|

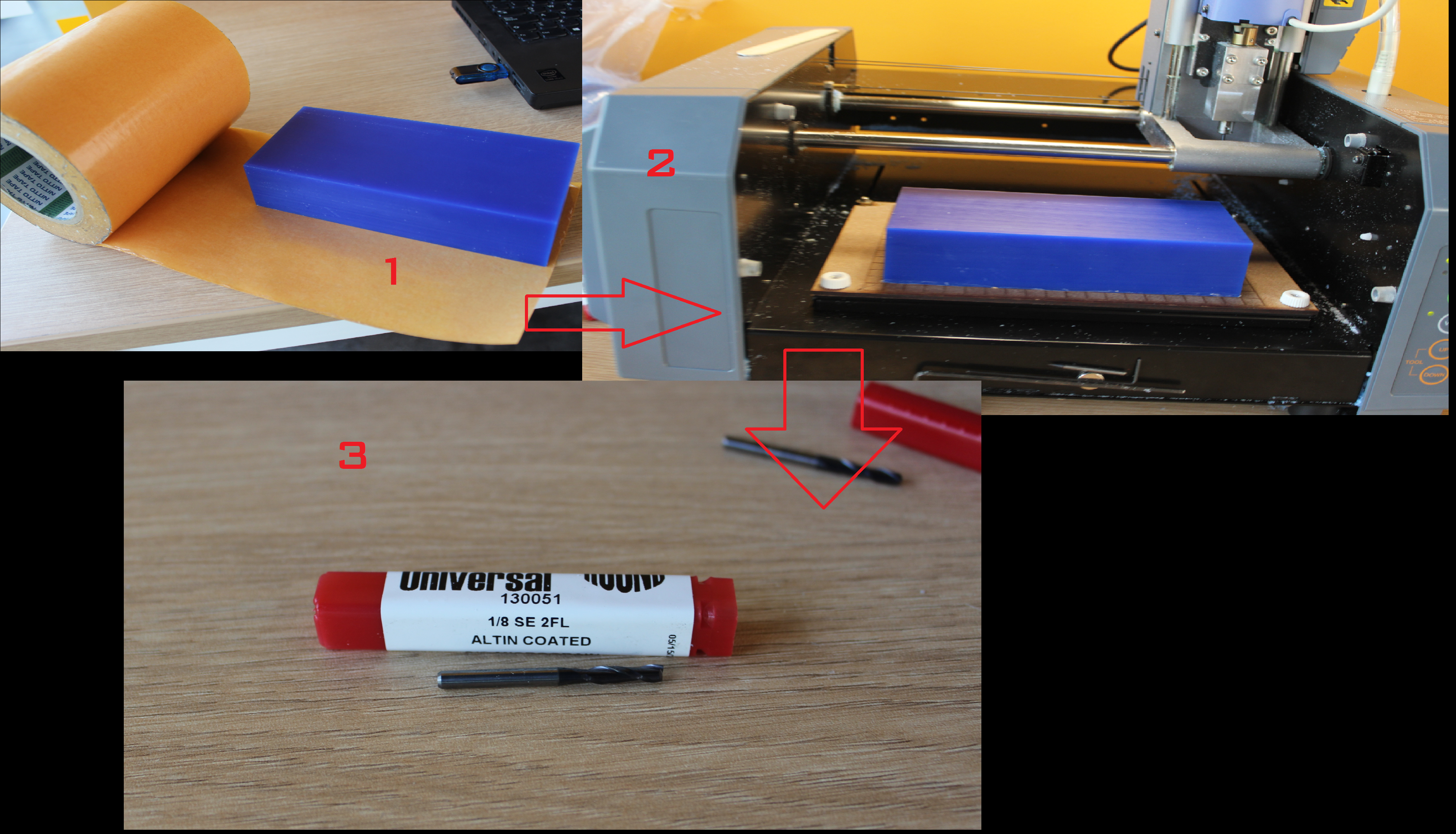

Tools 1.-end mill 1/8' Meterials 2.-plywood 15mm 3.-machinable wax 4.-Tin-Cure silicone Rubber (OOMOO25) SOFTWARE 5.-Fab Modules 6.-Autodesk inventor MACHINES 7.-Roland Modela |

|

in this assignment I will try molds to make parts of my final project |

|

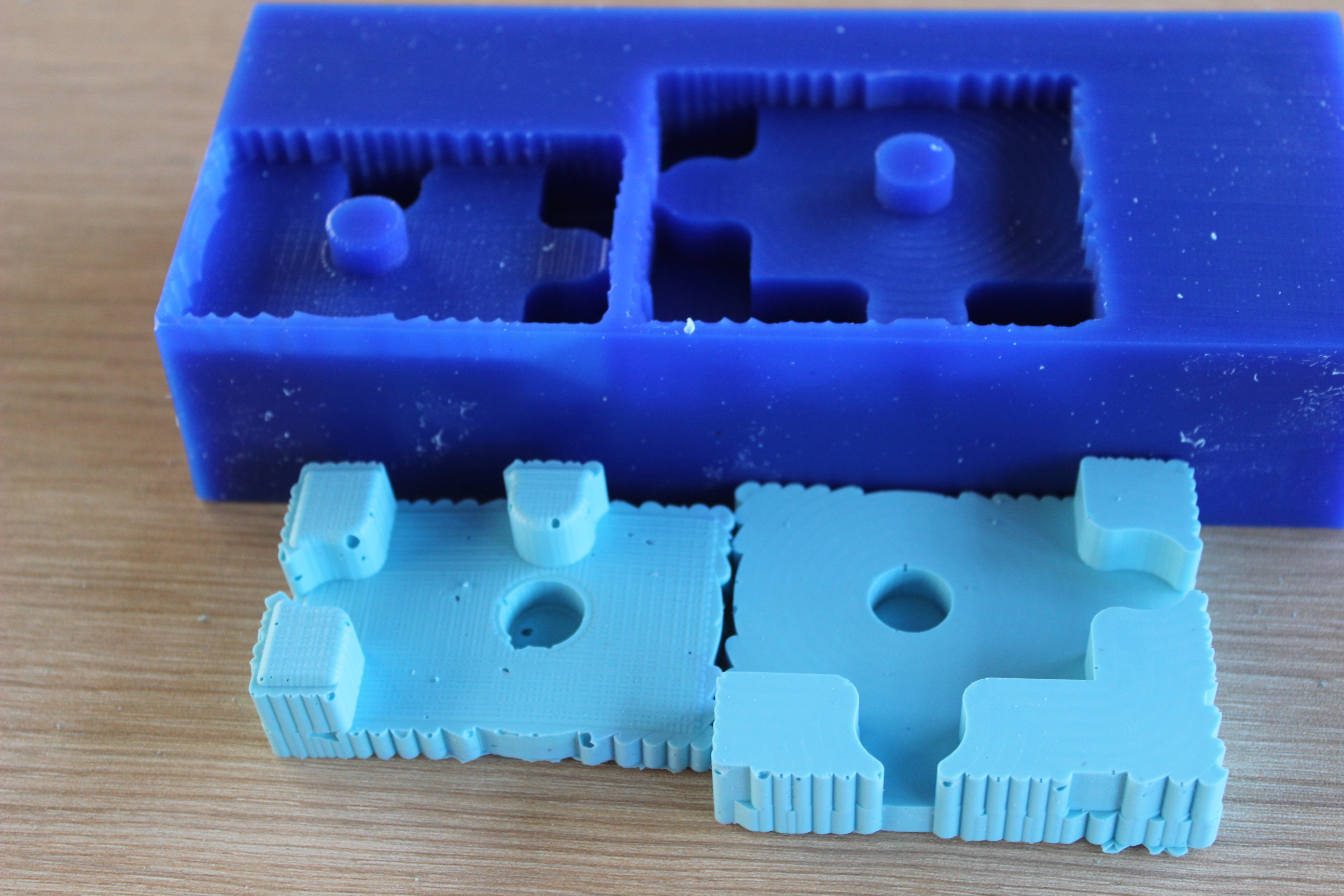

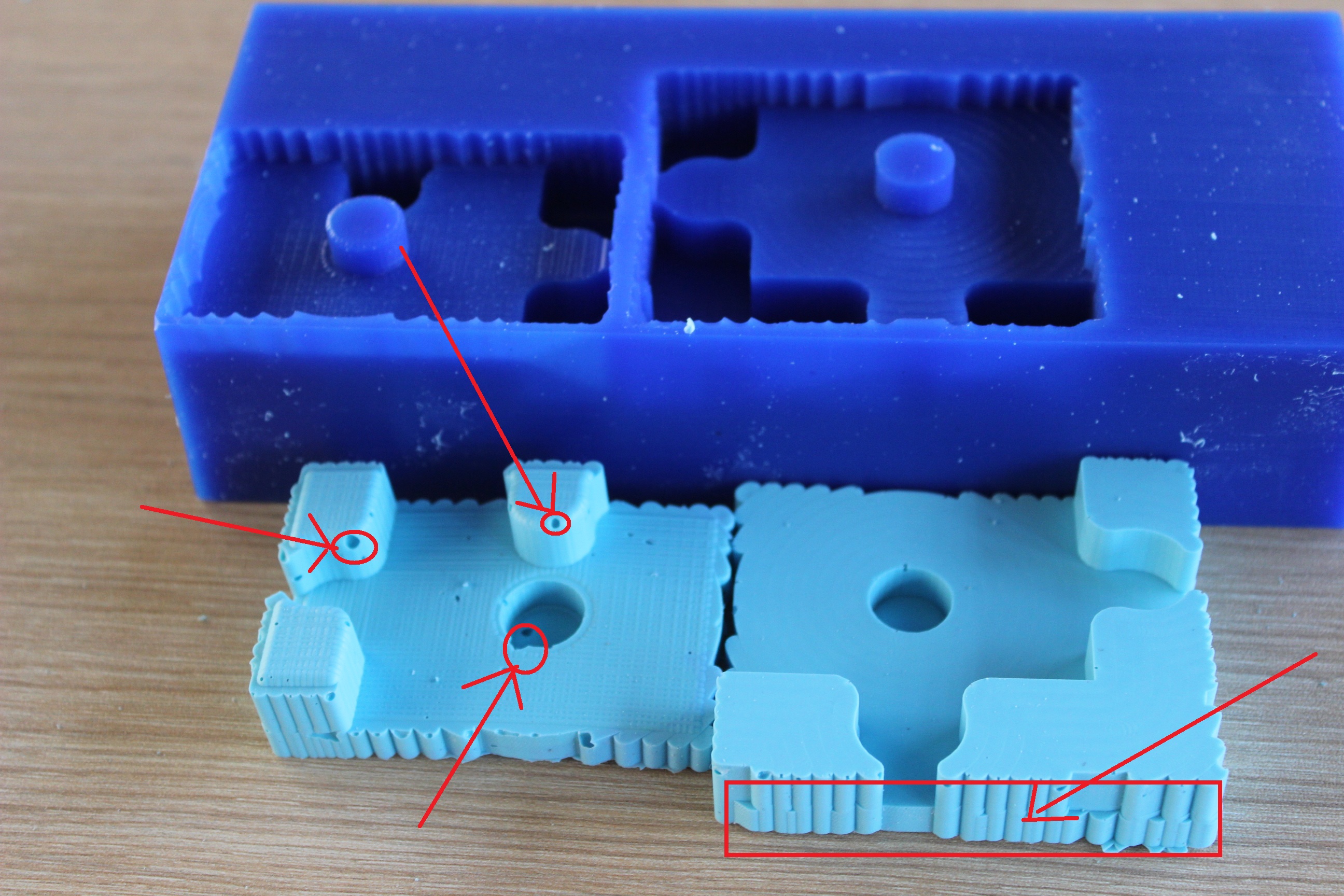

I made a design in A. inventor, is based on the typical shape of a piece of a puzzle design, also has in the middle a cylindrical shape protruding, this meant that it can be placed on the board fixedly.I design errors that affect during the process, and I will show you |

|

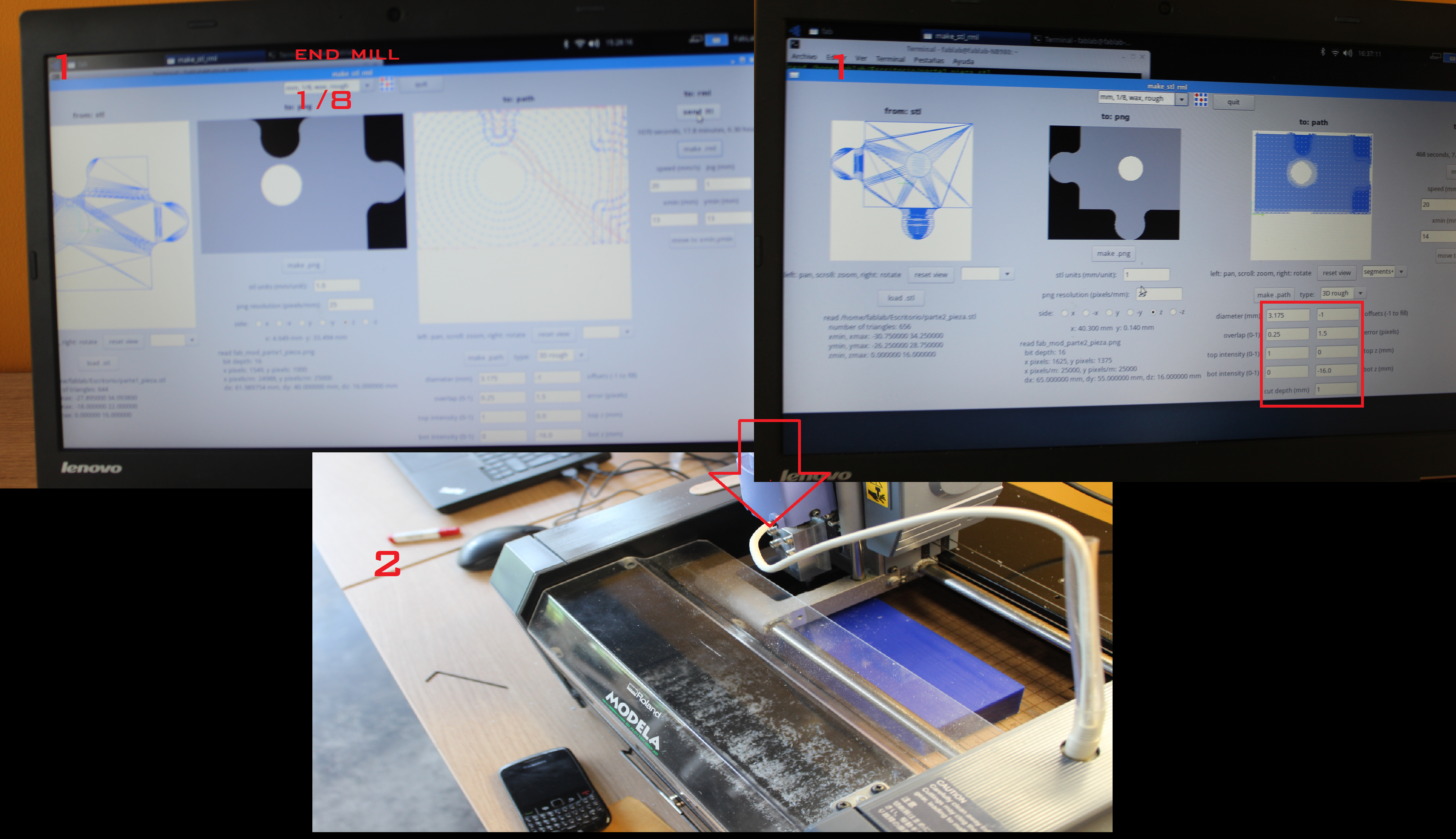

then have the design ready, prepare the material (machinable wax) and the machine (Roland models) with the indicated tool (end mill 1/8) |

|

load my files on the fabmodules, before making sending the design, calibrate the machine in X, Y and Z |

|

over the mold, remove the remains to have the final piece and go to next step |

|

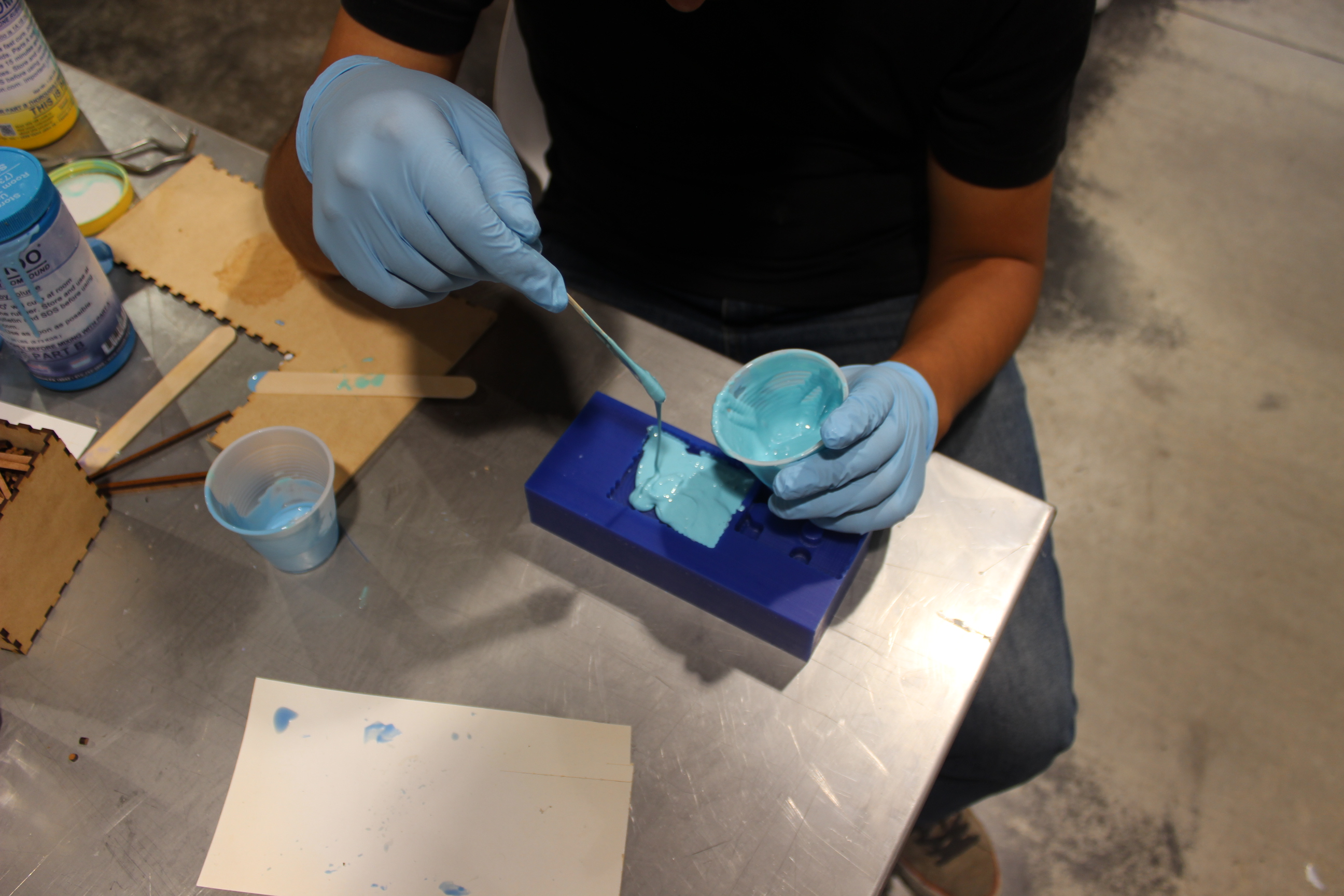

then prepare the silicone Rubber

1. First choose the material in this case (in-Cure silicone Rubber (OOMOO25)) 2. then check to see if we have all the necessary materials for mixing 3.-filled two containers each material making sure of the quantity equal. 4.-finally realize the mixture |

|

Carefully put the mixture in the mold |

|

Recommend us to have the material in the mold for 12 hours |

|

after taking the final mold, I analyze the mistakes I had the imperfections and especially the lack of the side face to take this mold to make the piece in other material Problems and conclusions-the design needs to be modified as it has a very small margin to make the mold -imperfections can be a bad mix, errors when pouring the mixture -It is necessary to design the mold walls to avoid imperfections |

|

I will continue working on my design as this process will be key to making my final project and will continue doing testing and improving my results design files ( DOWNLOAD ) |

|

|

Second attempt as I prepare a blend of PMC/12130

1. First choose the material to prepare a blend (PMC/12130 Type A and B) 2. the amount is 1: 1, prepare the mixture, then I put in the mold 3.-in the next day,I remove the mold. I have better results than the first case |

|

Then I have to prepare Smooth cast

1. First choose the material to prepare a blend (Smooth cast 305 Part A and part B) 2. the amount is 1: 1, prepare the mixture 3.- then I put in the mold, This process can be dangerous, we must be careful 4-5.- after 10 minutes we can remove the piece, in this case,n this case I get the part without any component inside the application onwards depera have some component in and use it in my project or other aplications |