08.computer-controlled machining

Making data

I made the data of the chair which could stack to top and bottom.

Preparations

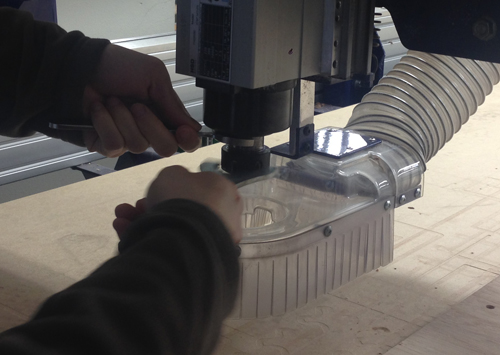

Bit replacement

loosen a screw behind cover and lower it below. loosen a screw of parts with two pliers.

setting CAM

Our lab use "Vcarvepro" for making path. Shallow hole (6mm depth) was drawn for drive screws into the base board. Bit was set and path was made in [toolpath] menu. After setting, path was saved.

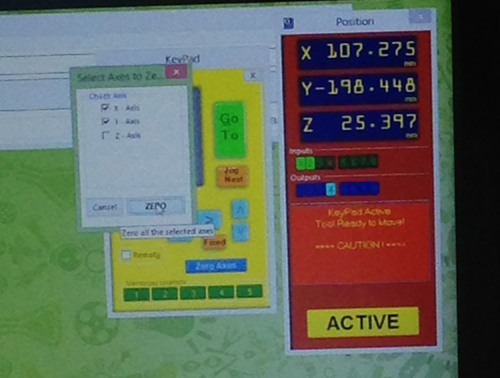

XYZ setting to SHOPBOT

Z setting

z axis was auto set.command is [C2] in SHOPBOT3 software.

XY setting

XY axis was set with [keypad] in SHOPBOT3.

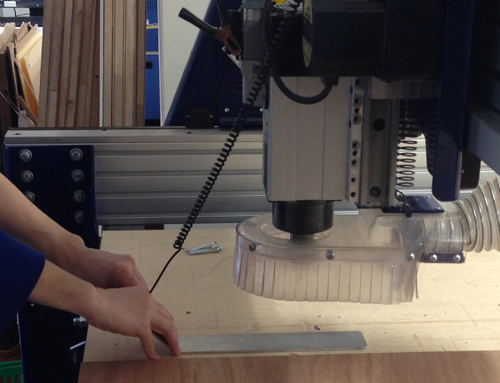

fixing wood and making path

At first, open hole before data cut and drive screws. When doing it, Shopbot software should be "preview" mode.

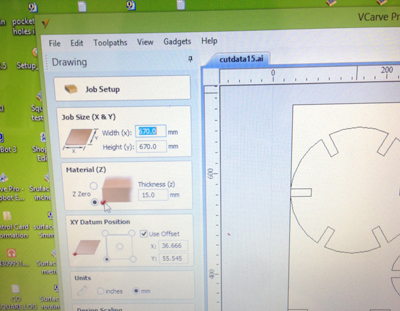

Reading data using "V carve pro". and input material size into value of [jobsize] and [material].

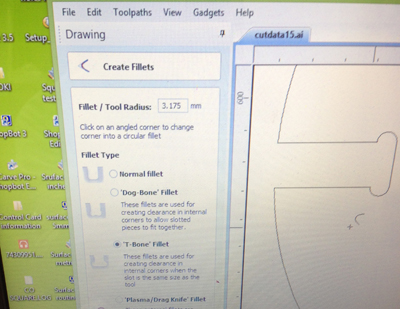

I add fillets to all parts to be easy to assemble it.

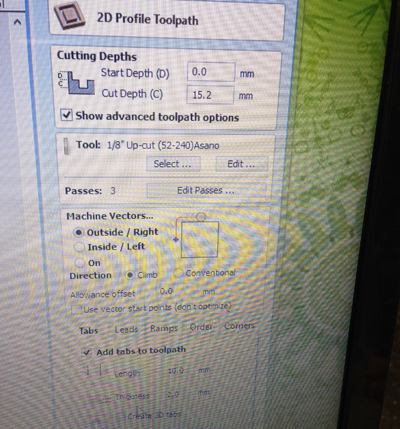

after that, I set cut-path. Thickness of the material was [15mm], but this time, I input +0.7mm to [cutdepth]. and, add [tool path] to all parts so that these don't fall.

If setting is completed, making a path and check a preview, and the data has to be saved Shopbot format.

cutting

On Shopbot-software,the date should be checked "preview" mode. And checking that key is locked for spindle will turn. Switch to "move" mode without a mistake for data and read it again. After checking XYZ is 0 ,then [START] is pushed. Then, switch on the dust collector, and cutting begins when after push Enter on PC. !!!!!!!Please check spindle is turning!!!!!!!!!!!

finishing

Wood was bad, and edges became messy, so it was adjusted with a belt sander and a band saw.

The chair / shelf which can stack both top and bottom was completed!