Fab Chesdool

I call the stool Chesdool because for it's dual funtions as stool and stackable chest/shelve.

Because I'm currently not in Fablab, I only have access to a small CNC.

For that reason, I scale the Chestool down quite a bit so I can cut it out.

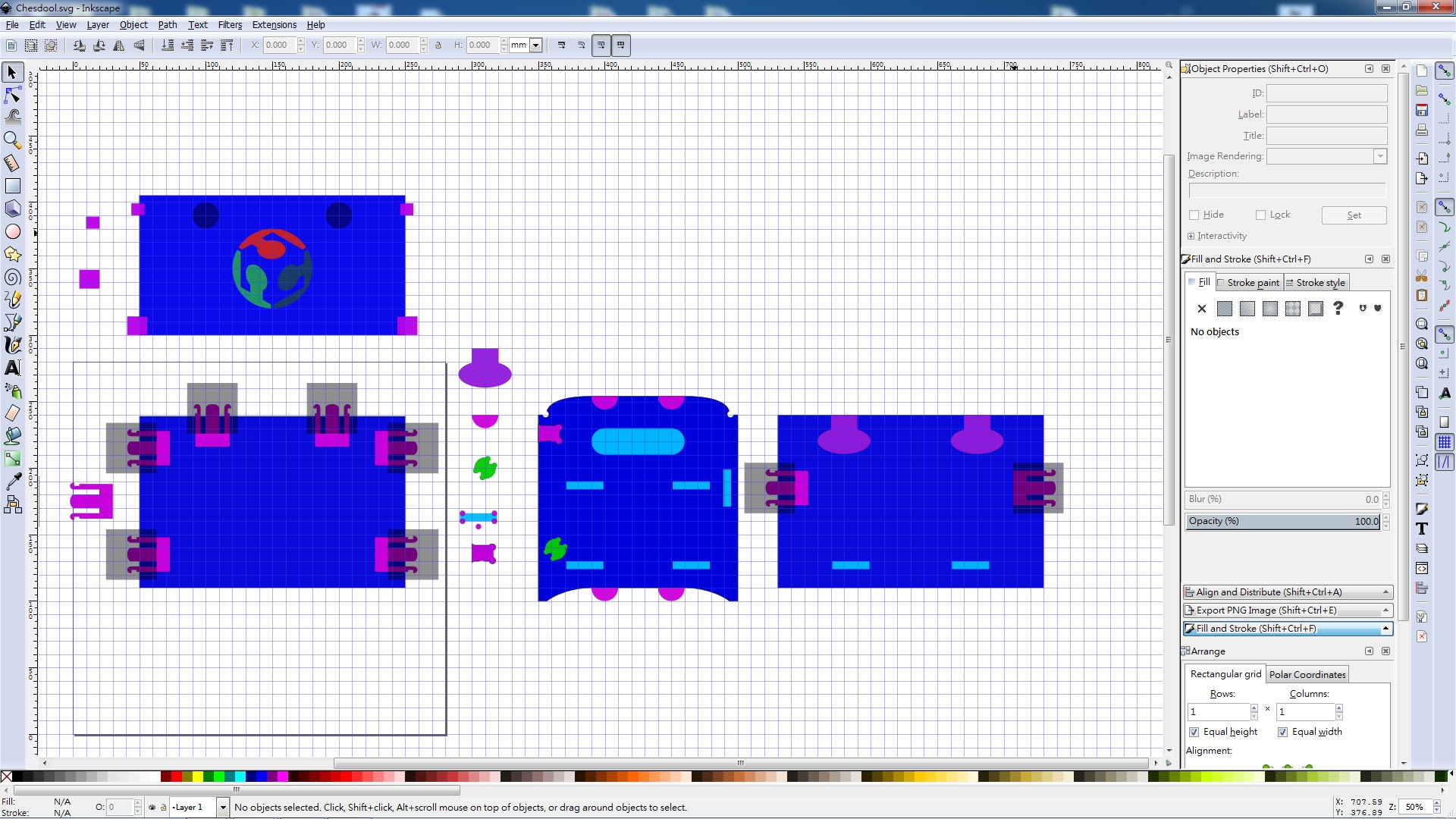

For this time, Inkscape is used for drawing the Chesdool.

The design is sort of parametric, at least the press fit joints are.

More practices are in need for me to learn how to make the whole design parametric.

For turning the design into G-Code, I use CamBam because it's more detailed parameter and the affordable price.

First, I cut out the press fit joint to do a tolerance test, and I'm glad I did it! The fits is a bit too tight, so I change the design a bit.

The side panel of the Chesdool.

The other side panel and the door of the stool, aka the front panel.

Everything cutted out and sanded.

Showing the way Chestools stack.

Almost fully assembled Chestool. Because of the scale down, the top of the stool is too small to work. First because I don't have a small enough mill bit. Second, the wood is too thick to bend for the tight curves on the edge.

Showing the Chestool open it's door.

Showing the door hinge mechanism, and also the extra holes for putting a devider in the storage space.

Showing the open position of the hinge.

1/8 of the leg assemblys.

1/8 of the leg assemblys.

1/8.

1/8.