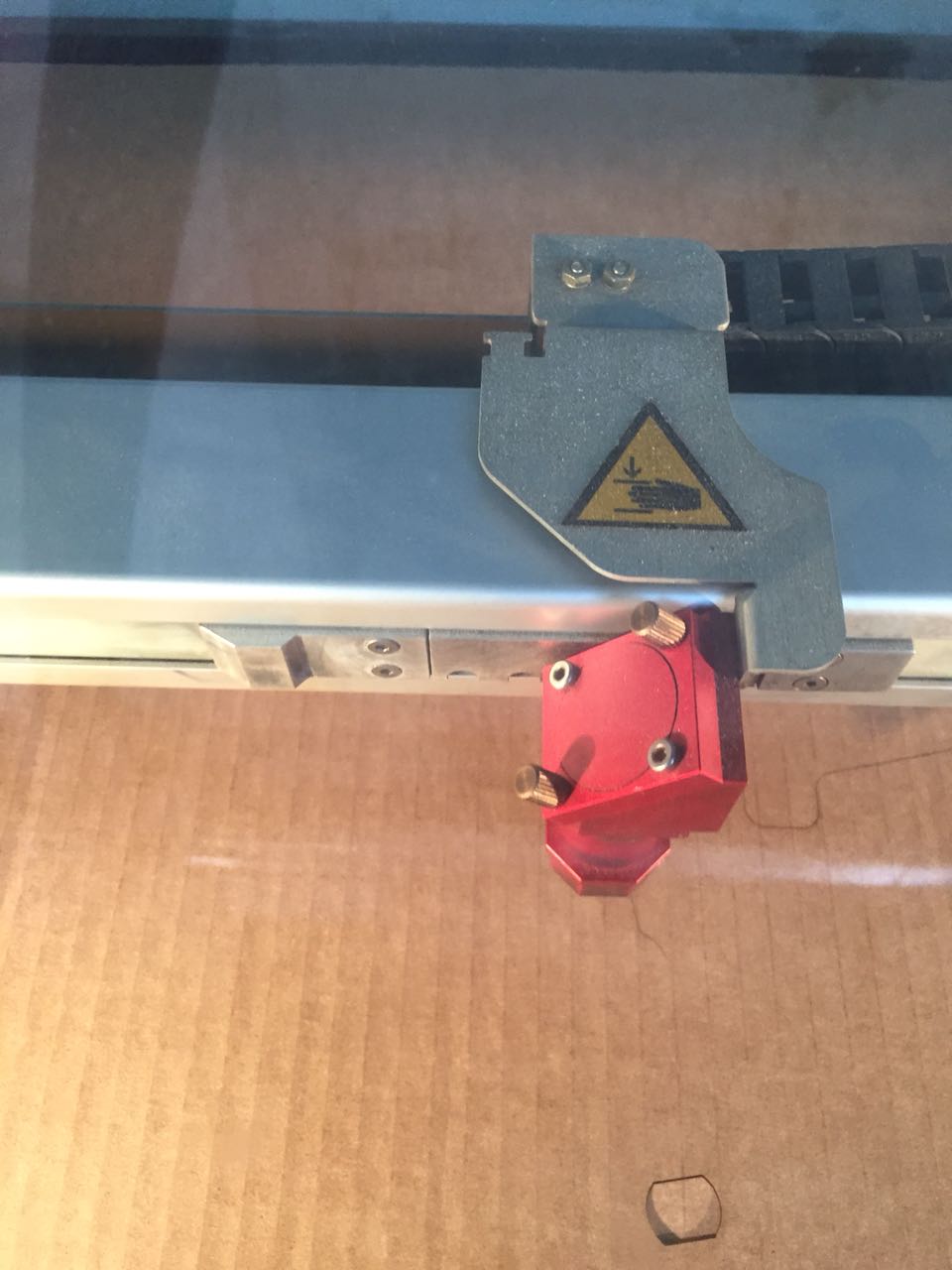

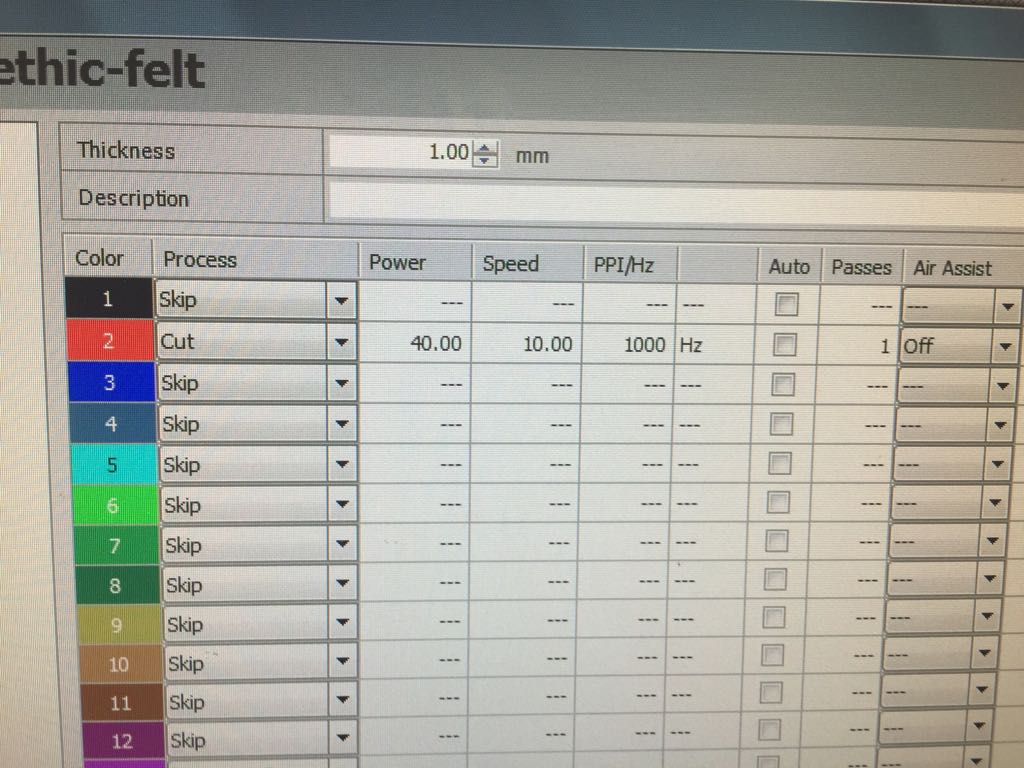

After check everything was right I run a few test to get in the righ parameters for cut car 3 mm the laser cut (30, 0.9 , 1000) and I cut it.

i learned a bit on grasshopper but for the future i want to learn fusion 360 because it intrage better the 3D modeling with the parametric modeling.

Here is the file.