CAD modeling

My velomobile will be in combinated sandwich and bent wood techniques.

This techniques implies differents constraints of modeling :

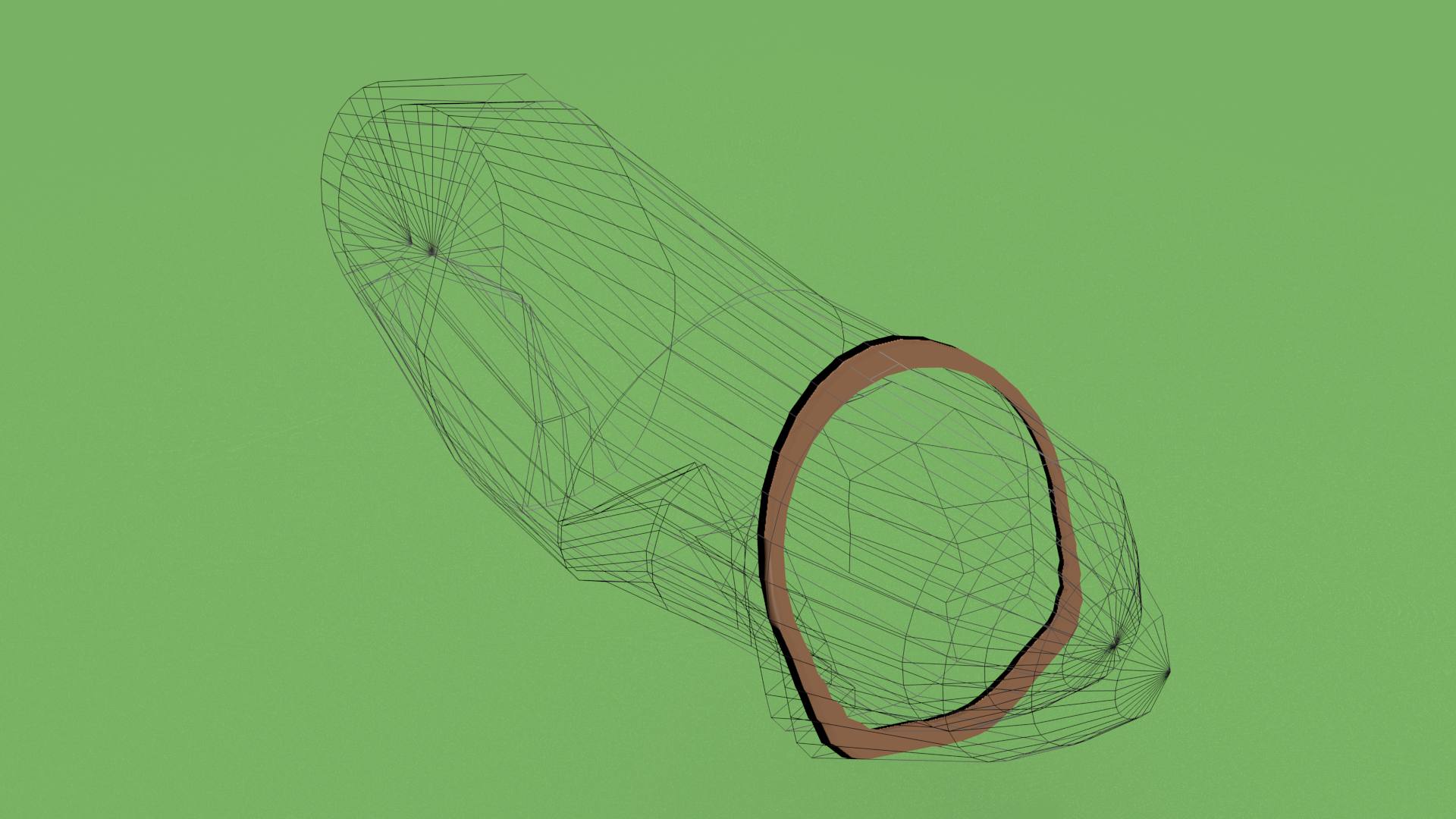

bent wood can be modelised by a mesh work, more difficultly by parametrical or CSG modeling.

on the other and, sandwich technique is very easy to modelise by CSG, and not so practicle with mesh or parametric.

Choice of tool

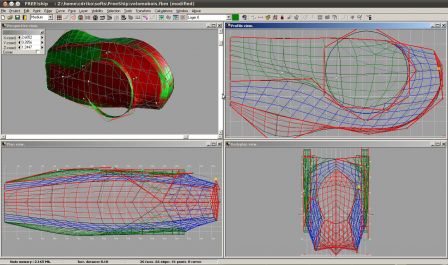

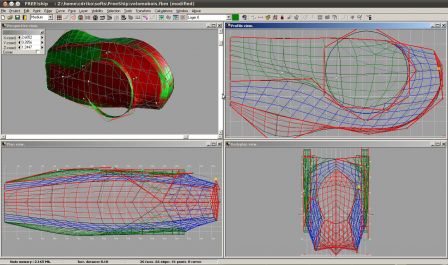

I try several years ago, freeship, wich is a dedicaced software for building boats.

But it's very limitated, particulary to combine this technique of construction with others.

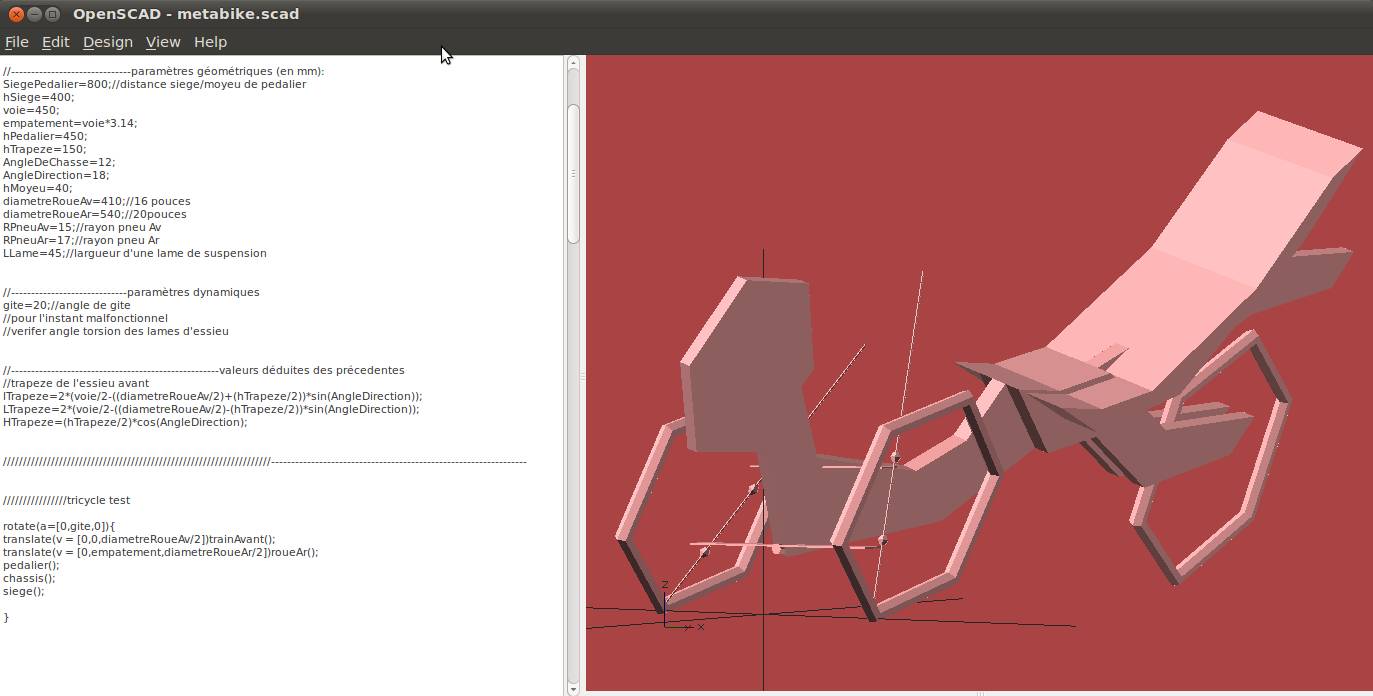

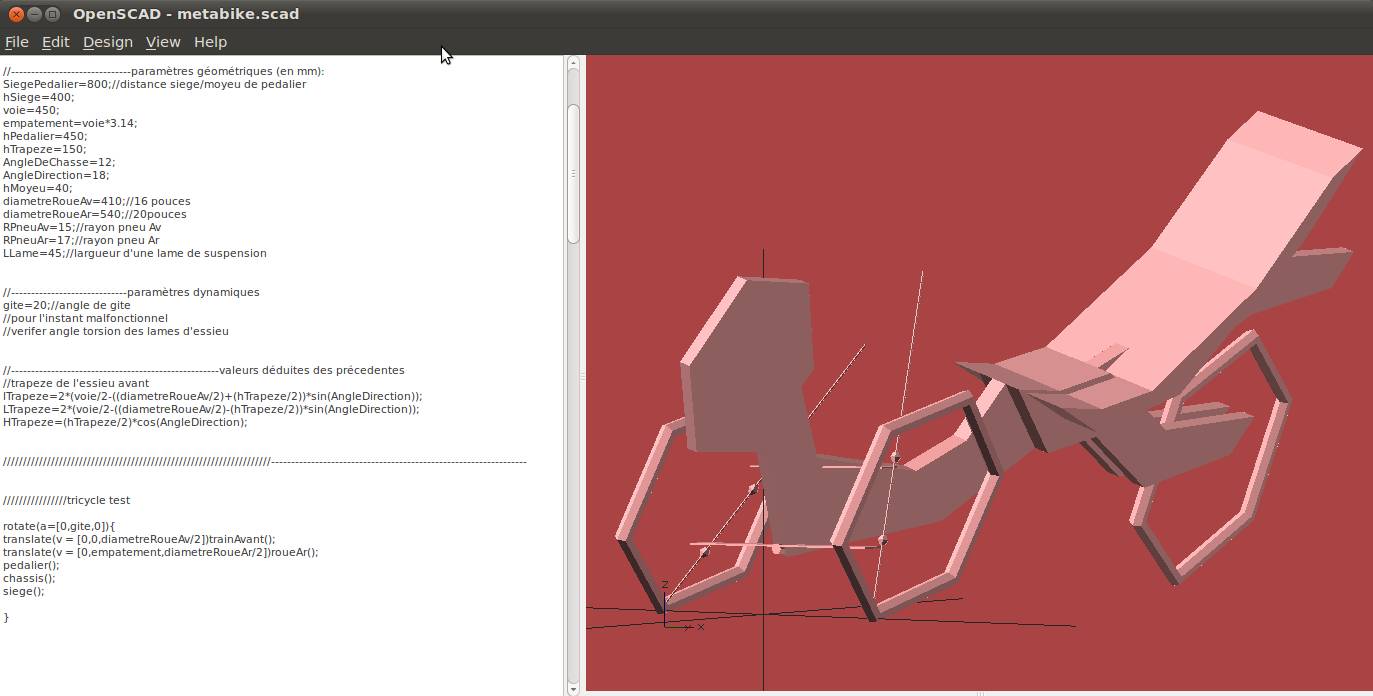

Usualy, as cad Modeler, I like to use openscad

because it's a powerfull parametric CSG modeler. Unfortunatly, it's not so practical for modelling assembly of large amount of parts.

I made some small tries with freecad because I think it will be a great tool,

but, I don't success to understand well it, particulary for modelling a velomobile in one week...

Finaly I use blender because I know it well, and I discover a technique to made a small CSG inside...

modelisation

|

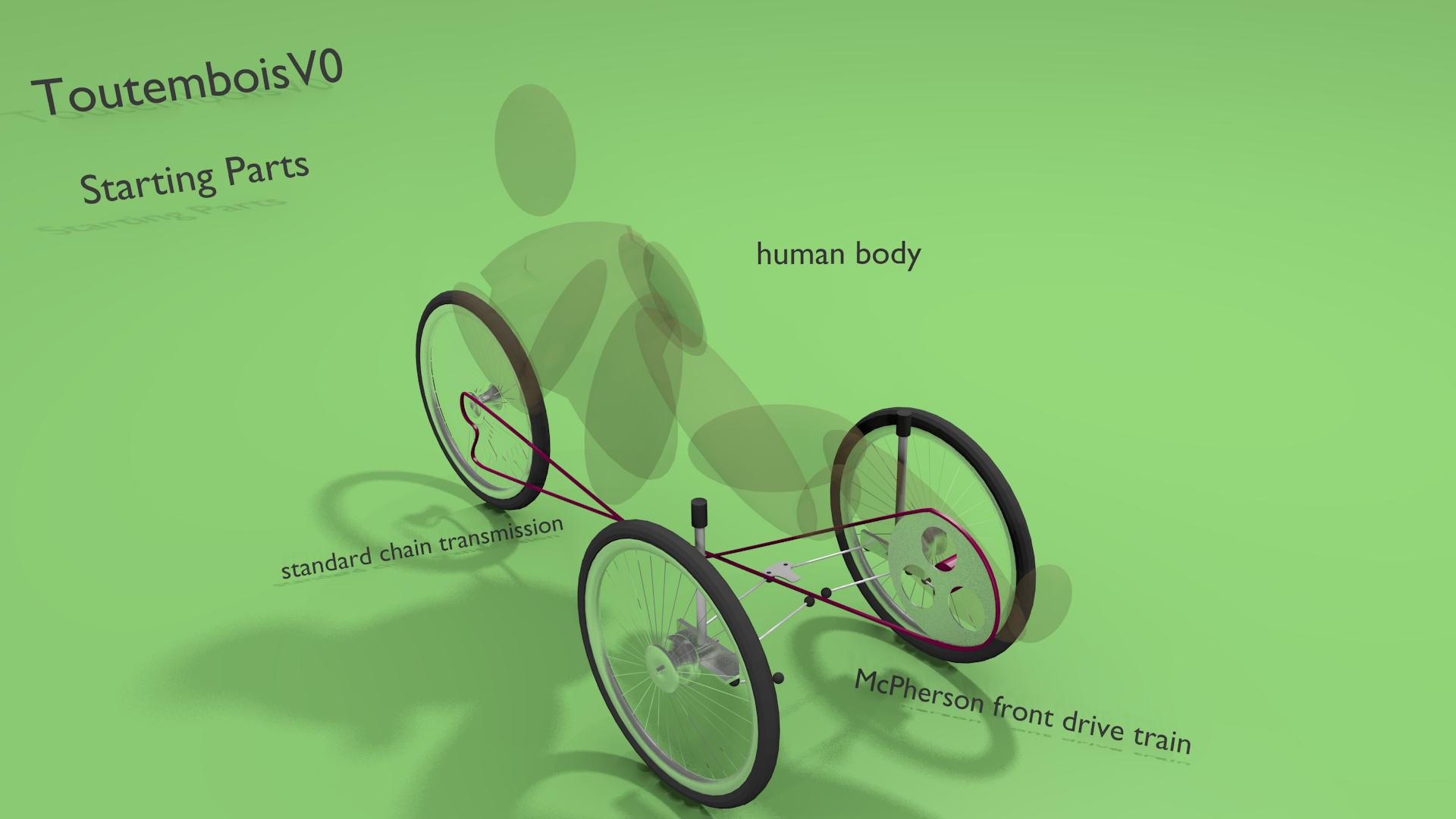

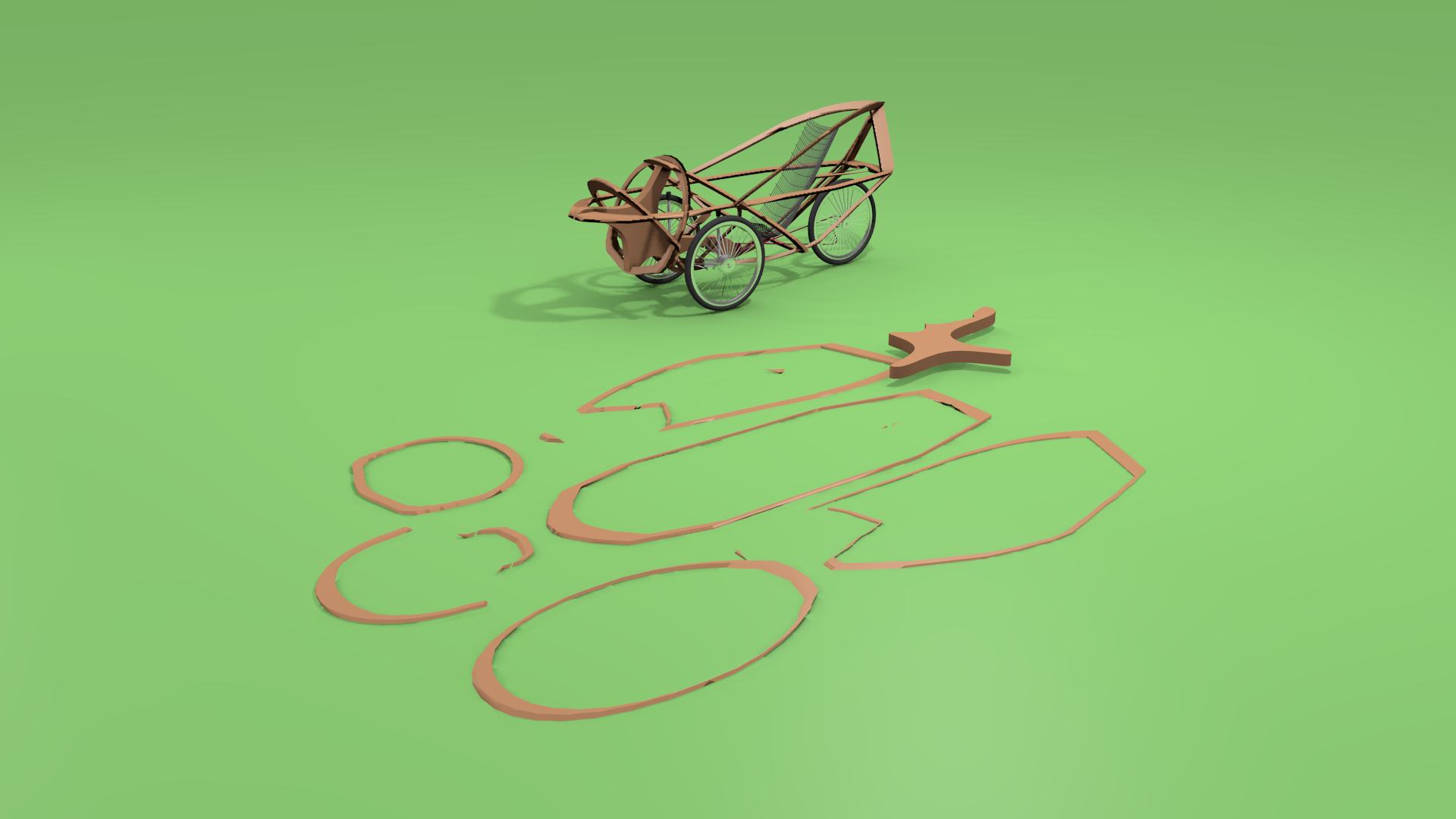

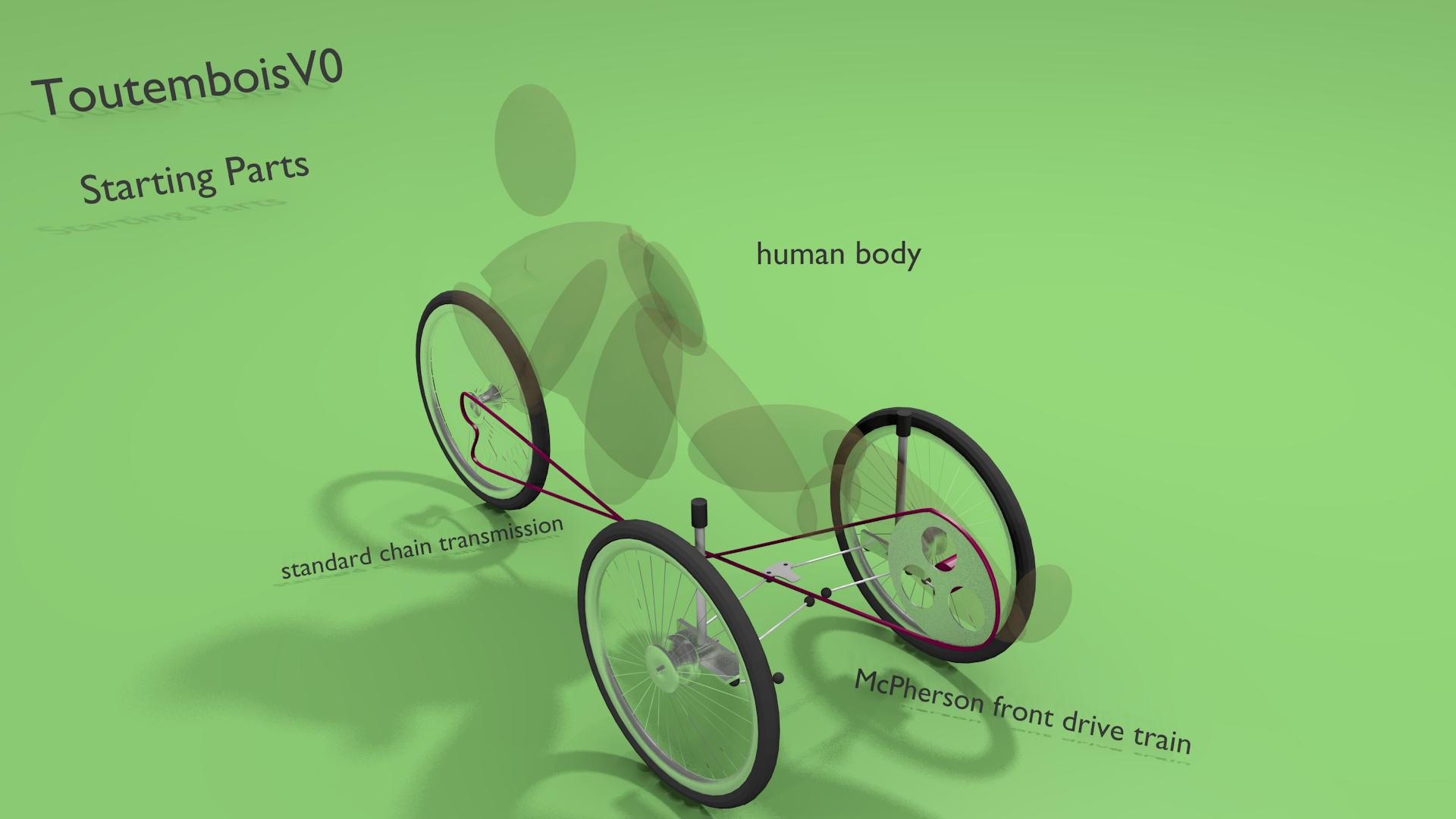

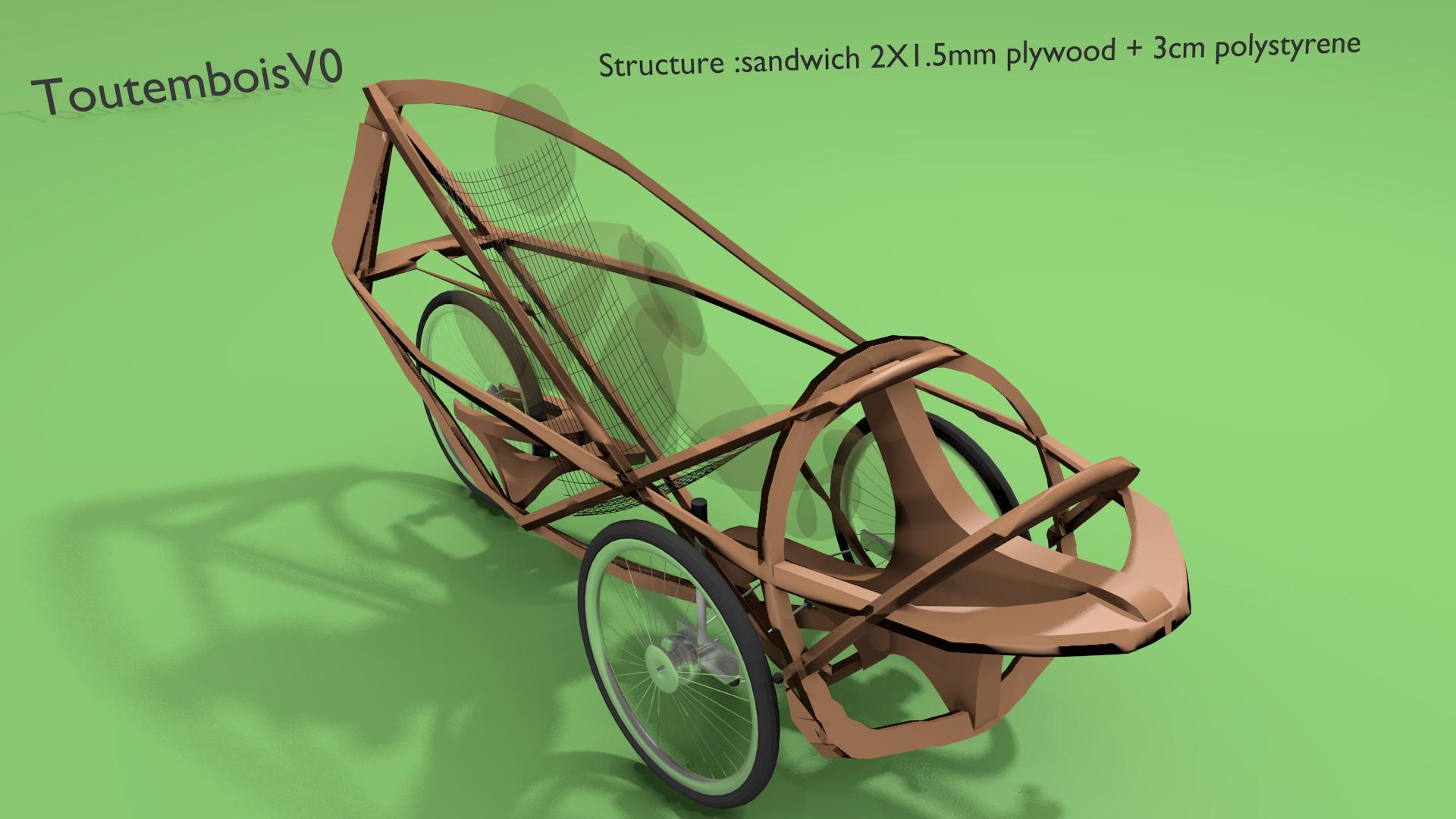

The modelisation start from base parts :

- standard chain transmission (taken from regular bicycle)

- McPherson front drive train (sel by velomobiel nederlands) : I use this because it's the more specific parts, and I don't have enought time to build them during the academy

- obviously a human that is the final user of the machine (from 1.7 to 1.9m)

|

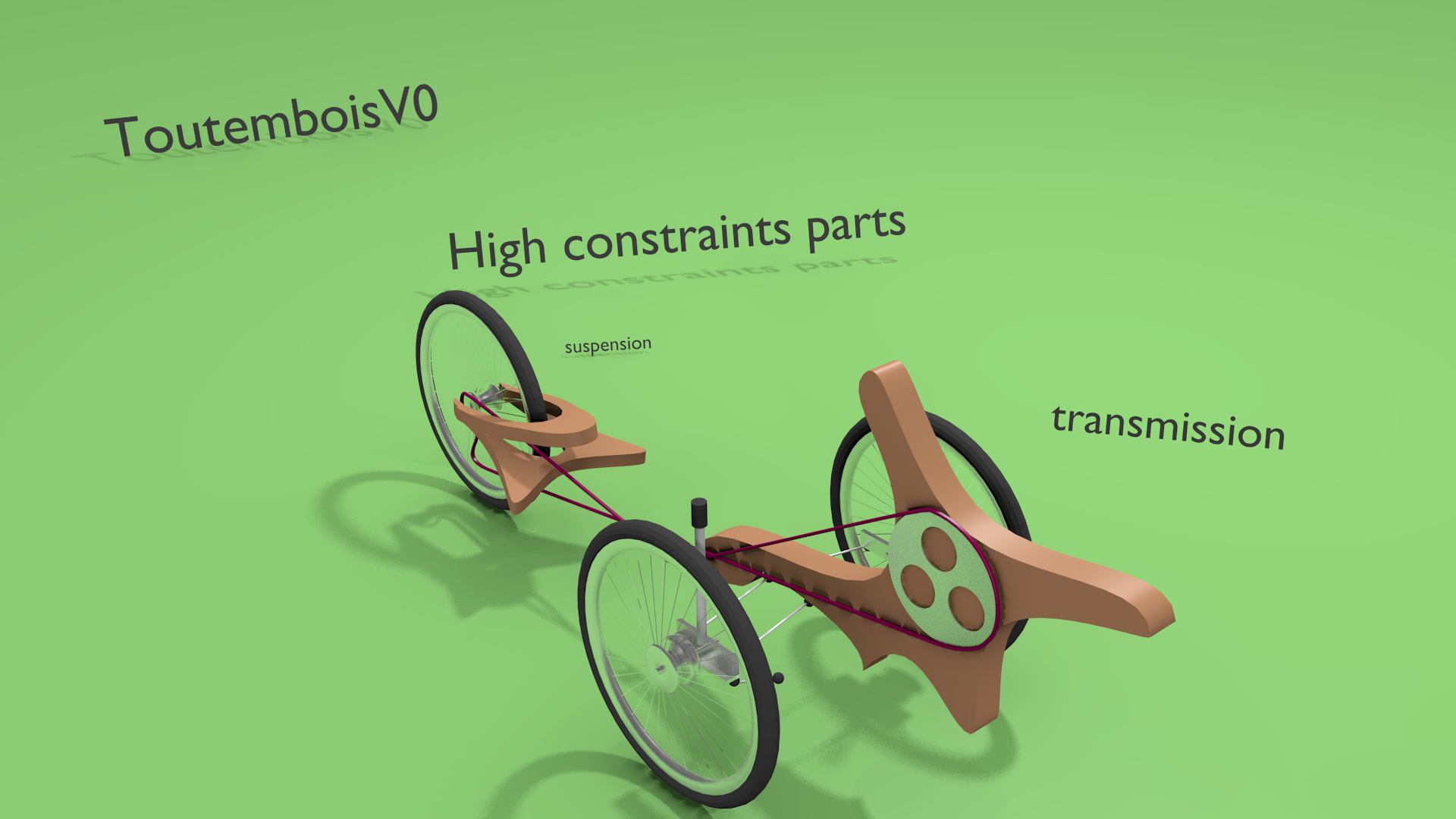

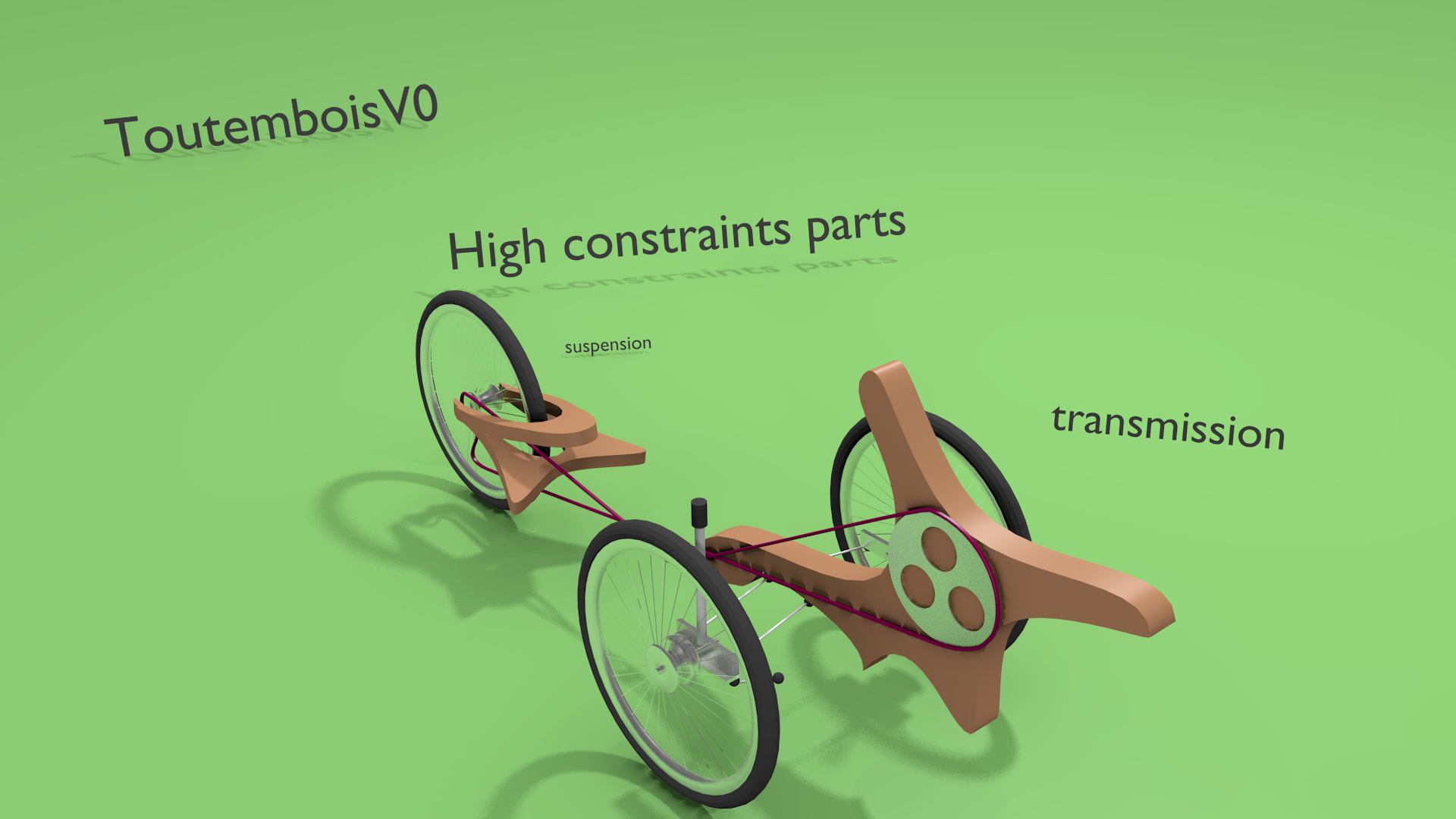

particular attention will be given to transmission support, and rear suspension.

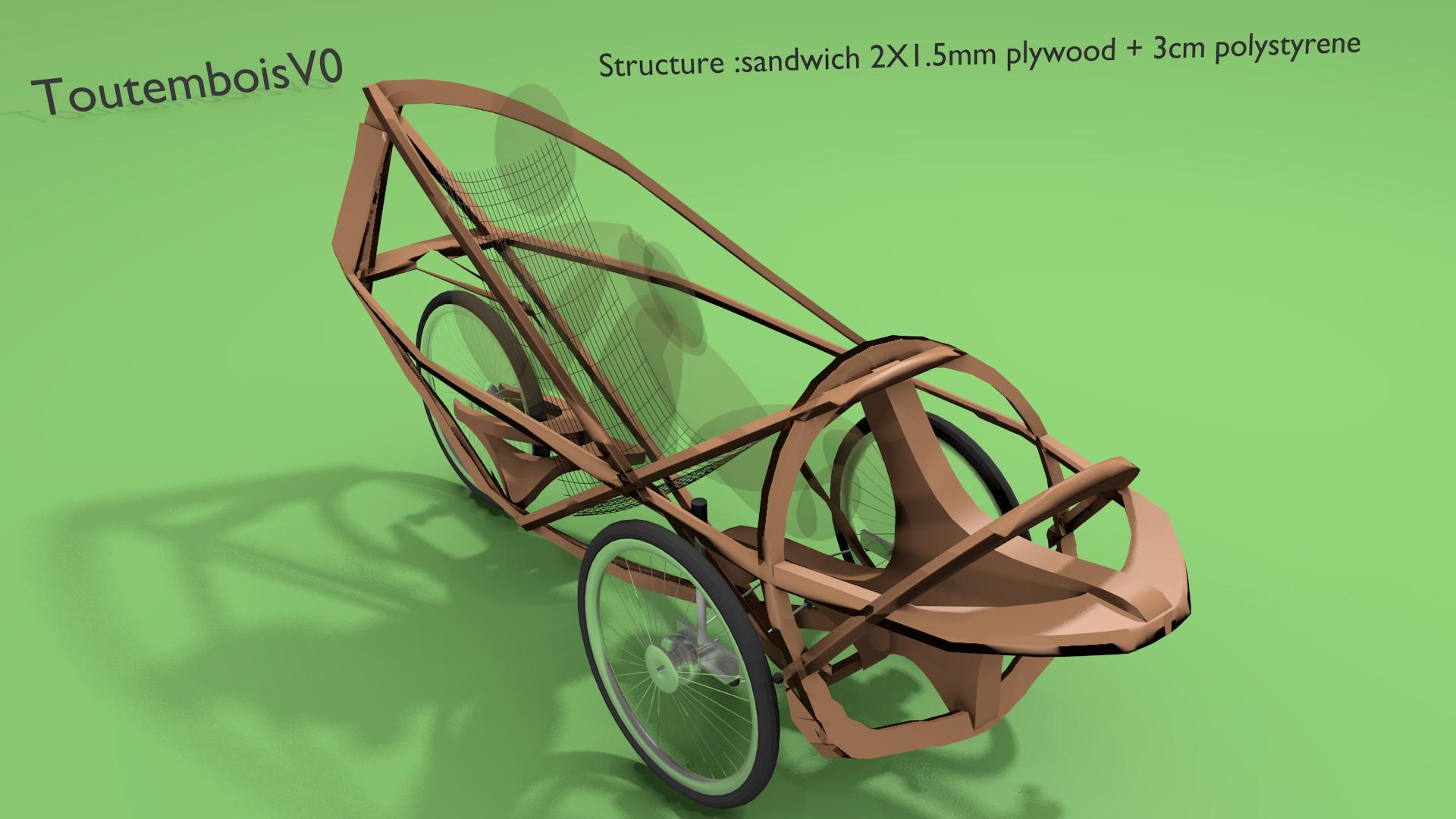

Front transmission support wich is place of very hight constraints will be build in sandwich 1.5mm plywood / 60mm styrodur / 1.5mm plywood

|

|

|

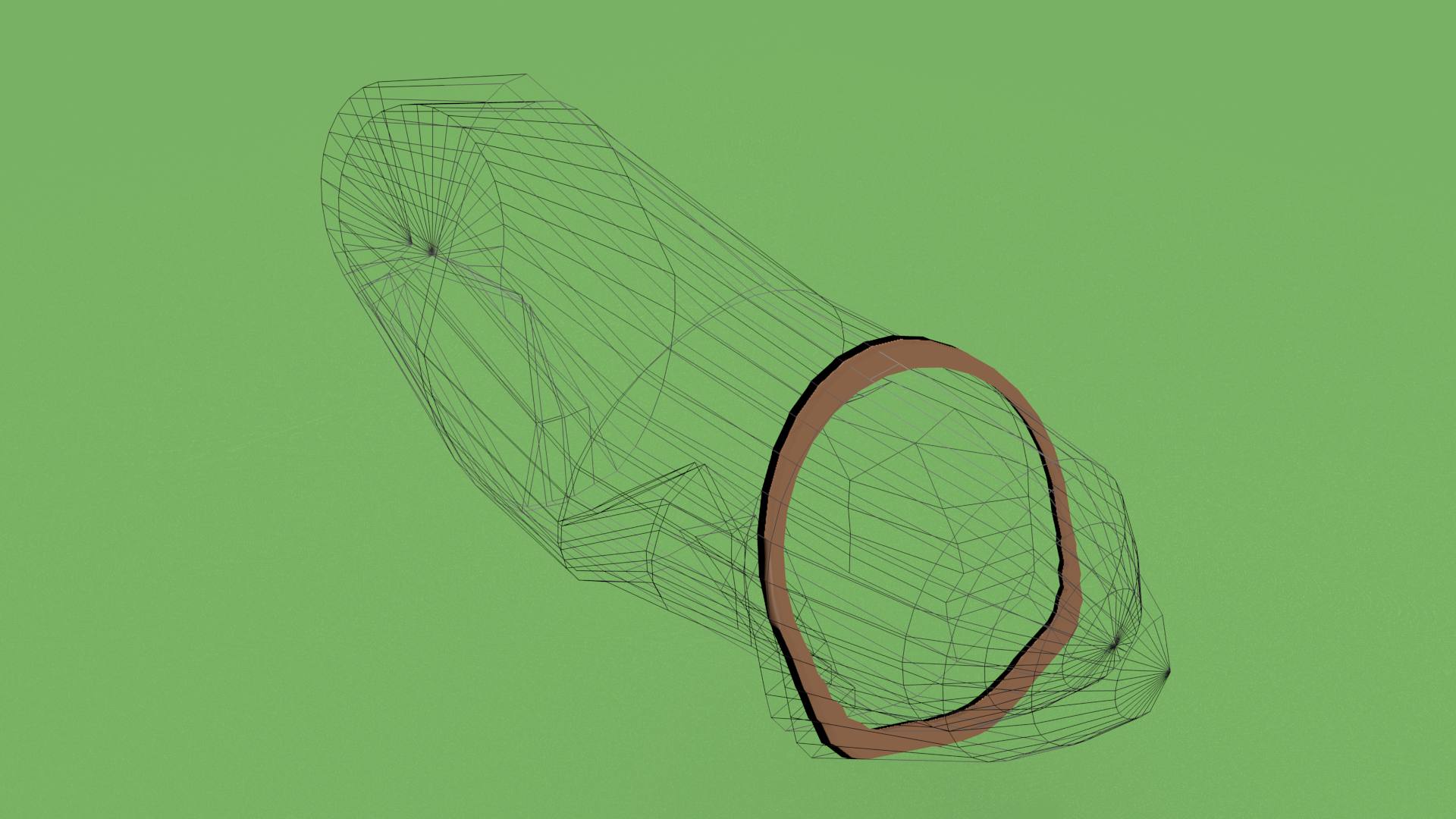

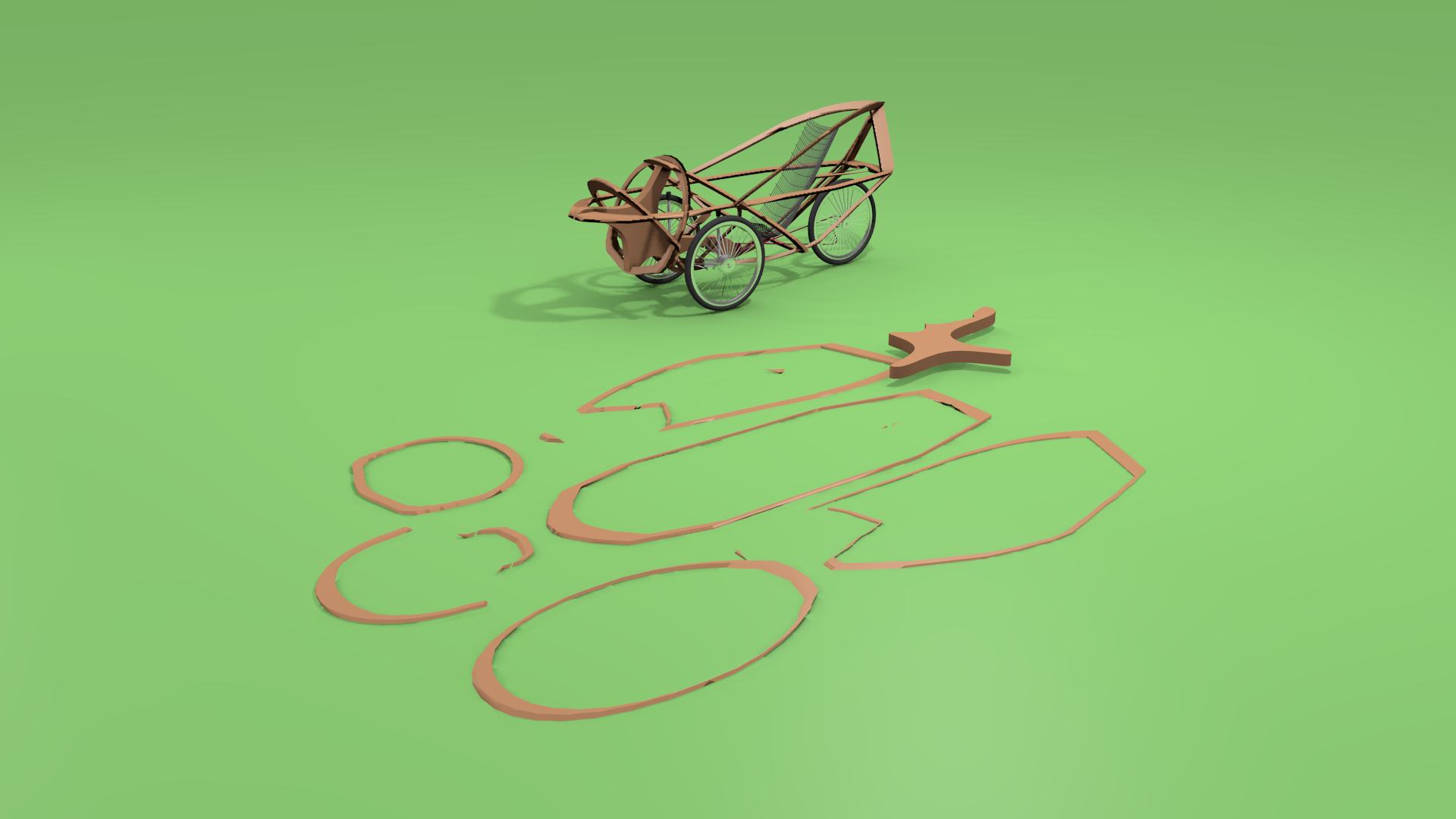

The principe of modelisation of the frame is using CSG :

first I modelise the outside and the inside of the body.

Next I place a board, with two boolean modifiers :

- {intersection} with outside

- {substraction} with inside

With this technique, A can do very quickly a strip planking modelisation of external frame parts.

|

The external frame will be built in sandwich 1.5mm plywood / 30mm styrodur / 1.5mm plywood

I will try to made intersections of the parts in place where there are lot of constraints (as attach of wheels for exemple)

With this, I will try to avoid inconvenients that Titus VanDenBrink find for strictly bent plywood body.

Additionaly, I hope simplify the construction by scarf joint (mi-bois) assembly of the parts.

|

|

|

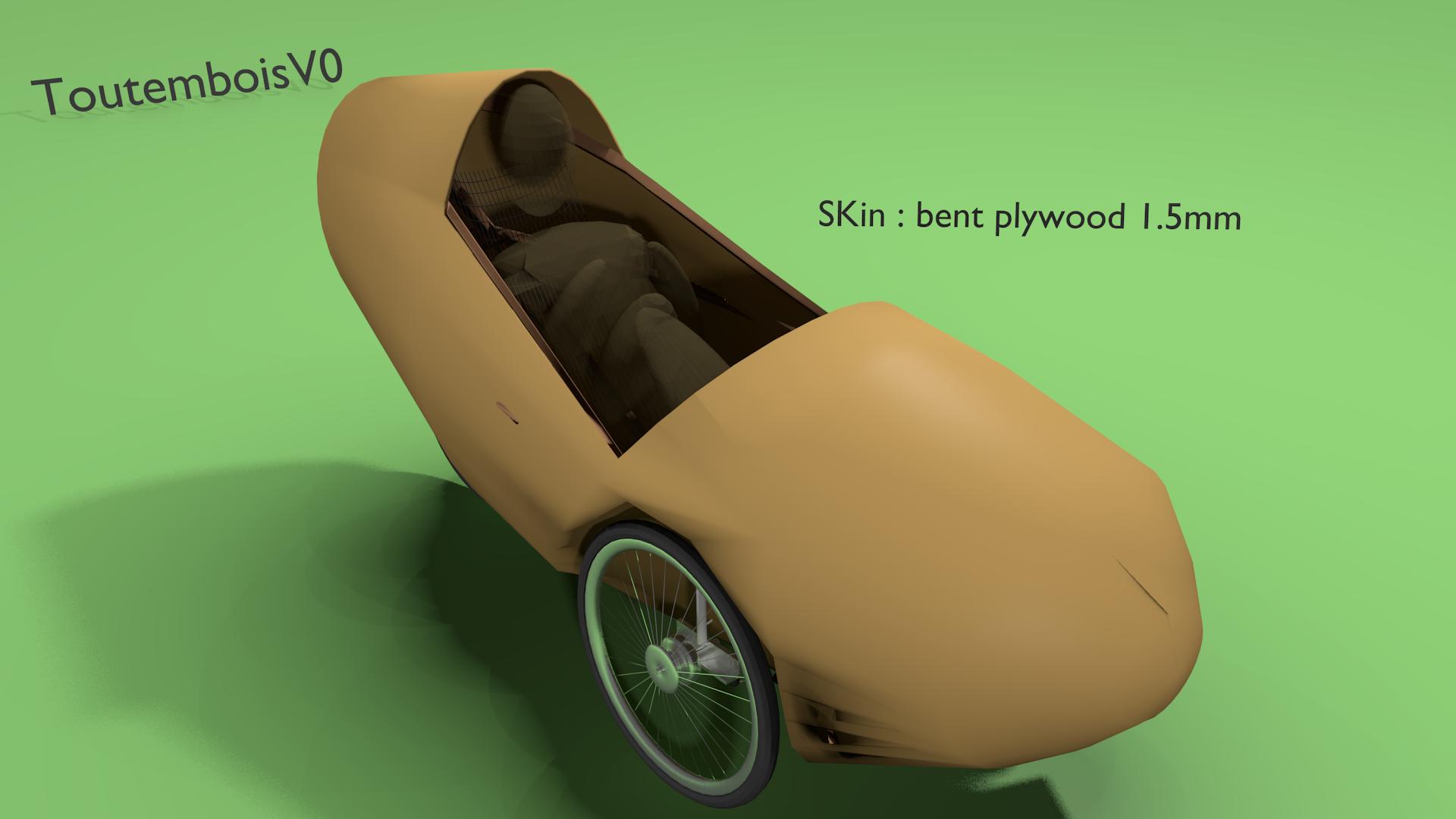

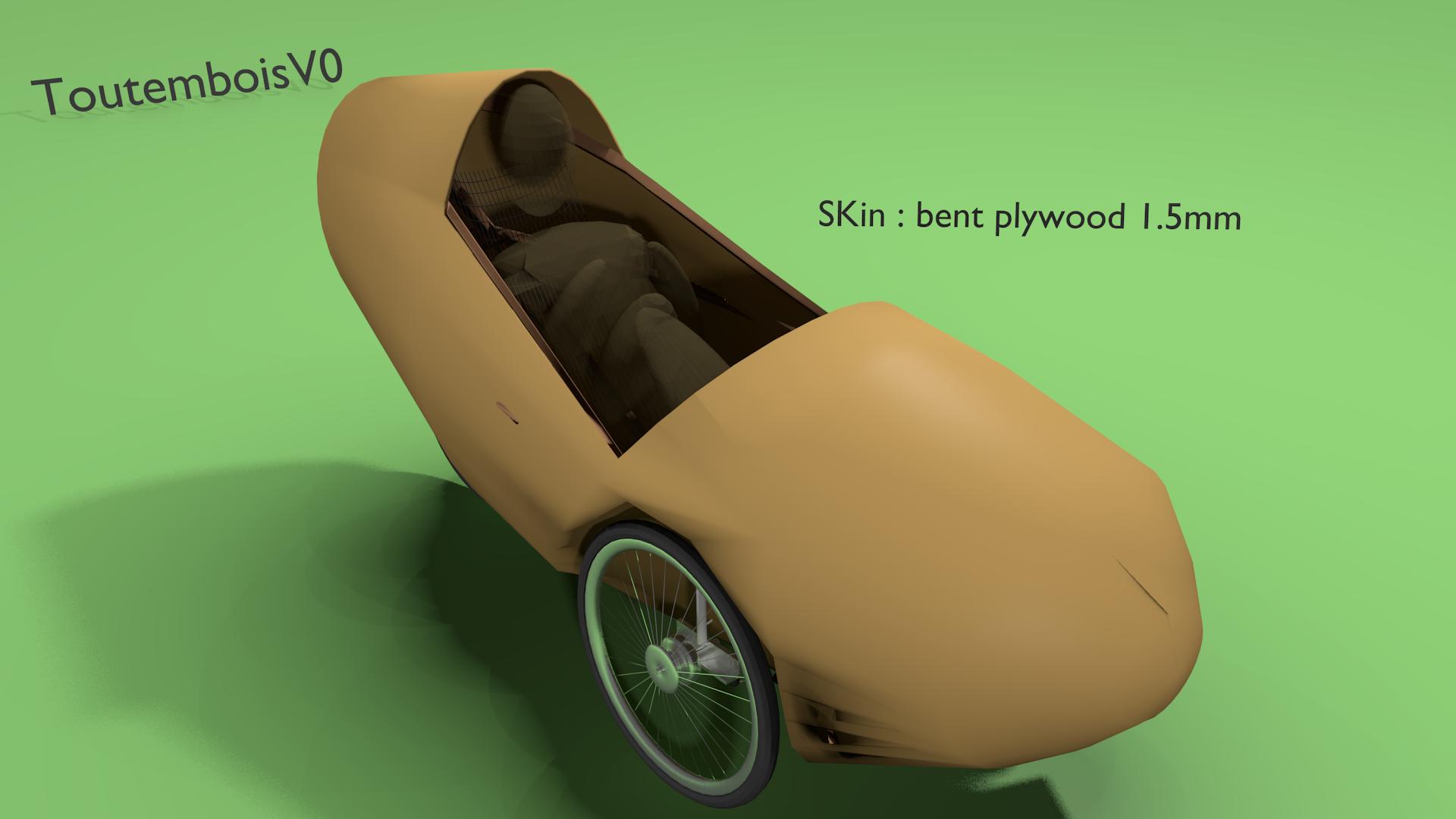

Finaly, the external body, modelised as mesh

will be improved to be developable

using UVmapping functionnality of blender.

This body will be built in bent plywood 1.5mm.

|

The target is to made the frame totaly cutable in a laser cutter (plywood and polystyrene)

The design is looking great but the conception isn't finished :

lot of small details have to be adjust, and as i know in bicycle fabrication : the devil is in the details ;)

here the first blender file