Composites

Assignment

design and make a 3D mold (~ft2), and produce a fiber composite part in it academy.cba.mit.edu

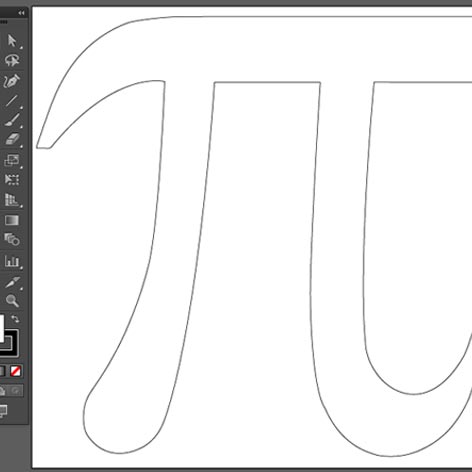

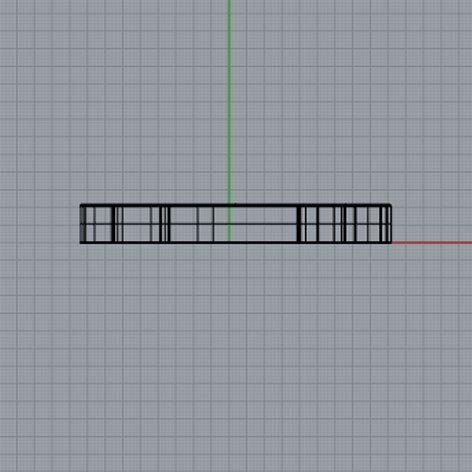

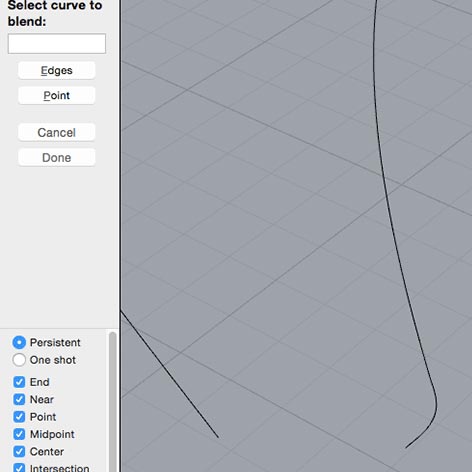

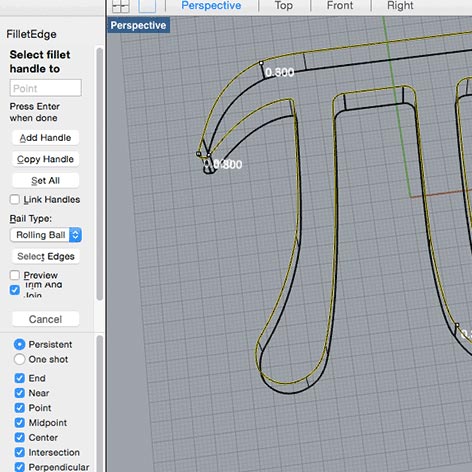

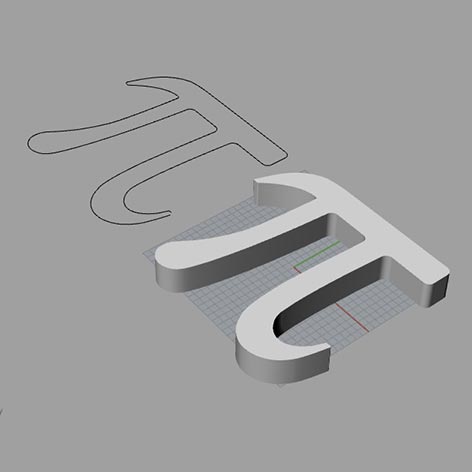

For this assignment I choose to design a Pi Symbol in Illustrator & then extrude it in Rhino. I've learned that cleaning the bezier points properly is super important in order to be able to do make the edges smooth "FilletEdge"

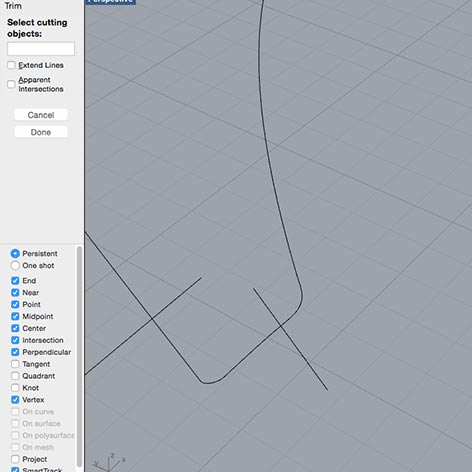

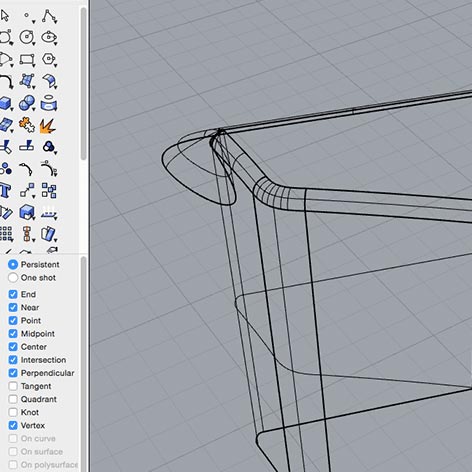

Trimming in Rhino is super tricky since you have to create cutting lines & then cut the parts inside of this lines.

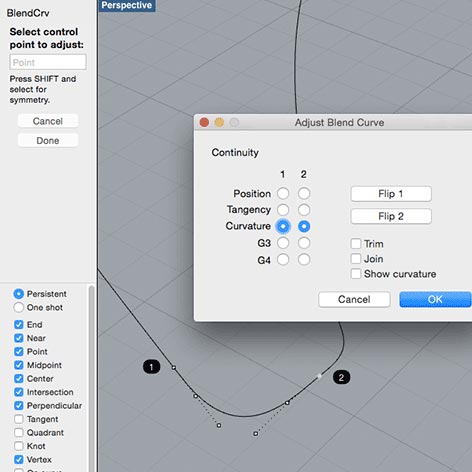

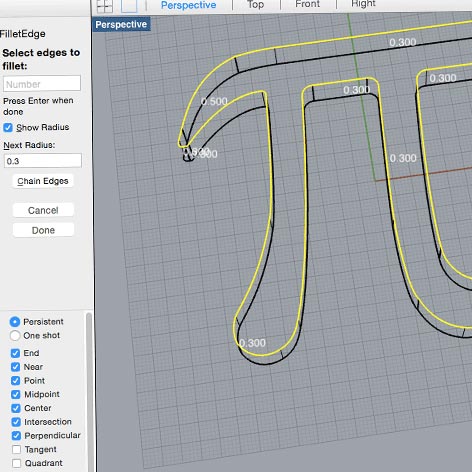

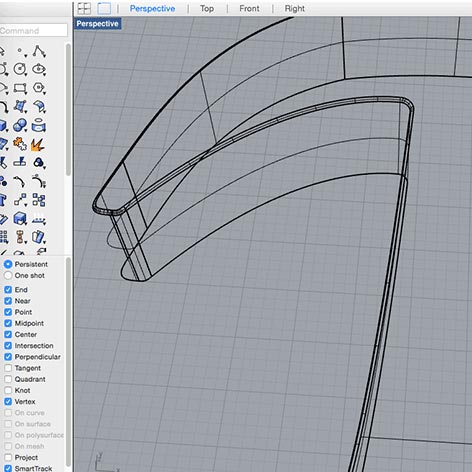

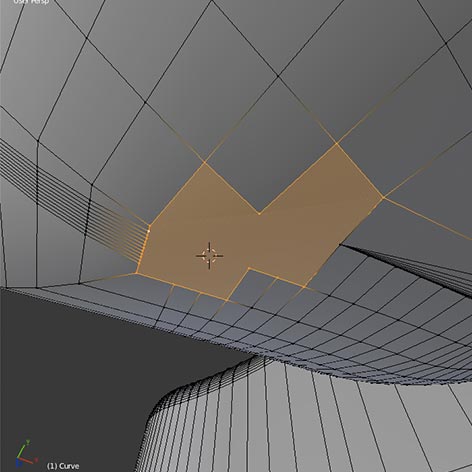

After trimming the interior to create a more smooth curve it is necessary to use the "BlendCrv" command. Then try again the "FilletEdge" which took a few tries from 0.5 to 0.3 that actually worked!

With the value 0.5 the "FilletEdge" had issues with the corners. I modified the corners making them smoother & more open (wider curve) but it did not work at 0.5 or 0.4...

The value 0.3 finally worked perfectly!

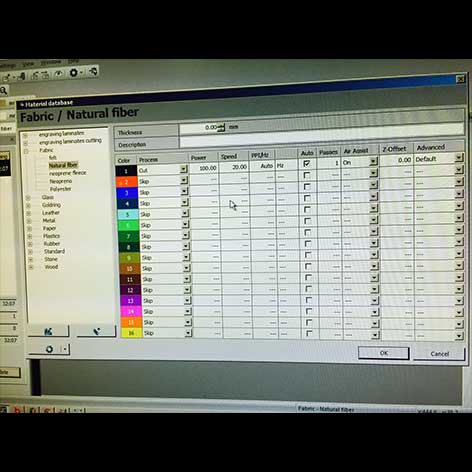

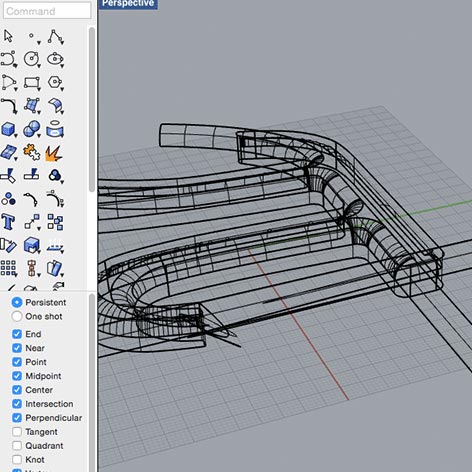

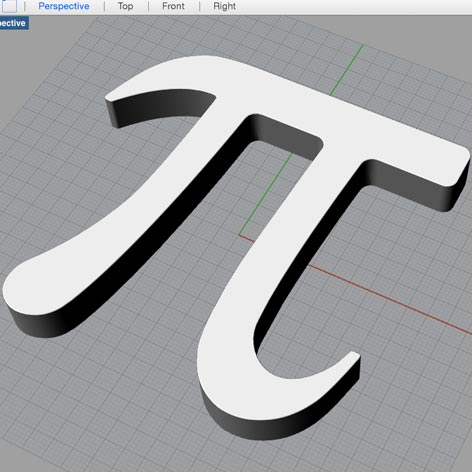

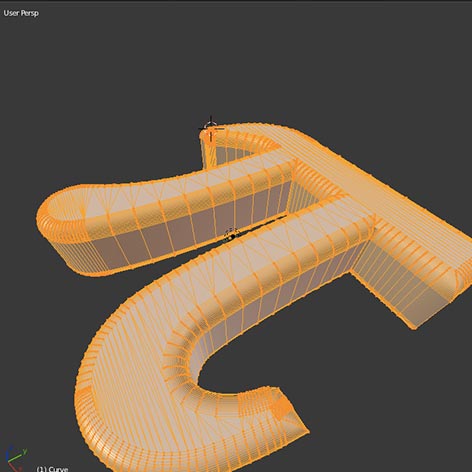

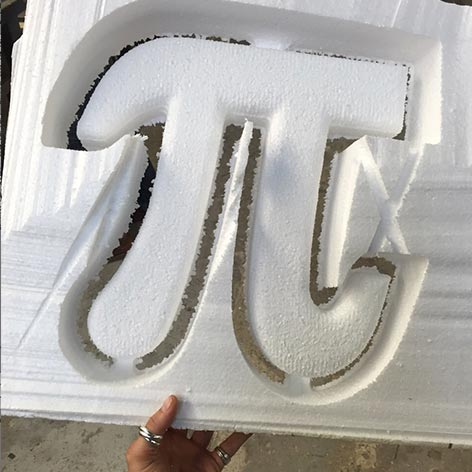

Saved the 3D model into a 3dm, dxf & stl to create the gcode to be able to mill it in the shopbot. I also saved another stl of the top part of the pi symbol to be cut in the laser cutter so it will create the composite mold shape.

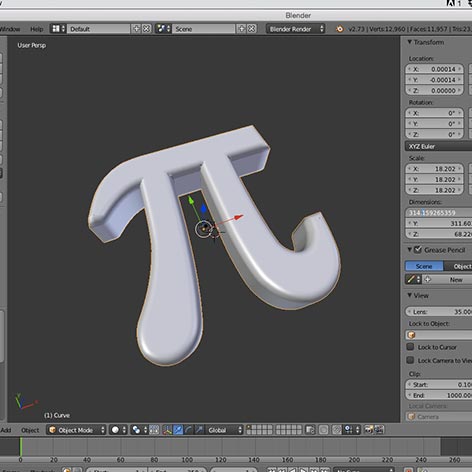

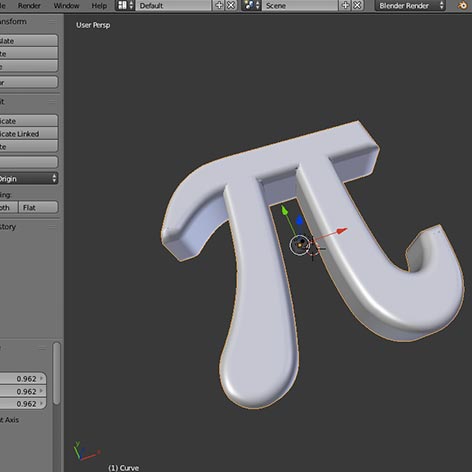

The Rhino FilletEdge was really hard to create and finally realised that Blender is such a better tool.

Saved the Blender & Svg files & also the Gcode to send to the milling machine!

Created in Rhino the unfolded pi symbol to be able to laser cut it so it can be applied more accurately, evently & smoothly to the mold so it will create a nice sharp & high definition shape.

The unfolded letters needed a outer