computer-controlled machining

Week 9 Overview

This week Fab Academy covered using computer controlled machines. We mainly discussed

the most popular machines, various materials, tool choices, feeds & speeds, lubricants and safety.

The assignment for the week was to

- make something big.

and learn how to use a large CNC like the shop bot.

What big things to make?

There are 2 different things I made for this assignment.

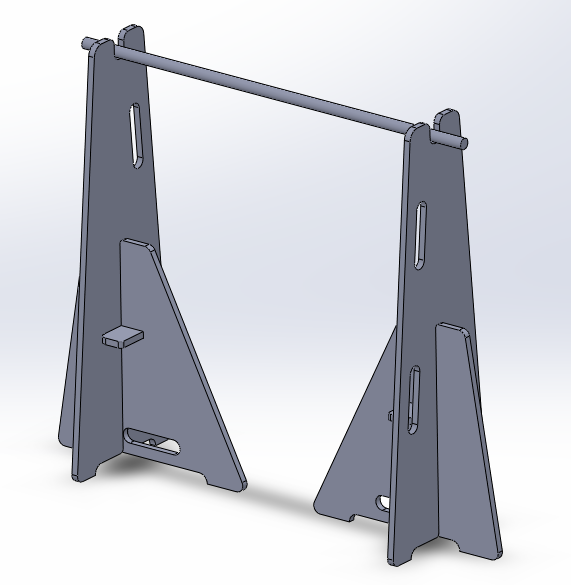

Firstly, I made a bicycle stand

that hold the back wheel of the bicycle up off the ground. This is for carrying out maintenance on

the bicycle in the back yard.

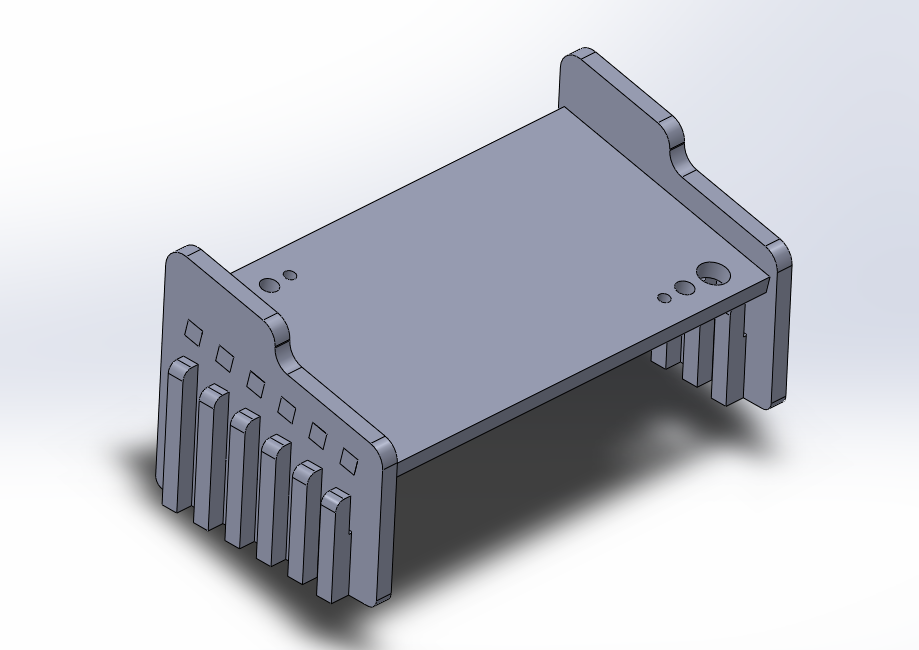

Secondly I made 2 small knelling stools.

Step 1) Making the 3D models

I made the 3D model of the stool and bicycle stand in solidworks.

I wanted all of these things to be designed so they are flat pack and

can be put away in storage or transported. So I made the joints to slot together tightly.

After making the model in Solidworks I saved it as a DXF to import it into the software to use on the

large CNC.

Download the solidworks and DXF files for the Bicycle stand

Download the solidworks and DXF files for the Stool

Step 2) Converting the 3D models into gCode to send to the Machine in vCarve

I used vCarve to import and 3D models, create the tool paths and generate the gCode.

I created a detailed document of the process I went through to do this -

Detailed description of vCarve usage here

I also followed a guide provided by MakLab where we made our 'Something Big' pieces.

Here's MakLab's guide

Download the vCarve file

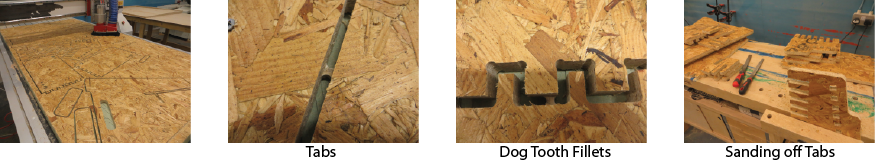

Step 3) Cutting the pieces on the CNC router (using NcSTudio software)

The material I used was 18mm OSB. I managed to fit into 1 sheet. I would have liked nicer material but

it would have cost a lot more.

The tool bit I used for both internal and external cuts was a 6.3mm upcut end bit (1/4 inch).

I used the following settings for the router to cur 18mm OSB:

- Stepover: 40%

- Pass Depth: 4mm

- Cut Depth 19mm

- Feedrate: 4m/minute

- Plunge Rate: 2m/minute

- Spindle Speed: 20,000 rpm

I made a very detailed description of this set up here

Download the gCode (NcStudio file)

Below are some pics of it being cut and sanding off the tabs.

Step 4) Assemble Final Pieces

The stool fit together perfectly but the bikes stand needed a bit of

sanding along the joints to get the pieces to fits together. In future I'd do a test run of this

taking into account the tool thickness and material thickness and the length of the joints.

You can see the final pieces assembled in the photos below.

The final stools work pretty well but were a bit too low and the tilt forward could have been great.

If I was making them again I would change this. Instead I changed around the supports so the tallest supports are

closer to the front of the stool. This lifts the stool higher off the ground and allows it to rock a little

back and forwards which it nice for sitting on. It ruins some of the aesthetics though. Some meditation stool actually have a curved base so you can

adjust them to an angle that suit the person using it best.

Week 9, Mar 20

3D model of the Bike Maintenance Stand

3D model of the knelling stool