Machine design

Link to Machine design Documentation

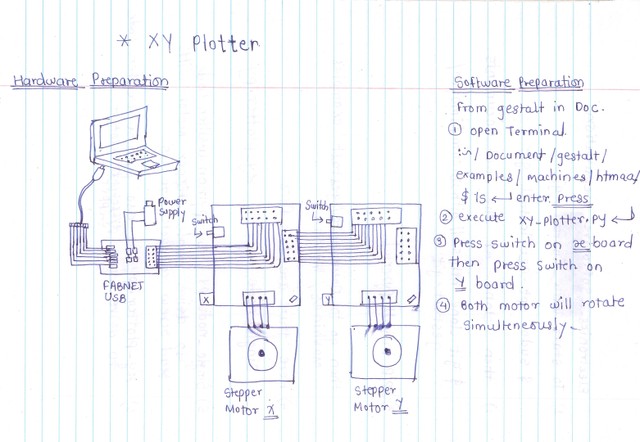

This weeks assignment task is Make machine and. we three has decided to make 'Time lapse machine'. This machine will have slider connected to the Stepper motor so it will give linear motion and on top of the slider we are fixing another motor with camera holder so we can rotate camera in angle 360.also using Gestalt boards.

We got 2D profile cuts from the tutorial and used Epilog Laser to cut these parts and fixed one stepper motor on x-axis direction i.e Linear motion of the slider. On the slider we fabricated another box which will rotate with another stepper motor and also it will hold the camera.

We are working on Time Lapse machine for photograohy, means used to describe a way of filming something in which

many photographs are taken over a long period of time and are shown quickly in a series so that a slow action (such as

the opening of a flower bud) appears to happen quickly.

Apeksha made map to move on for group assignment task. How it would be evaluate That gave us clear idea and was easy to plan

further. Then we started working on it.

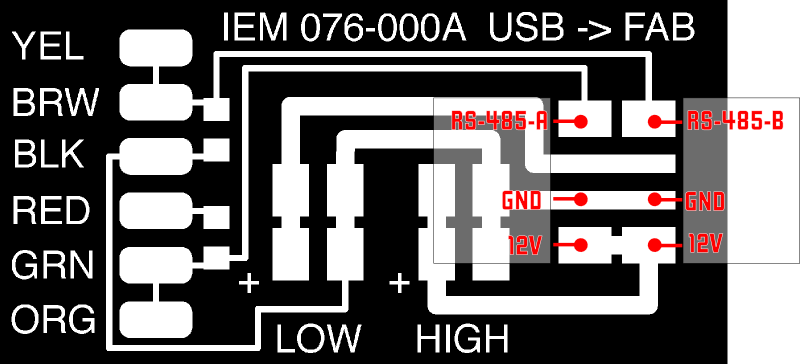

We want firstly the fab net board. which i get on fab academy page. I milled that board and solder color cable and componant to it.

We want firstly the fab net board. which i get on fab academy page. I milled that board and solder color cable and componant to it.

|

This is one more time I got chance to mill pcb on Modela machine and I was filling much confident to mill board. So I followed

procedure once again which I did in Electronic production But this time I take care of little but importantant

aspect that must be consider while working on milling.

Upto this we together brock couple of bits while milling a pcb. I didnt know why this happning. Every time I cheked level of bed. It was

well align everytime. But letter found that the problem was with double side tape. I had stick a board using foam tape to mill PCB. But now

for this time I used proper double side tape.

We had paste acrylic on bed as base and then used to past pcb over it. That was another problem while using 1/32 bit. It get brocken

because of hardness of acrylic. I solved the problem TEMPRERY using single side pcb's back side keeping it up.

Over I align and paste PCB with the same double side tape on which I had to mill fabnet board.

I was very happy when the board it printed completely without any mistek. there was no track distraction bit was ok. Everything was good

then I soldered smd componant on the board. Solder wire with color code on it. And hencde the board is ready. But I did silly mistek again

I displaced board and hence coudnt able to cut the interior using 1/32

Suhas has finished the laswr cutting part. He cutted outer part of base or slider box for Time Lapse Machine

Suhas and me assembled the parts together. And fitted the assembly with motor. during this Apeksha had setup the pythen

for programming.

So I contribute in Electronics fabrication and assembly of lesser cut parts with suhas. Now we are ready with all set up and acceseries

Also Apeksha was looking for programming. Also I work on hardware set up.

Further apeksha took lead in programming using pythen.

here is Working video