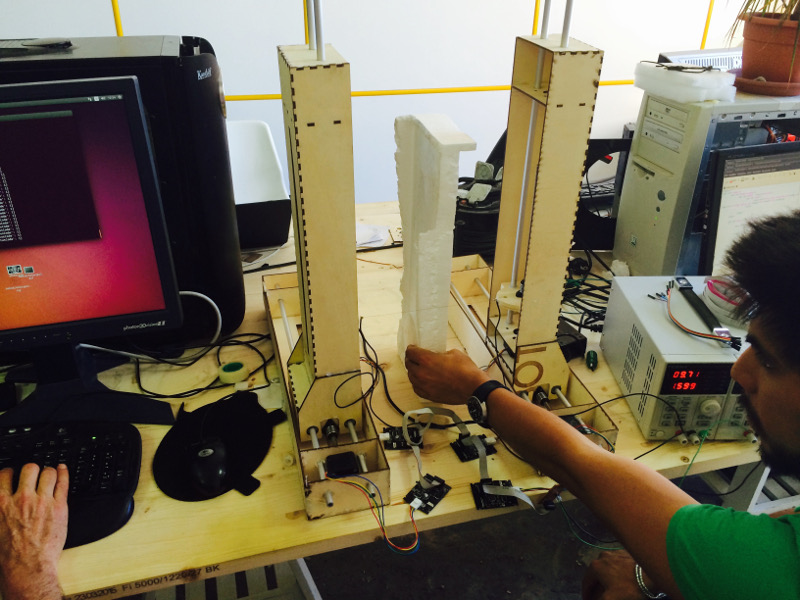

make a machine, including the end effector, build the passive parts and operate it manually, document the group project and your individual contribution

automate your machine document the group project and your individual contribution

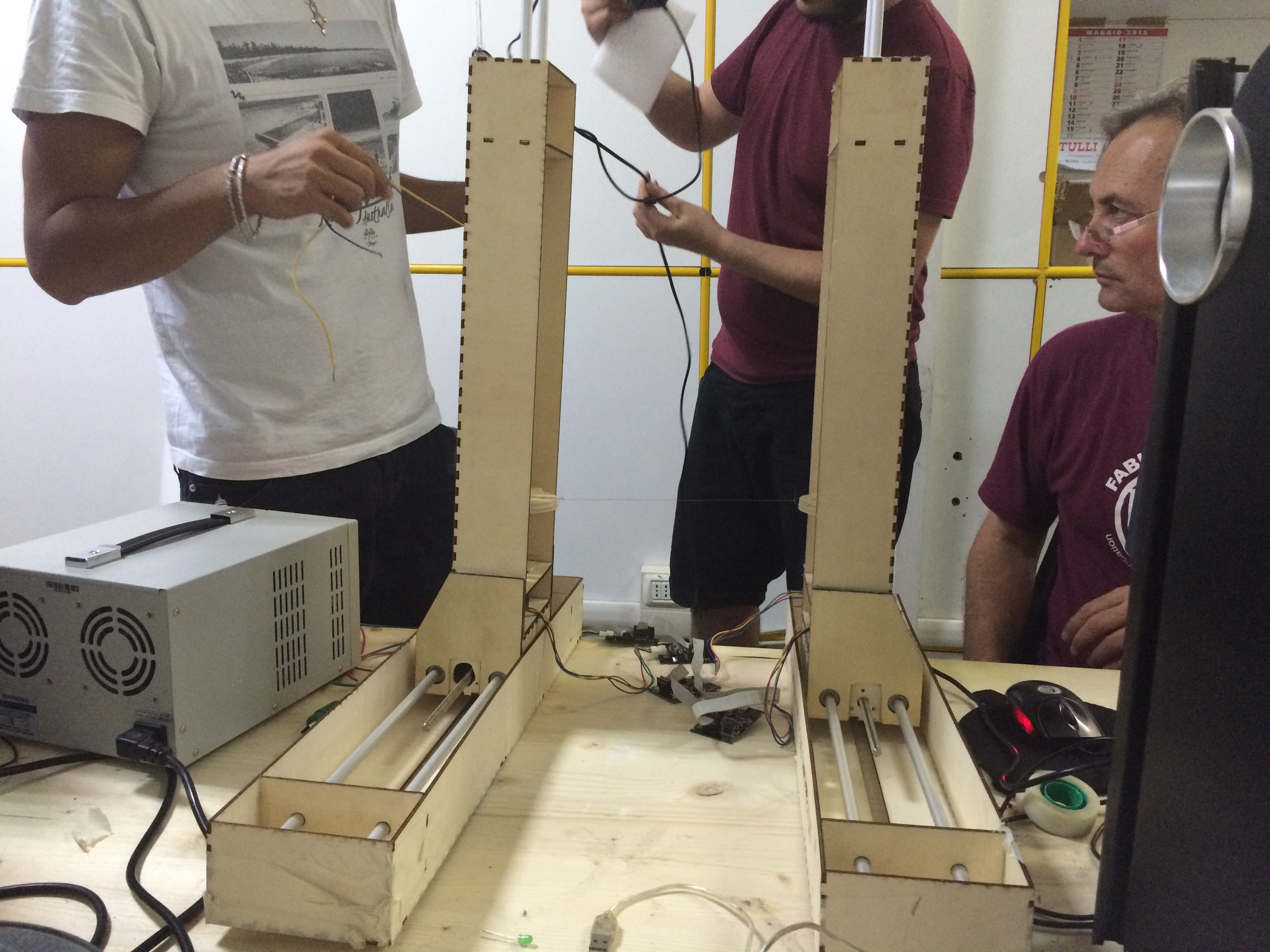

During this module , we worked as a team , fortunately the skills of each of us are needed to complete the assignment in the best way .

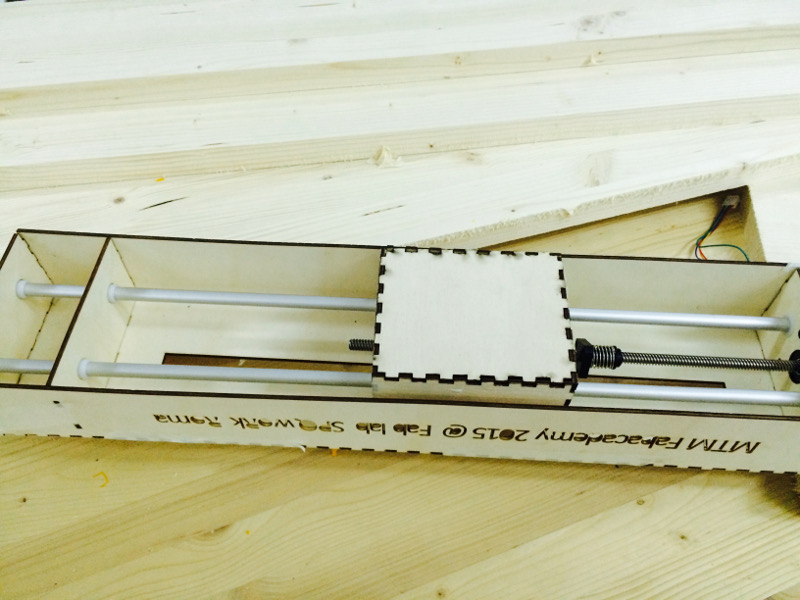

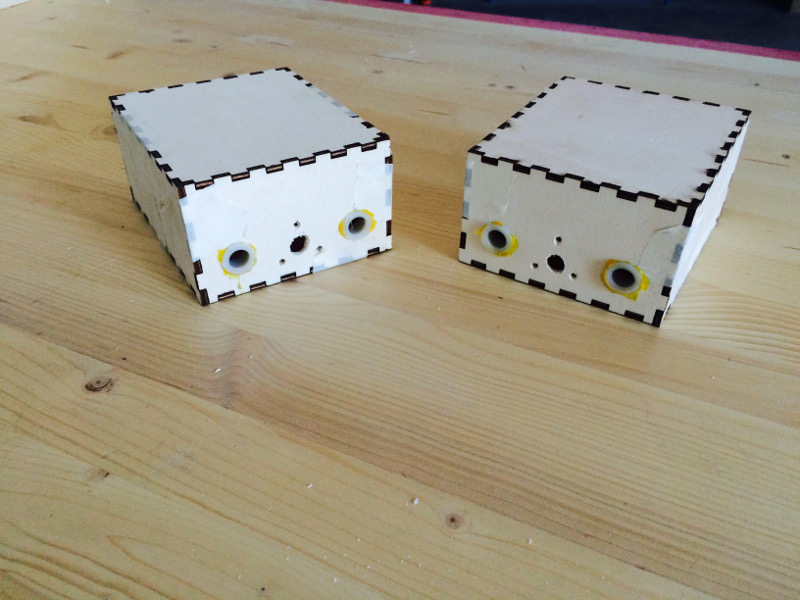

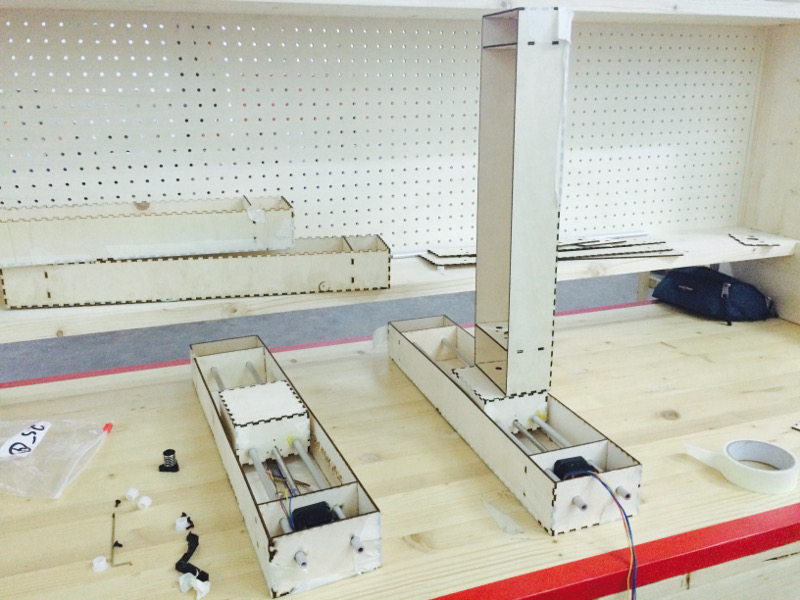

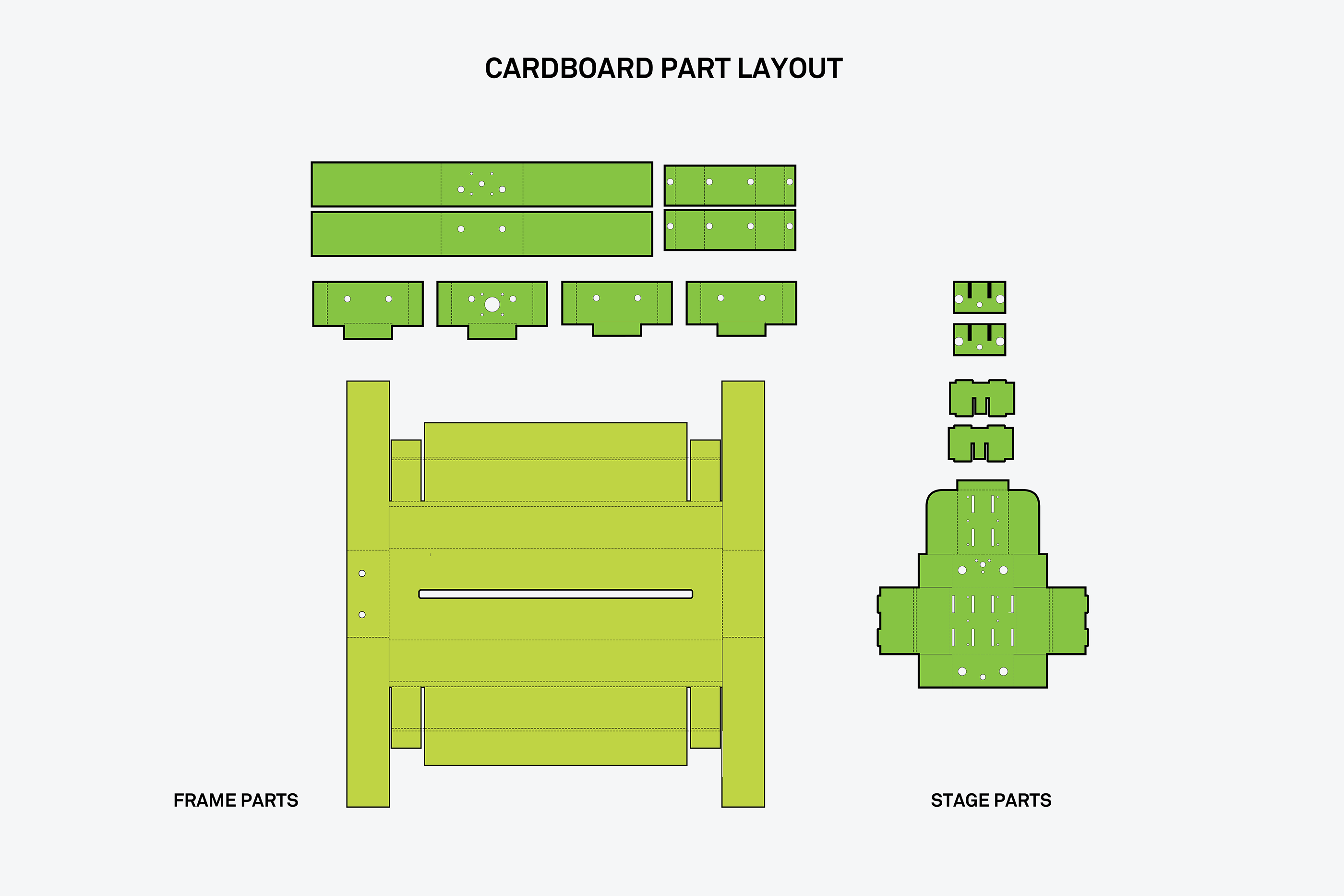

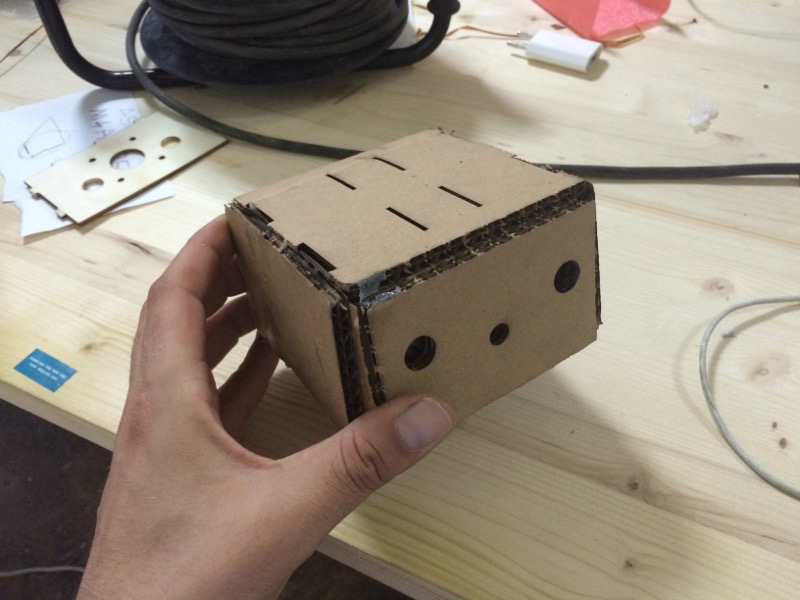

Antonio and I have dealt with the structural part , the creation of the file to be cut by laser .

Compared to the board of Nadya to use the cardboard , we changed the material using wood .

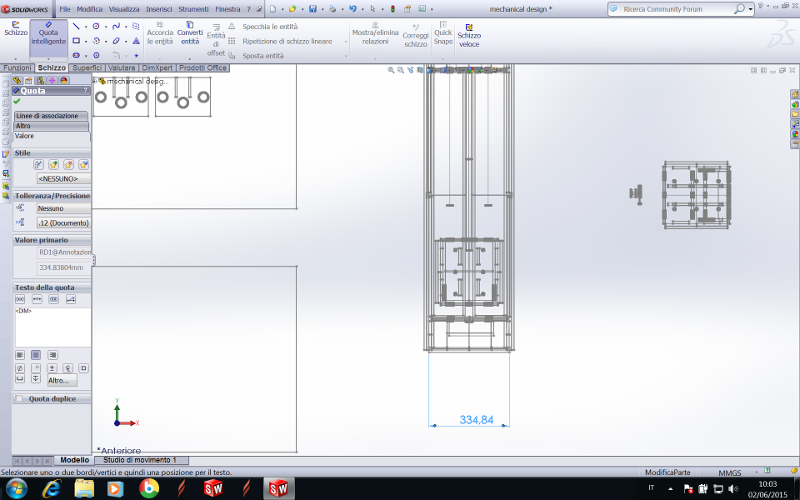

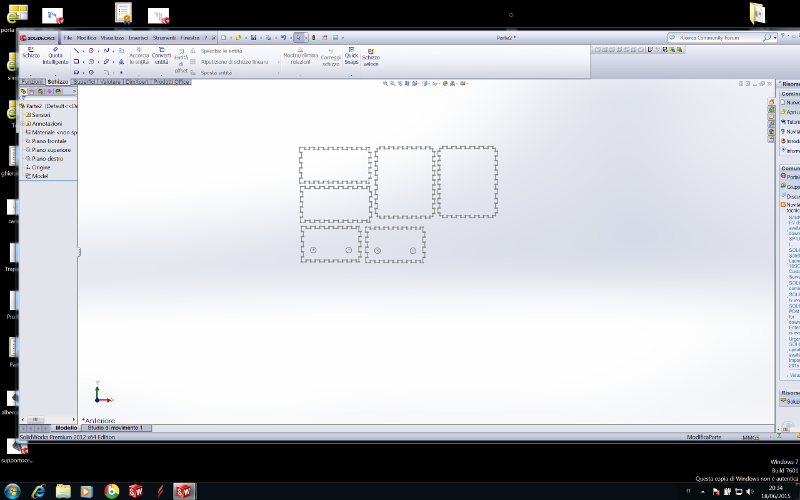

During the months of Fabacademy I acquired a good skill in the use of Solid Works , this program allows you to work on both models 3d models 2d , it is sufficient to draw without extrude surfaces . First I imported the design that I downloaded from the slide that has provided Nadya , this helped me only to have the exact measurements of the modules , then I provvdduto to draw everything from scratch .

After some tests with the cardboard recovered near the laboratory , we realized that the material was not suitable to the project so we opted for the wood . Here in Rome we have difficulty accessing this material , and paradoxically for us is cheaper to buy a panel playwood that sort of cardboard . A panel of 2500mm x 1250mm playwood with thickness 3mm Opinions more it costs less than € 10.

Recommended Laser setting for Triunph 80 Watt:

Playwood 3mm

Cut: Speed 10, Power 70, Corner Power 60

(every laser/cardboard is different... test first!)