This assignment was very interesting for me, From school days I like to play with clay and something like this kind of experience i'll

get in this assignment as per last week discussion with Neil and local tutor I have design OPEN SOURCE symbol and mill on wax

for molding and casting

Spirit of Open Source being one of the important ones,I thought I should choose its logo to mold and cast.Ofcourse,

this selection took a long while.I thought of many objects but did not feel like to taking ahead. Open Source logo resolved

the situation So I"Enbedd" open source symbol image in inkscape,searched PNG file. Sometimes it need to resize to setup in inkscape.

At this point, I Exported the output as Plane svg file and exited from inkscape to move on to blender

Now to made 3d design (mold) i had to use blender which I never ever used. Local guru Pradnya along with suhas (fab academy

student) helps me to do that. So first import plan SVG in blender.

While using blender I found many trouble addition,substration of parts making group in design

I am searching for simple software for design

But atlast I have decided to take challenge of blender and yes I did sucessfully with lot of pain

Up next I conver 2D into 3D and set application wise dimensions set blender environment.

I dont understand what she did for that Now image had to convert in actul 3D.

This is done by using

modifler in blender software called solidifi modifier.As shown in the image,

the solidify modifier was applied to logo, to build a 3D

object.With necessary dimenssions.Ideally at this point desing would almost be ready.

So next was to edit meshes using netfab. So export this 3D file in ".stl"

netfab mainly used for editing the meshes, in order to make design 3D printable - bridge the gap between content and Machine.

highlited part,So now open that.stl file in netfab where it look like this.repair stl file in net fab

to add bridges to holes gap n export final stl file to make mold

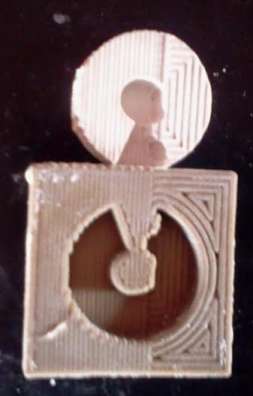

After all design and correction part, its time to mill the design on modella machine

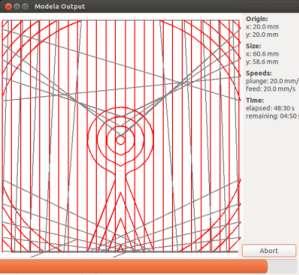

So I have already save .stl file to .png format,open FAB modules and fill all information as per asked like

File format, process done,etc.select bit size 1/8mm, wax-rough make .stl to .png and then .rml and start milling.

Following image shown tool path before milling object

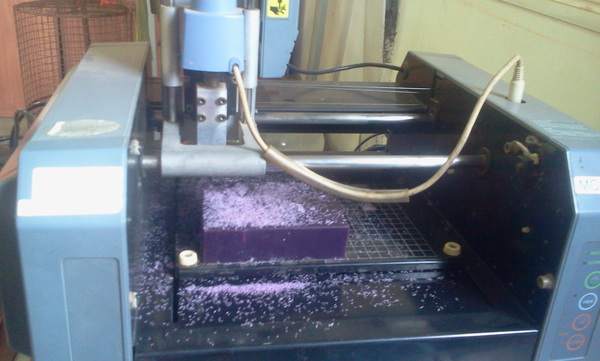

In my lab I have Modella MDX20 milling and scaning machine.First start modella machine press view button set X-Y axis

After all this set up press down key till bit reached to wax surface give gravity and send job for printing

When I have finished milling I have been clean wax with brush and clean machine too.then remove wax from machine

Now its time for molding I thought to use sago material,for an experiment if it will work then we can conduct current and blink LED

Sago is a starch extracted from the spongy centre, or pith,of various tropical palm stems, especially Metroxylon sagu.

It is a major staple food for the lowland peoples of New Guinea and the Moluccas, where it is called saksak, rabia

and sago

Firstly I had to boiled a sago material that gave me stiky and like melt rubber composition. But it was not like that,

We have a parabolic shape solar cooker(prince 40) at Vigyan Ashram. So I decided to used it, because its eco friendly. And I

put a container at center point where sunlight concentrate to boil sago at noon time.It took half hour.I got stiky solution and

I have done it now just have to pour on wax, and leave it to get dry. I done it, pour it on mold, spread it

Now I have to move on with silicon rubber solution and I purchase that solution from local mareket

cost is very cheap and easy available in market with prapotion I filled solution in wax mold slowly slowly

After this I keep that for drying

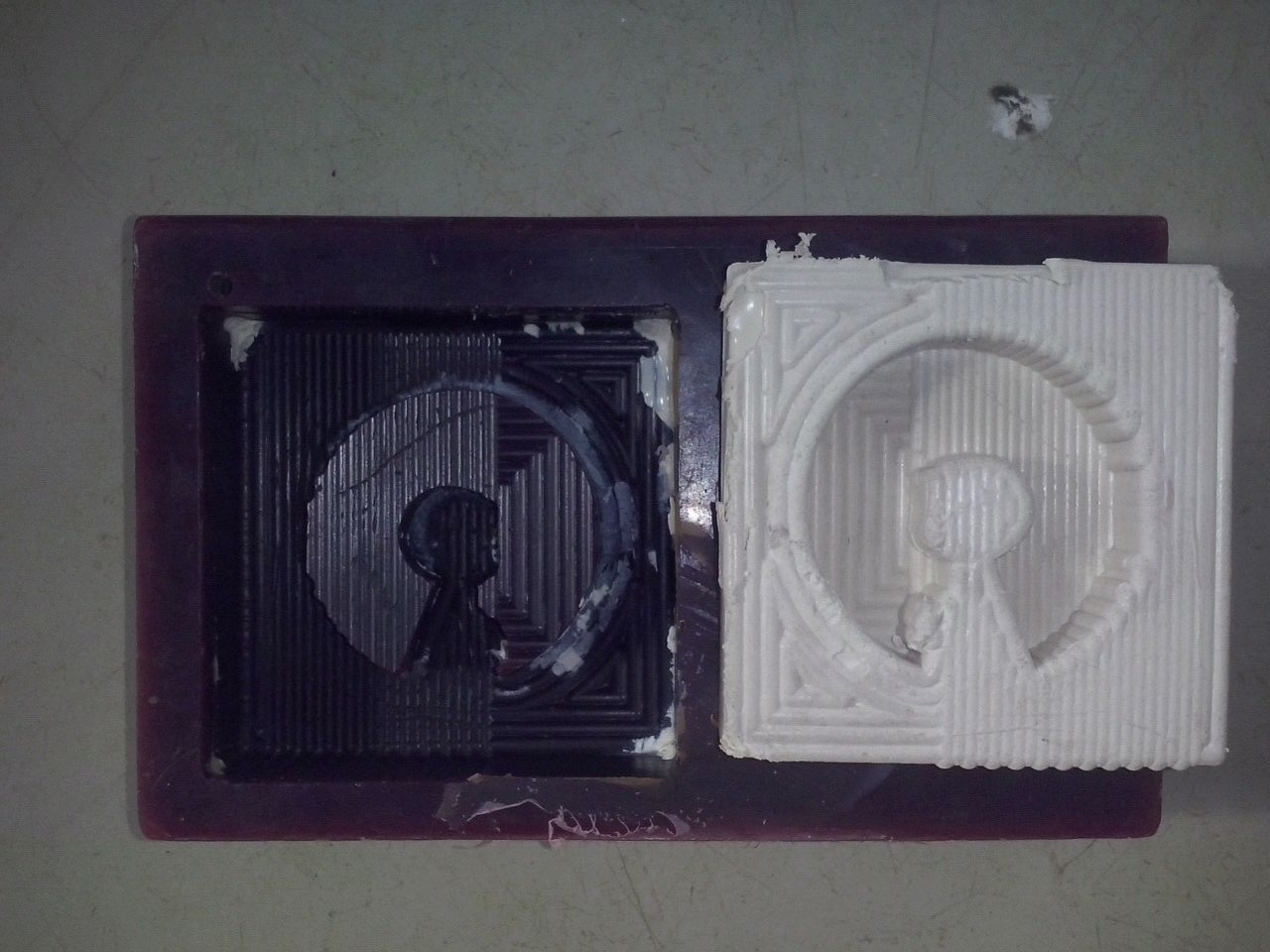

But mold not sucessfully completed it was broken. I figure out reason then I found that it was just because of bubbles

much time to dry so again i had to wait for long time.Again got the same result. I am not getting what was wrong with that?

So I decided to asked for help sculptor (Statue Maker) for guidance if I doing it in the wrong way and for suggetion.

Sculptor suggest me to pour solution layer by layer. Let each layer to be dry. Then feel mold in such way.

Hope now this time it works.As per the Instruction from sculptor I pour rubber solution layer by layer.

This worked.yeeeee

I have mixed hydrostone in prapotion with water and stirr properly then filled mold with casting material and dry for 5hours

and my Casting is done sucessfully.