Applications and Implications

May 20, 2015

Assignment:

Plan and document a final project that integrates the range of units covered.

Final Project: An affordable desktop CNC

This week I started researching existing desktop CNCs as well as hatching new ideas for my prototype.

Existing Examples:

While researching similar projects, I found the following the most inspirational:

Desktop CNCs:

Will Langford's Foldafab

Ilan Moyer's Fab-In-A-Box

David Carr's Mantis

Jonathan Ward's A-Z

Natan Linder's Little John

Nadya Peek's Cardboard Stages

MIT's Machines that Make

A Gestalt Framework for Virtual Machine Control of Automated Tools by Ilan Moyer

Spindles:

Sam Calisch's BLDC motor spindle

Ilam Moyer's DC motor spindle

RTF Technologies' spindle

Materials and Components Required:

* Body: Wood prototype, final Cast Concrete

* Bed: 1/4in-0.64cm 6061 Aluminum Mounting plate

* Spindle Motor: Refurnished Dremel Drill

* End Mill Tool Holding: ER-11 collet to allow use of various size tooling, largest Shrank Size: 1/8in. or 3mm and smallest end mill size: 0.010in or 0.025cm

* XYZ Bearings Acetal Resin Sleeve Bearings

* XYZ Stepper Motors with 0.000125in-0.003175mm Microstepping

* External power brick and power cord - IEC Type B,

* Axis control: Gestalt Nodes

* Spindle PCB

* Relay PCB

Resourcing of Materials and Components:

I will resource from local Austrian or European stores:

Sorotec

CNC Shop

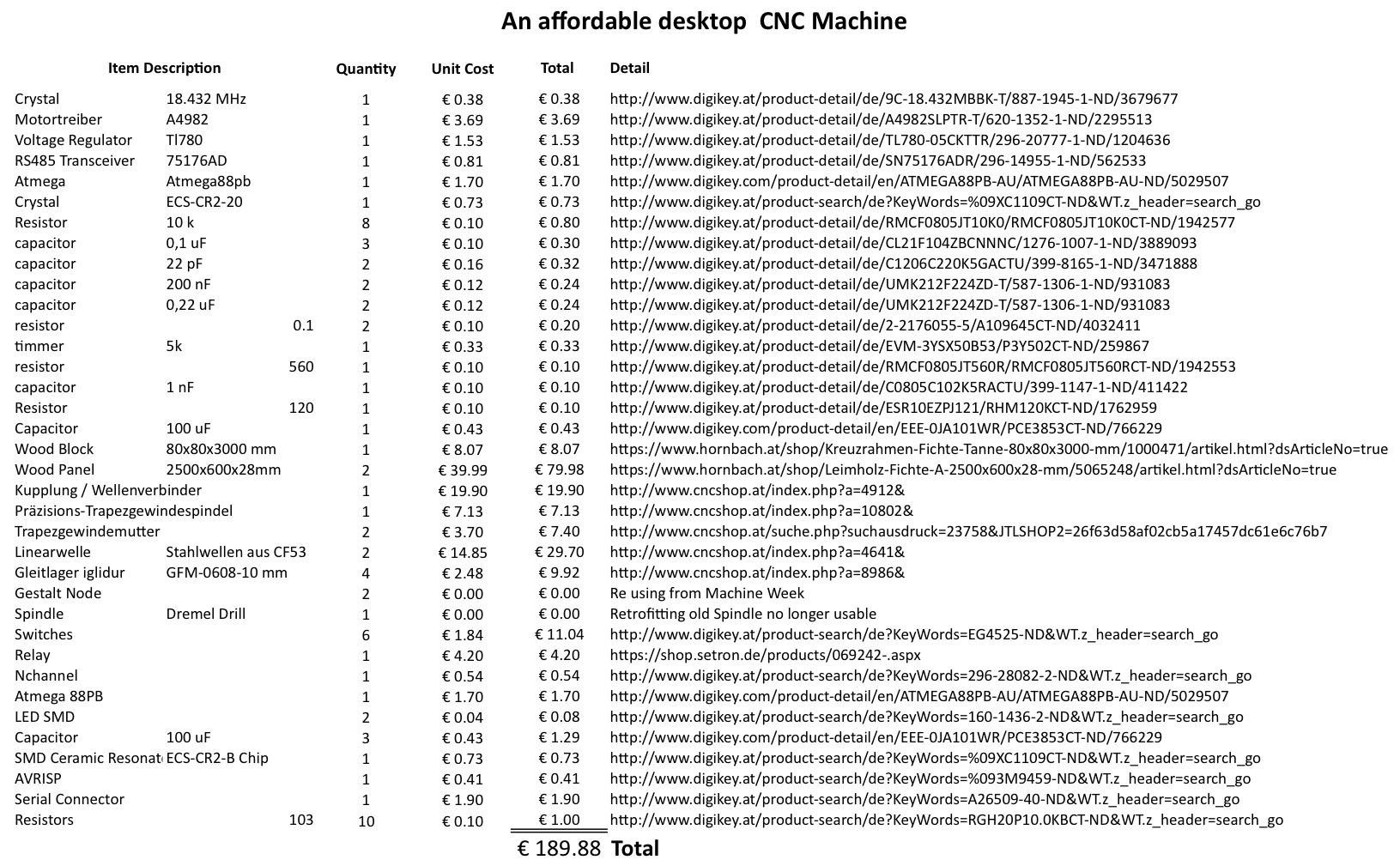

Cost Projection:

This is a list of all the materials and components used in my final project:

In this link you can find my Bill of Materials Excel File:

An affordable CNC Machine Bill of Materials

Processes Used:

* Prototyping of Body: CNC milling of Wood and Laser Cutting of Stages

* Final Body: Casting in Concrete

* Electronics: Circuits designed in Eagle then milled and/or etched with soldered components

* Coding: Programming in C or Python

* Assembly: by hand

Tasks required for completion:

* Understanding how to program and build the 3 axis mechanical movement and their relationship.

* Design and Build Mechanics.

* Electronic Design and Build

* Assembly

Outstanding questions:

I feel that the mechanical part of the project is a matter of development. The biggest hurdle for me will be to program and design its electronics.

Schedule:

I am lucky in that next week when we design our Mechanical-Machine project I can start working on the mechanics of my final project. I intend to develop the first prototype in wood. I will also integrate the electronics and mechanics of the machine week project into my final project. Once I have the first prototype I could realistically develop a schedule.

Evaluation of Success:

While I am in some ways reinventing the wheel, I hope I will succeed in integrating and customizing existing desktop CNC designs and technologies into my own design. If anything, the simple fact that this would be my very first designed / self built machine, mechanics and electronics included, that alone would be my biggest achievement if it remains in an affordable spectrum.