In vigyan Ashram one of my colleaues is working on Solar dryer. So my Idea is to make that solar

dryer on shopbot.

Currently we are using pinewood battom frame for solar dryer to dry vegitables

for long time use. In this, care

should be taken that neutrition of vegitables should not affect by

overheating or direct exposure to sunlight. So,

use of polythine paper solved the problem. It protects

UV light, so working on it.So now my part in this project is,

have to design dryer body structure.

Below Images will give some idea of Solar dryer.

So descussion with colleauses highligts following two points points.

-Slope should be there

-Natural ventilation

Then I start thinking on it.For I was doing rough work.I decided following structure to cut and

finalized measurments

Next thing was to draw 3D view. I preferred Google SketchUp as it is an open source and easy. My friend

Shraddha in Vigyan Ashram suggest me ProE. She helped me alot to design 3D stucture of dryer.

We together (alongwith my friend) design dryer in 3D. But we made some changes. we design double

deck dryer but it is rejected for the reason that vegitable on upper deck will creat shadow on vegitables

on downward deck that wont dry vegitables

So Finally we complete a dryer only single deck. As following images.

I got the clear idea about solar dryer. how it looks. Now I have to drow design in Inkscape.

Because I used to with this software. I did the design in inkscape. Make it ready for Shopbot

We dont have ShopBot machine at Vigyan Ashram Fab Lab. So we asked for permisson to College of

Engineering, Pune's FabLab. and they allow us to use machine.

I lost the file design for above dryer. I format my computer

Instead I design heat retention box in ShopBot assignment

Before cutting such a dryer, I decieded to cut heat retension box instead. Because this is first

time I went to use ShopBot machine. So this small object gave idea about ShopBot.

Firstly I had to design such box in Inkscape. As ShopBot required PDF file so I save designs in

PDF formate.

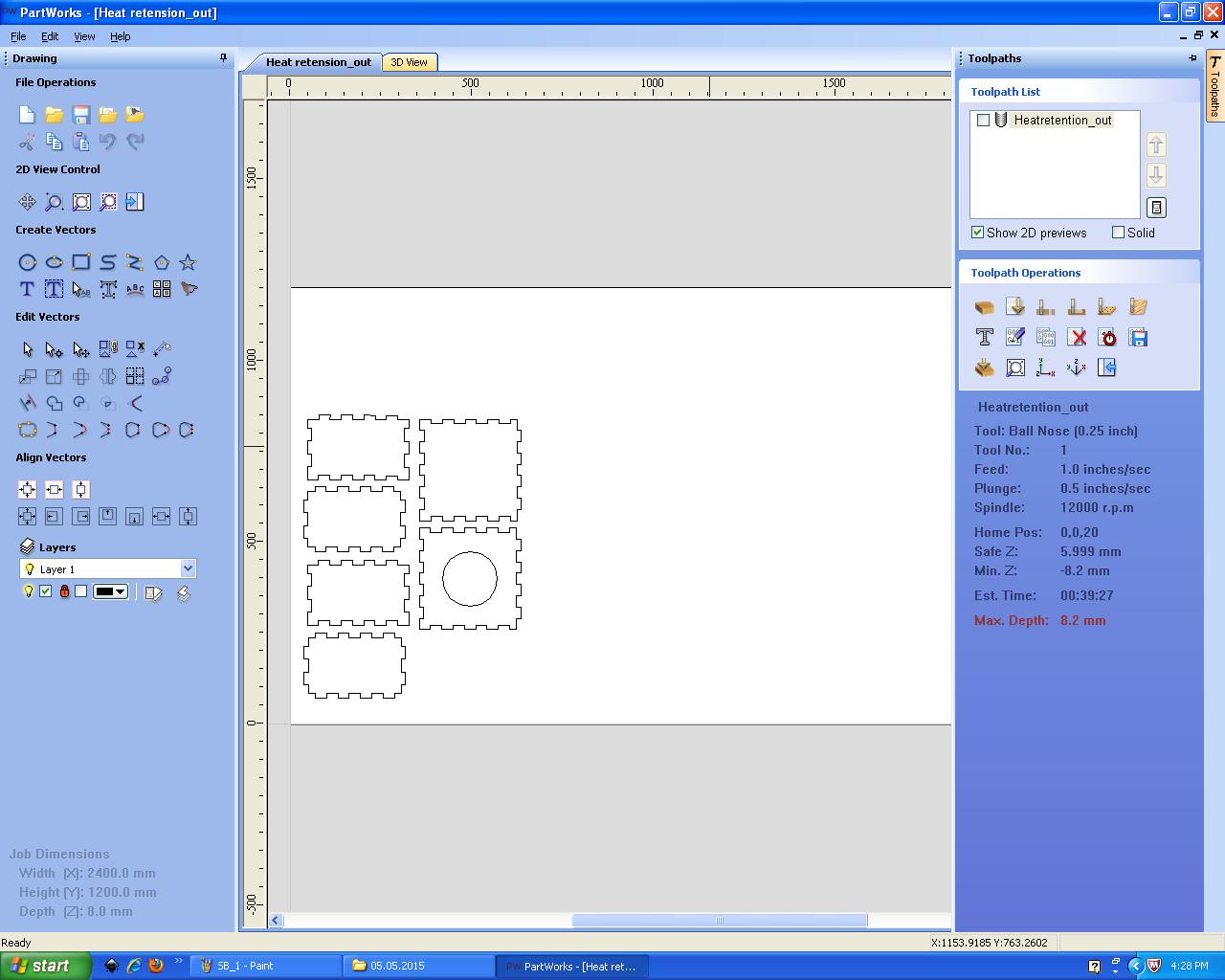

For ShopBot we used software named Partwork. PartWork is a software which allow us to creat toolpath

of object which we have to cut. I need to set properties depth, width, and hight as well as tool size

for cutting and some editing tool

ShopBot need PDF file, which is I already save after editing or designing box. So Import that file in

Open PDF file in PartWork,

Secondly, need to set toolpath

To create toolpath,

1) set material size, I had used 12 mm sheet

2) dimension as per bed size of ShopBot as we used 8*4 foot bed size machine

In toolpath, have to select a lot properties such as select only those internal designs. I made one

mistek, I had a box to cut. Its top side which had a cercular hole at center but I had creat tool path

for outer firsly and cut it. Then it became dificult to cut circle inside,such misteks, object displace

during final cut so we cant then cut designe on that cutted object.

Important points to select in select box,

1) Cut Depth always higher than sheet size in my case I have used 8 and 12 mm so I put 8.2 and 12.2 cut

depth respectively.

2) Tool, In this have to select drill bit appropriat size. I have used 0.25 inches tool

3) Now put a profile name and calculate.

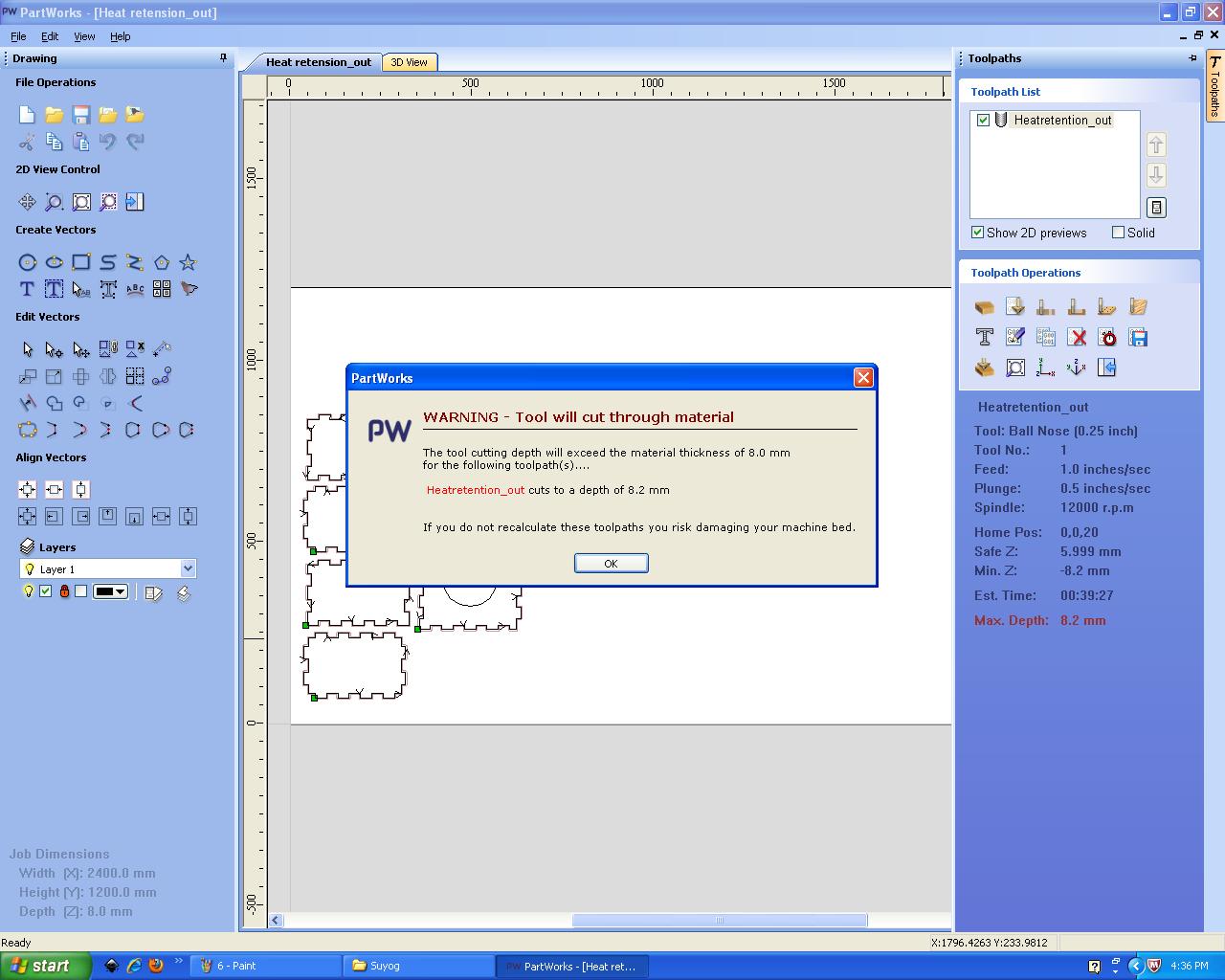

Here warnining massege should appear It highlights that object will cut through sheet.

Also in Part work I checked 3D view. Its showed that, how many passes it took to cut trough sheet

Open ShopBot consol set axic for tool Select axie to zero.

Then give command to start cutting.

This is cutted part of Heat Retentaion box. Middle part is the part it has circle

inside where i made mistek. I followed the same procesure for that part

Unfortunatly shop bot is under maintainance

Even I could not correct mistake of heat retation box. But I have understand operation of ShopBot. I will cut my actual

object on ShopBot erlier I have explained.

Download Heat retention box design file

HOME

|