08_COMPUTER-CONTROLLED MACHINING

josefinaPETRINI

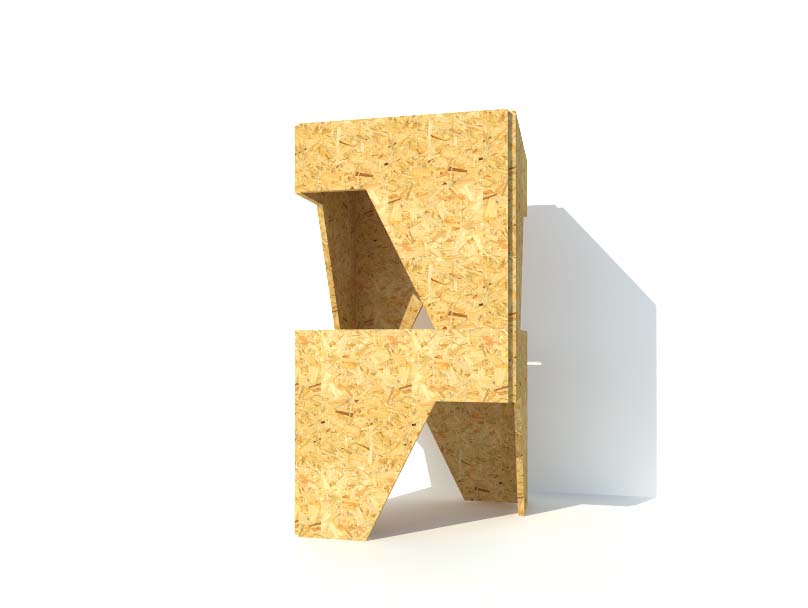

_MAKE SOMETHING BIG

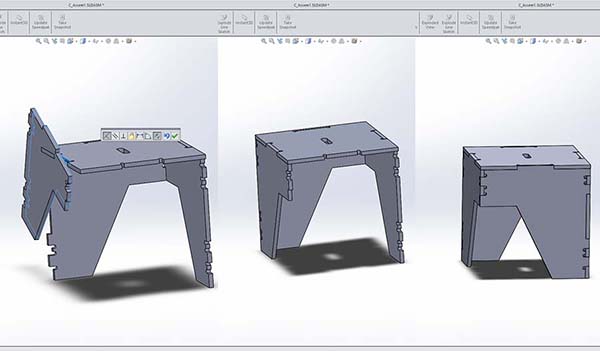

Assembled parts in SolidWorks.

Assembled parts in SolidWorks.

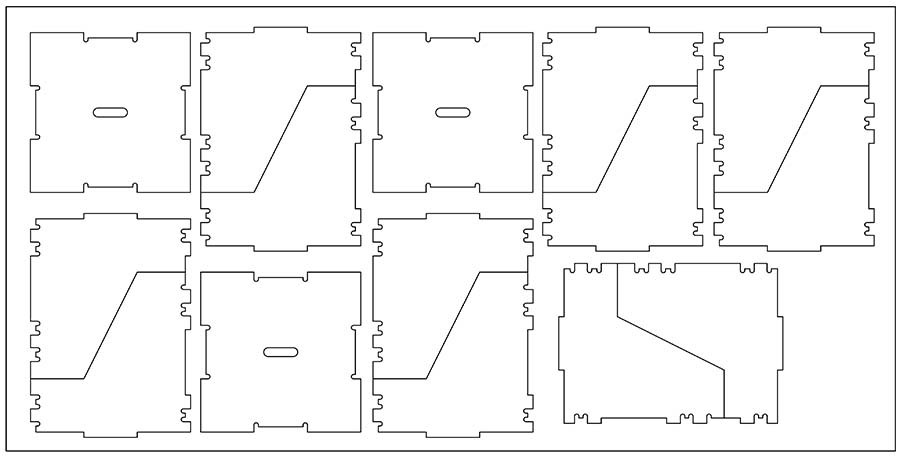

Following the premise of doing the least cuts possible was only useful for the design but not for the cutting as the 6mm drill path runs on a inner line, so anyway I would have two lines.

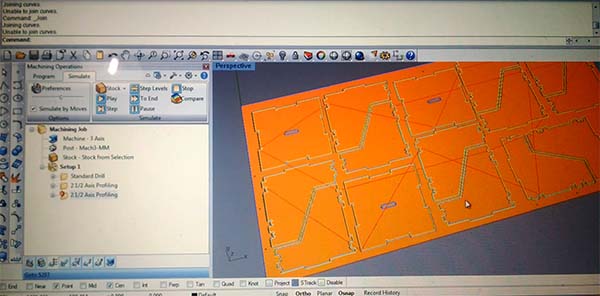

When the archive was ready I took the following steps:

Following the premise of doing the least cuts possible was only useful for the design but not for the cutting as the 6mm drill path runs on a inner line, so anyway I would have two lines.

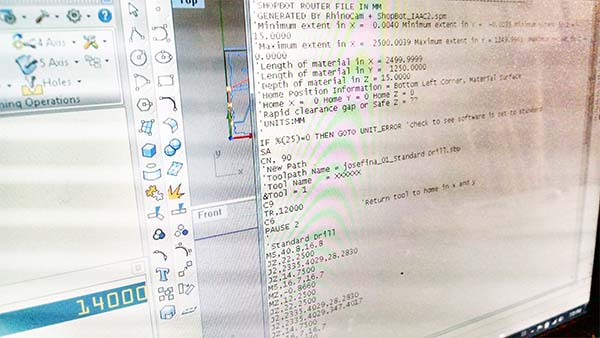

When the archive was ready I took the following steps:

As OSB is made by compressed pieces of wood, a 10000 speed value is fine. I first tried 12000 and the wood was breaking easily. Before sending the code, make sure that the outlines are correct, otherwise this is the result:

The space I left for the pieces to fit was 0.2mm but it still needed some sanding for them to fit perfectly.

After the assembly

Seat/Storage

FILES