Thursday 4:th of June.

Mill(er) Time.

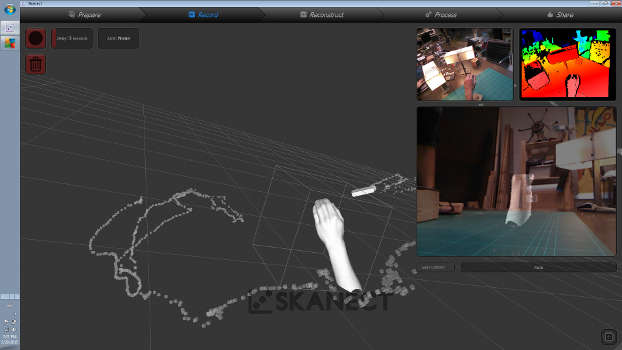

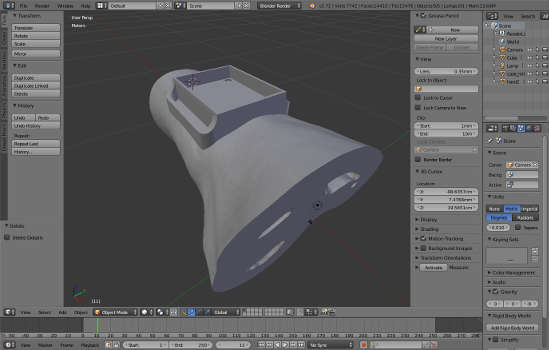

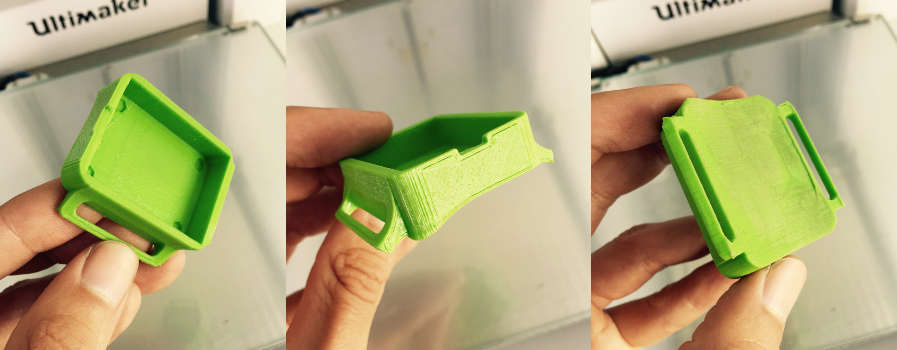

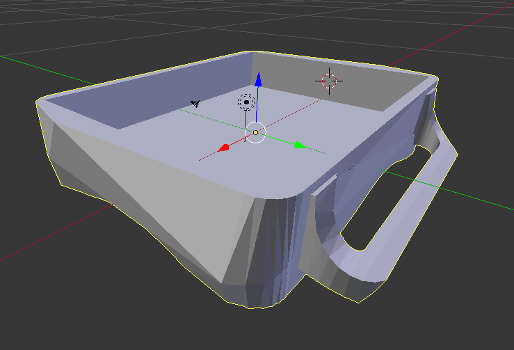

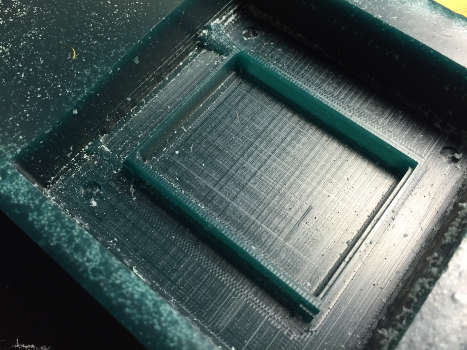

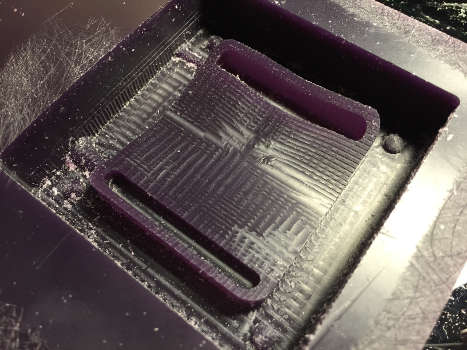

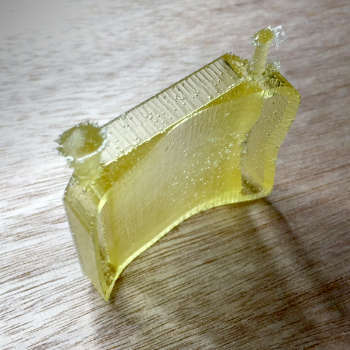

My 3D printed part had a hole in it where it was the thinnest. It was probably to thin to print. and will definitely case problems in the molding process. So I went back to my 3D model and increased the distance to... and re did the mold in Blender

I milled the top half on the Roland modella first with a 1/8 bit and final pas with a 1/32 bit end mill. On the first pass, of the final cut, the drill bit really dug in to the side. Remember tilted walls! I compensated for this with the clearance setting. After a couple of tries I got a nice working setting clearance diameter 3.35mm, clearance length 2.

Roland MDX 20 clearance settings from Anders Haldin on Vimeo.

For the bottom half I got curious if I would do the final pass with the 1/8 bit as well... I had no small details in the design that required a smaller end mill. Dangerous to start experimenting when you are on a tight schedule... but I'm here to learn so I went for it. I used the default settings in (local) Fab modules I only change the overlap to 65%... and it turned out very well.

Inspecting my finish molds I noticed that the first one had not milled properly. It was missing about 1 mm in depth. I assume something got pushed when the end mill got stuck in wax. I will redo that one tomorrow.

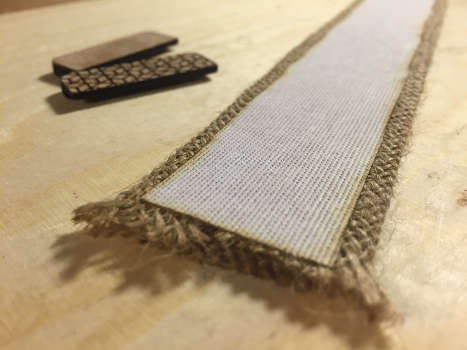

While my mold was milling I looked at some burlap and thought maybe I should use this for the strap? Plastic leather and old wood just seems like an weird material combination but burlap and old wood fits much better, get more of a worn beach look. And could I raster burlap with the laser... just burn it a little bit?

Not such a good idea maybe vinyl cut and spray paint is a better option...

Not such a good idea maybe vinyl cut and spray paint is a better option...

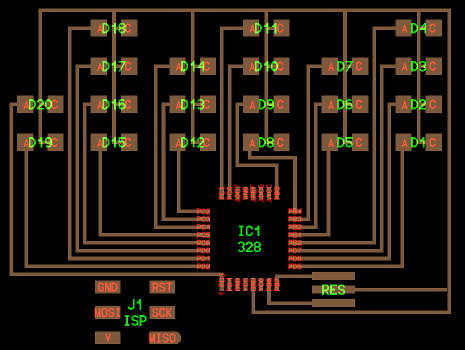

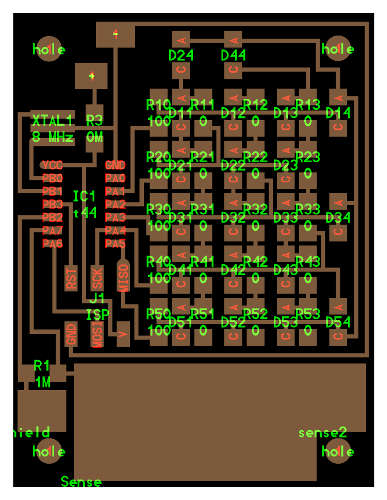

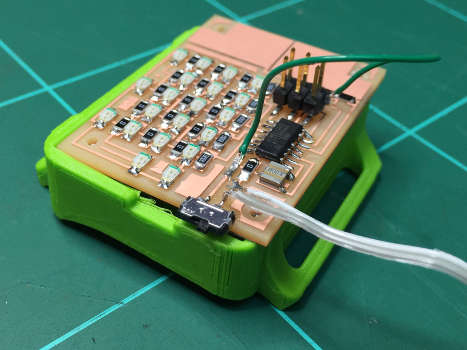

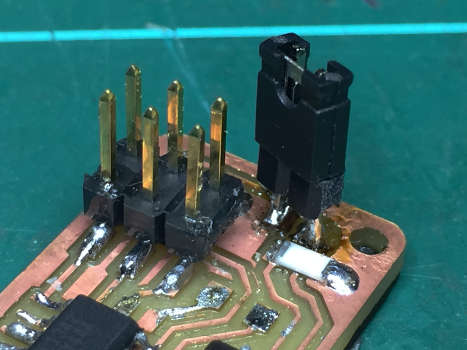

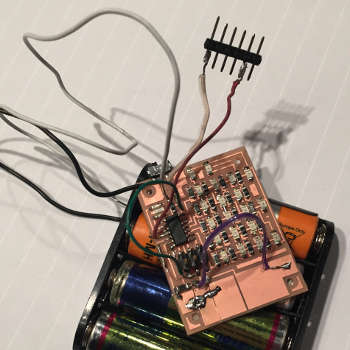

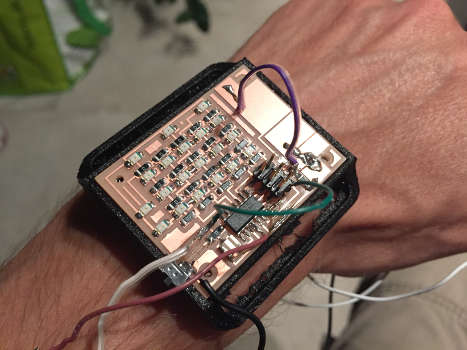

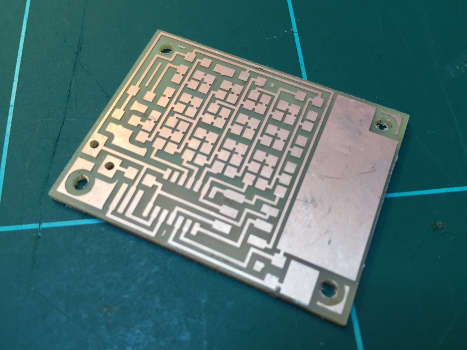

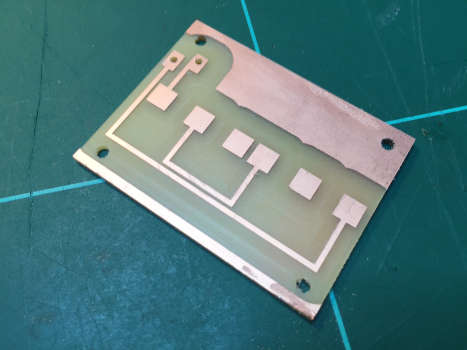

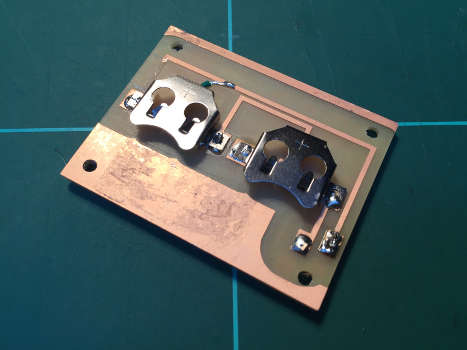

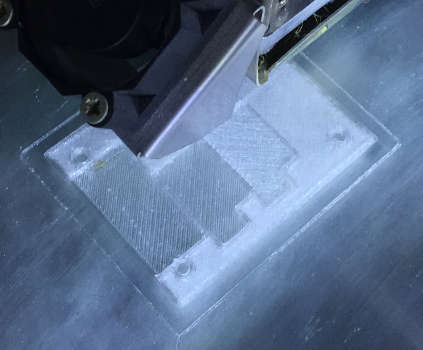

Milling double layered PBC

I moved on to mill the PBC, I'm making a double sided board, having batteries on the back side, I had made both side in Kokopelli retro and just commented/uncommented the part I wanted to export. The working order for milling a two sided PCB is:

- Run the trace job

- Run the cut holes job

- Run the cut out board job

- Remove it and clean up the back side.

- Add double sided tape to the milled side.

- Place it back using the cut out frame ass a reference.(make adjustments before pressing it down)

The board came out nicely but I had unfortunately made an design error, plugged the returning battery cable from + not - as it should be... so we are back to jumper wires.

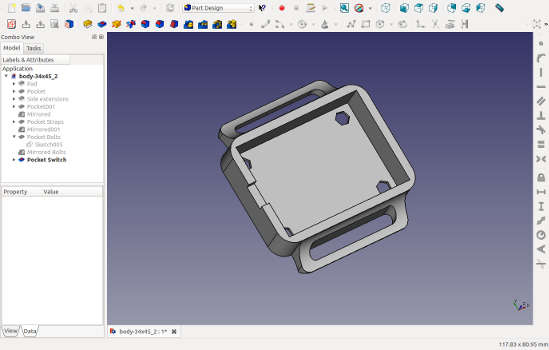

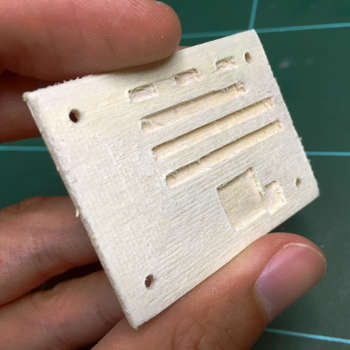

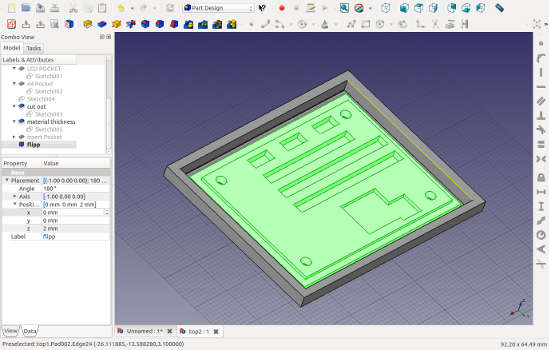

Designing Top part

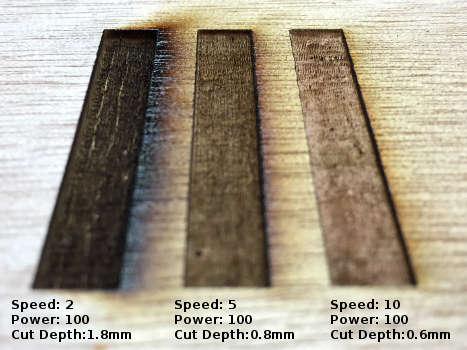

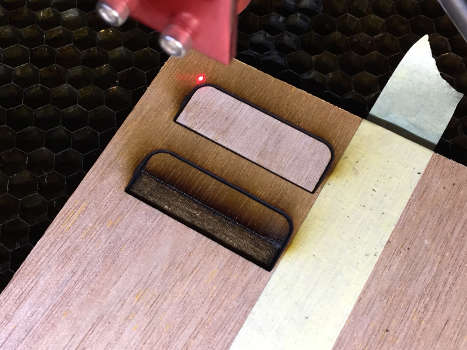

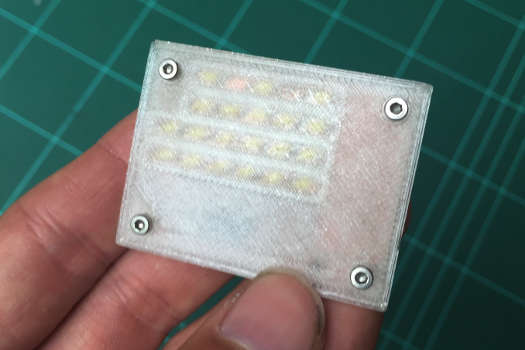

I modeled the top part in free cad. I used boolean operator to get different depths (0.3mm, 0.5mm and 0.8 mm) for a thickness test. I'm experimenting with transparent filament but I'm quite sure I want it in wood in the end. I started to do a test print to see if my measurement was correct.

The transparent material I'm using is transparent XT-COPOLYESTERdepending on the temperature you print at you get different translucence.Printing at 240 degrees gives more translucence then 270 degrees.

Print settings:

Speed 65% (of 150)

nozzle temperature 240

bed temperature 90

material flow 118%

I was recommended to use masking tape for better adhesion and to avoid wrapping. But I could not get it to stick so I went back to the trusted glue stick. Even here I had problems but when I slowed down the speed to 65% it worked like a charm.

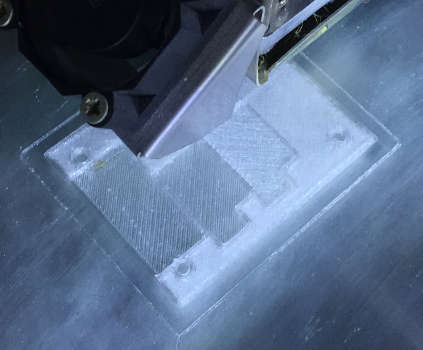

Transparent test print.

Transparent test print.

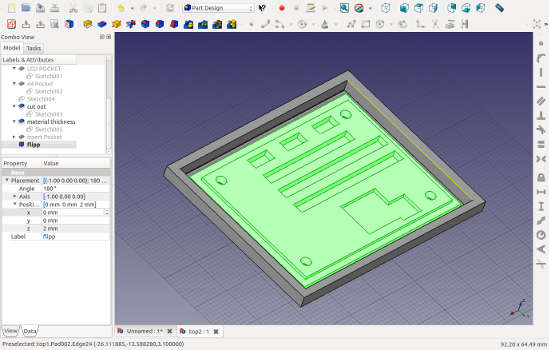

Top designed in Freecad.

Top designed in Freecad.

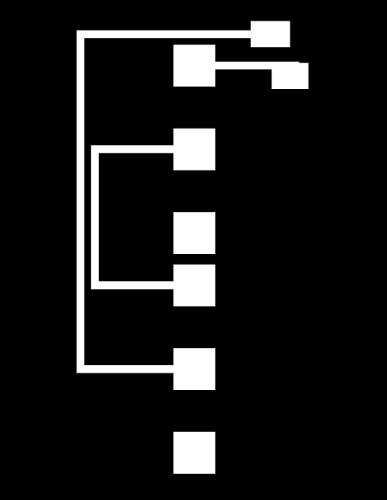

Writing out all the tasks and finding dependencies.

Writing out all the tasks and finding dependencies.