|

Tools 1.-end mill 1/4' Meterials 2.-plywood 15mm SOFTWARE 3.-shopbot 3 4.-Autodesk inventor 5.-vcarve Pro MACHINES 6.-shopbot |

|

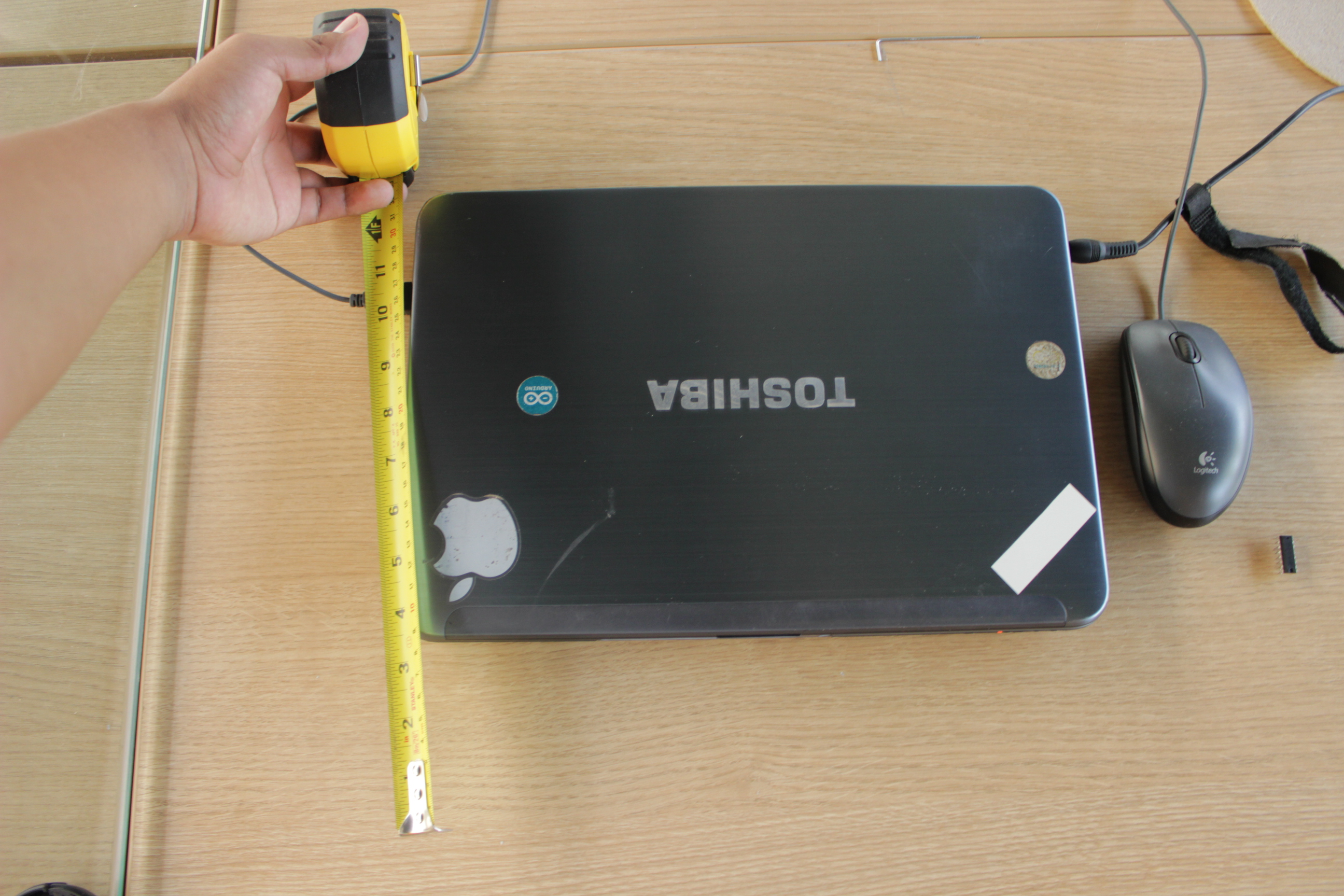

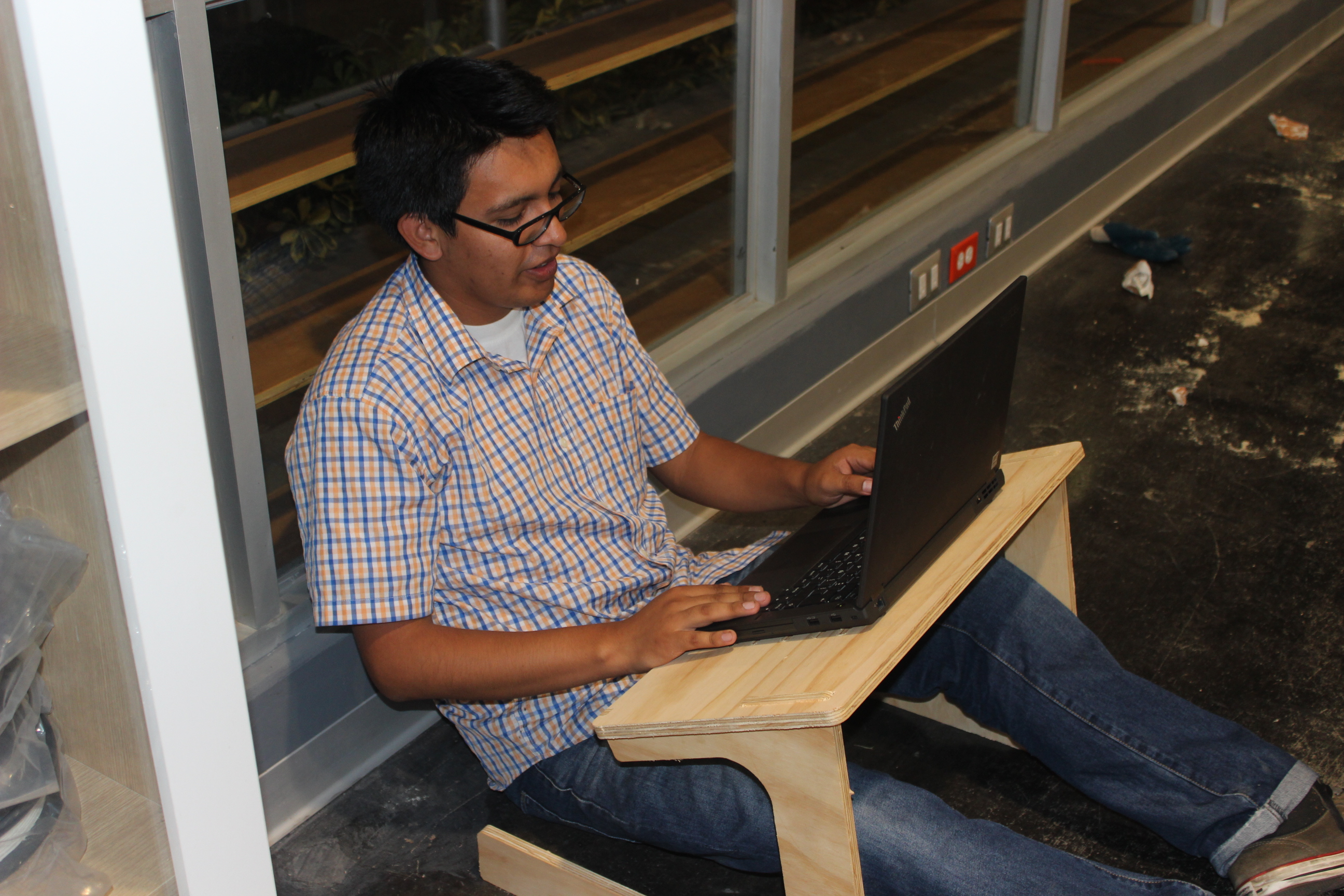

I want to make a suport for my laptop so, First I take the measurements of a laptop |

|

width and length of my laptop |

|

stamation of inclination of the laptop |

|

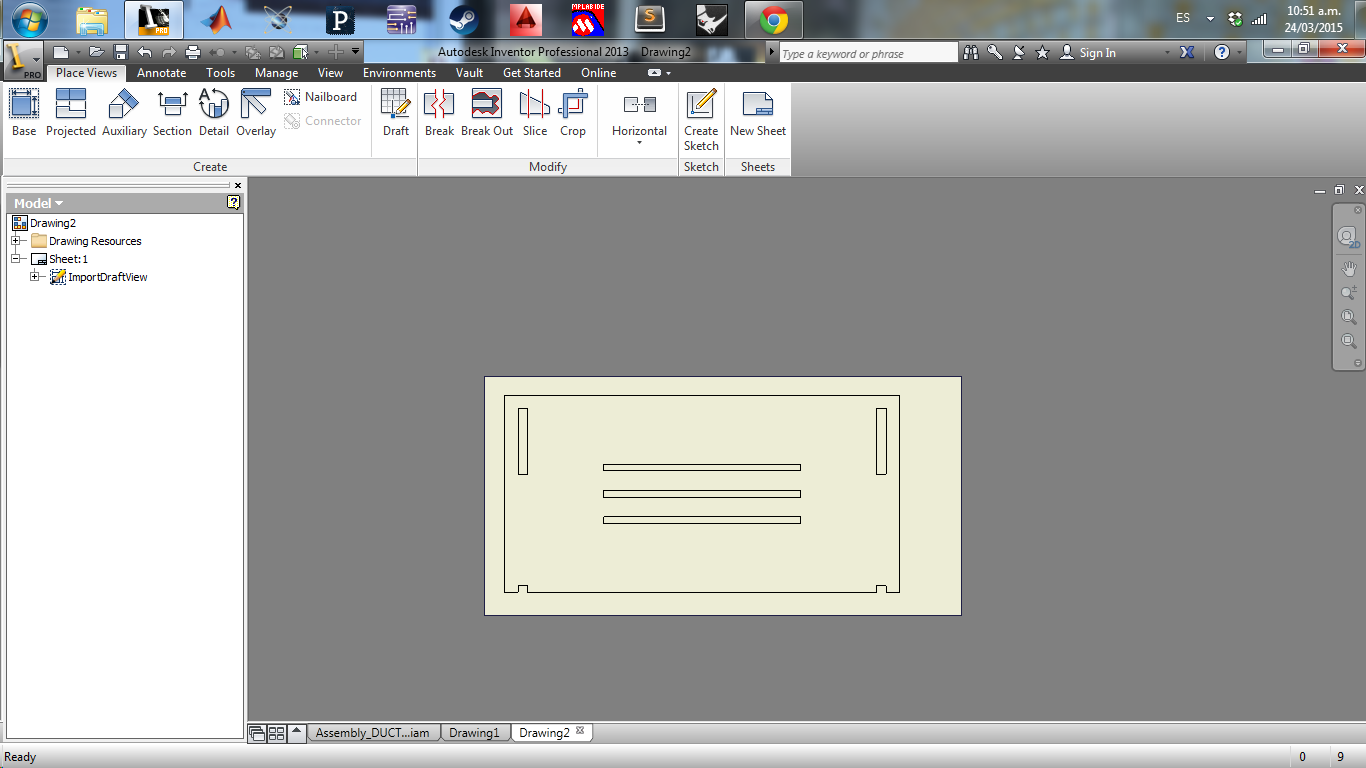

I build the pieces based on the measures for this I use INVENTOR CAD software |

|

the structure is simple, 3 parts and two equal parts |

|

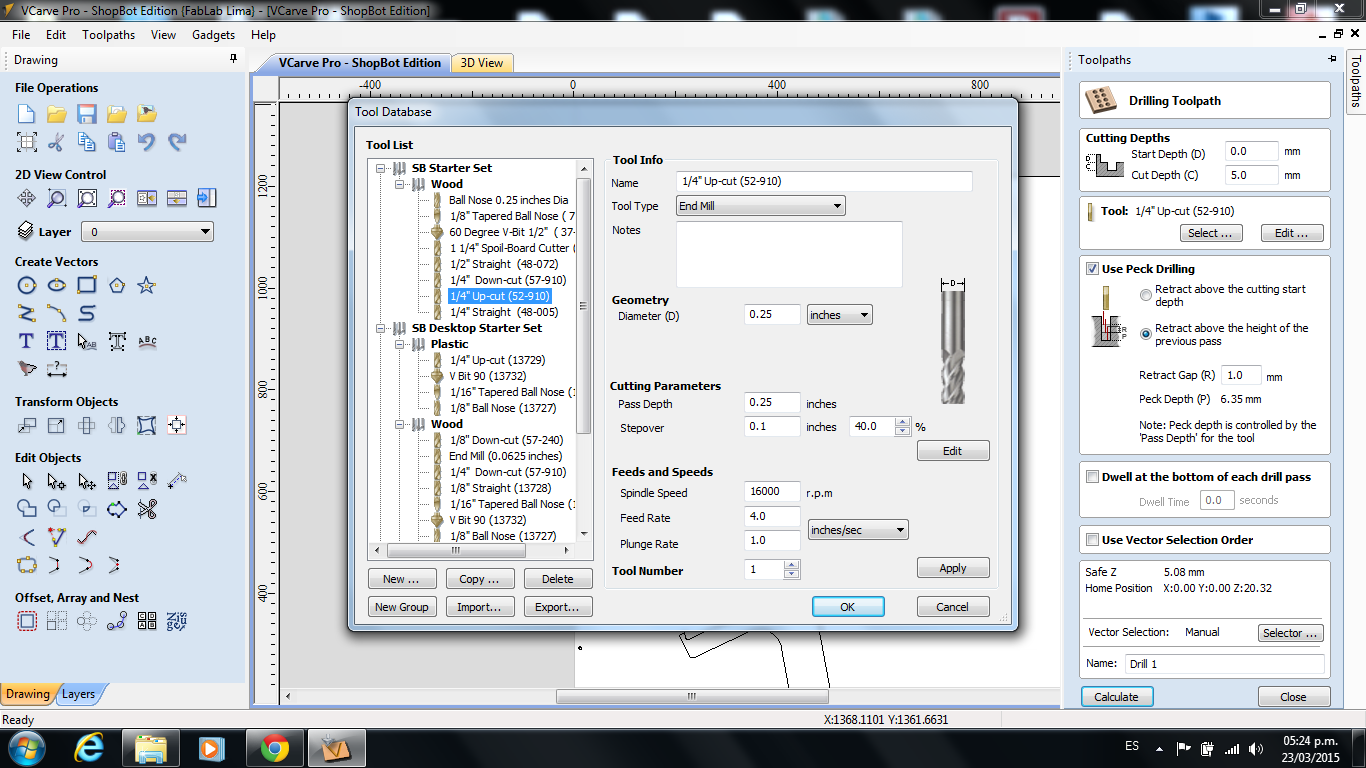

I import DXF files on VCARVE PRO software and I verify that all vectors are closed |

|

I choose the correct end mill and verify all the correct configurations, I take note of RPM "16000" then I calculate chipload parameter, first I configurate drill then perfil |

|

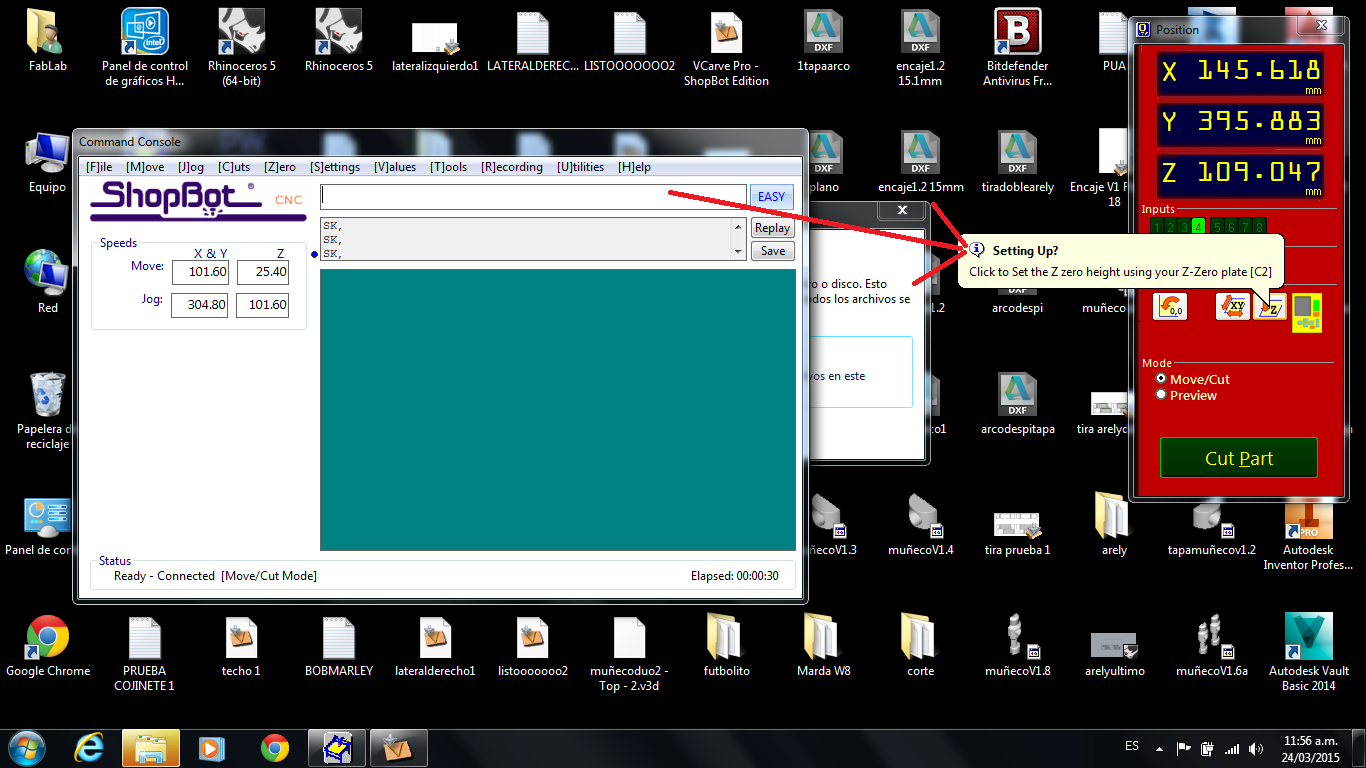

I put plywood on the shopbot, then I prepare the machine |

|

|

|

first I calibrate the Z axis |

|

after that I calibrate the X/Y axis |

|

then I can send my curt configuration |

|

|

|

FILES |

|

After learning the whole process of manufacture with shopbot, I designed and built a bigger piece of furniture that will serve to save materials and objects within the FabLab |

I designed 2 pieces, They will double to build the full furniture.

I designed 2 pieces, They will double to build the full furniture.

|

These pieces were also designed in AutodeskInventor

These pieces were also designed in AutodeskInventor

|

|

As in previous case, we export the file in DXF format to carry the machine shopbot |

|

FILES |