WEEK ASSIGNMENT:

Make a machine, including the end effector, build the passive parts and operate it manually, automate your machine, document the group project and your individual contribution.

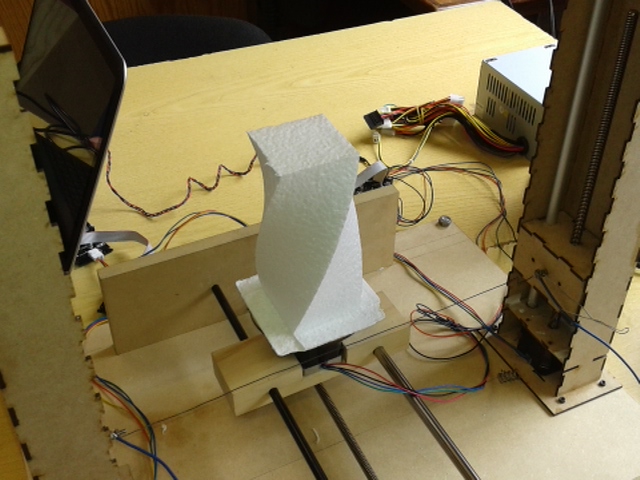

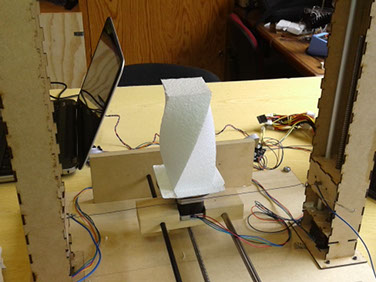

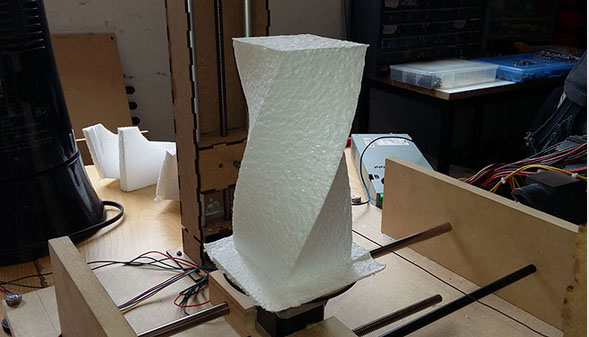

I think this assignment is the most entertaining, it took us a week to decide what kind of machine we wanted. At last we inspired on Nadia's work and build on it. So we decide to make a Styrofoam cutting machine with an extra axle.

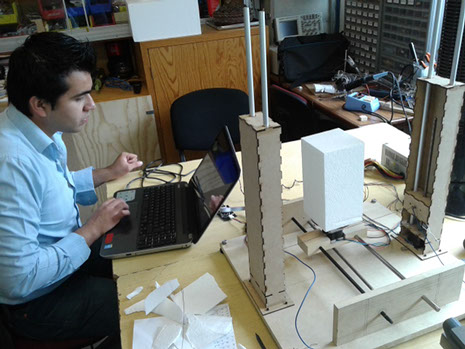

The machine was designed and mechanical constructed the by me and Itan Fuentes, and Huber Giron's contribution was automate the machine.

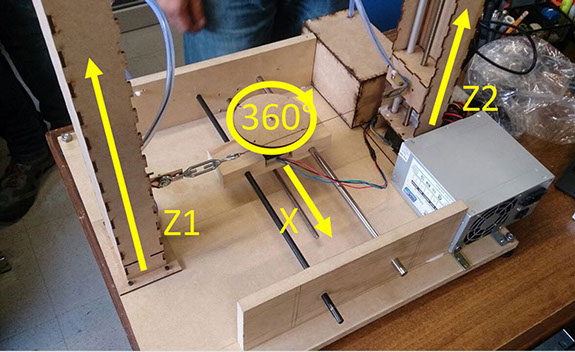

The Styrofoam cutting machine have 4 stepper motors: one on "X" and one in a 360° that move the base, and two in "Z" that move the tool: hot wire.

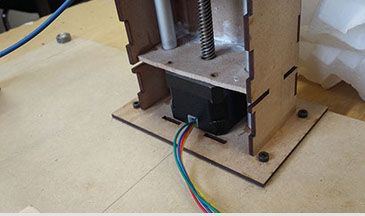

We recycled an old base as it can be tell by the two guides on the x axle. I designed the Z axle posts and laser cut it. You can find the dxf file by clicking HERE. And the machine circular base by clicking HERE.

There is a mistake on the Z axis design regarding to the size of the motor. I did not consider in the design the material's width, so what we did was to manually cut the assembly "teeth" and glue it to the Z post.

I designed this code for the machine:

/////////CODE:///////// PIRULI

0,0,0,0

0,180,180,0

0,150,150,0

150,150,150,0

150,180,180,0

0,180,180,0

30,180,180,0

30,150,150,0

30,0,0,64

0,0,0,64

0,150,150,64

30,150,150,64

30,0,0,128

0,0,128

0,150,150,128

30,150,150,128

30,0,0,192

0,0,0,192

0,150,150,192

30,150,150,192

30,0,0,256

0,0,0,256

We learned a lot making this machine. We are planning to continue with this machine to make it bigger and improve software so it can easily make circular patterns.

We also have to improve the Z axle to include a spring on one side of the hot wire so each Z post can move differentially. This way we could make an additional movement to obtain interesting pieces.