Mechanical Design, Machine Design

This next two week are a group project

(Dorota

Eve

Coral

). For this weeks we had to make a machine, including the end effector, build the passive parts and operate it manually.

we divided the tasks like: Dorota: electronics and programming Carolina: design and electronics Coral: website, video, design Eva: design, lasercutting.

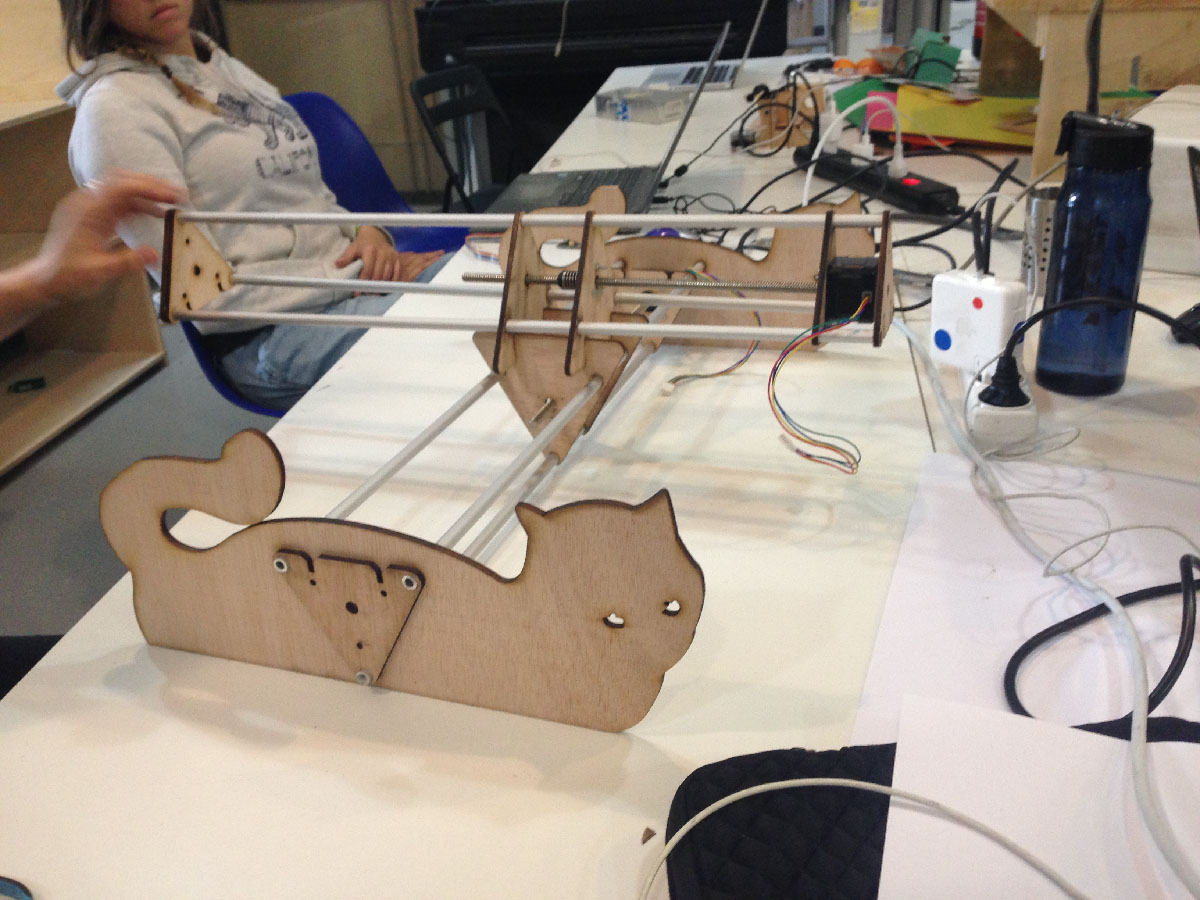

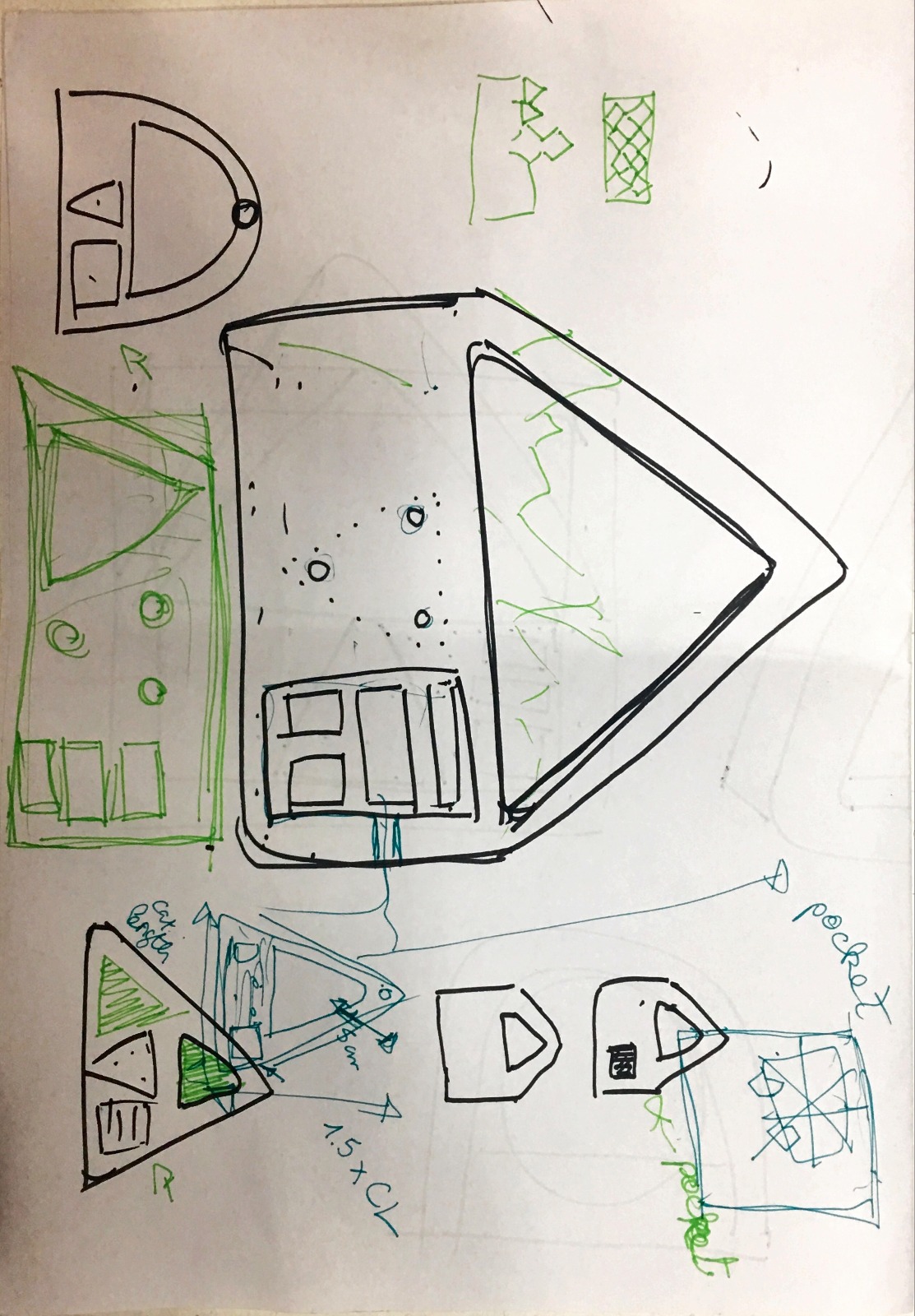

But in the end i help much more the Eve's part than dorota. We started studing different project together to choose the best option for our design. The mains project tha we based was Nadya Peek, Xavi Dominguez (barcelona 2016) and FabLab Ajaccio. After analizing all the design we decided to do something more similar to the FabLab Ajaccio in 2016 .

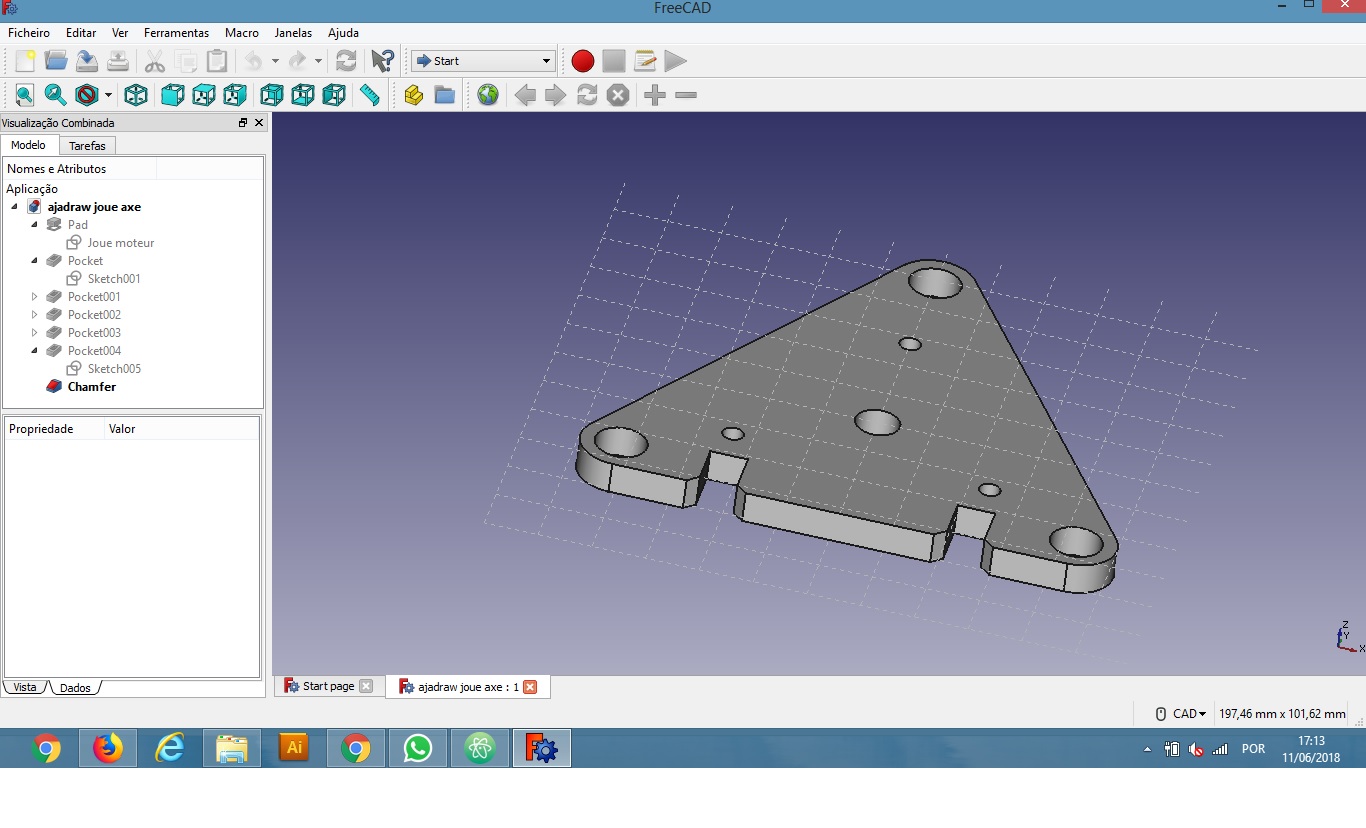

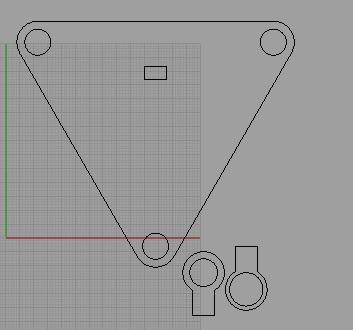

We started to design the basing in some of the files avalible on their website. We have a lot of troubles trying to get the files because the links were broken. So I had to download FreeCad to be able to open the few files that we had and save in dxf file so we could work on it.

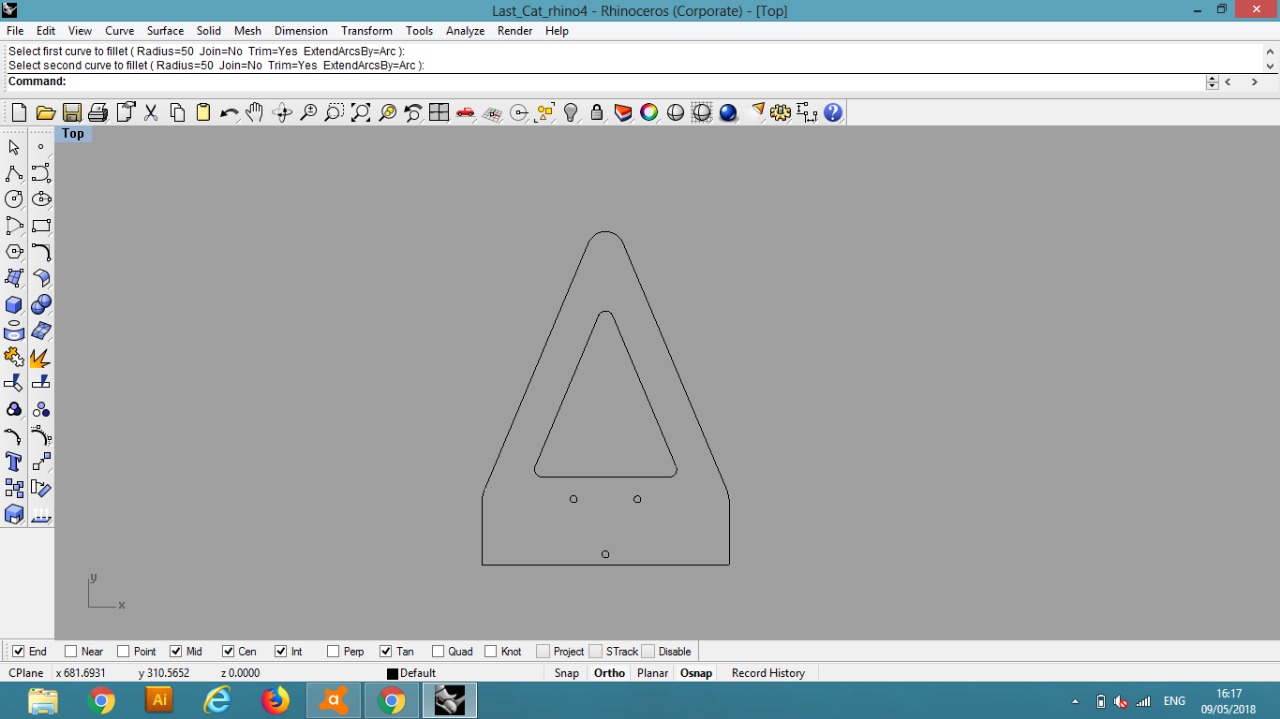

After that each one of us worked on a different part, based on their design, i worked in the first version of the penholder. For that i use one of the triangles that hold the axis and put a small piece to hold the pen. I made more than on size to fit more than one pen. It was simple so we could undertand better how the machine worked.

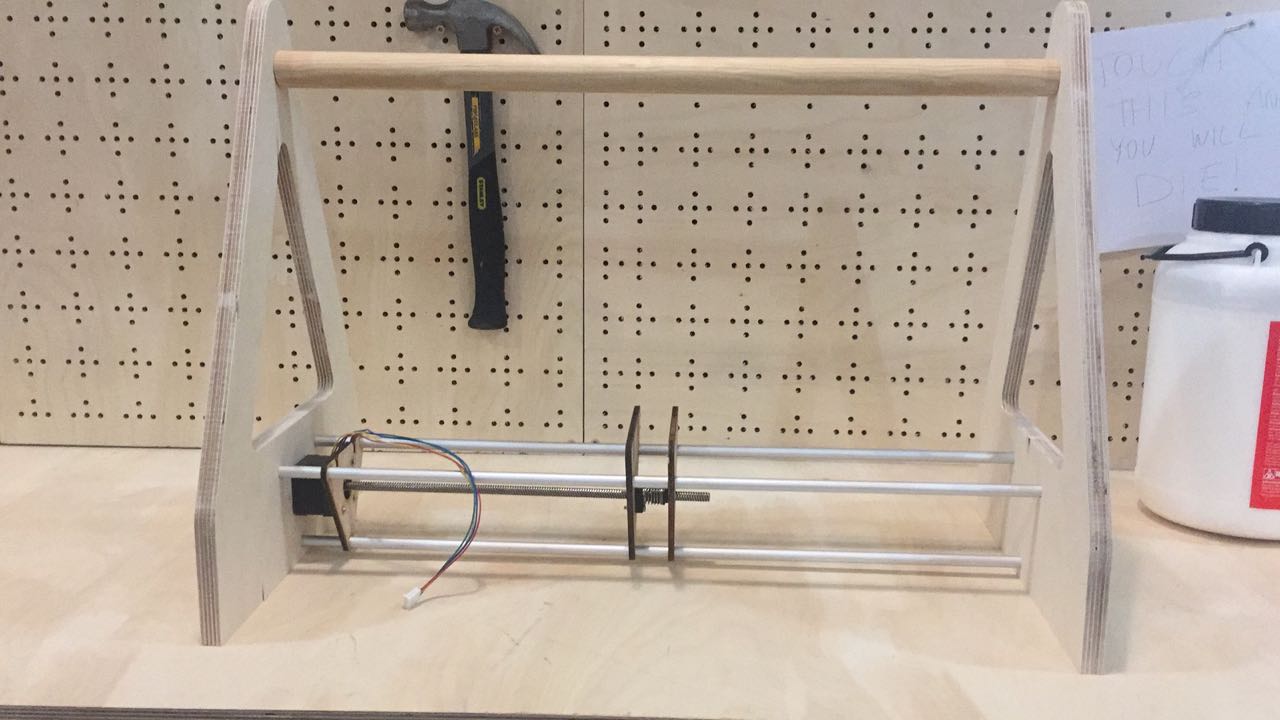

We made the first carbord prototype in order to determine the design changes that had to be made. I was the one in charge of the cut, and for the cardboar i used 23/90/1000 parameters. After that we made the final for the first week in wood, i also cuted it on lasercut.

After we tested and undertand how the machine worked, we redesign it. At this point i was responsable to redesign the extrenal base, we chosse to cut it in CNC to make it more stable.

I cut the inner part in laser while Eve was cutting the external in CNC. After all the pices cutted we had to put it together.

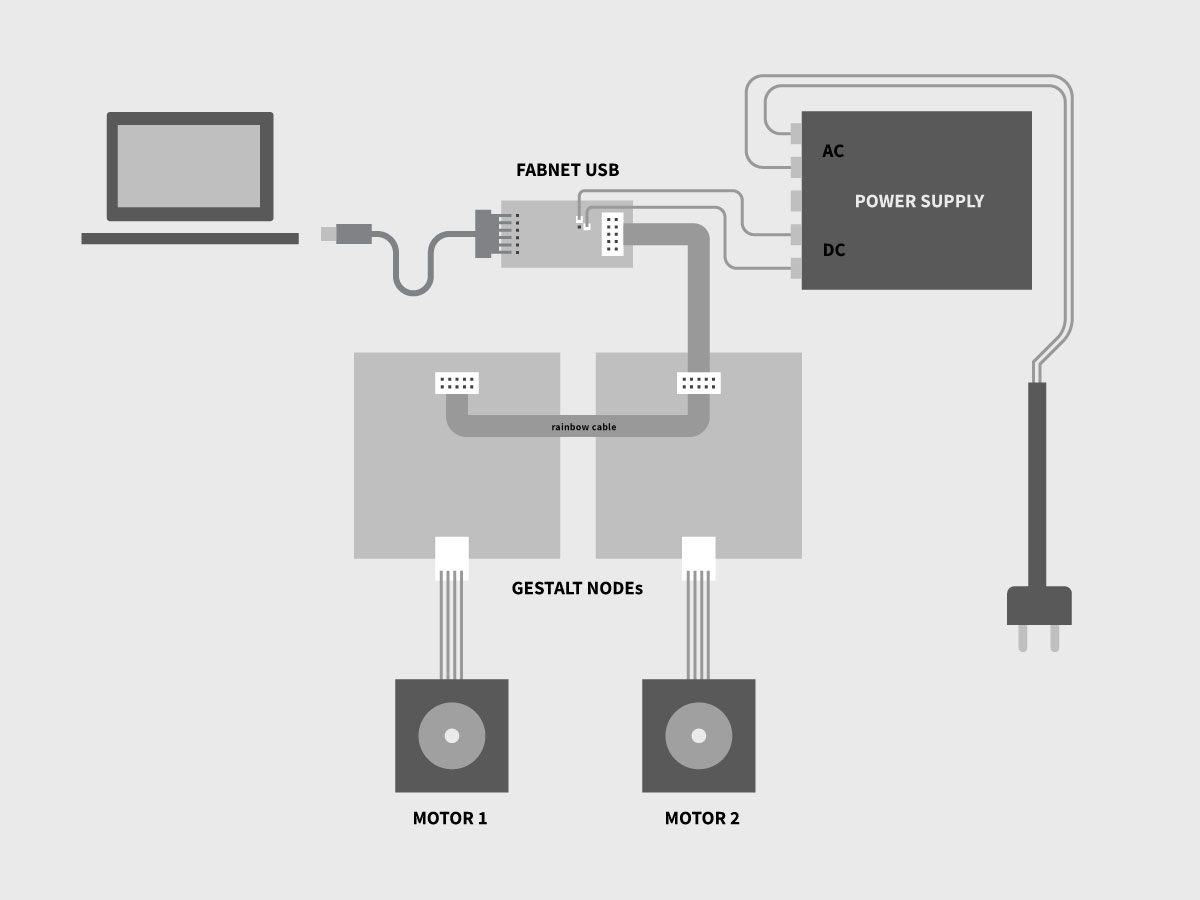

In the eletronic part i help dorota to figure how to use the (

Gestalt Nodes.

We started try to undertand connections between boards, motors (two stepper motors), fab usb (RS-485 bus) and battery (12 Volts and 2.1 Ampere). And she made this schematics from what we undertand:

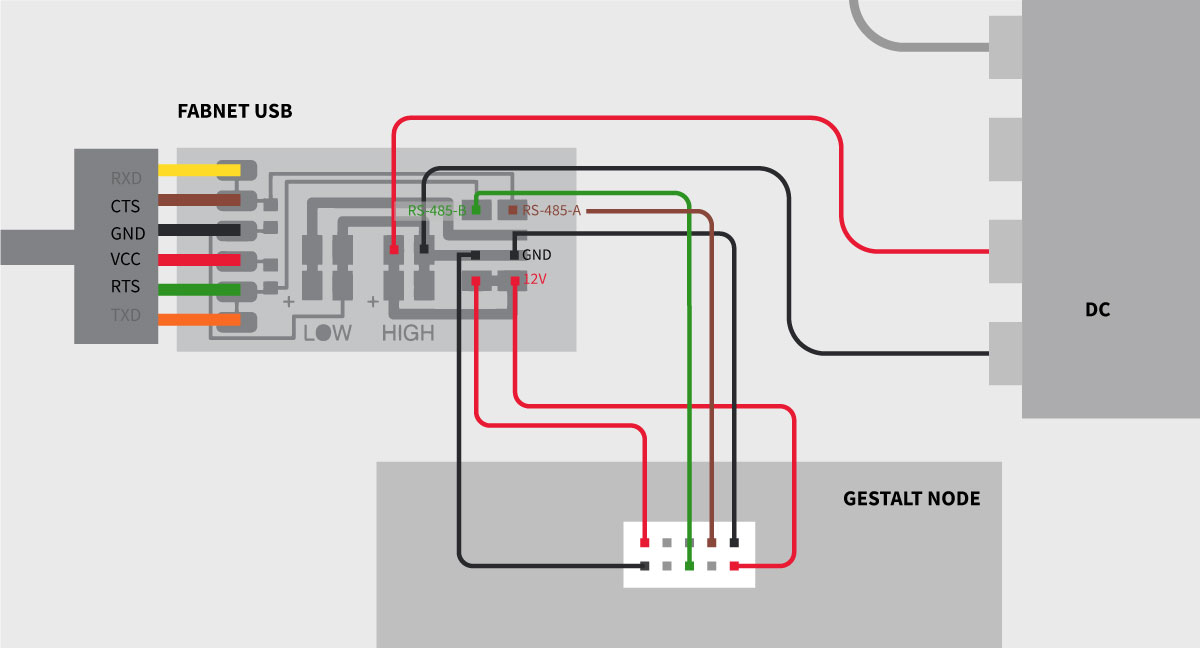

After that we have to find out how to connect the cables. Because the FAB NET USB has 8Pins and geatalt node has 10 pins

and the are out of the same order we had to use cable which at the end is divided.

For more information of eletronic or programming check

her page.

For a better result i believe we should redesign to make it more stable, and also make the board be able to read a G code.